Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hazardous Locations

Caricato da

EnzopvvDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hazardous Locations

Caricato da

EnzopvvCopyright:

Formati disponibili

General Facts for Discussion About Hazardous Locations (This NEC Study Guide was prepared by Gaylord Poe

2008)

1. Excluding the Zone classification system, Hazardous Locations are classified as Class 1, Class 2, and Class 3. Each of these classifications consists of two Divisions. 2. After reviewing NEC Art. 500.5 this generalization can be made: When defining the Divisions of each classification, Division 1 means that the hazard is present during normal operations and Division 2 means that the hazard is present only during accidental conditions, malfunction conditions, or certain conditions of storage. 3. Class 1 locations are locations that contain flammable gases or vapors. Class 2 locations are locations that contain combustible dusts. Class 3 locations are locations that contain easily ignitable fibers or flyings. 4. Gasoline dispensing is a Class 1 location. A flour processing area is a Class 2 location. A woodworking shop is a Class 3 location. 5. In general, equipment that is listed for Class I locations is not automatically suitable for use in Class II and Class III locations. In other words, the Classifications are not in a certain order with Class 1 being the best. Class 1, Class 2, and Class 3 are just names. The type of hazard present for each Classification is different and is addressed differently. 6. Junction boxes in Class I Division 2 locations do not have to be explosion proof. 7. After reviewing Art 501.15 this generalization can be made: Seals must be installed ahead of all arcing and sparking devices and at all boundaries. 8. For Class I Division 1 and Division 2 locations, conduit seals required at boundaries can be on either side of the boundary under specific conditions. 9. In general, motors in Class I Division 1 locations have to be specifically listed for Class I Division 1 locations. It should be noted that there are provisions in 501.125 (A) (2) for using motors not specifically listed for Class I Division 1 locations by means of purging with fresh air, or isolating with an inert gas, or submerging in specific liquids.

Copyright 2008. Inspection Bureau Inc. Cincinnati, OH.

10. Motors identified for use in Class I Division 1 locations are OK for use in Class I Division 2 locations. 11. Conduits and cables for Intrinsically Safe Systems have to be sealed only at the boundaries. 12. In commercial garages, the GFCI protected receptacle rules apply only to 125 volt, single phase, 15- and 20-ampere receptacles in the shop area that are installed in areas where electrical diagnostic equipment, electrical hand tools, or portable lighting equipment are intended to be used. 13. In commercial garages, care must be taken when installing plug-in type retractable work lights. They not only must be constructed a certain way, guarded and non-conductive but most importantly they must not be able to enter the hazardous area unless they are identified as suitable for the hazardous location. 14. In general, customer waiting areas and general office areas adjacent to shop areas of commercial garages must be cut-off or ventilated to avoid being included in the classified location. 15. When a Minor Repair Garage is used as quick lube store, pits or depressions below floor areas can become totally unclassified by complying with the ventilation requirements of 511.3(D)(3)(a).

Copyright 2008. Inspection Bureau Inc. Cincinnati, OH.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- SPS321 Sports Safety and Emergency Care Mohd Fadzil B. Hj. Kamarudin Sr113 Uitm/InstedtDocumento9 pagineSPS321 Sports Safety and Emergency Care Mohd Fadzil B. Hj. Kamarudin Sr113 Uitm/InstedtMozil Fadzil KamarudinNessuna valutazione finora

- HRFuture Sept 2020 MJLKJDocumento59 pagineHRFuture Sept 2020 MJLKJGlecy KimNessuna valutazione finora

- Beta Lactam Antibiotics Structure, Classification and MechanismDocumento15 pagineBeta Lactam Antibiotics Structure, Classification and MechanismNiharika ModiNessuna valutazione finora

- C & W Meat Packers Carly Courtney Cynthiana KY Notice of Suspension Humane Treatment LivestockDocumento4 pagineC & W Meat Packers Carly Courtney Cynthiana KY Notice of Suspension Humane Treatment LivestockghostgripNessuna valutazione finora

- Mechanical Syllabus PDFDocumento225 pagineMechanical Syllabus PDFshashiNessuna valutazione finora

- Testing Antibiotics with Disk Diffusion AssayDocumento3 pagineTesting Antibiotics with Disk Diffusion AssayNguyễn Trung KiênNessuna valutazione finora

- Hemifacial Spasm A NeurosurgicalDocumento8 pagineHemifacial Spasm A NeurosurgicaldnazaryNessuna valutazione finora

- Functional Electrical StimulationDocumento11 pagineFunctional Electrical StimulationMohd Khairul Ikhwan AhmadNessuna valutazione finora

- SPJ LAS Q2 Week 1 To 5Documento67 pagineSPJ LAS Q2 Week 1 To 5Lovilyn EncarnacionNessuna valutazione finora

- Operant WorksheetDocumento4 pagineOperant Worksheetssnpl1415Nessuna valutazione finora

- The Regent's Park - Risk AssessmentDocumento3 pagineThe Regent's Park - Risk AssessmentEiman'E'RostamiNessuna valutazione finora

- Tinea IncognitoDocumento1 paginaTinea IncognitoJana AtanasovaNessuna valutazione finora

- 2) Water Quality and Health in Egypt - Dr. AmalDocumento50 pagine2) Water Quality and Health in Egypt - Dr. AmalAlirio Alonso CNessuna valutazione finora

- Pediatric Nutrition and Nutritional Disorders: PediatricsDocumento4 paginePediatric Nutrition and Nutritional Disorders: Pediatricsapi-3829364Nessuna valutazione finora

- Hazard Full SlideDocumento31 pagineHazard Full SlideRenKangWongNessuna valutazione finora

- Osteoporosis: What Is Osteoporosis? What Are Osteoporosis Symptoms?Documento2 pagineOsteoporosis: What Is Osteoporosis? What Are Osteoporosis Symptoms?Ayman FatimaNessuna valutazione finora

- eBR PharmaDocumento5 pagineeBR PharmaDiana OldaniNessuna valutazione finora

- Statistics: Dr. Ebtisam El - HamalawyDocumento20 pagineStatistics: Dr. Ebtisam El - Hamalawydruzair007Nessuna valutazione finora

- Nutrition Care Plan - DysphagiaDocumento1 paginaNutrition Care Plan - DysphagiaElaine ArsagaNessuna valutazione finora

- BSc Medical Sociology Syllabus DetailsDocumento24 pagineBSc Medical Sociology Syllabus Detailsmchakra72100% (2)

- TOFPA: A Surgical Approach To Tetralogy of Fallot With Pulmonary AtresiaDocumento24 pagineTOFPA: A Surgical Approach To Tetralogy of Fallot With Pulmonary AtresiaRedmond P. Burke MD100% (1)

- HANDBOOK-McLean-and-Syed-2015-The Oxford Handbook of Identity Development PDFDocumento625 pagineHANDBOOK-McLean-and-Syed-2015-The Oxford Handbook of Identity Development PDFEsp Success Beyond100% (13)

- Manajemen Pemeliharaan Puyuh Periode Layer Di CV Agri Bird Karanganyar Jawa TengahDocumento54 pagineManajemen Pemeliharaan Puyuh Periode Layer Di CV Agri Bird Karanganyar Jawa TengahRyah NurNessuna valutazione finora

- BSN 3G GRP 4 Research TitlesDocumento6 pagineBSN 3G GRP 4 Research TitlesUjean Santos SagaralNessuna valutazione finora

- Cognidox - A Complete Guide To Medical Device DevelopmentDocumento38 pagineCognidox - A Complete Guide To Medical Device DevelopmentcivicbladeNessuna valutazione finora

- Chapter 14 Pharmacy Law and Ethics Notes Complete Notes by Noteskarts Acc To ER20Documento4 pagineChapter 14 Pharmacy Law and Ethics Notes Complete Notes by Noteskarts Acc To ER20Shamant TNessuna valutazione finora

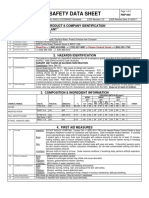

- Abc Sealant SDSDocumento5 pagineAbc Sealant SDSKissa DolautaNessuna valutazione finora

- Neonatal LupusDocumento19 pagineNeonatal Lupusyogeshraval368Nessuna valutazione finora

- 2.4 Maxillofacial Trauma (Sia) - Sales&TanDocumento11 pagine2.4 Maxillofacial Trauma (Sia) - Sales&Tanmr dojimamanNessuna valutazione finora

- Asset Integrity Know HowDocumento6 pagineAsset Integrity Know HowFatemeh MehrbakhshNessuna valutazione finora