Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Guaranteeing Clean Cooling Fluids

Caricato da

Donaldson Europe B.V.B.A.Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Guaranteeing Clean Cooling Fluids

Caricato da

Donaldson Europe B.V.B.A.Copyright:

Formati disponibili

CLEAN FLUID CASE STUDY

Guaranteeing clean cooling fluids

The Case

SF-Filter is an international company headquartered in Switzerland. The Polish division of SF-Filter is located in Lubin where a state-of-the-art training and system design center is located. SF-Filter is a Authorized Donaldson Distributor and delivers innovative hydraulic filters for mobile machine OEM bus and agriculture markets and heavy industrial applications. One of their customers faces filtration issues with CNC machines.

The Challenge

An important customer of SF-Filter in Poland produces tools for metal processing industries. Their CNC machine park consists out of 20 fully operational machines, all equipped with cooling systems and Cimcool D16C fluid (water/oil emulsion and HWCF). Due to low initial supplier availability (US import), the new CNC machines were foreseen with 20 water filter housings with melt-blown polypropylene elements or single housing with cellulose media element similar to the initial supplier element (576x153 mm size). The new water filters or single housings showed very poor cleanliness and did not filter metal particles (between 0,45 m and 7 m) which resulted in short filter elements life and low liquid pressure. Also the solution offered was not integrated into the CNC machines in a professional manner.

The Solution

When it comes to proper cleanliness levels and ensuring long filter quality, Donaldson filtration is the best choice. SF-Filter recommended their customer to use Donaldson HFK08 in-line filter series. Which feature: Donaldson Synteq media elements which can work with HWCF , Synteq media elements with =1000 micron rating, (ISO 16889) Big housing with large filter element to prevent frequently service, In-line style mounting to fit with new tank and immersion coolant pump (Grundfos),

The customer installed 2x2 system with two K080087 (HFK08) housings with 10 m elements (P176222) in the firts stage after pump and two K080087 filters with <4 m elements (P164405) in the second stage. This resulted in a 15/13/10 ISO Cleanliness level and a drop of 5 m particles to 0! In the near future all CNC machines will be equipped with Donaldson Synteq media elements and HFK08 housings. Use Donaldson Synteq media as a warranty for clean cooling liquid.

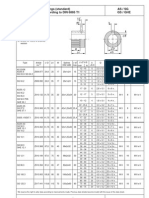

HFK08 Max Flow: 300 gpm (1135 lpm)

HFK08 In-Line/Tank Mount Filters Working Pressures to: Rated Static Burst to: Flow Ranges to: 350 psi 2413 kPa 24.1 bar 500 psi 3448 kPa 34.5 bar 300 gpm 1135 lpm

Features

In-line model shown

HFK08 is available in two styles: in-line and in-tank. Both styles feature a cast aluminum head and steel body for maximum strength and durability. Its single, center retention bolt simplifies servicing. Flow is from inside to outside of the filter cartridge. Three in-stock HFK08 models offer our proprietary Synteq synthetic media designed especially for liquid filtration. A wider range of filter media is available to purchase separately, as are fluoroelastomer seals. A visual service indicator is built into the HFK08 head.

Donaldson Europe b.v.b.a. Interleuvenlaan 1 3001 Leuven Belgium Engine-europe@donaldson.com www.donaldson.com

Europe +32-16-38-3811 North America 800-374-1374 Mexico +52-449-910-6150 Latin Am. & Carib. +52-449-910-6150 Brazil +55-11-2119-1604 South Africa +27-11-997-6000

South East Asia 65-6311-7373 Greater China 852-2405-8388 Japan 81-42-540-4112 Australia 61-02-4350-2033 India +91-124-2290060

2012 Donaldson Company, Inc. Donaldson Company, Inc. reserves the right to change or discontinue any model or specification at any time and without notice.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Analysis and Design of Bridge Substructures PDFDocumento195 pagineAnalysis and Design of Bridge Substructures PDFsuheilbugs100% (1)

- Ahsmrw30dam SD101Documento48 pagineAhsmrw30dam SD101ibrahimNessuna valutazione finora

- 4-2.0L Gasoline EngineDocumento187 pagine4-2.0L Gasoline EngineMarco Antonio Tomaylla Huamani100% (1)

- Clan Survey Pa 297Documento16 pagineClan Survey Pa 297Sahara Yusoph SanggacalaNessuna valutazione finora

- MBR Presentation LatestDocumento12 pagineMBR Presentation LatestRuchi GuptaNessuna valutazione finora

- Getting Started With DockerDocumento8 pagineGetting Started With DockerdenisaNessuna valutazione finora

- Job Description - NOC EngineerDocumento2 pagineJob Description - NOC EngineerMd ShujauddinNessuna valutazione finora

- Mail Scanner - Community Ubuntu DocumentationDocumento4 pagineMail Scanner - Community Ubuntu DocumentationAjith PathiranaNessuna valutazione finora

- TQM Model ExamDocumento5 pagineTQM Model ExamsaswarajNessuna valutazione finora

- Sika Cemflex 1Documento3 pagineSika Cemflex 1rasasiNessuna valutazione finora

- Chopra Scm5 Ch13Documento58 pagineChopra Scm5 Ch13Faried Putra SandiantoNessuna valutazione finora

- Project Goals/ ObjectivesDocumento51 pagineProject Goals/ ObjectivesJoyce Abegail De PedroNessuna valutazione finora

- TOR of The Feasibility Study of Crop RecommendationDocumento6 pagineTOR of The Feasibility Study of Crop RecommendationGangadhar ChaudharyNessuna valutazione finora

- User Manual For Online Super Market WebsiteDocumento3 pagineUser Manual For Online Super Market WebsiteTharunNessuna valutazione finora

- 1 1 6 Blood Splatter Analysis Experimental DesignDocumento4 pagine1 1 6 Blood Splatter Analysis Experimental Designapi-343751193100% (1)

- SSMT Solution ManualDocumento12 pagineSSMT Solution ManualPraahas Amin0% (1)

- History of Gun PowderDocumento32 pagineHistory of Gun PowderHerbert GongonNessuna valutazione finora

- Experiment No. 1: Aim: Study of Tanner Tools THEORY: Tanner ToolsDocumento24 pagineExperiment No. 1: Aim: Study of Tanner Tools THEORY: Tanner ToolsVarun GargNessuna valutazione finora

- LSZH Apch11 Rwy28 IlsDocumento1 paginaLSZH Apch11 Rwy28 Ilssamykarim2009Nessuna valutazione finora

- Center Pivot Cable / Wire Raintec Span Cable Raintec Motor DropDocumento1 paginaCenter Pivot Cable / Wire Raintec Span Cable Raintec Motor Drophicham boutoucheNessuna valutazione finora

- ToshibaDocumento316 pagineToshibaRitesh SharmaNessuna valutazione finora

- Spherical Pillow Block Manual (MN3085, 2018)Documento13 pagineSpherical Pillow Block Manual (MN3085, 2018)Dillon BuyeNessuna valutazione finora

- Six Tsakalis Pedal ManualDocumento1 paginaSix Tsakalis Pedal ManualAdedejinfoNessuna valutazione finora

- Pelland Pumptrack2018Documento60 paginePelland Pumptrack2018ksnakaNessuna valutazione finora

- Scan 1111111111Documento1 paginaScan 1111111111angela1178Nessuna valutazione finora

- Solenoid ValvesDocumento23 pagineSolenoid ValvesmcsecNessuna valutazione finora

- ' ' Shail Ahmad: Privet of India Acres N Inches List of ClientDocumento3 pagine' ' Shail Ahmad: Privet of India Acres N Inches List of Clientapi-243316402Nessuna valutazione finora

- G1 Group 1CDocumento72 pagineG1 Group 1CNH SyzlnNessuna valutazione finora

- NEF 50006 BSI WidescreenDocumento13 pagineNEF 50006 BSI Widescreenmiguelq_scribdNessuna valutazione finora

- As / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1Documento1 paginaAs / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1hadeNessuna valutazione finora