Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aluminim WPS

Caricato da

Karthikeyan ShanmugavelCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aluminim WPS

Caricato da

Karthikeyan ShanmugavelCopyright:

Formati disponibili

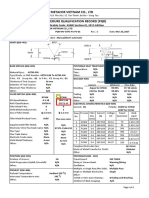

WELDING PROCEDURE SPECIFICATION

WPS - 2010-xxxx-23 WELDING PROCESS: GTAWSUPPORTING PQR: 200-23-P P-WS-100-2 REV. NO.: 2 and GTAWDATE: 10/8/2009 ASME: X **APPLICABILITY**

AWS: X OTHER: P-WS-10-2 2010-xxxx-23 P-WS-151-1

P-WS-10-1 P-WS-100-1

JOINT: This WPS shall be used in conjunction with the General Welding Standards (GWS) and Welding Fabrication Procedure (WFP) sections and criteria for joint details, repairs, NDE, inspection etc. Weld Joint Type: Butt/Groove/Fillet See GWS 1-06 and WFP's for joint details 0 - 3/32 Root Opening: Backgrind root: or purged Bkgrd Method: Grind if not purged FILLER METALS: A No: N/A SFA Class: Class: Preparation: Backing: Backing Mat.: GTAW Flux: N/A F No: Size: 0 ER4043 Class: 23 and 23 Size: 1/16 Full/Partial Penetration Thermal (plasma) /Mechanical None/Strap/back welding Al Backing Retainer: N/A and 3/32 ER4043 1/8

5.10 and 5.10 Insert: N/A Insert Desc.: N/A Flux: Type: NA Filler Metal Note:

Weld Metal Thickness Ranges: 0.032 thru 0.75 AWS Root Pass: 0.032 thru 0.75 AWS Balance: ASME Root Pass: ASME Balance: 0.032 thru 0.064 thru 0.187 0.75

BASE MATERIAL Spec. B-209 Al- Plate & sheet Qualified Pipe Dia. Range: Qualified Thickness Range: QUALIFIED POSITIONS: Preheat Min. Temp.: Interpass Max. Temp.:

P/S No. 23 Gr No. All to: P/S No. 23 Gr No. All Grade: All to: Spec. B-209 Al- Plate & sheet Grade: All 6 ASME: 0.75 AWS: 0.032 thru 0.750 0.032 thru 0.750 AWS: ASME: AWS: All ASME: All Argon GAS: Shielding: Gas Composition: 100 / 0 / 0 10 to 25 Gas Flow Rate cfh: Argon Backing Gas/Comp: Backing Gas Flow cfh: Trailing Gas/Comp: 3 to 10 N/A DATE: Vert. Prog.: or % 0/ 0/ 0 to 0 100 % 0% 10/8/2009 0% V/Up

70 F 500 F

70 F Preheat Maintenance: PWHT: Time @ F Temp. 0 0 F Temp. Range: to APPROVAL: 0 F

Signatures on file at ENG

Thursday, October 08, 2009

Page 1 of 2

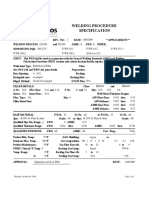

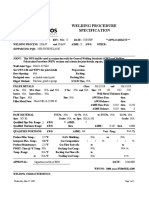

WPS NO: 2010-xxxx-23 WELDING CHARACTERISTICS: Current: AC and AC 25 to 12 to 300 22 Flame: N/A Tungsten Type: EWTh-2 Tungsten Dia.: 3/32 Transfer Mode: N/A Pulsing Cycle: 40 Background Current: 40% Braze temp. F 0 to 0 to 60 Ranges: Amps Volts Fuel Gas: N/A

WELDING TECHNIQUE: For fabrication specific requirements such as fittup, cleaning, grinding, PWHT and inspection criteria refer to Volume 2, Welding Fabrication Procedures Technique: Manual Single Pass or Multi Pass: GMAW Gun Angle : No Pass >1/2": Maximum K/J Heat Input: 0 PROCEDURE QUALIFIED FOR: Charpy "V" Notch: N/A Comments: Nil-Ductil Transition Temperature: N/A Dynamic Tear: N/A M 0 to 0 Cleaning Method: Stringer or Weave bead (S/W): S/W or Forehand or Backhand for GMAW (F/B): GMAW/FCAW Tube to work distance: Travel speed: Variable N/A Gas Cup Size: # 5 Wire Brush, File, Grind Oscillation: N N/A

Weld Layer 1 2 3 4

Manual Process GTAWGTAWGTAWGTAW-

Filler Metals Size ER4043 ER4043 ER4043 ER4043 1/16 3/32 1/8 1/8 Amp Range 25 to 160 150 to 250 240 to 300 to Volt Range 12 to to to to Travel/ipm to to to to

Nozzle Angle 0 to 0

Other

REM. * Weld layers are representative only - actual number of passes and layer sequence may vary.

ML-1/2 projects or jobs must determine if the supporting documentation for this WPS complies with quality requirements of the project/job. Use of LANL Welding Procedures and Welder Qualifications for non-LANL work shall be at the sole risk and responsibility of the Subcontractor, and the Subcontractor shall indemnify and save LANL and the Government harmless from any and all claims, demands, actions or causes of action, and for any expense or loss by reason of Subcontractor's and their employees posession and use of LANL procedures and qualifications.

Thursday, October 08, 2009

Page 2 of 2

Potrebbero piacerti anche

- Wps For Aluminium WeldingDocumento8 pagineWps For Aluminium Weldingvishal bailur50% (2)

- Mitech Welder ManualDocumento13 pagineMitech Welder ManualkapasuduNessuna valutazione finora

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 pagineIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Safe Distance Stored Energy Calculator - Pneumatic TestingDocumento3 pagineSafe Distance Stored Energy Calculator - Pneumatic TestingKarthikeyan ShanmugavelNessuna valutazione finora

- International Standard: Friction Stir Welding - Aluminium Specification and Qualification of Welding ProceduresDocumento7 pagineInternational Standard: Friction Stir Welding - Aluminium Specification and Qualification of Welding ProceduresAngel Stiven Romero DiazNessuna valutazione finora

- Essential Variables API 1104Documento4 pagineEssential Variables API 1104Madidj_2014Nessuna valutazione finora

- PQRDocumento2 paginePQRHoangNessuna valutazione finora

- Aws D1.6 - SS316 WPSDocumento1 paginaAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Documento2 pagineWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNessuna valutazione finora

- WPS Resrvoire Sous Pression Smaw SawDocumento6 pagineWPS Resrvoire Sous Pression Smaw SawDanem HalasNessuna valutazione finora

- Welding DefectsDocumento50 pagineWelding DefectsPuiu75% (4)

- Welding Procedure Specification: Page 1 of 1Documento2 pagineWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Wps - PQR 401 TerbaruDocumento12 pagineWps - PQR 401 TerbaruJeffri MalauNessuna valutazione finora

- Appendix 1 - Visual Inspection PlateDocumento4 pagineAppendix 1 - Visual Inspection PlateLaith Salman100% (1)

- Wps Is 2062 GR B Butt-OkDocumento2 pagineWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- PQR-WPS-WPQR XXX Rev 0Documento6 paginePQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- AISI 1015 Carbon Steel (UNS G10150) : Topics CoveredDocumento3 pagineAISI 1015 Carbon Steel (UNS G10150) : Topics CoveredKarthikeyan ShanmugavelNessuna valutazione finora

- SG21-3 Operation and Maintenance ManualDocumento154 pagineSG21-3 Operation and Maintenance ManualPurnama Abhie100% (2)

- Aluminium WPSDocumento2 pagineAluminium WPSAnonymous yCpjZF1rF100% (1)

- Wps AluminiumDocumento2 pagineWps Aluminiumsatrahe100% (1)

- WPS & Materials Applicable MatrixDocumento5 pagineWPS & Materials Applicable Matrixundeath123100% (1)

- Essential and Non-Essential Variables For WPS - PQRDocumento4 pagineEssential and Non-Essential Variables For WPS - PQRNatarajan MurugesanNessuna valutazione finora

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocumento2 pagineElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- WPS - EngineerDocumento20 pagineWPS - Engineerhunghoanglong100% (1)

- PT Kuwera Karya Me: PanduDocumento2 paginePT Kuwera Karya Me: PanduGalang Pratama PutraNessuna valutazione finora

- MEI - Aluminium MIG WeldDocumento56 pagineMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- Weld Fit Up Inspection Employee TrainingDocumento10 pagineWeld Fit Up Inspection Employee TrainingBadiuzzama Azmi100% (1)

- I-963 Welder Certificate Smaw-Gtaw-1Documento1 paginaI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- WIS5 - Appendix 2Documento86 pagineWIS5 - Appendix 2Reza Fakhrizal100% (1)

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Documento21 pagineAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNessuna valutazione finora

- Astm A 384Documento2 pagineAstm A 384Shandy HaykalzNessuna valutazione finora

- WPQ WeldCanada PDFDocumento1 paginaWPQ WeldCanada PDFAhmad DanielNessuna valutazione finora

- WPS Format For AWS D1.1 - WPS - FCAWDocumento1 paginaWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNessuna valutazione finora

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocumento2 pagineName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNessuna valutazione finora

- For Fillet Weld Joint Project:Production ManifoldDocumento1 paginaFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Sample API 1104 WpsDocumento6 pagineSample API 1104 Wpsjacquesmayol100% (2)

- WPS - 024Documento4 pagineWPS - 024MAT-LIONNessuna valutazione finora

- P91 Profile WpsDocumento6 pagineP91 Profile WpsManzar KhanNessuna valutazione finora

- ASME 9 - CalculatorDocumento2 pagineASME 9 - CalculatorEmel Besir100% (1)

- WPS, PQR & WPQTDocumento14 pagineWPS, PQR & WPQTSky RNessuna valutazione finora

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocumento2 pagineBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNessuna valutazione finora

- Fillet Weid Break and Macroetch Test PlateDocumento1 paginaFillet Weid Break and Macroetch Test PlatewijiestNessuna valutazione finora

- UT Formula SheetDocumento2 pagineUT Formula SheetOktayKulNessuna valutazione finora

- WQTDocumento1 paginaWQTRamkunwar YadavNessuna valutazione finora

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKparesh2387Nessuna valutazione finora

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Documento2 pagineWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- Welding Acceptance Criteria On Pipe LineDocumento2 pagineWelding Acceptance Criteria On Pipe LinewahyuNessuna valutazione finora

- Welding ParametersDocumento34 pagineWelding ParametersmilindNessuna valutazione finora

- CSWIP 3.1 Course Note 2016 With Question & AnswersDocumento3 pagineCSWIP 3.1 Course Note 2016 With Question & AnswersSakthi Pk100% (1)

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocumento1 paginaD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1Nessuna valutazione finora

- Wps Magi Tig Exemple PDFDocumento6 pagineWps Magi Tig Exemple PDFJaime PatrónNessuna valutazione finora

- AWS D1 1 Acceptance StandardsDocumento2 pagineAWS D1 1 Acceptance Standardsrohim100% (1)

- 24 Practical Visual InspectionDocumento5 pagine24 Practical Visual InspectionMai Anh TaiNessuna valutazione finora

- Weld DefectsDocumento16 pagineWeld DefectsKeith Rutherford100% (2)

- 004 Gtaw P5aDocumento16 pagine004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- WPS-PQR Gmaw LtiDocumento2 pagineWPS-PQR Gmaw Ltibgonzalez198150% (2)

- WPQR6Documento3 pagineWPQR6Dimitris NikouNessuna valutazione finora

- RT Exm Astar PDFDocumento1 paginaRT Exm Astar PDFSASINessuna valutazione finora

- Multiple PQR QualificationDocumento4 pagineMultiple PQR QualificationKarthikeyan ShanmugavelNessuna valutazione finora

- Welding Current & Welding VoltageDocumento9 pagineWelding Current & Welding VoltageAbhishek AnandNessuna valutazione finora

- Aluminim WPSDocumento2 pagineAluminim WPSmahmoud_allam3Nessuna valutazione finora

- WPS Sa 517Documento2 pagineWPS Sa 517DHANANNJAI SINGH -Nessuna valutazione finora

- 1000 XXXX HY80 HSLA100Documento2 pagine1000 XXXX HY80 HSLA100srb metallurgNessuna valutazione finora

- Welding Procedure SpecificationDocumento2 pagineWelding Procedure SpecificationSAKDA MAPRADITKULNessuna valutazione finora

- Welding Procedure Specification: Monday, April 27, 2009 Page 1 of 2Documento2 pagineWelding Procedure Specification: Monday, April 27, 2009 Page 1 of 2srb metallurgNessuna valutazione finora

- Ship Loose Spools Packing DetailsDocumento2 pagineShip Loose Spools Packing DetailsKarthikeyan ShanmugavelNessuna valutazione finora

- Rietu To: TR TR Saving CurrentDocumento2 pagineRietu To: TR TR Saving CurrentKarthikeyan ShanmugavelNessuna valutazione finora

- ASTM ComparisonDocumento1 paginaASTM ComparisonKarthikeyan ShanmugavelNessuna valutazione finora

- Iob Service Charges 01012019Documento4 pagineIob Service Charges 01012019Karthikeyan ShanmugavelNessuna valutazione finora

- ASME Section I and VIII-Div-1 Training Course OutlineDocumento2 pagineASME Section I and VIII-Div-1 Training Course OutlineKarthikeyan ShanmugavelNessuna valutazione finora

- KT-100/ KT-200 Series Ultrasonic Thickness GaugesDocumento1 paginaKT-100/ KT-200 Series Ultrasonic Thickness GaugesKarthikeyan ShanmugavelNessuna valutazione finora

- Ammonia Vaporizer ITPDocumento2 pagineAmmonia Vaporizer ITPKarthikeyan ShanmugavelNessuna valutazione finora

- CH4 2 Welding Joint PreparationDocumento46 pagineCH4 2 Welding Joint PreparationMatija BušićNessuna valutazione finora

- Cooker ManualDocumento2 pagineCooker ManualKarthikeyan ShanmugavelNessuna valutazione finora

- Ammonia Vaporizer ITPDocumento2 pagineAmmonia Vaporizer ITPKarthikeyan ShanmugavelNessuna valutazione finora

- Coimbatore: PSG College of Technology Campus Peelamedu, Coimbatore 641 004 PH: (0422) 2580733, EmailDocumento1 paginaCoimbatore: PSG College of Technology Campus Peelamedu, Coimbatore 641 004 PH: (0422) 2580733, EmailKarthikeyan ShanmugavelNessuna valutazione finora

- All in One Standards Introduction PDFDocumento136 pagineAll in One Standards Introduction PDFKarthikeyan ShanmugavelNessuna valutazione finora

- ITPDocumento2 pagineITPKarthikeyan Shanmugavel100% (1)

- Pipe and Tube Comparison and Application AreasDocumento8 paginePipe and Tube Comparison and Application AreasKarthikeyan ShanmugavelNessuna valutazione finora

- Flow Chart - QCDocumento2 pagineFlow Chart - QCKarthikeyan Shanmugavel100% (1)

- Release Note For DeliveryDocumento6 pagineRelease Note For DeliveryKarthikeyan ShanmugavelNessuna valutazione finora

- Chart Hydrostatic Test ASME RenewalDocumento4 pagineChart Hydrostatic Test ASME RenewalKarthikeyan ShanmugavelNessuna valutazione finora

- Surface Preparation StandardDocumento5 pagineSurface Preparation StandardKarthikeyan ShanmugavelNessuna valutazione finora

- C69300 AlloyDocumento4 pagineC69300 Alloyyadu kumar singhNessuna valutazione finora

- Fabricator201602 DLDocumento116 pagineFabricator201602 DLRenato Pinto de AndradeNessuna valutazione finora

- Prirucka UTP AJDocumento487 paginePrirucka UTP AJnebojsa70Nessuna valutazione finora

- Airframe JeppesenDocumento39 pagineAirframe JeppesenWalter Jair Rodriguez Munoz (LATAM)Nessuna valutazione finora

- 3-A Sanitary Standard For Machine Leveling Feet and SupportsDocumento15 pagine3-A Sanitary Standard For Machine Leveling Feet and SupportsCHRISTIAN ZAVALA100% (1)

- Hydraulic Cylinder RemanufacturingDocumento12 pagineHydraulic Cylinder RemanufacturingDAVID ALFONSO CARABALLO PATIÑONessuna valutazione finora

- Inspection & Test Plans 1 of 50Documento49 pagineInspection & Test Plans 1 of 50abdul azizNessuna valutazione finora

- Welding StandardsDocumento14 pagineWelding Standardsrusf123100% (1)

- Astm A 497Documento5 pagineAstm A 497John Errol Saldevar MarcosNessuna valutazione finora

- Inspector Course OutlineDocumento23 pagineInspector Course Outlinebhingmeh yotalNessuna valutazione finora

- WPS Astm - A 53Documento2 pagineWPS Astm - A 53S. K. M. ShujonNessuna valutazione finora

- Indian Oil Corporation Limited: Vendor Code:........................Documento72 pagineIndian Oil Corporation Limited: Vendor Code:........................ANIMESH JAINNessuna valutazione finora

- Technology WeldingDocumento925 pagineTechnology Weldingdonnyars1979Nessuna valutazione finora

- WPQ Form As Per En-287Documento2 pagineWPQ Form As Per En-287Anonymous 0rt9KWmNNessuna valutazione finora

- Optimization of Fatigue Life of Welded Joints by Vikrant Ullhas Garud.Documento89 pagineOptimization of Fatigue Life of Welded Joints by Vikrant Ullhas Garud.vikrant GarudNessuna valutazione finora

- Procedure For Ferrit TestingDocumento11 pagineProcedure For Ferrit TestingKarrar TalibNessuna valutazione finora

- Introduction of Spot WeldingDocumento24 pagineIntroduction of Spot Weldingmithun pariharNessuna valutazione finora

- A Review On Steel Connections and Structural Behavior A Review On Steel Connections and Structural BehaviorDocumento13 pagineA Review On Steel Connections and Structural Behavior A Review On Steel Connections and Structural BehaviorPatrickNessuna valutazione finora

- Terminology and Weld PreparationsDocumento26 pagineTerminology and Weld PreparationsAd Man GeTigNessuna valutazione finora

- Improvised C-ClampDocumento22 pagineImprovised C-ClampWinser BelzaNessuna valutazione finora

- COLLECTOR INSTRUCTIONS MANUAL. WUNDER CLS 1808 & 2108 & 2510 ModelsDocumento19 pagineCOLLECTOR INSTRUCTIONS MANUAL. WUNDER CLS 1808 & 2108 & 2510 ModelsCiprian BalcanNessuna valutazione finora

- Murex Filler Metal Selection GuideDocumento44 pagineMurex Filler Metal Selection GuideJUAN VASCONessuna valutazione finora

- Da 950092 001Documento1 paginaDa 950092 001munnaNessuna valutazione finora

- Lorch PDFDocumento12 pagineLorch PDFAnonymous stV08Js44V100% (1)

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Documento1 paginaWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNessuna valutazione finora

- Design of BIW Welding FixturesDocumento3 pagineDesign of BIW Welding FixturesRawendrraw KuriNessuna valutazione finora

- Oisd 141 PDFDocumento31 pagineOisd 141 PDFajayNessuna valutazione finora