Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sump Revised Design

Caricato da

Anonymous nwByj9LCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sump Revised Design

Caricato da

Anonymous nwByj9LCopyright:

Formati disponibili

RCC SUMP DESIGN REFERENCE : 1. IS 456-2000. 2. IS 3370-2009 Part 1&2. 3. SP-16 -1978. DATA : Sump Size : 3.

30m (L) X 2.80m(B) X 2.80m(H) Concrete Grade : For cover slab M20. For Tank M25. Steel Grade : Fe 415 Unit weight of water : 10 KN/m3 Live Load(Vehicular traffic) for Cover slab 10 KN/m2 DESIGN: DESIGN OF COVER SLAB: Slab size : 3.30m x 2.80m L/B =3.30/2.80= 1.18 =1.20< 2.0 Hence the slab has to be designed as two way simply supported slab. d required =2800/25 = 112mm. However from deflection point of view provide D=150mm d=150-20-12/2= 124mm. > d required. O.k. Loads: Live Load(Assumed) = 10.0 KN/m2 Self weight 0.15x25 = 3.75 KN/m2 Finishing = 1.0KN/m2 Total Load = 14.75KN/m2 Effective span =2.80+0.124=2.924m The slab has to be designed as two way simply supported slab using coefficient given in Table 27 of IS 456-2000. Bending Moment Mx Factored B.M. Bending Moment My = xWl2 = 0.084x14.75 x2.9242 = 10.59 KN.m. = 15.89 KN.m.

= yWl2 = 0.059x14.75 x2.9242 = 7.44 KN.m. Factored B.M. = 11.16 KN.m. Max. B.M. Mu= 15.89KN.m Mu.lim. =0.138 fck b d2 =0.138 x 20x 1000 x 1242 =42.44 KN.m > 15.89KN.m Hence under reinforced section. K= Mu/b d2 =15.89 x106/1000 x 1242 =1.03 From Table 2 of SP 16 pt =0.3046 Ast= 0.3046 x 1000 x 124 =377.70 mm2

100 Using 12mm bars spacing = ast x 1000 Ast =113 x 1000 =299 mm 377.70 Max spacing limit to 3d (3x124=372) or 300mm whichever is less. Provide 12mm dia bars at 150mm C/c. (Ast provided=753.33mm2) Reinforcement along Long Diretion: Mini. Ast = 0.12 x 1000x 150 =180mm2 100 Since B.M.=11.16 KN.m < 15.89KN.m Provide same reinforcement. Provide 12mm dia bars at 150mm C/c. Max spacing limit to 5d (3x114=342) or 450mm whichever is less. Check for Deflection : Actual span ratio = 2924/124 =23.58 d Actual pt required = 377.7 x 100 =0.30% 1000x 124 Max. Permissible Span ratio from Chart 23 of SP16 =28.0 > 23.58 d Hence O.k.

10 tmt bars @ 200 c/c

8 tmt bars @ 200 c/c

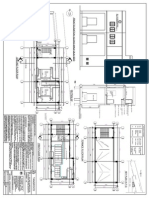

SECTION OF TOP COVER SLAB

DESIGN OF WATER TANK DESIGN OF SIDE WALL:

This has to be designed by Working Stress Method with the following permissible stresses to avoid leakage problem..Using M25 concrete and Fe415 (HYSD) steel

cbc = 8.50N/mm

st=150 N/mm cbc = 280

3x8.5

Design Constants: m=Modular ratio =280/3

=10.98 =11.00

n=m

cbc m cbc+ st

= 11

x 8.5

= 0.384

11x8.5+150

j= 1 n = 1- 0.384/3 = 0.872 3 K=

n j =1/2 x 8.50 x 0.384 x 0.872 =1.423 The water tank has to be designed for the following two cases. 1) Tank is full and no earthfill outside. 2) Tank is empty and active earth pressure acting from outside. Case 1: When Tank is full and no earth pressure outside

cbc

Long Wall: Assume wall thickness D=230mm. d=230-30-10/2=195mm Ph = w xH=10 x 2.80 =28.0 KN/m2 Cantilever moment M= (1/2x28.0 x 2.80) x2.80/2=54.88 KN.m Ast = M/

st

x j = 54.88 x 106

=2152 mm2

150x0.872x195 Using 20mm dia bars spacing required = = 314 x 1000 = 146 mm 2152 Provide 20 mm bars at 140 mm C/c near inner face in vertical direction. Horizontal bars in Long wall Since long wall is predominantly acting as a cantilever, distribution steel is provided & checked for axial Tension when tank is full without earth pressure from outside. Since the thickness of wall is more than 225mm, minimum % of steel to be provided is Mini. % of steel = 0.3 0.1( 230-100 ) = 0.263% (450- 100 ) Ast = 0.263 x 230 x 1000 =604mm2 100 Steel required ob each face =604/2=302 mm2 Using 10 mm bars spacing required = 78.5 x 1000 = 260 mm 302 Provide 10mm bars at 150mm C/c inside the face. Check for Direct Tension : TL= w (H-h) B/2 = 10 x (2.80-1.0) 2.8/2= 22.20KN, Ast required = 22.50 x 103 = 168 mm2 150 Distribution steel takes care of this Tensile forces . Case 2: When Tank is empty Ph =k

+ wH where K= 1- sin = 1-sin 30 =1/3

1

1+ sin

1

1+ sin 30

w =18-10=8 KN/m2

Ph= (1/3 x 8x 2.80) +(10x2.80) =35.47KN/m2

s=

s-

M=(1/2 x 35.47x HxH/3) =(1/2x 35.47 x 2.80x 2.80/3) =46.35 KN.m. Depth of balanced section = sqrt M/k b = Sqrt 46.35 x 106 1.423x1000 =180.48mm However provide D=230mm, d=230-30-20/2=190mm > 180.48mm Ast required = M/ st j = 46.35 x 106 150 x0.872x 190 =1865mm2 Using 20mm bars spacing required = 314 x 1000 =168mm 1865 Provide 20mm bats at 140mm C/c near inner face of the wall to have similar spacing as provided for outer wall. DESIGN OF SHORT WALL : Vertical reinforcement : Cantilever action height for lower portion h= H/4(2.80/4=0.70m) or 1m whichever is more =1m. When water tank is empty and outside soil is saturated ph=(1/3x8x2.80)+(10x2.80)=35.47KN.m2 M= 1/2x35.47x1.0x1.0/3 = 17.74KN.m Ast = M st x j = 17.74 x 106 150x0.872x190

= 713.83mm2 Using 20mm bars spacing = 314 x 1000 =440mm 713.83 Direct compression due to load on 1m wide long wall P= 35.47 x (2.80-1.0) x1.0 =63.85 KN. Concrete alone can resist if water tank is full and no earth fill. Ph= 10 x 2.80 =28.00KN/m2 M= x 28.0 x 1.0x 1.0/3 =4.67 KN.m . Ast= 4.67 x 106 = 188mm2 150x0.872x190 Provide mini reinforcement in vertical direction which is 20mm at 140mm C/c At Mid span : B.M. is half of 4.67/2 =2.34 KN.m

Provide same reinforcement 20mm bars at 140mm C/c near outer face.

10 tmt bars @ 150 c/c

EARTH SIDE

WATER (INSIDE)

SECTION OF WALL

DESIGN OF BASE SLAB: Assume thickness of base slab =400mm d = 400-50-12/2=344mm Height from base slab =2.80+0.40=3.20m Upward pressure when soil is saturated =10x3.20 =32.0 KN/m2 In bottom slab there is no projection. Effective span=2.80+0.23=3.03m

Downward Loads: Weight of top slab =0.15x3.76x 3.26x25 Weight of long wall =2x0.23x3.76x2.80x25 Weight of short wall =2x0.23x3.26x2.80x25 Weight of bottom slab =3.76x3.26x0.40x25 Total Load =

= 45.97KN. =121.07KN =104.97KN =122.57KN 394.58KN

Provide 150mmx 150mm haunches at junction. Provide junction reinforcement 10mm bars at 150mm C/c. Self weight of slab directly get transmitted to soil. Net upward soil pressure=(10x3.20)- (0.4x1x1x25) =32.0-10.0=22.0KN/m2 Bending moment: Considering net upward pressure B.M.=22.0x3.032/8= 29.95 KN.m Considering weight of water alone B.M. =(10x2.80)x 3.032/8=38.12KN.m Considering higher moment, Ast required = M = 38.12 x 106 st x j 150x0.872x344

= 847mm2 Minimum Ast = 0.263 x 1000x400=1052mm2 100 Providing reinforcement on both faces Ast on each face = 1052/2=526mm 2 Using 16mm bars spacing = 201 x 1000= 237mm 847 Provide 16mm bars at 150mm C/c Distribution Steel: Since the thickness of wall is more than 225mm, minimum % of steel to be provided is Mini. % of steel = 0.3 0.1( 230-100 ) = 0.263% (450- 100 ) Minimum Ast = 0.263 x 1000x400=1052mm2 100 Ast on each face =1052/2= 526mm2 Using 12mm dia bars spacing = 113 x 1000=214.83mm 526 Provide 12mm dia bars at 150mm C/c in longitudinal direction near both faces.

12 tmt bars @ 150 c/c

10 tmt bars @ 150 c/c

SECTION OF BASE SLAB

DESIGN ABSTRACT Cover Slab: Slab Thickness =150mm Main rod : 12mm dia bars at 150mm C/c (alternate cranked) along short direction 12mm dia bars at 150mm C/c (alternate cranked) along Long direction

Side wall : Thickness : 230mm Vertical rod inner and outer face : 20mm dia bars at 140mm C/c Horizontal rod : 10mm dia bars at 150mm C/c Base Slab: Slab Thickness : 400mm Main rod : 16mm Dia bars at 150mm C/c/ Distributors : 12mm dia bars at 150mm C/c.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Staad Pro NotesDocumento134 pagineStaad Pro NotesAnonymous nwByj9L100% (31)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Is 808-1989 Steel TableDocumento24 pagineIs 808-1989 Steel TableAtul Kumar Engineer86% (28)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- STAAD PRO V8i Continuous BeamDocumento6 pagineSTAAD PRO V8i Continuous BeamAnonymous nwByj9LNessuna valutazione finora

- RCC Detailing Guide for Building ConstructionDocumento21 pagineRCC Detailing Guide for Building ConstructionAnonymous nwByj9L100% (1)

- ETABS Extended 3D Analysis Building System ExampleDocumento41 pagineETABS Extended 3D Analysis Building System ExampleAnonymous nwByj9L100% (2)

- Staad FoundationDocumento25 pagineStaad FoundationAnonymous nwByj9L100% (2)

- Land Based SensorsDocumento40 pagineLand Based SensorsJ.MichaelLooneyNessuna valutazione finora

- Open Die ForgingDocumento7 pagineOpen Die ForgingCharanjeet Singh0% (1)

- Boeing 757-767 Study Guide SummaryDocumento134 pagineBoeing 757-767 Study Guide SummaryEldonP100% (2)

- Reservoir Saturation ToolDocumento19 pagineReservoir Saturation ToolAli Jay JNessuna valutazione finora

- Validation Rules in SAP FIDocumento3 pagineValidation Rules in SAP FINethaji GurramNessuna valutazione finora

- PFR Lime Kiln Process With Blast Furnace Gas and OxygenDocumento4 paginePFR Lime Kiln Process With Blast Furnace Gas and OxygenVitor Godoy100% (1)

- Pushover CE&CRDocumento9 paginePushover CE&CRAnonymous nwByj9LNessuna valutazione finora

- Planwin / RCDC Is A Total End To End Solution For RCC Building Design and Drawing. It Offers FollowingDocumento4 paginePlanwin / RCDC Is A Total End To End Solution For RCC Building Design and Drawing. It Offers FollowingAnonymous nwByj9LNessuna valutazione finora

- Staad Pro-Open ChannelDocumento5 pagineStaad Pro-Open ChannelAnonymous nwByj9LNessuna valutazione finora

- Staad Auto Load CombinationDocumento1 paginaStaad Auto Load CombinationAnonymous 48jYxR1CNessuna valutazione finora

- ETABS Example-1Documento64 pagineETABS Example-1Anonymous nwByj9L0% (1)

- Compound WallDocumento3 pagineCompound WallAnonymous nwByj9L0% (1)

- Steps To E-Filing For ITDocumento4 pagineSteps To E-Filing For ITAnonymous nwByj9LNessuna valutazione finora

- WindDocumento9 pagineWindAnonymous nwByj9LNessuna valutazione finora

- Staad Pro-Open ChannelDocumento5 pagineStaad Pro-Open ChannelAnonymous nwByj9LNessuna valutazione finora

- Section IIDocumento105 pagineSection IIAnonymous nwByj9LNessuna valutazione finora

- Section VIIDocumento29 pagineSection VIIAnonymous nwByj9LNessuna valutazione finora

- Section VDocumento18 pagineSection VAnonymous nwByj9LNessuna valutazione finora

- Fire Barrier Wall: Cable TrenchDocumento1 paginaFire Barrier Wall: Cable TrenchAnonymous nwByj9LNessuna valutazione finora

- Section Viii AnnexuesDocumento11 pagineSection Viii AnnexuesAnonymous nwByj9LNessuna valutazione finora

- Schematic Layout of Bazaar Road SSDocumento1 paginaSchematic Layout of Bazaar Road SSAnonymous nwByj9LNessuna valutazione finora

- Trench 2Documento1 paginaTrench 2Anonymous nwByj9LNessuna valutazione finora

- Section IDocumento37 pagineSection IAnonymous nwByj9LNessuna valutazione finora

- 8 7 Battery Room: S C A D A RTCCDocumento1 pagina8 7 Battery Room: S C A D A RTCCAnonymous nwByj9LNessuna valutazione finora

- Trench 1Documento1 paginaTrench 1Anonymous nwByj9LNessuna valutazione finora

- sch-2 - 06.01.2014Documento1 paginasch-2 - 06.01.2014Anonymous nwByj9LNessuna valutazione finora

- Schematic Layout of Bazaar Road SSDocumento1 paginaSchematic Layout of Bazaar Road SSAnonymous nwByj9LNessuna valutazione finora

- Bazzar Road SS-GFDocumento1 paginaBazzar Road SS-GFAnonymous nwByj9LNessuna valutazione finora

- WindDocumento139 pagineWindAnonymous nwByj9LNessuna valutazione finora

- Bazzar Road Control Room Building DesignDocumento39 pagineBazzar Road Control Room Building DesignAnonymous nwByj9LNessuna valutazione finora

- Materials Refractive Index and Extinction CoefficientDocumento276 pagineMaterials Refractive Index and Extinction CoefficientDr-Mandeep SinghNessuna valutazione finora

- Thermal DiffusivityDocumento3 pagineThermal DiffusivityPrincess_Ira_E_2471Nessuna valutazione finora

- Lipinski Rule of FiveDocumento21 pagineLipinski Rule of FiveSasikala RajendranNessuna valutazione finora

- Schottky DiodeDocumento5 pagineSchottky Diodeilg1Nessuna valutazione finora

- Retaining Wall ReporterDocumento18 pagineRetaining Wall ReporterJoefel BessatNessuna valutazione finora

- Dell EMC Avamar NDMP Accelerator For NASDocumento58 pagineDell EMC Avamar NDMP Accelerator For NASmanish.puri.gcpNessuna valutazione finora

- UntitledDocumento135 pagineUntitledtaraji dawlaNessuna valutazione finora

- Wiring Diagram SCH17: Service InformationDocumento16 pagineWiring Diagram SCH17: Service Informationابو حمزة صبريNessuna valutazione finora

- Hydraulic Filter ReportDocumento6 pagineHydraulic Filter ReportSandrock_01sr2Nessuna valutazione finora

- GPT 7000L User: Manual'Documento26 pagineGPT 7000L User: Manual'Adel Abo AdamNessuna valutazione finora

- Sand, Salt, IronDocumento1 paginaSand, Salt, IronKevin ChoyNessuna valutazione finora

- MSC Thesis Final Version Stephan de HoopDocumento92 pagineMSC Thesis Final Version Stephan de HoopSanjay singhNessuna valutazione finora

- MediaanditsterilzationDocumento15 pagineMediaanditsterilzationAyushi MauryaNessuna valutazione finora

- PI ControllerDocumento5 paginePI Controllerdanuega1Nessuna valutazione finora

- Shop Exercise 5Documento16 pagineShop Exercise 5Athena GrotesqueNessuna valutazione finora

- Data Mining QuestionsDocumento9 pagineData Mining QuestionsSwarnim ShuklaNessuna valutazione finora

- Integumentary SystemDocumento8 pagineIntegumentary SystemAshley Brithanie RamosNessuna valutazione finora

- Java Programming 3-4: Sorting and Searching Practice ActivitiesDocumento2 pagineJava Programming 3-4: Sorting and Searching Practice ActivitiesДжон КрасулинNessuna valutazione finora

- AS TRONIC, The ZF-AS TRONIC Software Can Be: 4.7.6 EOL Programming Documentation of The EOL ProgrammingDocumento3 pagineAS TRONIC, The ZF-AS TRONIC Software Can Be: 4.7.6 EOL Programming Documentation of The EOL ProgrammingThylaneNessuna valutazione finora

- Messenger No69Documento72 pagineMessenger No69European Southern ObservatoryNessuna valutazione finora

- ContentServer PDFDocumento16 pagineContentServer PDFdaniel leon marinNessuna valutazione finora

- Maths EnglishDocumento26 pagineMaths EnglishmeenasarathaNessuna valutazione finora

- Electric Charges and Fields All DerivationsDocumento9 pagineElectric Charges and Fields All DerivationsFlame kaiserNessuna valutazione finora

- Synchronised Ujt Triggering CircuitDocumento2 pagineSynchronised Ujt Triggering Circuitsvinod s67% (3)