Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Electrical Jointing

Caricato da

nishanth1320 valutazioniIl 0% ha trovato utile questo documento (0 voti)

52 visualizzazioni5 pagineELECTRICAL COUPLING

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoELECTRICAL COUPLING

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

52 visualizzazioni5 pagineElectrical Jointing

Caricato da

nishanth132ELECTRICAL COUPLING

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

%LE LL C EE T CC RI RRC II A CC L

JO JJ IN OO T NN ING NN

Oorros|on of Oonnectors

E|ectr|ca| Jo|nt|ng

Jo|nt Oompounds

EJO No. 2

A|v300

Scratch Brushes

Two factors are associated with corrosion:

1. Atmospheric action

2. Galvanic action

For atmospheric action to result in corrosion, there must be moisture and oxygen.

Galvanic action results in corrosion when two dissimilar metals in the electrolytic series, for

example, aluminium and copper, are in physical contact. In this case, moisture acts as an

electrolyte.

In such an instance, the copper becomes a cathode and receives a positive charge; the

aluminium becomes the anode and receives a negative charge.

The resultant current flow attacks the aluminium leaving the copper unharmed.

Both factors described above are influenced by environmental conditions - the chemical attack of

airborne pollutants.

This occurs in rural areas to a lesser extent than in urban centres and more so in heavy industry

locations such as steelworks, chemical plants, refineries, etc.

The problem of the mechanical jointing of two dissimilar metals in physical contact with each

other, such as aluminium and copper, stems from their difference in electrical potential.

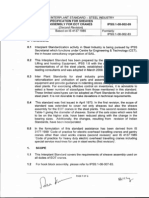

The column of metals listed here shows their relative positions in the Electrolytic Series, with the

more anodic metals in the higher positions and the more cathodic in the lower.

The extent, or severity, of the corrosive action is proportional to the distance of separation of the

metals in the list. i.e. the magnitude of the difference in electrolytic potential of the two metals,

aluminium and copper, is quite considerable.

Aluminium to Aluminium Connections

No problem exists in the jointing of these conductors as electrolytic action is nonexistent.

Nevertheless, care must be taken to prevent crevice corrosion and to select an aluminium alloy

connector body not liable to stress corrosion cracking.

Aluminium to Copper Connections

The best choice is an aluminium bodied connector since it is not subject to the galvanic attack of

the more vulnerable element - the aluminium conductor. It is good practice to use contact sealant

on the aluminium connector body and brushed into the strands of the aluminium conductor.

Wherever possible, install the aluminium conductor above the copper to prevent pitting from the

galvanic action of copper salts washing over the aluminium connector and conductor when in a

lower position.

Copper to Copper Connections

No problem exists in the jointing of these conductors as electrolytic action is nonexistent.

Electronics

Electrical Jointing

Corrosion of Connectors

www.dulmison.com.au 1-2

E

l

e

c

t

r

i

c

a

l

J

o

i

n

t

i

n

g

Magnesium

Aluminium

Duralumin

Zinc

Cadmium

Iron

Chromium Iron (active)

Chromium-Nickel-Iron (active)

Soft solder

Tin

Lead

Nickel

Brasses

Bronze

Monel

Copper

Chromium Iron (passive)

Chromium-Nickel-Iron (passive)

Silver solder

Silver

Gold

Platinum

Electronics

Electrical Jointing

The Electrolytic Series

www.dulmison.com.au 1-3

ANODIC

(Corroded End)

CATHODIC

(Protected End)

E

l

e

c

t

r

i

c

a

l

J

o

i

n

t

i

n

g

A particular phenomenon associated with the jointing of aluminium conductors, concerns the

oxide film that forms rapidly on the surface of freshly cleaned aluminium exposed to air. This

oxide film is an insulator and must be removed with a scratch brush in order to achieve a

satisfactory and reliable electrical joint. The problem with aluminium is that the freshly cleaned

surface will quickly re-oxidise, hence it is important to coat the surface with a contact sealant.

Contact Sealants

Various sealant formulations have been developed to provide improved electrical and mechanical

performance as well as environmental protection to the contact area. The use of sealants is

recommended for aluminium to aluminium or aluminium to copper connections. Sealants are also

recommended for copper to copper joints which are subject to severe corrosive environments.

Non-gritted sealants are recommended for flat connections and as a groove sealant in bolted

connectors such as parallel groove clamps. Our gritted sealant is primarily used in compression

connectors. The sharp metallic grit particles provide multi-contact current carrying bridges

through remaining oxide films to ensure superior electrical conductivity.

Electronics

Electrical Jointing

Electrical Jointing of Aluminium

www.dulmison.com.au 1-4

EJC2

Alvania

ALV300

Alminox

ALM325G

A mineral oil based corrosion inhibitor with added

fluoride to dissolve aluminium oxide. Drop point 65.6

o

C

A mineral oil based corrosion inhibitor with added

lithium. Drop point 180

o

C

A mineral oil based corrosion inhibitor with added zinc

grit. Drop point 188

o

C. Provides excellent outdoor

weathering protection.

Palm to Palm Joints

- Alum to Alum

- Alum to Copper

Bolted Connections

- Alum to Alum

- Alum to Copper

- Copper to Copper

Palm to Palm

- Copper to Copper

Compression Joints

Bolted Connections

- Alum to Alum

- Alum to Copper

Product

Name Description

Recommended

Applications

E

l

e

c

t

r

i

c

a

l

J

o

i

n

t

i

n

g

EJC2

Recommended for use with flat, aluminium surface to

surface bolted joints, such as busbar joints & terminal lugs.

EJC2 contains fluoride which, together with scratch

brushing, assists in breaking up the oxide film by chemically

etching the connecting surfaces to ensure a low resistance

joint. Catalogue number EJC2, supplied in 225g squeeze

tubes.

ALMINOX

Recommended for aluminium to aluminium bolted or

compression connections. Alminox contains sharp,

conductive zinc granules suspended in a viscous petroleum

base. Under pressure these granules make high pressure

contact points with the parent metal to effect a sound

electrical connection, whilst the base material seals the joint

to prevent further corrosion. Catalogue number ALM325G,

supplied in 325g squeeze tubes.

ALV300

Recommended for all bolted connections, such as parallel

groove clamps, either aluminium to aluminium, or bi-metal

copper to aluminium. When applied immediately after

scratch brushing, ALV300 seals the exposed surface to

prevent re-oxidation and permanently excludes the future

ingress of air and moisture. ALV300 is extremely adhesive,

resistant to water and has high temperature resistance to

ensure continuous operation under all situations. Catalogue

number ALV300, supplied in 225g squeeze tubes.

Electronics

Electrical Jointing

Contact Sealants and Scratch Brushes

www.dulmison.com.au 1-5

Scratch Brushes

The use of a suitable scratch brush to remove any

existing oxide film, dirt or grease from the conductor

is essential to ensure a sound electrical connection.

Dulmison produces separate brushes for use on

aluminium and copper conductors to prevent

transference of metal particles.

White brush for use on aluminium.

Cat number: SB3

Black brush for use on copper.

Cat number: SB4

E

l

e

c

t

r

i

c

a

l

J

o

i

n

t

i

n

g

Potrebbero piacerti anche

- Electrical Jointing GuideDocumento5 pagineElectrical Jointing Guideroy_nhpNessuna valutazione finora

- Massive AnodeDocumento6 pagineMassive AnodeusamaanfieldNessuna valutazione finora

- Research On Corrosion Mechanism of Overhead ConductorDocumento4 pagineResearch On Corrosion Mechanism of Overhead ConductorJALIR ANDRE HUAYLLAS SOTONessuna valutazione finora

- Electronic Applications: Part One: Key Benefits How It Helps Fact Sheet Multiuser FAQ Contact Order NowDocumento2 pagineElectronic Applications: Part One: Key Benefits How It Helps Fact Sheet Multiuser FAQ Contact Order NowAnOnYmOuS_1995Nessuna valutazione finora

- Advantages & Disadvantages of Aluminium. Connection of Aluminium To SteelDocumento7 pagineAdvantages & Disadvantages of Aluminium. Connection of Aluminium To SteelDeepti Shrimali0% (1)

- Aluminium and CorrosionDocumento12 pagineAluminium and CorrosionMehman NasibovNessuna valutazione finora

- Aluminium's Corrosion Resistance - Aluminium DesignDocumento7 pagineAluminium's Corrosion Resistance - Aluminium DesignCarlos LuNessuna valutazione finora

- Aluminum Vs COPPERDocumento4 pagineAluminum Vs COPPERTapi SkNessuna valutazione finora

- Aluminum Vs Copper in TrafoDocumento6 pagineAluminum Vs Copper in TrafosamuraivickyNessuna valutazione finora

- Dissertation HidayatDocumento54 pagineDissertation HidayatHong Keat Oh100% (1)

- General Characteristics of AluminiumDocumento2 pagineGeneral Characteristics of AluminiumAjay SinghiNessuna valutazione finora

- Aluminum The Wiring Material of The FutureDocumento7 pagineAluminum The Wiring Material of The FuturevkmsNessuna valutazione finora

- Long Life Corrosion Protection of Steel by Zinc-Aluminium Coating Formed by Thermal Spray ProcessDocumento8 pagineLong Life Corrosion Protection of Steel by Zinc-Aluminium Coating Formed by Thermal Spray ProcessmotokaliNessuna valutazione finora

- Aluminium Uses in Electrical EngineeringDocumento7 pagineAluminium Uses in Electrical EngineeringTigrilloNessuna valutazione finora

- Comparative Studies of The Susceptibility of Copper and Aluminum To Processing in Wire Drawing ProcessDocumento7 pagineComparative Studies of The Susceptibility of Copper and Aluminum To Processing in Wire Drawing ProcessIJAR JOURNALNessuna valutazione finora

- Stanley Engineering TB68-1 Corrosion MethodsDocumento8 pagineStanley Engineering TB68-1 Corrosion MethodskpNessuna valutazione finora

- HeliCoil Technical Information Corrosion Screw ThreadsDocumento6 pagineHeliCoil Technical Information Corrosion Screw ThreadsAce Industrial SuppliesNessuna valutazione finora

- Device Corrosion: Enumerate The Electrical Contact Degradation and The Types of Mechanism Involved in ItDocumento10 pagineDevice Corrosion: Enumerate The Electrical Contact Degradation and The Types of Mechanism Involved in ItSreekanth KrishnamurthyNessuna valutazione finora

- AnodizingDocumento9 pagineAnodizingalphadingNessuna valutazione finora

- Metalurgical Material ProjectDocumento17 pagineMetalurgical Material ProjectJonathan LukwichiNessuna valutazione finora

- What Is The Definition of Hot ShortDocumento4 pagineWhat Is The Definition of Hot ShortJuan CadenaNessuna valutazione finora

- 2 Aluminium Fusion Welding 2015Documento21 pagine2 Aluminium Fusion Welding 2015Tuyen Nguyen100% (1)

- Electrical Inspection Service Guide to Aluminum Wiring IssuesDocumento2 pagineElectrical Inspection Service Guide to Aluminum Wiring IssuesJorge Ignacio MVNessuna valutazione finora

- PART 169 How Do I Resistance Spot Weld Aluminium AlloysDocumento2 paginePART 169 How Do I Resistance Spot Weld Aluminium Alloysravindra_jivaniNessuna valutazione finora

- Galvanic/Dissimilar Metal Corrosion: What It Is and How To Avoid ItDocumento2 pagineGalvanic/Dissimilar Metal Corrosion: What It Is and How To Avoid ItCuauhtémoc FloresNessuna valutazione finora

- Joining Dissimilar Alloys - Review of Welding TechniquesDocumento16 pagineJoining Dissimilar Alloys - Review of Welding TechniquesPrajwalNessuna valutazione finora

- Compatibility Of: Aluminium and SteelDocumento3 pagineCompatibility Of: Aluminium and SteelNasaii AhmadNessuna valutazione finora

- Anodizing: HistoryDocumento9 pagineAnodizing: HistorytechzonesNessuna valutazione finora

- Corrosion of Aluminum and Its Alloys: Forms of CorrosionDocumento3 pagineCorrosion of Aluminum and Its Alloys: Forms of CorrosionInternational Journal of computational Engineering research (IJCER)Nessuna valutazione finora

- Corrosion Control: Figure 6-1. Seaplane OperationsDocumento26 pagineCorrosion Control: Figure 6-1. Seaplane Operationsjefferson toasaNessuna valutazione finora

- Aircraft Corrosion CleaningDocumento26 pagineAircraft Corrosion CleaningselenezgiNessuna valutazione finora

- BurndyDocumento43 pagineBurndyJose Antonio Guadiana SánchezNessuna valutazione finora

- Corrosion of Small-Diameter PipelinesDocumento2 pagineCorrosion of Small-Diameter PipelinesMarcelo Varejão CasarinNessuna valutazione finora

- Properties and Weldability of Aluminium and its AlloysDocumento45 pagineProperties and Weldability of Aluminium and its Alloysravisankar varadharajalu0% (1)

- The Use of Aluminium Alloy in The Production of Ex ProductsDocumento3 pagineThe Use of Aluminium Alloy in The Production of Ex ProductsSaber AbdelaalNessuna valutazione finora

- Mixed Metal Anodes Data Sheet: Pipeline Maintenance LimitedDocumento5 pagineMixed Metal Anodes Data Sheet: Pipeline Maintenance LimitedDotty RoseNessuna valutazione finora

- Corrosion Testing of Metals - Is It Needed?: Presented atDocumento21 pagineCorrosion Testing of Metals - Is It Needed?: Presented atandrea assanelliNessuna valutazione finora

- CA03 ParchamentoJVMDocumento7 pagineCA03 ParchamentoJVMJohnrey ParchamentoNessuna valutazione finora

- Vol8no2 Aluminum WiringDocumento2 pagineVol8no2 Aluminum Wiringkrazeehawaiian23Nessuna valutazione finora

- 2011 16 6 STWJ Patil Srivastava Anurag deDocumento5 pagine2011 16 6 STWJ Patil Srivastava Anurag desongyang hanNessuna valutazione finora

- Copper in Comparison With Aluminium As Common Material in Conductors of LV and MV CablesDocumento5 pagineCopper in Comparison With Aluminium As Common Material in Conductors of LV and MV CablesChana WannapookNessuna valutazione finora

- Joining Aluminium and Copper WiresDocumento1 paginaJoining Aluminium and Copper WiresdanishNessuna valutazione finora

- Cathodic Protection of Steel in ConcreteDocumento5 pagineCathodic Protection of Steel in ConcretegersomNessuna valutazione finora

- Shielding Gas For Welding of Aluminium Alloys by TIG/MIG Welding-A ReviewDocumento10 pagineShielding Gas For Welding of Aluminium Alloys by TIG/MIG Welding-A ReviewdietersimaNessuna valutazione finora

- Why Copper or Aluminum CableDocumento4 pagineWhy Copper or Aluminum CableLouie FernandezNessuna valutazione finora

- Copper For Busbars HandbookDocumento1 paginaCopper For Busbars HandbookvoNessuna valutazione finora

- A New Low-Melting-Point Aluminum BrazeDocumento8 pagineA New Low-Melting-Point Aluminum BrazeA K SinghNessuna valutazione finora

- Comparative Corrosion and Current Burst Testing of Copper and Aluminum Electrical Power ConnectorsDocumento6 pagineComparative Corrosion and Current Burst Testing of Copper and Aluminum Electrical Power ConnectorsRuben HockNessuna valutazione finora

- Definition of CorrosionDocumento19 pagineDefinition of CorrosionWilliam Dave DomasinNessuna valutazione finora

- Welding consumables guide to electrodes and filler metalsDocumento12 pagineWelding consumables guide to electrodes and filler metalsMuhammed SulfeekNessuna valutazione finora

- Bonding To ALumiumDocumento2 pagineBonding To ALumiumthinnnhNessuna valutazione finora

- J C Gupta & SonsDocumento9 pagineJ C Gupta & Sons068999Nessuna valutazione finora

- The Properties of 7xxx Series AlloyDocumento6 pagineThe Properties of 7xxx Series Alloyac3.evfrezNessuna valutazione finora

- Investigation Into Possible Electrical Fire Outbreaks at Welders' Workshops at Siwdo KokompeDocumento13 pagineInvestigation Into Possible Electrical Fire Outbreaks at Welders' Workshops at Siwdo KokompeAlexander DeckerNessuna valutazione finora

- Trilogy Connector Design Contact FinishesDocumento3 pagineTrilogy Connector Design Contact FinisheschopanalvarezNessuna valutazione finora

- Corrosion and Its PreventionDocumento28 pagineCorrosion and Its PreventionMehul Neha Bisht100% (2)

- AnodizingDocumento13 pagineAnodizingRatheesh VidyadharanNessuna valutazione finora

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksDa EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksNessuna valutazione finora

- MentalRay Arch and DesignDocumento122 pagineMentalRay Arch and DesignRoyBerendsenNessuna valutazione finora

- IS800 10boltDocumento30 pagineIS800 10boltmaheshNessuna valutazione finora

- Is-00304 - High Tensile Brass Ingots CastingDocumento10 pagineIs-00304 - High Tensile Brass Ingots Castingnishanth132Nessuna valutazione finora

- Is 276 Manganese Steel CastingDocumento12 pagineIs 276 Manganese Steel CastingShankhaPathakNessuna valutazione finora

- Material Properties of SteelDocumento33 pagineMaterial Properties of Steelpinku_thakkarNessuna valutazione finora

- Is-00228-Part06 - Chemical Analysys of SteelDocumento7 pagineIs-00228-Part06 - Chemical Analysys of Steelnishanth132Nessuna valutazione finora

- Safeguarding Equipment and Protecting Workers From Amputations Small Business Safety and Health Management SeriesDocumento38 pagineSafeguarding Equipment and Protecting Workers From Amputations Small Business Safety and Health Management Seriesnishanth132Nessuna valutazione finora

- Ladle Hook 1 08 009 83Documento3 pagineLadle Hook 1 08 009 83amitkumarkarmakarNessuna valutazione finora

- Sheave Pulley 1-08-002-09Documento6 pagineSheave Pulley 1-08-002-09nishanth132Nessuna valutazione finora

- Is-00305 - Aluminium Bronze Ingots & CastingDocumento10 pagineIs-00305 - Aluminium Bronze Ingots & Castingnishanth132Nessuna valutazione finora

- Is-00277 - Galvazized Steel SheetsDocumento10 pagineIs-00277 - Galvazized Steel Sheetsnishanth132Nessuna valutazione finora

- Is-00292 - Leaded Brass Ingots CastingDocumento10 pagineIs-00292 - Leaded Brass Ingots Castingnishanth132Nessuna valutazione finora

- Is-00228-Part05 - Chemical Analysys of SteelDocumento7 pagineIs-00228-Part05 - Chemical Analysys of Steelnishanth132Nessuna valutazione finora

- IS 00228 Part13Documento6 pagineIS 00228 Part13Jignesh TrivediNessuna valutazione finora

- Is-00228-Part02 - Chemical Analysys of SteelDocumento8 pagineIs-00228-Part02 - Chemical Analysys of Steelnishanth132Nessuna valutazione finora

- Is-00228-Part03 - Chemical Analysys of SteelDocumento10 pagineIs-00228-Part03 - Chemical Analysys of Steelnishanth132Nessuna valutazione finora

- Is-00228-Part01 - Chemical Analysys of SteelDocumento4 pagineIs-00228-Part01 - Chemical Analysys of Steelnishanth132Nessuna valutazione finora

- Total Carbon by Gravimetric MethodDocumento6 pagineTotal Carbon by Gravimetric Methodnishanth132Nessuna valutazione finora

- Is 00191Documento34 pagineIs 00191nishanth132Nessuna valutazione finora

- Is 00210Documento12 pagineIs 00210nishanth132Nessuna valutazione finora

- Lndian Standard: Specification. FOR High Heat Duty Fireclay Refractorie$Documento8 pagineLndian Standard: Specification. FOR High Heat Duty Fireclay Refractorie$nishanth132Nessuna valutazione finora

- Is 00005Documento20 pagineIs 00005Jignesh TrivediNessuna valutazione finora

- Is 00195Documento6 pagineIs 00195nishanth132Nessuna valutazione finora

- Is 00002Documento6 pagineIs 00002Jignesh TrivediNessuna valutazione finora

- Is 00025Documento9 pagineIs 00025jbt1311Nessuna valutazione finora

- Sinter Plant: Item W Eight QTY Material THK Width/Id Length Drg. No./ Size DesignationDocumento1 paginaSinter Plant: Item W Eight QTY Material THK Width/Id Length Drg. No./ Size Designationnishanth132Nessuna valutazione finora

- Is 00028Documento13 pagineIs 00028Gabriel PowellNessuna valutazione finora

- Is 00006Documento5 pagineIs 00006Jignesh TrivediNessuna valutazione finora

- Is 00207Documento4 pagineIs 00207nishanth132Nessuna valutazione finora

- Investigating The Mechanical Properties of Compression Molded CarDocumento33 pagineInvestigating The Mechanical Properties of Compression Molded Carnishanth132Nessuna valutazione finora

- Article On Sanskrit LanguageDocumento51 pagineArticle On Sanskrit LanguagekrcsonlineNessuna valutazione finora

- A New Anode Material For Oxygen Evolution in Molten Oxide ElectrolysisDocumento6 pagineA New Anode Material For Oxygen Evolution in Molten Oxide ElectrolysisjnNessuna valutazione finora

- Aluminium ADC12Documento1 paginaAluminium ADC12Gowtham Raj KNessuna valutazione finora

- Stripping Solution Section Processing Solution Immersion ElectrolyticDocumento2 pagineStripping Solution Section Processing Solution Immersion ElectrolyticDavid WongNessuna valutazione finora

- 3 s2.0 B978012822974300063X MainDocumento11 pagine3 s2.0 B978012822974300063X MainFernando Andrés Ortega JiménezNessuna valutazione finora

- Innovations in Precision Grinding AbrasivesDocumento21 pagineInnovations in Precision Grinding AbrasivesDaniel FigueiredoNessuna valutazione finora

- Astm B308 - 6061-T6Documento6 pagineAstm B308 - 6061-T6Aman Sharma100% (1)

- Aluminum 6082-T4: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocumento1 paginaAluminum 6082-T4: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloydeepscubNessuna valutazione finora

- MSDS CaODocumento14 pagineMSDS CaOGİZEM DEMİRNessuna valutazione finora

- Module-1 Overview of Civil Engineering SystemsDocumento20 pagineModule-1 Overview of Civil Engineering SystemsManvanth B CNessuna valutazione finora

- Alphonsa School, Kalamjote - Preboard - ChemistryDocumento4 pagineAlphonsa School, Kalamjote - Preboard - Chemistryakshayashivakumar96Nessuna valutazione finora

- 2020 2021 Class X Chemistry Part 1 AWDocumento135 pagine2020 2021 Class X Chemistry Part 1 AWThanveer Ahmad100% (1)

- Formula Number of Equivalents Equivalent Weight Positive IonsDocumento3 pagineFormula Number of Equivalents Equivalent Weight Positive IonsAhmed Khalid HussainNessuna valutazione finora

- METALS NON METALS ExerciseDocumento10 pagineMETALS NON METALS ExercisePrathmesh Naman100% (1)

- Recruitment and Selection at NALCODocumento98 pagineRecruitment and Selection at NALCOakash moharanaNessuna valutazione finora

- 2 - AIChE Journal, Vol. 51, No. 11, (November 2005) PDFDocumento204 pagine2 - AIChE Journal, Vol. 51, No. 11, (November 2005) PDFRodrigo CastroNessuna valutazione finora

- Fluoride Content of Clay Minerals and Argillaceous Earth MaterialsDocumento7 pagineFluoride Content of Clay Minerals and Argillaceous Earth MaterialsLaura TartauNessuna valutazione finora

- Fulltext01 PDFDocumento132 pagineFulltext01 PDFCecySoriaNessuna valutazione finora

- Hilirisasi Produk Dan Kandungan Lokal: Aluminium Billet & Alloy PT Inalum (Persero) Location: Kuala Tanjung, Sum-UtDocumento15 pagineHilirisasi Produk Dan Kandungan Lokal: Aluminium Billet & Alloy PT Inalum (Persero) Location: Kuala Tanjung, Sum-Utfarhan fahmiNessuna valutazione finora

- CLEANING AND CORROSION CONTROLDocumento31 pagineCLEANING AND CORROSION CONTROLHyori AnapadaNessuna valutazione finora

- Aluminum Flyer DistDocumento2 pagineAluminum Flyer Distasavari87Nessuna valutazione finora

- Die Casting Defects PDFDocumento4 pagineDie Casting Defects PDFJojokiba YosNessuna valutazione finora

- Copper AlloysDocumento61 pagineCopper Alloysbvalinhas100% (2)

- Catalog Ledux OfficeDocumento46 pagineCatalog Ledux OfficeIuliaDamianNessuna valutazione finora

- Chemsheets As 008 (Amount of Substance)Documento36 pagineChemsheets As 008 (Amount of Substance)Durjoy ChakrabortyNessuna valutazione finora

- Light Anhydrous Silicic Acid 1572Documento2 pagineLight Anhydrous Silicic Acid 1572TrinhphuongNessuna valutazione finora

- Construction Materials Ii: 1.1 Ferrous MetalDocumento6 pagineConstruction Materials Ii: 1.1 Ferrous MetalQila HusinNessuna valutazione finora

- Dwnload Full Labor Economics 7th Edition George Borjas Test Bank PDFDocumento35 pagineDwnload Full Labor Economics 7th Edition George Borjas Test Bank PDFjosiahdunnmg100% (11)

- Exposure of Metals and Alloys by Alternate Immersion in Neutral 3.5 % Sodium Chloride SolutionDocumento5 pagineExposure of Metals and Alloys by Alternate Immersion in Neutral 3.5 % Sodium Chloride Solutionjose floresNessuna valutazione finora

- BS 00336 2010Documento44 pagineBS 00336 2010HazimNessuna valutazione finora