Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Butterfly Valve Info PDF

Caricato da

CSTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Butterfly Valve Info PDF

Caricato da

CSCopyright:

Formati disponibili

1

APPLICATION OF BUTTERFLY VALVES FOR FREE DISCHARGE,

MINIMUM PRESSURE DROP, AND FOR CHOKING CAVITATION

Butterfly valves are commonly used as control valves in applications where the pressure

drops required of the valves are relatively low. Butterfly valves can be used in applications as

either shutoff valves (on/off service) or as throttling valves (for flow or pressure control). As

shutoff valves, butterfly valves offer excellent performance within the range of their pressure

rating. Typical uses would include isolation of equipment, fill/drain systems, bypass systems,

and other like applications where the only criteria for control of the flow/pressure is that it be on

or off. Although butterfly valves have only a limited ability to control pressure or flow, they

have been widely used as control valves because of the economics involved. The control

capabilities of a butterfly valve can also be significantly improved by coupling it with an operator

and electronic control package.

Butterfly valves allow high flows with relatively low pressure loss from the valves, and

are typically used for flow control for valve openings from 30 to 70 degrees of full open. At

valve openings greater than 70 degrees, the pressure loss of a butterfly valve is too low to

produce any significant effect on flow or the energy loss of a flow system. Two special

applications for a butterfly valve include the use of a valve for free discharge and the use of a

butterfly valve for flashing or choking cavitation service. Free discharge typically produces high

pipe velocities at moderate pressure drops, and choking cavitation typically produces high

velocities with large pressure drops. The following paper also includes a review of flow

coefficients and the application of non-line sized valves, or valves installed in larger diameter

pipes with the aid of pipe reducers.

Butterfly Valves Types

The butterfly valves used in water works applications vary from traditional resilient

seated butterfly valves to the more specialized AWWA valves as detailed in AWWAs C504

standard. Regulations do not generally require the use of AWWA valves in water works service

but most operators will specify AWWA valves for the majority of applications based on their

experience with AWWA valves and their reputation for long service life.

Basic resilient seated valves are designed in accordance with industry standards such as

MSS SP-67 and most frequently come in lugged and wafer configurations. They are considered

by most to be a general service type of valve and as such, are usually restricted to use in the

ancillary systems within water treatment and distribution systems. They are usually limited in

size to around 48 inches in diameter. and pressure ratings for these valves are typically 75, 150,

or 300 psi. The design of the valves with different ratings are very similar. The stem diameter,

disc thickness, and disc to seat interference are the main features which differ as the rating

changes. Flow characteristics and limits are not generally defined in the standards/specifications

nor are they defined by manufacturers in most cases.

2

AWWA valves are considered by most users to be a more robust valve design and in

most cases have greater body wall thicknesses, larger shaft diameters, and thicker discs than

resilient seated valves with equivalent pressure ratings. In addition, AWWA valves would most

frequently be supplied in a double flanged configuration rather than the lugged or wafer styles

although all of these configurations are available in the marketplace. Currently the AWWA

C504 standard defines three shutoff pressure ratings and two flow velocity sub-ratings. Pressure

rating breaks are made at 25, 75, and 150 psi. Flow velocities are defined for the AWWA valves

as specific breaks are made in the line velocities at 8 and 16 feet per second. An increasing

number of applications however, are pushing beyond these traditional pressure/flow velocity

limits with applications at 250 and 300 psi becoming common.

A third category of butterfly valve, the high performance butterfly valve, is occasionally

utilized in water treatment and distribution applications. These valves are characterized by

higher pressure and/or temperature ratings, different disc seating/sealing technology, and

premium materials. These valves frequently follow the design guidelines outlined in MSS SP-

68. The primary distinguishing design feature is a stem which is offset from the centerline of the

pipe. This offset design generates a camming action which allows for different types of seating

technologies when compared to resilient seated valves. These alternate seating technologies

frequently incorporate advanced seal materials, such as PTFE, RTFE, and other advanced

polymers which help the valve achieve higher pressure and temperature ratings. A high

performance butterfly valve is therefore a butterfly valve which has extended the performance

boundaries (in terms of pressure, temperature, and/or corrosion resistance) of traditional butterfly

valves.

Butterfly Valve Characteristics

Within the quarter turn family of valves, ball valves are dominant in the sub-2 inch size

category. Above 2 inches in size, butterfly valves become much more prevalent primarily for

economic reasons. Butterfly valves exhibit a number of characteristics which make them

especially well suited to use in general service type applications. Those characteristics include:

Economical: Because butterfly valves can be designed in a physically compact package

where the closure mechanism (disc) is partially contained by the system piping in the open

position, they are very economic in terms of material usage. Since material costs are a

significant portion of the product cost, the final valve is also very cost efficient.

Compact: The compact package also makes for a valve which is comparatively light and

therefore relatively easy to handle. The compactness lends the valves to installation in places

where other valves will not easily fit while the lightness makes installation and maintenance

relatively easy.

Configuration: The variety of body styles in which butterfly valves are available lends the

valves to a variety of installation configurations and preferences. Typical body style

offerings include wafer, semi-lug, lugged, and flanged valves.

Performance: Butterfly valves are generally good performing valves in addition to being

3

economical. Performance characteristics for most designs include bi-directional sealing, low

pressure loss at high flow rates, simple operation, and reliable sealing.

Actuation: A variety of actuation options exist for butterfly valves including handle

operation (typically only valves 8 and smaller), manual gear operators, and a wide variety of

power operators including pneumatic, electric, and hydraulic.

Butterfly Valve Seats

For butterfly valves where the seat is mounted in the valve body, four basic types of seat exist:

1. Boot seats are the traditional seat style. This type of seat is a separate component which

typically has a U shaped cross section and completely lines the ID of the valve body. They

are retained in the valve body by interlocking dovetails at either face of the valve body.

The primary advantage of this type of seat is its replaceability but they are generally also

available in a wider variety of materials.

2. Cartridge seats also completely line the ID of the valve body but are generally rigid seats by

virtue of a hoop of rigid material encapsulated by a elastomer jacket. The resulting

assembly forms a rigid cylindrical shaped seat. These type of seats are also replaceable and

can offer advantages in vacuum applications.

3. Molded in seats are physically bonded to the valve body during the rubber molding process.

This style of valve offers good performance characteristics but is generally more limited in

material options and seat wear or damage is not repairable. The primary advantage of this

type of seat is its pressure rating and its ability to be used in dead-end or end of line

applications where no end flange is supporting the valve.

4. Mechanically retained seats are most common in high performance valves and in the water

works industry where large diameter valves make the other seat styles described above

impractical to manufacture. Seats are retained by a number of methods including mechanical

metal fasteners and retention keys formed with advanced adhesives. A few valve designs in

the industry mount the elastomeric seat on the disc edge. In this style of valve, mechanical

seat retention is used almost exclusively.

The boot, cartridge, and molded in seats are most common in the smaller valve sizes (through

roughly 24) and define the range of seat configurations for resilient seated butterfly valves

. The mechanically retained seats are typically only used on larger diameter (24 and larger)

AWWA style valves and in high performance valves.

Seat materials for butterfly valves vary but the predominant elastomers utilized would be EPDM

and NBR. Additionally, other elastomers in common use include CR (trade name Neoprene),

SBR, and occasionally more exotic materials such as fluoroelastomers, silicones, or others.

When high performance valves are utilized, thermoplastic seats are also frequently used.

PTFE and RTFE are the most common materials but other material types are used for some

applications.

4

In general terms, any of these materials described here are suitable in water service. The

conditions which lead to a preference of one material over another are just temperature or

other chemical constituents in the water. For example, EPDM gives excellent service in high

temperature (up to approximately 300 degrees F) water and low grade steam. In this

environment its performance is usually significantly superior to NBR which is generally

restricted to somewhere in the 200 degree F neighborhood. EPDM is not, however, a good

performer in environments where hydrocarbons are found while NBR is excellent in

environments where there are hydrocarbons. Generalizations such as this about these

material families can be made but the actual performance of the seat material varies widely

even within the material family due to differences in the compounding of the material.

Because of this, it is extremely important that application data be provided to the

manufacturer in order for the best seat material recommendation to be made. The primary

information that is needed to make the material selection is as follows: temperature (min. /

max. and typical), operating cycle, and chemical makeup of the water including

concentrations. From this information, a recommendation can usually be made or detailed

questions can be generated to help finalize the selection.

Minimum Pressure Drop

A common misconception in sizing large butterfly valves is the need for a minimum pressure

drop or large flow coefficient at full open. Most high performance (low pressure loss)

butterfly valves have flow coefficients large enough that the need or selection for minimum

pressure drop and maximum flow coefficient is irrelevant. The pressure loss of a full open

butterfly valve is so small in comparison to the overall loss of the flow system, that it has

very little effect. The larger the flow coefficient at full open, the smaller the range of

openings for flow control. The concern for minimum pressure loss is often misguided

because of the uncertainty of the pressure losses for rest of the flow system. The minimum

pressure loss of a butterfly valve is usually less than the variation or accuracy of determining

the pipe friction loss for the system.

Free Discharge

Free discharge from a butterfly valve is similar in nature to the condition of choking or

flashing cavitation. Both conditions choke the flow passages and separation zones of the

valve with vapor or air. The result of choking is then a limit of flow for a given upstream

pressure and a reduction in the efficiency or flow coefficient of the valve. The free discharge

flow and dynamic flow torques are less than those calculated for the same pressure drop of a

non-cavitating or non-free discharge condition. Knapp (1950) has classified cavitation as

being either a vaporous or gaseous type. Free discharge is similar in nature to gaseous

cavitation in that free air is drawn into the separation zones from downstream of the valve

instead of from the liquid flow itself.

5

H K

V

g

2

2

C

Q

P Sg

V

GPM

/

Choking Cavitation

Choking or flashing cavitation in a valve is a maximum design limit that results in a level of

extreme cavitation. Free discharge at lower pipe velocities and flows will not produce

undesirable effects. Dynamic flow and actuator torques are lower than expected, and any

cavitation will be significantly reduced. The presence of free air will cushion the cavitation

collapse and in many cases will prevent cavitation vapor from even forming. The major

disadvantage of free discharge is the reduction in flow and flow coefficient. However, it is

important to note that free discharge conditions can produce much larger pressure

differentials and velocities than from similar conditions in which downstream piping will

limit flow and pressure drop. Care must be taken in designing for free discharge from a

butterfly valve to avoid pipe velocities that exceed the maximum design velocities (ie 12 to

16 fps for some classes of AWWA valves).

Choking cavitation occurs when the local pressure inside a valve decreases to the vapor

pressure of the liquid, and the contracted flow through the valve flashes to vapor. At choking

cavitation, the maximum flow for a given upstream pressure (regardless of downstream

pressure) is reached. Typically, the flows to produce large vapor pockets downstream of the

valve are very large, and often exceed the maximum design flow and design structural

stresses for the valve and actuator. Flashing cavitation can also produce precipitous effects to

downstream piping and other flow components. It is not recommended to operate butterfly

valves at or near any limit of choking or flashing cavitation

Flow Coefficients

The most common formula used to relate the pressure differential to the flow is the Darcy-

Wiesbach equation (Equation 1).

(1)

where K is referred to as the resistance coefficient, H is the net pressure differential or head

loss in feet (meters), V is the flow velocity at the inlet in fps (m/s), and g is the gravitational

constant 32.2 fps (9.806 m/s). The parameter V/2g is also referred to as the velocity head.

As simple as the Darcy-Wiesbach equation is, the coefficient K has been used to denote a

number of flow phenomena such as the cavitation parameter and numerous flow coefficients

and constants.

A flow coefficient equation widely used by the valve industry (per ISA S75.01) is Equation 2.

(2)

6

P P Sg f

Q

d

net ISA

0008986

2

4

.

C

d

C

d

Sg f

C

d

V net

V ISA

V ISA

2

2

2

2

2

2

1 0008986

1

]

1

1

]

1

1

]

1

.

C

d K

V net

2

2

8906032

1

]

1

.

Where P is the pressure drop in units of psi, Q

gpm

is in units of gpm, and Sg is the specific

gravity of the fluid.

It is very important to note that the P used in the ISA Cv

ISA

equation is not the net pressure

drop P

net

. The pressure drop used in the ISA Cv

ISA

equation is determined from testing

requirements that include an additional 8 diameters in length of pipe and friction loss in the

measured pressure drop. ISA S75.01 does not allow for the subtraction of the manifold loss

between pipe taps and test valve from P

ISA

. For valves with a flow coefficient Cv/d

2

less

than 20 (where d is in units of inches), the difference between P

net

and P

ISA

is negligible.

The difference between pressure drops can be significant for Cv/d

2

values greater than 20.

Most water works valves have values of Cv/d

2

greater than 20. Equations 3 and 4 were

derived (ref Rahmeyer and Driskell) for converting the ISA test pressure drop (including 8

diameters of manifold loss) to a net pressure drop.

(3)

Where Q is in units of gpm, d is in units of inches, and P is in units of psi.

(4)

Another difficulty with using Cv as a loss coefficient is that Cv is not dimensionless. The

units of Cv are a function of gpm and psi. However, the net resistance coefficient K is

dimensionless, and can be converted directly to Cv

net

by Equation 5.

(5)

A flow coefficient that has limited use by several researchers (Tullis and Ball 1973) is the

coefficient C

d

(Equation 6). C

d

is dimensionless and is dervied directly from K (Equations 6

and 7), and has two important advantages in its use. The range of C

d

will always vary from

0 to 1, where the value 1 represents an ideal valve with no pressure loss. Most types of

numerical analysis or modeling require a relationship of flow coefficient as a function of an

independent variable such as valve opening. Experience has show that the generation or

curve fit of such relationships produces much simpler and accurate relationships if the flow

coefficient is in the form of C

d

.

7

C

V

g H V

K

d

+

+

2

1

1

2

K

C

d

1

1

2

+

P P

P

V 1

2

1

2

2

P P

P

V

(6)

(7)

Cavitation Parameters

The cavitation parameter or index is a dimensionless ratio used to relate the conditions which

inhibit cavitation (P

2

-P

V

) to the conditions which cause cavitation (P). There are numerous

forms of the dimensionless number or parameter which have been used to mathematically

describe cavitation. The most fundamental form is

2

of Equation 8 which uses the

downstream valve pressure (P

2)

, the vapor pressure of the liquid (P

V)

, and the pressure drop of

the valve (P). It is necessary to use

2

for determining specific cavitation effects such as

size and scale effects. However,

2

can be difficult to use for scaling or sizing a control valve

because of the lack or uncertainty of the value of the downstream valve pressure P

2

. Equation

9 is an alternate form of the cavitation parameter that allows the use of the upstream

pressure P

1

instead of the downstream pressure. This form of is much better suited for

scaling and sizing valves. It is also important to notes that

2

can be converted to by just

adding the value of 1. Equation 9 is the cavitation parameter that will be used for this paper.

(8)

(9)

The cavitation parameter can be used to predict the pressure drop or discharge at which a

control valve or orifice will begin to experience a given level of cavitation. If the

calculated for the actual operating pressures of a valve or orifice is less than the value of for

a cavitation limit, the valve or orifice will experience a level of cavitation more severe than

that associated with the limit.

The choking cavitation limit represented by

CHOKED

can be related to the Pressure Recovery

Factor F

L

by Equation 10. F

L

is a form of the choking cavitation parameter that is used by

most valve manufactures and valve design procedures (ISA 1985).

8

F

Q

C P P

L

GPM

V V CHOKED

1

096

1

.

CONSTANT

K

+ 1161

94364

.

.

CHOKED

K

+ 10851

20762

.

.

(10)

Butterfly valves have been tested by many different researchers and valve vendors for

cavitation limits. Equations 11 and 12 show the best fit equations from numerous tests of all

sizes and models of valves for the cavitation limits of constant and choking cavitation.

(11)

(12)

Equations 11 and 12 had minimum linear regression coefficients of R

2

=0.97 and a scatter or

accuracy of 10 to 15% accuracy when applying the equations for different sizes and models

of valves. Equations 11 and 12 have been provided as an aid for the preliminary sizing of

butterfly valves for constant cavitation and for free discharge. The most accurate method for

predicting cavitation limits is to still use actual test data for a specific valve type and size.

Coefficient of Dynamic Flow Torque

Dynamic flow torque is the flow torque produced by the flow forces on the valve disc about

the valve shaft. Most butterfly valves produce a dynamic flow torque that has the rotational

direction that will close the valve. Some types of eccentric butterfly valves that are installed

with the valve seats upstream of the valve shaft will experience flow torque above 70 to 80

degrees of opening that will tend to open the valve. The dimensionless flow torque

coefficient that has been used by many valve vendors and designers is C

TDP

of Equation 13. It

must be cautioned that there are other definitions and applications of C

TDP

that are not

dimensionless. For example, it is common to derive C

TDP

from units of ft.lbs of torque,

inches of disc diameter, and psi of pressure drop. This application is not dimensionless and

produces coefficient values that are 1/12 th that of a dimesionless coefficient.

Another dimensionless coefficient for dynamic torque is C

TV

of Equation 14. C

TV

differs

from C

TDP

in that it is based on velocity instead of pressure drop. The advantage of C

TV

is

that because velocity is used to calculate dynamic torque, C

TV

can be applied directly to

applications of installing small sizes of valves in larger pipes and for use in free discharge.

Equation 15 can be used to calculate C

TV

from values of C

TDP

. It must be cautioned that the

9

C C F

C

V V L

V

CHOKED

*

C C F

C

TDP TDP L

TDP

CHOKED

*

2

C

Dynamic FlowTorque

Pd

T

Pd

TDP

3 3

C K

C

TV

TDP

2

C

T

V d

TV

2 3

P

P P

V

CHOKED

*

1

K K

CHOKED

*

units normally used with C

TV

are foot pounds of torque instead of inch pounds as used with

C

TDP

.

(13)

(14)

(15)

Effect of Free Discharge and Choking on Flow and Torque Coefficients

The flow coefficients and torque coefficients for a butterfly valve are determined by testing

the valves in a test setup with pressurized flow both upstream and downstream of the test

valve. Both types of coefficients are based on the pressure drop associated with the flow

profiles and separation zones produced in pressurized flow. As discussed, choking cavitation

and free discharge cause changes to the flow profiles and separation zones, and almost always

reduce the efficiency or increase the pressure loss of the valve.

To predict flow and dynamic flow torque for the conditions of choking cavitation, equations

16, 17, 18, and 19 were derived from the choked cavitation parameter to correct the flow and

torque coefficients for choked flow.

(16)

(17)

(18)

(19)

10

Q C P Pa

GPM FREE DISCHARGE V

*

1

V

g H

K

FREE DISCHARGE

2

*

( ) T C P Pa d

FREE DISCHARGE TD

*

1

3

Where K*, Cv* and C

TDP

* are the corrected coefficients to be used to calculate flow and

torque for choking cavitation. It can be rationalized that free discharge is a form of choking

cavitation in which the flow is choked by free air instead of vapor. Tests have verified the

use of the corrected coefficients (Equations 16 through 19) to calculate flow and torque for

free discharge conditions. Equations 20, 21, and 22 are then used to calculate the pipe

velocity, flow, and dynamic torque for a free discharge condition.

(20)

(21)

(22)

Where P

a

is the atmospheric pressure. Table 1 compares calculations for free discharge with

actual test data for a 12-inch symmetrical and a 36-inch eccentric butterfly valve.

11

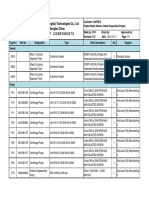

Table 1 Free Discharge Test Data and Calculations

12" SYM. BFV 36" ECC. BFV

Standard Valve Test Coefficients .................................... ....................................

Valve Opening 50 degrees 30 degrees

Cv 1,645 6,950

K 6.829 29.699

C

TDP

0.0783 0.0171

CHOKED

1.985 1.1815

F

L

0.71 0.92

Free Discharge Tests .................................... ....................................

P

1

-P

a

20 psig 42 psig

Q

MEASURED FREE DISCHARGE

5,137 gpm 41,405 gpm

V

MEASURED FREE DISCHARGE

14.57 fps 13.33 fps

T

MEASURED FREE DISCHARGE

1,423 in. lbs 26,813 in. lbs

Calculations .................................... ....................................

Cv* 1,167 6,394

K* 13.5554 35.0893

C

TDP

* 0.03945 0.01446

Q

CALCULATED FREE DISCHARGE

5,220 gpm 41,437 gpm

V

CALCULATED FREE DISCHARGE

14.81 fps 13.34 fps

T

CALCULATED FREE DISCHARGE

1,363 in. lbs 27,485 in. lbs

12

C

K

d

D

d

D

S

_

,

_

,

1

]

1

15

1 067 033

2

2

4

4

.

. .

C

d

D

K

R

+

_

,

1

15 1

2

2

2

.

P valveand reducer C P net valve

R

*( ) ( )

K KC

R

*

K K

d

D

* . +

_

,

15 1

2

2

2

( ) ( ) P P P P C P

V V S 1 1

* +

Non-line Sized Valves

Control valves are not always installed in the same line size as the valve. Non-line size valve

installations create additional connection losses which need to be added to the net valve loss.

Therefore, it is necessary to correct the net pressure drop of the valve (P) to the total loss

(P*) of the valve and pipe reducers. Equation 23 shows the Pressure Correction Factor used

with Equation 24 to convert the net pressure loss to the total loss of a non-line sized valve.

The equations to correct non-line sized valves are based on the assumption that the pipe

reducers will be standard symmetrical pipe fittings (Hutchison 1976 and ISA 1985).

(23)

(24)

The total flow coefficient K* of the valve and reducers can be calculated from either

Equation 25 or 26.

(25)

(26)

The upstream pressure P

1

* of the non-line sized valve and reducers can be calculated from

Equation 2 and the Cavitation Correction Factor, C

S

, of Equation 28.

(27)

(28)

13

C C C

TDP TDP R

*

*( )

( )

valveand reducers

net valve C

C

S

R

+

( ) +

R

PSE SSE 1 1

( )

( ) 1 1

R

PSE

( )

( )

PSE

P P

P P

V

V

R

n

1

]

1

1

1

1

The cavitation parameter for the combined valve and pipe reducers can then be calculated

from the net cavitation limit with Equation 29. If the valve is line sized (d=D), the correction

factor C

S

will equal 0 and the correction factor C

R

will equal 1.

(29)

The coefficient of dynamic torque used with a valve and reducers, C

TDP

*, can be calculated

from Equation 30. It must be cautioned that the application of C

TDP

* is based on the diameter

of the valve and the pressure drop of the combined valve and pipe reducers. To avoid any

confusion in calculating dynamic torque, the use of the coefficient C

TV

is recommended

where d is the diameter of the valve and V is the velocity of the valve inlet.

(30)

Equations 23 through 30 are based on theoretical derivations and on the procedures presented

by the ISA S75.01 Standards (1985) for control valves. The equations in ISA and in this

paper have been verified with limited testing.

Cavitation Scale Effects

(31)

(32)

(33)

Values of n for incipient and constant limits of cavitation for typical butterfly valves are n =0.25

to 0.28. The value of n for incipient damage is n =0.18 for a butterfly valve, and n =0 for

the limit of choking cavitation.

14

K

t

d

t

d

t

d

t

d

t

d

O O O O O

+

_

,

_

,

+

_

,

_

,

+

_

,

214 8024 10073 5996 16797 18031

2 3 4 5

. . . , , ,

SSE

d

d

R

Y

+

_

,

Y K

0159

18

.

/

C C

d

d

V V R

R

_

,

2

2

(34)

(35)

From numerous tests of butterfly valves, the cavitation limits of incipient and constant cavitation

can be scaled with Equation 36. The value of Y for the limits of incipient damage and

choking are Y =0.

(36)

Valve Size Scale Effects

For different sizes of geometrically similar valves, the flow coefficients K, Cv/d

2

, and Cd are

constant. The flow coefficient Cv is not constant with valve size and has to be scaled by pipe

area.

(37)

However, butterfly valves of identical design and model, typically will vary slightly in

geometry for different sizes because of the structural requirements for the disc and disc shaft.

The valve seats also differ in size ratio because many of the valve sizes will have the same

height and thickness of seat. J ames Ball (Ball and Tullis 1973) presented a study of the

variation of flow resistance for similar butterfly valves with differences in valve disc

diameter (d

o

) and thickness (t). The valves that were different models and types of butterfly

valves that included high performance, with seats upstream and downstream, and

symmetrical and boot seated butterfly valves. His data was presented in a plot of the flow

coefficient Cd versus the ratio t/d

o

. Equation 38 is the regression of the data presented in his

plot. The regression analysis had a R

2

of 96.3% and a maximum scatter of data of 8%. It is

suggested to use Equation 38 as a means to extrapolate know values from one valve size to

another.

(38)

R

SSE

Potrebbero piacerti anche

- Corrosion Failures: Theory, Case Studies, and SolutionsDa EverandCorrosion Failures: Theory, Case Studies, and SolutionsNessuna valutazione finora

- Brochure 1Documento20 pagineBrochure 1련서긔Nessuna valutazione finora

- SV5 Safety Valve-Installation Maintenance ManualDocumento12 pagineSV5 Safety Valve-Installation Maintenance ManualGOKUL PRASADNessuna valutazione finora

- NORSOK P-001 Process Design PDFDocumento26 pagineNORSOK P-001 Process Design PDFMarcelNessuna valutazione finora

- SV80 Safety Valve-Installation Maintenance ManualDocumento24 pagineSV80 Safety Valve-Installation Maintenance ManualAriyo AninditoNessuna valutazione finora

- Bidirectional Sealing Ball Valves in Power ApplicationsDocumento3 pagineBidirectional Sealing Ball Valves in Power Applicationsxisefengchuang100% (1)

- Ball Valve Overhaul ProcedureDocumento7 pagineBall Valve Overhaul Procedurerocket789Nessuna valutazione finora

- COUPLINGDocumento11 pagineCOUPLINGabduallah rabahNessuna valutazione finora

- Basic Hydrocyclone OperationDocumento23 pagineBasic Hydrocyclone OperationGeorgi SavovNessuna valutazione finora

- EPRV Installation ManualDocumento21 pagineEPRV Installation ManualdrlijothomasNessuna valutazione finora

- Report On ValvesDocumento15 pagineReport On ValvesAnonymous b9J5NMNessuna valutazione finora

- Gland Packing InstallationDocumento2 pagineGland Packing InstallationPramod Kumar GiriNessuna valutazione finora

- Engineering Design Guidelines - Compressors Rev02 KLM Technology GroupDocumento32 pagineEngineering Design Guidelines - Compressors Rev02 KLM Technology GroupAhmed Fgt Kaasehg0% (1)

- Air Cooled Heat ExchangersDocumento2 pagineAir Cooled Heat ExchangersMohamad Arif IbrahimNessuna valutazione finora

- Blowout PreventorsDocumento7 pagineBlowout PreventorsRachitPandeyNessuna valutazione finora

- Contorl ValvesDocumento8 pagineContorl ValvesGaurav MishraNessuna valutazione finora

- Pressure Relief ValvesDocumento12 paginePressure Relief ValvesyvhtejaswaroopNessuna valutazione finora

- Isolation Valves - Linear MovementDocumento9 pagineIsolation Valves - Linear MovementEmad A.AhmadNessuna valutazione finora

- Chapter 7Documento28 pagineChapter 7lockas222Nessuna valutazione finora

- Separator ComponentsDocumento16 pagineSeparator ComponentsvsroilgasNessuna valutazione finora

- Assignment: Name Muhammad ArsalanDocumento8 pagineAssignment: Name Muhammad ArsalanMuhammad Arsalan TariqNessuna valutazione finora

- Separation of Co2 From MetheneDocumento8 pagineSeparation of Co2 From MetheneRaj KumarNessuna valutazione finora

- Pneumatic Control ValvesDocumento59 paginePneumatic Control Valvespatil_raaj7234Nessuna valutazione finora

- Rod Pumps For High Volume Fluid Production Harbison FischerDocumento20 pagineRod Pumps For High Volume Fluid Production Harbison FischerRichard More LeonNessuna valutazione finora

- JC Ball Valves Fig 6000fb 7000rb Iom Rev 4 1Documento39 pagineJC Ball Valves Fig 6000fb 7000rb Iom Rev 4 1Inspection Engineer100% (1)

- Level GaugeDocumento3 pagineLevel Gaugemerijan10Nessuna valutazione finora

- API 576 Inspection of Pressure-Relieving DevicesDocumento19 pagineAPI 576 Inspection of Pressure-Relieving DevicesTahseen JwadNessuna valutazione finora

- Mass Flow Versus Volumetric Flow PDFDocumento4 pagineMass Flow Versus Volumetric Flow PDFCris JacksonNessuna valutazione finora

- Unit 2: - Control ValvesDocumento21 pagineUnit 2: - Control ValvesCarn Joseph100% (1)

- Introduction To Valves - Only The Basics - Valves Are Mechanical Devices That Controls The Flow and Pressure Within A System or ProcessDocumento6 pagineIntroduction To Valves - Only The Basics - Valves Are Mechanical Devices That Controls The Flow and Pressure Within A System or Processamit100% (1)

- Consolidated Model 2700 Pressure Safety and Relief ValvesDocumento44 pagineConsolidated Model 2700 Pressure Safety and Relief Valvesjromero_rpgNessuna valutazione finora

- Ball Valve Seat Seal Injection SystemDocumento28 pagineBall Valve Seat Seal Injection SystemmudrijasmNessuna valutazione finora

- Relief Valves - NCCDocumento26 pagineRelief Valves - NCCNour HNessuna valutazione finora

- Basics of Valves Interview Questions & Answers: Directional Control ValveDocumento7 pagineBasics of Valves Interview Questions & Answers: Directional Control ValveJêmš NavikNessuna valutazione finora

- LNG Feed Pretreatment TechnologyDocumento6 pagineLNG Feed Pretreatment TechnologyCSNessuna valutazione finora

- SCFM KGHR ConvertDocumento9 pagineSCFM KGHR ConvertCSNessuna valutazione finora

- Technical Documentation 14.5045 - Compressores HATLAPADocumento116 pagineTechnical Documentation 14.5045 - Compressores HATLAPAGilson CardosoNessuna valutazione finora

- Erosion Due To FlowDocumento3 pagineErosion Due To FlownguyenNessuna valutazione finora

- Seat Leakage Article Valve WorldDocumento2 pagineSeat Leakage Article Valve WorldjshadwanNessuna valutazione finora

- Safety Valve LaserDocumento15 pagineSafety Valve Lasersajjad_naghdi241Nessuna valutazione finora

- Pressure Enthalpy ExplainedDocumento14 paginePressure Enthalpy ExplainedSaif A. Abdul AmeerNessuna valutazione finora

- Installation, Operation and Maintenance Manual For Emergency Relief ValveDocumento18 pagineInstallation, Operation and Maintenance Manual For Emergency Relief ValveVaeco Đoàn Tncs Hcm100% (1)

- Moog ValveDocumento76 pagineMoog Valveramkrishna100% (1)

- Control-Valve Seat Leakage - Hydrocarbon Processing - August 2011 PDFDocumento10 pagineControl-Valve Seat Leakage - Hydrocarbon Processing - August 2011 PDFPiush KumarNessuna valutazione finora

- Cryogenic Service Ball ValveDocumento2 pagineCryogenic Service Ball ValvesaminasritnNessuna valutazione finora

- Gas Liquid Separation TechnologyDocumento26 pagineGas Liquid Separation TechnologyCSNessuna valutazione finora

- Gas Liquid Separation TechnologyDocumento26 pagineGas Liquid Separation TechnologyCSNessuna valutazione finora

- Ipc 15 Valve CharacteristicsDocumento41 pagineIpc 15 Valve CharacteristicsHarsh RavalNessuna valutazione finora

- Check ValvesDocumento14 pagineCheck ValvesMAGUNAMNessuna valutazione finora

- Hazop Close Out Report V-8701 Flare Ko Drum Draining Facilities at Ngl-4Documento79 pagineHazop Close Out Report V-8701 Flare Ko Drum Draining Facilities at Ngl-4Vedran KosanovicNessuna valutazione finora

- 1 Overview of UOP Gas Processing Technologies and ApplicationsDocumento25 pagine1 Overview of UOP Gas Processing Technologies and ApplicationsCS100% (4)

- Design and Use of Check ValvesDocumento10 pagineDesign and Use of Check Valvesjenshid0% (1)

- 329 Cryogenic Valves September 2016Documento8 pagine329 Cryogenic Valves September 2016TututSlengeanTapiSopanNessuna valutazione finora

- Development of A Multi-Stage Choke Valve SizingDocumento221 pagineDevelopment of A Multi-Stage Choke Valve SizingsekharsamyNessuna valutazione finora

- LESER - Pilot Operated Safety Valve From LESERDocumento2 pagineLESER - Pilot Operated Safety Valve From LESERAgis Rijal AtmawijayaNessuna valutazione finora

- Attachment M - John Fowler - AnnexXRevBDocumento5 pagineAttachment M - John Fowler - AnnexXRevBBùi Văn HợpNessuna valutazione finora

- M2.7 ValvesDocumento27 pagineM2.7 ValvesUJWAL UMESHNessuna valutazione finora

- Bv421 Pressure Reducing ValveDocumento4 pagineBv421 Pressure Reducing ValveFAIYAZ AHMEDNessuna valutazione finora

- The A To Z of Valve MaterialsDocumento4 pagineThe A To Z of Valve Materialscool47guy09Nessuna valutazione finora

- Pressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3-IDocumento16 paginePressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3-Isabi_shiNessuna valutazione finora

- Pneumatic Actuated Ball Valve PE4320Documento2 paginePneumatic Actuated Ball Valve PE4320Fa ChNessuna valutazione finora

- Hopkinson Valves IOM ManualDocumento7 pagineHopkinson Valves IOM ManualGiorgiana RosuNessuna valutazione finora

- Module 1 - Basics of Bioprocess Technology: ValvesDocumento5 pagineModule 1 - Basics of Bioprocess Technology: ValvesnavneetNessuna valutazione finora

- Control ValvesDocumento26 pagineControl ValvesSandi Aslan100% (1)

- PSV Back PressureDocumento0 paginePSV Back PressureDana GuerreroNessuna valutazione finora

- DBB CatalogueDocumento28 pagineDBB CatalogueHeri SetyantoNessuna valutazione finora

- Durco Plug Valve Dimensions PDFDocumento28 pagineDurco Plug Valve Dimensions PDFjtai1983Nessuna valutazione finora

- Body Wall Thickness of Pressure Safety Valves - SetPoint InstructionDocumento3 pagineBody Wall Thickness of Pressure Safety Valves - SetPoint InstructionFabio Peres de LimaNessuna valutazione finora

- SWI Products MetalDocumento21 pagineSWI Products MetalPrasanth PrasadNessuna valutazione finora

- Acoustic Induced Vibration - Flare Systems PDFDocumento2 pagineAcoustic Induced Vibration - Flare Systems PDFsri9987Nessuna valutazione finora

- ValvesDocumento25 pagineValvesAlbertoNessuna valutazione finora

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988Da EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNessuna valutazione finora

- Asset Integrity Management A Complete Guide - 2020 EditionDa EverandAsset Integrity Management A Complete Guide - 2020 EditionNessuna valutazione finora

- Immigration Process To France - Step by Step - VLSTS Salarié 2018Documento2 pagineImmigration Process To France - Step by Step - VLSTS Salarié 2018CSNessuna valutazione finora

- Envelope-Stream 1CL Design Lean Winter PDFDocumento1 paginaEnvelope-Stream 1CL Design Lean Winter PDFCSNessuna valutazione finora

- Envelope-Stream 1L Design Lean Winter PDFDocumento1 paginaEnvelope-Stream 1L Design Lean Winter PDFCSNessuna valutazione finora

- Long-Term Resident card-EU (Foreigner in France For 5 Years)Documento6 pagineLong-Term Resident card-EU (Foreigner in France For 5 Years)CSNessuna valutazione finora

- 3 Basic Methods Gas SeparationDocumento2 pagine3 Basic Methods Gas SeparationmojexNessuna valutazione finora

- CircleDocumento2 pagineCircleCSNessuna valutazione finora

- ERI WP IsoBoost at Jackalope ONLINE Update Nov 2014Documento12 pagineERI WP IsoBoost at Jackalope ONLINE Update Nov 2014CSNessuna valutazione finora

- 05 - LupionDocumento69 pagine05 - LupionCSNessuna valutazione finora

- BasicDocumento11 pagineBasicCSNessuna valutazione finora

- Example For Z Distribution Confidence Intervals 1Documento7 pagineExample For Z Distribution Confidence Intervals 1CSNessuna valutazione finora

- ABC Revision WorkbookDocumento23 pagineABC Revision WorkbookCSNessuna valutazione finora

- Joule Thomson Expansion J TDocumento6 pagineJoule Thomson Expansion J TISLAM I. Fekry100% (2)

- 4.10 Exercise 1 - Analysis and SynthesisDocumento1 pagina4.10 Exercise 1 - Analysis and SynthesisJohn TanNessuna valutazione finora

- Chemical & Process Technology - Problems Caused by Two Phase Gas-Liquid FlowDocumento4 pagineChemical & Process Technology - Problems Caused by Two Phase Gas-Liquid FlowCSNessuna valutazione finora

- Advanced Mercury Removal TechnologiesDocumento11 pagineAdvanced Mercury Removal TechnologiesCSNessuna valutazione finora

- Advanced Mercury Removal TechnologiesDocumento11 pagineAdvanced Mercury Removal TechnologiesCSNessuna valutazione finora

- Thermodynamic Property Method For Process Modelling PDFDocumento22 pagineThermodynamic Property Method For Process Modelling PDFCSNessuna valutazione finora

- Stahdard Chapter1Documento44 pagineStahdard Chapter1Ramesh KrishnanNessuna valutazione finora

- Standard A4Documento221 pagineStandard A4pridivysNessuna valutazione finora

- 5 UOP Separex Membrane TechnologyDocumento50 pagine5 UOP Separex Membrane TechnologyCSNessuna valutazione finora

- ARCA Fly BIOVENT GBDocumento6 pagineARCA Fly BIOVENT GBXavierNessuna valutazione finora

- Exp#6 Head Loss Due To Pipe FittingDocumento4 pagineExp#6 Head Loss Due To Pipe FittingSurenderan Logan0% (1)

- Vickers Direction ControlDocumento13 pagineVickers Direction ControlSombat MahamadNessuna valutazione finora

- Unbalanced Vane PumpsModern Industrial Hydraulics - Modern Industrial HydraulicsDocumento5 pagineUnbalanced Vane PumpsModern Industrial Hydraulics - Modern Industrial HydraulicsRaghu KrishnanNessuna valutazione finora

- HG Metaris MHPVB & MPVH Cut-Sheet WebDocumento4 pagineHG Metaris MHPVB & MPVH Cut-Sheet Webpiyush sharmaNessuna valutazione finora

- The Orbit Valve: Book 1Documento12 pagineThe Orbit Valve: Book 1Rodomiro GolindanoNessuna valutazione finora

- Master ThesisDocumento115 pagineMaster ThesisMelese SefiwNessuna valutazione finora

- Landscape Irrigation Products Catalog: The Intelligent Use of WaterDocumento196 pagineLandscape Irrigation Products Catalog: The Intelligent Use of WaterCosmin BonghezNessuna valutazione finora

- MassflowmetersandcontrollersDocumento19 pagineMassflowmetersandcontrollersMilectron Ion100% (1)

- ElectricActuatorBasics CEPMagazine JustinLedger PDFDocumento6 pagineElectricActuatorBasics CEPMagazine JustinLedger PDFElvis Alberto Rodriguez BravoNessuna valutazione finora

- Pompe Manuale Si ElectriceDocumento54 paginePompe Manuale Si Electricemih4iNessuna valutazione finora

- Catalogue 201: Surgical Suction Units Aerosol Delivery Systems Diagnostics I Wellness I Home-CareDocumento64 pagineCatalogue 201: Surgical Suction Units Aerosol Delivery Systems Diagnostics I Wellness I Home-CareEssamoual MohamedNessuna valutazione finora

- Component List V01 PDFDocumento9 pagineComponent List V01 PDFshenNessuna valutazione finora

- Art 1120Documento18 pagineArt 1120Alain DefoeNessuna valutazione finora

- Lubrication Pump EZ002 - GB0601Documento13 pagineLubrication Pump EZ002 - GB0601Alberto GalindoNessuna valutazione finora

- 04 01 Vlookup Exact Match 1Documento7 pagine04 01 Vlookup Exact Match 1Deepak SinghNessuna valutazione finora

- Handheld Pneumatic: Paving BreakersDocumento4 pagineHandheld Pneumatic: Paving BreakersherrerafaridcrNessuna valutazione finora

- Sigma 2 Type 2: AS/NZS1716: 2012 - Respiratory Protective Devices Lic 5021 BSI BenchmarkDocumento16 pagineSigma 2 Type 2: AS/NZS1716: 2012 - Respiratory Protective Devices Lic 5021 BSI BenchmarkErkan OzturkNessuna valutazione finora

- Midea Servisnaya-Instrukciya-Mfm-Arn1Documento55 pagineMidea Servisnaya-Instrukciya-Mfm-Arn1Miodrag VranjesevicNessuna valutazione finora

- ML081130514 PDFDocumento37 pagineML081130514 PDFdanferreiro8318Nessuna valutazione finora

- Type 3256 Angle Valve ANSI Version: T 8066 EN Series 250 Type 3256-1 and Type 3256-7 Pneumatic Control ValvesDocumento12 pagineType 3256 Angle Valve ANSI Version: T 8066 EN Series 250 Type 3256-1 and Type 3256-7 Pneumatic Control ValvesagrovadoNessuna valutazione finora

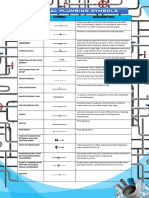

- General Plumbing Symbols: Name Symbol DescriptionDocumento3 pagineGeneral Plumbing Symbols: Name Symbol DescriptionJohn Dave RamirezNessuna valutazione finora

- Steering Unit: Service ManualDocumento28 pagineSteering Unit: Service ManualmusafirNessuna valutazione finora

- Parker-Veriflo - 25000178 - Valve Selection GuideDocumento4 pagineParker-Veriflo - 25000178 - Valve Selection GuideXavierNessuna valutazione finora

- Tomoe-General Catalogue-201904Documento559 pagineTomoe-General Catalogue-201904Khairul Rizal Zainal BadriNessuna valutazione finora