Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Welding Cracks

Caricato da

Ashish JindalDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Welding Cracks

Caricato da

Ashish JindalCopyright:

Formati disponibili

Crack is a discontinuity caused by the tearing of the metalwhile in a plastic condition or fracturing of the metal whencold.

Cracks occur because the stress at that point in theweldment exceeds the ultimate tensile strength or ultimateshear strength of the base metal or weld metal.Cracking can occur in the weldment, at the fusion line or inthe base metal.Cracks may be classified according to location and directionof line and they may range in size from large cracks toextremely small fissures. Mainly weld cracking are of two types: 1) Hot Cracks, 2) Cold Cracks Hot-cracks takes place whenthe weld metal is half liquid andhalf solid and has no tensilestrength. In another way theyoccur during solidification

ARC CRACKS Definition: A depression left at the termination of the weld where the weld pool is left unfilled. Cause: Improper weld termination techniques Repair: If no cracks exist, simply fill in the crater. Generally welding from beyond the crater back into the crater. Longitudinal Crack Definition: A crack running in the direction of the weld axis. May be found in the weld or base metal. Cause: Preheat or fast cooling problem. Also caused by shrinkage stresses in high constraint areas. Prevention: Weld toward areas of less constraint. Also preheat to even out the cooling rates. Repair: Remove and reweld Transverse Crack Definition: A crack running into or inside a weld, transverse to the weld axis direction. Cause: Weld metal hardness problem

Crater Crack Definition: A crack, generally in the shape of an X which is found in a crater. Crater cracks are hot cracks. Cause: The center of the weld pool becomes solid before the outside of the weld pool, pulling the center apart during cooling Prevention: Use crater fill, fill the crater at weld termination and/or preheat to even out the cooling of the puddle Throat Crack Definition: A longitudinal crack located in the weld throat area. Cause: Transverse Stresses, probably from shrinkage. Indicates inadequate filler metal selection or welding procedure. May be due to crater crack propagation. Prevention: Correct initial cause. Increasing preheat may prevent it. be sure not to leave a crater. Use a more ductile filler material. Repair: Remove and reweld using appropriate procedure. Be sure to correct initial problem first.

Toe Crack Definition: A crack in the base metal beginning at the toe of the weld Cause: Transverse shrinkage stresses. Indicates a HAZ brittleness problem. Prevention: Increase preheat if possible, or use a more ductile filler material.

Root Crack Definition: A crack in the weld at the weld root. Cause: Transverse shrinkage stresses. Same as a throat crack. Prevention: Same as a throat crack Underbead Crack Definition: A crack in the unmelted parent metal of the HAZ. Cause: Hydrogen embrittlement Prevention: Use LOW HYDROGEN electrodes and/or preheat

Repair: (only found using NDT). Remove and reweld. Hot Crack Definition: A crack in the weld that occurs during solidification. Cause: Micro stresses from weld metal shrinkage pulling apart weld metal as it cools from liquid to solid temp. Prevention: Preheat or use a low tensile filler material. Repair: Remove and reweld, correct problem first, preheat may be necessary, increase weld size. Cold Crack Definition: A crack that occurs after the metal has completely solidified Cause: Shrinkage, Highly restrained welds, Discontinuities Prevention: Preheat, weld toward areas of less constraint, use a more ductile weld metal Repair: Remove and reweld, correct problem first, preheat may be necessary.

Repairs to Cracks Determine the cause Correct the problem Take precautions to prevent reoccurrence Generally required to repair using a smaller electrode

Potrebbero piacerti anche

- Weld CrackDocumento3 pagineWeld CrackHoangNessuna valutazione finora

- Welding Defects - Causes and RemediesDocumento51 pagineWelding Defects - Causes and Remediesmilind94% (18)

- Welding Defects - PresentationDocumento40 pagineWelding Defects - Presentationforgameslive100% (17)

- Welding Defects PresentationDocumento40 pagineWelding Defects PresentationGautam KumarNessuna valutazione finora

- Welding Defects - Causes and RemediesDocumento51 pagineWelding Defects - Causes and RemediesMukesh Dak100% (1)

- Weld Defects TrainingDocumento77 pagineWeld Defects TrainingQC apollohx100% (1)

- Welding DefectsDocumento68 pagineWelding DefectsRahulKumarNessuna valutazione finora

- KEMPPI Welding Technology Course: R.BanerjeeDocumento78 pagineKEMPPI Welding Technology Course: R.BanerjeeAnoop KushwahaNessuna valutazione finora

- Welding Defects PresentationDocumento41 pagineWelding Defects PresentationAhsan AliNessuna valutazione finora

- Cracks in WeldsDocumento19 pagineCracks in Weldsjesycuban100% (1)

- WeldingDocumento41 pagineWeldinggigiphiNessuna valutazione finora

- MODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsDocumento7 pagineMODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsNsidibe Michael EtimNessuna valutazione finora

- Day 1Documento47 pagineDay 1vinay1999Nessuna valutazione finora

- Vocabulário Inglês SoldaduraDocumento3 pagineVocabulário Inglês SoldadurabdromeiraNessuna valutazione finora

- Welding Defects: Defects May Occur Due To The Following ReasonsDocumento5 pagineWelding Defects: Defects May Occur Due To The Following ReasonsRavi ShankarNessuna valutazione finora

- Welding DefectsDocumento4 pagineWelding DefectsAhsan AliNessuna valutazione finora

- Welding DefectsDocumento5 pagineWelding DefectsDEEPAKNessuna valutazione finora

- Welding TerminologyDocumento5 pagineWelding TerminologyKaruppiah ArunachalamNessuna valutazione finora

- Cracks in Welds: Paper PresentationDocumento19 pagineCracks in Welds: Paper PresentationJigar Mevada100% (1)

- Welding DefectsDocumento38 pagineWelding Defectssajeev27100% (4)

- Defects WeldingDocumento206 pagineDefects WeldingJayesh100% (1)

- 21 Types Casting DefectsDocumento94 pagine21 Types Casting DefectsNarayanakumar A.PNessuna valutazione finora

- 17 Weldability of SteelsDocumento40 pagine17 Weldability of SteelsJawed Akhter100% (1)

- Figure 1: Groove Weld TerminologyDocumento28 pagineFigure 1: Groove Weld TerminologyAmyNessuna valutazione finora

- Inherent: They Are Usually Related To Discontinuities Found in TheDocumento10 pagineInherent: They Are Usually Related To Discontinuities Found in TheBhadresh PatelNessuna valutazione finora

- Weld Defects and DiscontinuitiesDocumento78 pagineWeld Defects and DiscontinuitiesGilbert MendozaNessuna valutazione finora

- 21 Casting Defects and How To Prevent Them in Your ProductsDocumento1 pagina21 Casting Defects and How To Prevent Them in Your ProductsmkmkhairiNessuna valutazione finora

- Welding Defect: Hydrogen EmbrittlementDocumento8 pagineWelding Defect: Hydrogen EmbrittlementShajin Mohammed ShamsudhinNessuna valutazione finora

- Welding Defects - Its Causes and Remedial Actions & Safety in Oxyfuel Gas CuttingDocumento144 pagineWelding Defects - Its Causes and Remedial Actions & Safety in Oxyfuel Gas CuttingSuraj RawatNessuna valutazione finora

- Weld DefectsDocumento6 pagineWeld Defects0502raviNessuna valutazione finora

- Defects in WeldsDocumento6 pagineDefects in WeldsSaran KumarNessuna valutazione finora

- Cswip QusDocumento4 pagineCswip QusRob WillestoneNessuna valutazione finora

- DefectologyDocumento91 pagineDefectologySivasankaran Raju100% (6)

- Welding ImperfectionsDocumento26 pagineWelding ImperfectionsABDELGHANI HIBAOUINessuna valutazione finora

- Extra QuestionDocumento5 pagineExtra QuestionIslam MohammedNessuna valutazione finora

- Welding DefectDocumento33 pagineWelding DefectabdoNessuna valutazione finora

- DefectologyDocumento91 pagineDefectologyravindra erabattiNessuna valutazione finora

- Welding Electrode ClassificationsDocumento18 pagineWelding Electrode ClassificationsMansukh KahlonNessuna valutazione finora

- Weld RepairsDocumento40 pagineWeld Repairsவிஷ்ணு ராஜசெல்வன்Nessuna valutazione finora

- Defects in MetallurgyDocumento49 pagineDefects in Metallurgyraghavendrajoshi870% (1)

- Revised Materials and Processes Sections 7 To 9Documento207 pagineRevised Materials and Processes Sections 7 To 9Ameem TariqNessuna valutazione finora

- Welding Defects: Their Causes and PreventionDocumento18 pagineWelding Defects: Their Causes and PreventionsanjaykumarmauryaNessuna valutazione finora

- Basic Welding TermsDocumento43 pagineBasic Welding TermsmailbkraoNessuna valutazione finora

- Cswip, NotesDocumento2 pagineCswip, NotesYuvaraja kNessuna valutazione finora

- Microstructure Study of Welded JointDocumento17 pagineMicrostructure Study of Welded JointRatul Islam Antor100% (1)

- Basic Types of Welded JointsDocumento21 pagineBasic Types of Welded JointstranngNessuna valutazione finora

- Hydrogen Cracks in Steels - IdentificationDocumento4 pagineHydrogen Cracks in Steels - IdentificationFsNessuna valutazione finora

- Forging Defects and Extrusion DefectDocumento8 pagineForging Defects and Extrusion DefectVenkat KrishnaNessuna valutazione finora

- Types of Welding Defects PDFDocumento12 pagineTypes of Welding Defects PDFDhiab Mohamed AliNessuna valutazione finora

- Ultrasonic Testing HandbookDocumento29 pagineUltrasonic Testing HandbookRafael HernandezNessuna valutazione finora

- Welding TolerancesDocumento3 pagineWelding Tolerancessaeedsaeed31Nessuna valutazione finora

- Casting DefectsDocumento14 pagineCasting Defectsadbsalman734Nessuna valutazione finora

- Pemilba CastingDocumento8 paginePemilba CastingRefky FNessuna valutazione finora

- Welding Defects and Remedies: Lack of Fusion Incomplete Penetration Undercutting Porosity Longitudinal CrackingDocumento9 pagineWelding Defects and Remedies: Lack of Fusion Incomplete Penetration Undercutting Porosity Longitudinal Crackinglakshmigsr6610Nessuna valutazione finora

- Welding Eithout Cold CracingDocumento7 pagineWelding Eithout Cold CracingJanno RubenNessuna valutazione finora

- 21 Weldability of SteelsDocumento40 pagine21 Weldability of Steelssaeidian100% (2)

- Farm and Workshop Welding, Third Revised Edition: Everything You Need to Know to Weld, Cut, and Shape MetalDa EverandFarm and Workshop Welding, Third Revised Edition: Everything You Need to Know to Weld, Cut, and Shape MetalNessuna valutazione finora

- The Home Blacksmith: Tools, Techniques, and 40 Practical Projects for the Home BlacksmithDa EverandThe Home Blacksmith: Tools, Techniques, and 40 Practical Projects for the Home BlacksmithNessuna valutazione finora

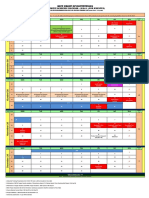

- Academic Calendar Odd Sem 2020-21Documento1 paginaAcademic Calendar Odd Sem 2020-21NAMRATA SHARMANessuna valutazione finora

- Experimental Design Graphic OrganizerDocumento2 pagineExperimental Design Graphic OrganizerApplesauce90Nessuna valutazione finora

- Eder606 Albersworth Reality Check FinalDocumento16 pagineEder606 Albersworth Reality Check Finalapi-440856082Nessuna valutazione finora

- Proposal Cafe Janji JiwaDocumento24 pagineProposal Cafe Janji JiwaIbamz SiswantoNessuna valutazione finora

- Aria Soho Fdom Is02Documento213 pagineAria Soho Fdom Is02cipcigan danutNessuna valutazione finora

- Digital Communication Lab Report: Experiment Number 7Documento9 pagineDigital Communication Lab Report: Experiment Number 7Saketh RaviralaNessuna valutazione finora

- HRA2 Service ManualDocumento59 pagineHRA2 Service ManualuserrnNessuna valutazione finora

- The Process of Oral CommunicationDocumento22 pagineThe Process of Oral CommunicationRussel David AlmueteNessuna valutazione finora

- Online Games Engagement QuestionnaireDocumento11 pagineOnline Games Engagement QuestionnairePrince Rj Cortes SorianoNessuna valutazione finora

- Smart Speaker Synopsis For 6th SemDocumento16 pagineSmart Speaker Synopsis For 6th SemSaurav MehtoNessuna valutazione finora

- Booklist Shubham Kumar PDFDocumento11 pagineBooklist Shubham Kumar PDFVivek VishwakarmaPSH'076Nessuna valutazione finora

- Solidity Part 2Documento103 pagineSolidity Part 2Muhammad Zahid FaridNessuna valutazione finora

- Chapter 5.2 Solutions - Numerical Analysis 9th EditionDocumento1 paginaChapter 5.2 Solutions - Numerical Analysis 9th EditionAmn RaheNessuna valutazione finora

- Operational Readiness ReviewDocumento6 pagineOperational Readiness ReviewSabahat Hussain0% (1)

- Vce Chemistry Unit 3 Sac 2 Equilibrium Experimental Report: InstructionsDocumento5 pagineVce Chemistry Unit 3 Sac 2 Equilibrium Experimental Report: InstructionsJefferyNessuna valutazione finora

- Username: Password:: Sign Up HelpDocumento5 pagineUsername: Password:: Sign Up Helpanon-846946Nessuna valutazione finora

- ATEX AssembliesDocumento5 pagineATEX AssembliesABHISHEK DOLLENessuna valutazione finora

- How To Install Kali Linux 2Documento36 pagineHow To Install Kali Linux 2ᎦᏂᎯᎦᎲ ᏦᎯᏁᎿᏂNessuna valutazione finora

- Master of Arts in Education (Physical Education)Documento1 paginaMaster of Arts in Education (Physical Education)Michael Mayo TaperoNessuna valutazione finora

- Engine Inspection Using Windrock Technology DiagnosticsDocumento4 pagineEngine Inspection Using Windrock Technology DiagnosticsImranFazal100% (1)

- Math 216 SyllabusDocumento4 pagineMath 216 Syllabusdoney_78100% (1)

- APA 7th Edition Condensed Referencing Style Handout 2020Documento13 pagineAPA 7th Edition Condensed Referencing Style Handout 2020Nia Singh100% (1)

- Before Practical Test Pass The Driving Theory TestDocumento3 pagineBefore Practical Test Pass The Driving Theory TestpassdrivetestNessuna valutazione finora

- Sample Science Lesson PlanDocumento5 pagineSample Science Lesson PlanLunafreya NyxNessuna valutazione finora

- civilBAMBOO AS A BUILDING MATERIALDocumento15 paginecivilBAMBOO AS A BUILDING MATERIALFajar KaruniaNessuna valutazione finora

- NRL Autonomous Systems Research Timeline: 1923 - 2012Documento12 pagineNRL Autonomous Systems Research Timeline: 1923 - 2012U.S. Naval Research Laboratory0% (1)

- Regenerative Desiccant Dryers: KAD, KED and KBD SeriesDocumento10 pagineRegenerative Desiccant Dryers: KAD, KED and KBD SeriesNaveen KumarNessuna valutazione finora

- Workbook 8 Spiritual AwakeningDocumento2 pagineWorkbook 8 Spiritual AwakeningcelcwzNessuna valutazione finora

- Philippine Business For Social Progress: A Case StudyDocumento52 paginePhilippine Business For Social Progress: A Case StudySynergos InstituteNessuna valutazione finora

- The Social Learning Theory (Tutorial WK 5)Documento14 pagineThe Social Learning Theory (Tutorial WK 5)Hasfiyah AssanNessuna valutazione finora