Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

5.4 Making PTO Connections

Caricato da

Wijayanto BekasiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

5.4 Making PTO Connections

Caricato da

Wijayanto BekasiCopyright:

Formati disponibili

MAKING PTO CONNECTIONS

HOSTA Task Sheet 5.4 Core

NATIONAL SAFE TRACTOR AND MACHINERY OPERATION PROGRAM

Introduction

After spotting the hitch to connect the tractor to the implement, the operator must attach the PTO shaft of the tractor to the implement by way of the implement input driveline (IID). See Task Sheet 5.4.1. These connecting shafts can be heavy, greasy, and difficult to manipulate in the cramped space between the tractor and the equipment. The youthful operator must have a strong grip and will often have to work at an awkward angle. Check the NAGCAT website to determine if you can handle the task of PTO connection. This task sheet discusses PTO design and how to make PTO connections through knowledge of that design.

The faster the PTO speed, the more teeth that are used to make the PTO connection between the tractor and the implement. PTO Sizes: PTO stub shaft diameter for a 540 rpm shaft is 1 3/8 inch. The 1000 rpm stub shaft with 21 splines or teeth is 1 3/8 inch. The 1000 rpm stub shaft with 20 splines or teeth has a diameter of 1 3/4 inch.

Figure 5.4.c. NAGCAT recommends that youthful farm workers wear snug-fitting clothes, non-skid shoes, and hearing protection while working around machinery. The youths ability to lift and connect the PTO shaft must be evaluated by an adult who understands the physical development of children.

540 rpm PTOs have 6 splines or teeth. 1000 rpm PTOs have

Figure 5.4.a. The 540 rpm PTO stub shaft has 6 splines or teeth and is 1 3/8 inch in diameter. Farm and Ranch Safety Management, John

Deere Publishing, 1994. Illustrations reproduced by permission. All rights reserved.

20 or 21 splines or teeth.

PTO Stub Shaft Design

PTO Speeds: Tractor PTOs are designed to rotate at 540 rpm or 1000 rpm. Shiftable, dual-speed PTOs may reach a maximum design speed of 630 rpm or 1170 rpm. PTO Splines: By counting the number of splines, or teeth on a PTO stub shaft, the beginning operator can identify the speed of the PTO shaft in rpms. A 540 rpm PTO shaft will have 6 splines or teeth. A 1000 rpm PTO shaft may have 20 or 21 splines or teeth.

Learning Goals

To be able to attach the PTO driveline between the tractor and the implement

Related Task Sheets: Reaction Time Figure 5.4.b. The 1000 rpm PTO stub shaft has either 20 splines or teeth with a 1 3/4 inch diameter or may have 21 splines or teeth with a 1 3/8 inch diameter. Age-Appropriate Tasks Mechanical Hazards Using 3-Point Hitch Implements Using Power Take-Off Implements 2.3 2.4 3.1 5.3 5.4.1

The Pennsylvania State University 2004

Cooperation provided by The Ohio State University and National Safety Council.

Page 2

MAKING PTO CONNECTIONS

Push Pin Steel Pin through PTO shaft Steel bolt through PTO shaft

Self-locking coupler

OLDER STYLE

NEWER STYLE

Figure 5.4.d. Various means to secure the PTO shaft to the stub shaft have been used over the years. Besides those connection methods shown above, another popular style is the push pin detent locking type shown in Figure 5.5.e. All types of locking device areas must be guarded as they are wrap points where the operator can become entangled in the PTO.

PTOs must be guarded to prevent an entanglement hazard.

you if necessary.

Connecting the PTO

Follow these steps to attach the PTO shaft of a 3-point hitch implement. 1. Connect the tractor to the drawbar or to the 3-point hitch of the implement using the approved steps. See Task Sheets 5.1, 5.2, and 5.3. 2. Attach the PTO shaft of the implement to the PTO stub shaft of the tractor. Here are some suggestions to make the PTO connection easier. A. Align the driveline PTO shaft splines with the splines of the stub shaft of the tractor. If the splines will not align, try turning the tractor PTO stub shaft slightly, or use the implement flywheel to move the implements PTO shaft. Have this procedure shown to

B. Press the detent lock push pin inward (Figure 5.4.e) as you slide the implement shaft onto the tractor stub shaft. C. Slide the implement shaft forward far enough to make sure the detent pin has snapped into the lock position.

PTO Care and Use

Dirt and grease can make the PTO shaft difficult to grasp and connect. Keep the PTO shaft off the ground. Wipe the excess grease from the PTO shaft with a cloth. Important: A new PTO shaft has paint inside the splines. This may prevent the shaft from fitting over the PTO stub. The paint must be removed.

Figure 5.4.e. The push pin detent lock on the PTO driveline has a metal rod which fits in the PTO stub shaft groove to secure it. A firm grip is needed to press the pin. Do you have enough hand strength to push this pin in all the way?

The Pennsylvania State University 2004

Cooperation provided by The Ohio State University and National Safety Council.

HOSTA TASK SHEET 5.4

Page 3

Adult Responsibilities:

PTO Phasing

Older PTO shafts can be separated or pulled apart. The two parts are made so that one part fits into the other. The PTO must be able to telescope in and out to permit machine operation over irregular terrain. If the parts become separated, they must be re-assembled in phase to avoid placing extra strain on the universal joints. Many shafts are designed to prevent this from happening.

Be sure implement is in working order. Be sure that all safety features are in place. Be sure the work area has no hazards. Be sure the youth has long hair tied up out of the way, has nonskid shoes, and snug-fitting clothes. Hearing protection is recommended as well.

Figure 5.4.g. This is what the task of connecting a PTO looks like. You must lift a heavy object at an awkward angle while squeezing in the lock mechanism detent pin. Watch someone else connect a PTO several times before doing this job. Continue practicing connecting a PTO on your own with supervision.

The adult in charge should also evaluate you using the following questions: 1. Can the youth drive the tractor skillfully? 2. Can the youth hitch and unhitch implements? 3. Does the PTO shaft weigh more than 10-15% of the youths body weight? To avoid back injury, this should be the maximum weight you should be asked to lift. 4. Can the youth follow a 5-step process? 5. Has the youth been trained in proper lifting techniques? 6. Has an adult demonstrated connecting and disconnecting a PTO? 7. Can the youth do the job 4 or 5 times under direct supervision? 8. Can an adult provide the recommended supervision? Your experience level may be acceptable to you, but proof of your expertise should be evaluated by a qualified tractor operator.

Connecting a PTO shaft will be easier after practicing the job several times.

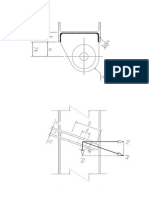

Figure 5.4.f. The upper portion of the drawing illustrates a correctly placed universal joint. You may wish to check the phasing on a PTO shaft.

NAGCAT Guidelines

NAGCAT recommendations for connecting and disconnecting a PTO shaft are shown in this section. These recommendations were developed by a knowledgeable group of safety experts as a means of helping parents to match youthful agricultural workers with the tasks that are appropriate to their development. The PTO guidelines are presented here.

Figure 5.4.h. This PTO stub shaft is protected with a tractor master shield and stub shaft cover. To remove the stub shaft cover, grip the cover firmly and turn counterclockwise. Store the stub shaft cover where it will be available to replace when the job is done.

The Pennsylvania State University 2004

Cooperation provided by The Ohio State University and National Safety Council.

Page 4

MAKING PTO CONNECTIONS

Safety Activities

1. Using an Internet search engine, type NAGCAT and view the many guidelines presented for the various farm jobs you may be assigned to do. Are you ready to accept these jobs based upon the guidelines presented? 2. Do a survey of the tractors on a farm to determine how many have 540 rpm PTO shafts and how many have 1000 rpm PTO shafts. Record the results. 3. Practice lifting a PTO shaft right handed while squeezing the locking mechanism of the PTO shaft connector. Practice lifting a PTO shaft left handed while squeezing the locking mechanism of the PTO shaft connector. From which side were you able to lift and squeeze best? 4. Check the phasing of three PTO shafts. Make a drawing of the universal joints on each end of the PTO shaft. Did you find any PTO shafts that were out of phase? If so, label this drawing to show what was wrong.

5. Fill in the blanks: A. A PTO shaft with 6 teeth on the shaft is designed for ________rpms of speed. B. A PTO shaft that has 20 teeth on the shaft is designed for ______rpms of speed. C. A PTO shaft that has 21 teeth on the shaft is designed for ______rpms of speed. D. What is the maximum weight that a 14 or 15-year-old worker should be expected to lift without straining the back muscles?_________________ % of their body weight. 6. Word scramble. Unscramble the following words. Then fill in the blanks to form a safety message about PTOs. _________ all PTO _______. d a u g r = ___ ___ ___ ___ ___ s s t a f h = ___ ___ ___ ___ ___ ___

7. From this phrase implement input driveline, write a word list using as many letters as you can. The words must have at least four letters. No two-letter or three-letter words are permitted. Letters may only be used as many times as they appear in the phrase. Example: RIVET can be found in the phrase.

References

1. 2. www.nagcat.org/Click on Guidelines/Scroll through the list to find a topic. February, 2003. www.asae.org/Click on Technical Library/ Scroll to Standards/Type in Power Take-Off/Download PDF file, ASAE S203, December 2001. Safety Management for Landscapers, Grounds-Care Businesses and Golf Courses, 2001, 1st Edition, John Deere Publishing, Moline, Illinois. Farm and Ranch Safety Management, John Deere Publishing, 1994. Illustrations reproduced by permission. All rights reserved.

Contact Information

National Safe Tractor and Machinery Operation Program The Pennsylvania State University Agricultural and Biological Engineering Department 246 Agricultural Engineering Building University Park, PA 16802 Phone: 814-865-7685 Fax: 814-863-1031 Email: NSTMOP@psu.edu

3.

Credits

Developed, written and edited by WC Harshman, AM Yoder, JW Hilton and D J Murphy, The Pennsylvania State University. Reviewed by TL Bean and D Jepsen, The Ohio State University and S Steel, National Safety Council. Version 4/2004

This material is based upon work supported by the Cooperative State Research, Education, and Extension Service, U.S. Department of Agriculture, under Agreement No. 2001-41521-01263. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.

4.

The Pennsylvania State University 2004

Cooperation provided by The Ohio State University and National Safety Council.

Potrebbero piacerti anche

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- Brake ActuatorDocumento16 pagineBrake Actuatorrene chapdelaineNessuna valutazione finora

- Agri-Fab, Craftsman Front Mount DethatcherDocumento12 pagineAgri-Fab, Craftsman Front Mount DethatcherKevins Small Engine and Tractor ServiceNessuna valutazione finora

- Titan Model 60: Surg-O-Matic Actuator For Trailer BrakesDocumento12 pagineTitan Model 60: Surg-O-Matic Actuator For Trailer BrakesRob GustNessuna valutazione finora

- POWERBLOCDocumento17 paginePOWERBLOCcyril DESPRATNessuna valutazione finora

- 5.3 Using 3-Point Hitch ImplementsDocumento4 pagine5.3 Using 3-Point Hitch ImplementseleyahobNessuna valutazione finora

- 2 - Tesco Top Drive Safety ManualDocumento18 pagine2 - Tesco Top Drive Safety Manualzanella88Nessuna valutazione finora

- LT-103 3000instructions PDFDocumento24 pagineLT-103 3000instructions PDFAndres AlvarezNessuna valutazione finora

- Concept 10.5 Dual Disc Installation InstructionsDocumento6 pagineConcept 10.5 Dual Disc Installation Instructionstanijk444Nessuna valutazione finora

- PTO BZ 1000 Service ManualDocumento28 paginePTO BZ 1000 Service ManualalfonsofelipesaraviaNessuna valutazione finora

- 83-97 Ford Ranger, Bronco Ii 4" KitDocumento4 pagine83-97 Ford Ranger, Bronco Ii 4" KitRoberto Lopez RojasNessuna valutazione finora

- Falk Type UbDocumento12 pagineFalk Type UbJuan GalvesNessuna valutazione finora

- Owner'S Manual: Powertap SLDocumento39 pagineOwner'S Manual: Powertap SLsinkdeepNessuna valutazione finora

- Hughes Torque Converter Installation InstructionsDocumento3 pagineHughes Torque Converter Installation InstructionsMichael VasquezNessuna valutazione finora

- Rough Country Kit Lift 633XN2Documento8 pagineRough Country Kit Lift 633XN2veabreuNessuna valutazione finora

- How To Remove The Deck From A John Deere 455Documento3 pagineHow To Remove The Deck From A John Deere 455George ClarkNessuna valutazione finora

- Eaton Clutch ManualDocumento46 pagineEaton Clutch ManualEric Porter100% (4)

- Atra-4l80e-Rebuild (GM) Part 1Documento50 pagineAtra-4l80e-Rebuild (GM) Part 1highvoltkv100% (3)

- Atra 4l80e Rebuild (GM)Documento100 pagineAtra 4l80e Rebuild (GM)lee fox100% (20)

- AGR318 - Individual AssignmentDocumento7 pagineAGR318 - Individual AssignmentHaikal SapurataNessuna valutazione finora

- Front Disk Brakes ConversionDocumento4 pagineFront Disk Brakes Conversionzafar11Nessuna valutazione finora

- Value Leader Wood Chipper WC Series ManualDocumento19 pagineValue Leader Wood Chipper WC Series ManualBetstProducts67% (3)

- 2014 Organizing and Conducting A Safe Tractor Operation WorkshopDocumento16 pagine2014 Organizing and Conducting A Safe Tractor Operation WorkshopChris HuntNessuna valutazione finora

- 300-080-11 RSPC1 Instalation ManualDocumento24 pagine300-080-11 RSPC1 Instalation ManualLuis A DuarteNessuna valutazione finora

- 97-06 Jeep TJ 1 1/4" Body Lift KitDocumento4 pagine97-06 Jeep TJ 1 1/4" Body Lift KitJulio CorzoNessuna valutazione finora

- AXL - AxlesDocumento7 pagineAXL - AxlesDavid GaciaNessuna valutazione finora

- TT4100 Ops Manual 990039Documento23 pagineTT4100 Ops Manual 990039farid said errahmaniNessuna valutazione finora

- Rotary Tiller: Operation, Service & Parts Manual For "AS" SeriesDocumento16 pagineRotary Tiller: Operation, Service & Parts Manual For "AS" SeriesSuryaSuryaNessuna valutazione finora

- Briggs and Stratton Engine DisassemblyDocumento7 pagineBriggs and Stratton Engine DisassemblyThomas SjölingNessuna valutazione finora

- Briggs&Strattons or AdjustmentsDocumento4 pagineBriggs&Strattons or Adjustmentselfynguyen100% (3)

- Erection & Installation ProcedureDocumento3 pagineErection & Installation ProcedureForos IscNessuna valutazione finora

- Operating ManualDocumento34 pagineOperating ManualLauraNessuna valutazione finora

- Proclimb Procross Torsional Conversion KitDocumento8 pagineProclimb Procross Torsional Conversion KitcpcracingNessuna valutazione finora

- Operation & Preventive Maintenance Manual Winch Model 527Documento14 pagineOperation & Preventive Maintenance Manual Winch Model 527Gissel CQNessuna valutazione finora

- GM 3.0 LDocumento36 pagineGM 3.0 Lmeyyiti01Nessuna valutazione finora

- Study Fabn of Clutch Final ReadyDocumento109 pagineStudy Fabn of Clutch Final ReadySuresh KumarNessuna valutazione finora

- 80-96 F150 2 1/2" Lift Kit InstructionsDocumento4 pagine80-96 F150 2 1/2" Lift Kit Instructionsisaacllugo1Nessuna valutazione finora

- Lgf-432h-Emh-1025 - 490 - 4174 I+m ManualDocumento7 pagineLgf-432h-Emh-1025 - 490 - 4174 I+m ManualhansNessuna valutazione finora

- Lgf-432h-Emh-1025 - 490 - 4174 I+m ManualDocumento7 pagineLgf-432h-Emh-1025 - 490 - 4174 I+m ManualhansNessuna valutazione finora

- Golden Eagle Rake Manual 2016 COMPLETEDocumento20 pagineGolden Eagle Rake Manual 2016 COMPLETEИванов ИвановNessuna valutazione finora

- (OTO-HUI - Com) Rack and Pinion in The Freightliner CascadiasDocumento13 pagine(OTO-HUI - Com) Rack and Pinion in The Freightliner Cascadiaseng_ebrahim_2000Nessuna valutazione finora

- Repair Manual MP 1Documento11 pagineRepair Manual MP 1Tiffany DacinoNessuna valutazione finora

- ATRA 41TE Rebuild (Chrysler A 604)Documento115 pagineATRA 41TE Rebuild (Chrysler A 604)Patricio Bacigalupi100% (4)

- Power Front Disc Conversion Instructions MDC62DCDocumento11 paginePower Front Disc Conversion Instructions MDC62DCandrakin8Nessuna valutazione finora

- ATRA Ford AX4S AX4ODE Rebuild ProceduresDocumento145 pagineATRA Ford AX4S AX4ODE Rebuild ProceduresHugo Sanchez100% (3)

- Braked Drum StandDocumento10 pagineBraked Drum StandAliNessuna valutazione finora

- Firecharger Installation ADocumento10 pagineFirecharger Installation AAugmotorsNessuna valutazione finora

- Adjustable Tow Bar Instructions: Read, Understand, Follow and Save These InstructionsDocumento22 pagineAdjustable Tow Bar Instructions: Read, Understand, Follow and Save These InstructionsWilliam BarriosNessuna valutazione finora

- Fillo ManualDocumento8 pagineFillo ManualAndreas RousounidesNessuna valutazione finora

- Linkage in Farm MachineryDocumento4 pagineLinkage in Farm MachineryRehan RashidNessuna valutazione finora

- Bicycle Engine Kit Installation Guide - Raw 80ccDocumento9 pagineBicycle Engine Kit Installation Guide - Raw 80ccSokitome0% (1)

- HammerDocumento20 pagineHammerdatnguyen789jNessuna valutazione finora

- Failure Analysis Guide: Eaton Fuller Clutches February 2008Documento48 pagineFailure Analysis Guide: Eaton Fuller Clutches February 2008Angel DlsgNessuna valutazione finora

- A2 Drive Nut ReplacementDocumento7 pagineA2 Drive Nut ReplacementJibjab7100% (1)

- KingKutter FinishMower ManualDocumento44 pagineKingKutter FinishMower Manual78289571Nessuna valutazione finora

- Chevy Differentials: How to Rebuild the 10- and 12-BoltDa EverandChevy Differentials: How to Rebuild the 10- and 12-BoltValutazione: 5 su 5 stelle5/5 (8)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsDa EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsValutazione: 5 su 5 stelle5/5 (5)

- GM Turbo 350 Transmissions: How to Rebuild and ModifyDa EverandGM Turbo 350 Transmissions: How to Rebuild and ModifyNessuna valutazione finora

- Chevelle Performance Projects: 1964-1972Da EverandChevelle Performance Projects: 1964-1972Valutazione: 4.5 su 5 stelle4.5/5 (2)

- Surface Preparation & Painting Procedure r1Documento4 pagineSurface Preparation & Painting Procedure r1Wijayanto BekasiNessuna valutazione finora

- Stresses in BeamDocumento34 pagineStresses in BeamWijayanto BekasiNessuna valutazione finora

- Tail Lifting Lug Calculation MS WordDocumento11 pagineTail Lifting Lug Calculation MS WordWijayanto BekasiNessuna valutazione finora

- Steel Beams AnalysisDocumento15 pagineSteel Beams AnalysisWijayanto BekasiNessuna valutazione finora

- Lifting Lug ArrangementDocumento1 paginaLifting Lug ArrangementWijayanto BekasiNessuna valutazione finora

- Modco Closures: Operation, Maintenance & Welding InstructionsDocumento7 pagineModco Closures: Operation, Maintenance & Welding InstructionsWijayanto BekasiNessuna valutazione finora

- Cog CalculationDocumento4 pagineCog CalculationWijayanto BekasiNessuna valutazione finora

- Commissioning Results On Dtvv44079 S/D Dtvv44091Documento2 pagineCommissioning Results On Dtvv44079 S/D Dtvv44091Wijayanto BekasiNessuna valutazione finora

- Sample Itp For VesselDocumento10 pagineSample Itp For VesselWijayanto BekasiNessuna valutazione finora

- Nbi Vertical Agitator: Installation, Service and Maintenance InstructionsDocumento20 pagineNbi Vertical Agitator: Installation, Service and Maintenance InstructionsWijayanto BekasiNessuna valutazione finora

- Designed by Checked by Approved by Date DateDocumento1 paginaDesigned by Checked by Approved by Date DateWijayanto BekasiNessuna valutazione finora

- R100 Data SheetDocumento1 paginaR100 Data SheetWijayanto BekasiNessuna valutazione finora

- Tiger SharkDocumento2 pagineTiger Sharkstefanpl94Nessuna valutazione finora

- ch46Documento15 paginech46jose perezNessuna valutazione finora

- XII Bahasa Inggris No. 16-18Documento3 pagineXII Bahasa Inggris No. 16-18Auryn AnastashaNessuna valutazione finora

- BK3251 BekenDocumento13 pagineBK3251 BekenDanny DurhamNessuna valutazione finora

- AGC IPC Slash Sheet ReferenceDocumento4 pagineAGC IPC Slash Sheet ReferenceSelvakumar NatarajanNessuna valutazione finora

- Sony Chassis Ba-4 (C-TV KV-13M40 - 50 - 51, KV-14MB40, KV-20M40, KV-20S40 - 41, KV-20V80, Kv-21se80, Kv-21se40, Kv-21me40... Service Manual)Documento94 pagineSony Chassis Ba-4 (C-TV KV-13M40 - 50 - 51, KV-14MB40, KV-20M40, KV-20S40 - 41, KV-20V80, Kv-21se80, Kv-21se40, Kv-21me40... Service Manual)Mauro Mendez100% (1)

- Contact List For All NWGDocumento22 pagineContact List For All NWGKarthickNessuna valutazione finora

- 475英文说明书Documento33 pagine475英文说明书Jon Aldwin CamachoNessuna valutazione finora

- S7-1200 DataSheetDocumento14 pagineS7-1200 DataSheetperuhayaNessuna valutazione finora

- Culminating Activity: (A Proposal)Documento3 pagineCulminating Activity: (A Proposal)Landice Myoui100% (1)

- Sensus WP Dynamic Cold Water Meter (DN40-300)Documento4 pagineSensus WP Dynamic Cold Water Meter (DN40-300)Roderikus Rendy MNessuna valutazione finora

- PLSP 2 6 Aloha PDFDocumento35 paginePLSP 2 6 Aloha PDFKajenNessuna valutazione finora

- Unit of Work Football Y9Documento5 pagineUnit of Work Football Y9api-282209830Nessuna valutazione finora

- University of Colombo Faculty of Graduate Studies: PGDBM 504 - Strategic ManagementDocumento15 pagineUniversity of Colombo Faculty of Graduate Studies: PGDBM 504 - Strategic ManagementPrasanga WdzNessuna valutazione finora

- JIS B 01801 - 000 - 000 - 1997 - e - pr10 - I4Documento27 pagineJIS B 01801 - 000 - 000 - 1997 - e - pr10 - I4Flavio ShiratoNessuna valutazione finora

- Wyche Bridge 2000Documento12 pagineWyche Bridge 2000BhushanRajNessuna valutazione finora

- Spam DetectionDocumento142 pagineSpam DetectionRahul GantaNessuna valutazione finora

- Premium Protection Synthetic Motor Oils (AMO & ARO)Documento2 paginePremium Protection Synthetic Motor Oils (AMO & ARO)brian5786Nessuna valutazione finora

- MIL-W-22759 Rev E - Part34Documento1 paginaMIL-W-22759 Rev E - Part34David WongNessuna valutazione finora

- Transformer HandbookDocumento116 pagineTransformer HandbookAnder H. CaulfieldNessuna valutazione finora

- Electrical Machines (K-18EL101) (Mid-Term Presentation)Documento11 pagineElectrical Machines (K-18EL101) (Mid-Term Presentation)Noor SabaNessuna valutazione finora

- Assessment of Learning 1 Quiz 1Documento3 pagineAssessment of Learning 1 Quiz 1imalwaysmarked100% (4)

- Introduction To CMOS Circuit DesignDocumento20 pagineIntroduction To CMOS Circuit DesignBharathi MuniNessuna valutazione finora

- Heinzmann ControlsDocumento4 pagineHeinzmann ControlsShahzad AhmadNessuna valutazione finora

- 50rhe PDDocumento40 pagine50rhe PDm_moreira1974Nessuna valutazione finora

- Scan 0001Documento1 paginaScan 0001ochiroowitsNessuna valutazione finora

- The Butt Joint Tool: Product InformationDocumento8 pagineThe Butt Joint Tool: Product InformationElias de Souza RezendeNessuna valutazione finora

- Buying Solutions' Total Cost of Ownership (TCO) CalculatorDocumento93 pagineBuying Solutions' Total Cost of Ownership (TCO) Calculatorankitch123Nessuna valutazione finora

- C D C SDocumento4 pagineC D C SandriNessuna valutazione finora

- Dungeon Siege Game GuideDocumento21 pagineDungeon Siege Game GuideJesse StillNessuna valutazione finora