Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sample Inspection Report of Exchanger

Caricato da

rtrajan_mech5408Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sample Inspection Report of Exchanger

Caricato da

rtrajan_mech5408Copyright:

Formati disponibili

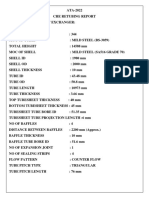

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

INSPECTION TEST REPORT ITEM TESTED INSPECTION DATE INSPECT BY DESIGN DATA YEAR MANUFACTURED CONSTRUCTION MATERIAL CORROSION ALLOWANCE 2002 CS / SS 304L 1.0 (S) / 0 (T) mm DESIGN PRESSURE TEST PRESSURE PRESSURE TEST DATE 15 (S) / 2,5 (T) kg/cm2 22 (S) / 4.8 (T) kg/cm2 2002 E-2570 30th January 2013 Khalid

FREQUENCY/ INTERVAL OF INSPECTION

MAX PERMITTED

INSPECTION INTERVAL (API) LAST INSPECTION DATE NEXT INSPECTION DATE REMAINING LIFE

120 Month(s) 30th September 2009 30th January 2023 <10 years

REASON FOR INSPECTION

Planned

Un-plan

Other (Process upset)

TYPE OF EXAMINATION/ TEST PERFORMED TYPE IF INSPECTION INSPECTION METHODS / TESTS USED HYDROSTATIC TEST OTHERS (PLEASE SPECIFY) Internal Visual Entire External UTG Coil

___________________ Signatory of Inspector Rev.5 / Sept 2011

__________________________ Signatory of R&I Supt/ Engineer Page 1 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

INSPECTION SUMMARY E-2570 was shutdown for maintenance due to process upset. The exchanger was remove and inspected at Ad-meth workshop before cleaning condition. Inspection findings are as follows: Shell side appeared in good condition No plugging of tubes was observed except for fouling built up on tubesheets Expanded bellow also appeared in good condition Baffle tie rod noted slight bend. No issue Eddy current testing could not be performed due to heavy deposits on the internal side of tubes

RECOMMENDATION/ ACTION To perform hydrotest for the exchanger as per test pressure. Results passed

ACTION PARTY Mechanical

DATE CLOSED 3rd Feb 2013

Rev.5 / Sept 2011

Page 2 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

THICKNESS DATA Location Channel plate Shell plate Shell cone 4 Glycol inlet nozzle(N5) 8 Glycol outlet nozzle(N6) 4 Hot oil inlet nozzle(HOS) 4 Hot oil outlet nozzle(HOR) 1 Drain nozzle(D) 1 Vent nozzle(V1) 1 Vent nozzle(V2) Current (t) mm 11.86 12.57 12.72 6.15 15.9 8.12 8.44 6.20 3.77 6.02 Previous (t) mm Design (t) mm 12.00 12.70 12.70 6.02 11.18 8.56 8.56 6.35 3.38 6.35 Corrosion Allowance (mm) 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 Condition Thickness within tolerance Thickness within tolerance Thickness within tolerance Thickness within tolerance Thickness within tolerance Thickness within tolerance Thickness within tolerance Thickness within tolerance Thickness within tolerance Thickness within tolerance

Rev.5 / Sept 2011

Page 3 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

EQUIPMENT GA / LAYOUT

Rev.5 / Sept 2011

Page 4 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

INSPECTION PHOTOGRAPHIC RECORD Photo Findings Overview of E-2570

Exchanger shell overview

Rev.5 / Sept 2011

Page 5 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Internal shell appeared in good condition

Channel head overview

Rev.5 / Sept 2011

Page 6 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Internal channel head condition

Shell cover(cone) overview

Rev.5 / Sept 2011

Page 7 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Internal view condition

Internal view condition

Rev.5 / Sept 2011

Page 8 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Floating tube sheet and tube bundle condition.

Tubesheet observed no plugging however fouling built up was observed

Rev.5 / Sept 2011

Page 9 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Close view of fouling built up

Generally tube bundle appeared in good condition

Rev.5 / Sept 2011

Page 10 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Floating head plate condition

Expansion bellow condition

Rev.5 / Sept 2011

Page 11 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

After cleaning condition Shell internal

Close view

Rev.5 / Sept 2011

Page 12 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Close view

Shell cover(cone)

Rev.5 / Sept 2011

Page 13 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Internal view

Close view

Rev.5 / Sept 2011

Page 14 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Expansion bellow condition

Channel head condition

Rev.5 / Sept 2011

Page 15 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Channel head cover

Floating head plate condition

Rev.5 / Sept 2011

Page 16 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Tubesheet condition

Close view of tubes

Rev.5 / Sept 2011

Page 17 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Close view of tubes

Tube bundle. One tie rod noted slight bend. No issue

Rev.5 / Sept 2011

Page 18 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

Close view.

Rev.5 / Sept 2011

Page 19 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

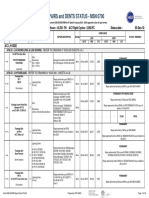

INSPECTION CHECKLISTS RECORD

Pressure Vessel Inspection Checklist

Tick relevant boxes

Item

Heat Exchanger (Shell & Tube) 1) Check before and after cleaning 2) Visual check shell, cover, channel cover, floating head cover and nozzles condition 3) Visual check any erosion-corrosion attack on the tube ends 4) Visual check external tube any corrosion or damage condition 5) Perform NDT for tube

Completed [ ] NA

Comments

Could not be carried out due to heavy deposits on internal tubes

6) Visual check any disclose grooving of tubes and enlargement of baffle holes. 7) Check anodes condition (if any) 8) Inspect the impingement or wear plates for any sign of corrosion or erosion 9) Obtain thickness for shell/ nozzles and dead legs area 10) Check any insulation damage / CUI/ external corrosion 11) Check foundations bolting is double-nutted/ support condition 12) Check platform, ladders, handrails and davis condition 13) Check any painting damage 14) Gasket seating surface any damage 15) Hammer test on Lifting lugs 16) Hammer test on Shell small piping connection 17) Kettle-type exchanger check weir condition

NA NA NA Thickness within tolerance

Furnace (Fire Heater) 1) Check before and after cleaning NA

Rev.5 / Sept 2011

Page 20 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

2) Check for porous refractory by hammer test and mark out for repair (if any) 3) Any damage of baffle brick 4) Check and damage or crack ferrules 5) Check any expose anchor 6) Replace feed tube (R1/R2) with correct material construction of Inconel with PMI (for F-8010 only) 7) Vacuum or remove dust on furnace bottom circumference of the refractory brick (for F-8010 only) 8) Fill up the bricks to bricks joints with Ceramic fibre if gap approximately >4mm (if any) 9) Check internal radiant coil thermo bond secured (for Hot Oil Heater only) 10) Check any sign of loose supports securing the radiant coils (for Hot Oil Heater only) 11) Check any ash formation built up / refractory drop out at the crossover fin coils from small doors area (for Hot Oil Heater only) 12) Obtain thickness for shell/ nozzles and dead legs area 13) Check any insulation damage / CUI/ external corrosion 14) Check foundations/ support condition 15) Check platform, ladders, handrails and davis condition 16) Check any painting damage 17) Check all internal apparatus like thermo well, etc condition Boiler 1) Check before and after cleaning 2) Check internal Steam drum and tubes condition 3) Check internal water drum condition 4) Check internal spacer tubes condition 5) Check for porous refractory by hammer test and mark out for repair (if any) 6) Perform require NDT 7) Obtain thickness for shell/ nozzles and dead legs area 8) Check any insulation damage / CUI/ external corrosion

NA NA NA NA NA NA

NA NA NA NA

NA NA NA NA NA NA

NA NA NA NA NA NA NA NA

Rev.5 / Sept 2011

Page 21 of 22

CHEVRON ORONITE PTE LTD INSPECTION TEST REPORT

9) Check foundations/ support condition 10) Check platform, ladders, handrails and davis condition 11) Check any painting damage 12) Check all internal apparatus like thermo well, etc condition

NA NA NA

Pressure Vessel (Column/ Vessel/ Reactor) 1) Check before and after cleaning 2) Visual check internal wall condition 3) Check chimney tray condition 4) Check bottom vortex strainer condition 5) Check demister pads condition 6) Check internal packing for any fouling or plugging in bed 7) Inspect the impingement or wear plates for any sign of corrosion or erosion 8) Perform require NDT 9) Inspect any loose of U-bolts & sign of cut or erosion between pipe 10) Check spray nozzle condition 11) Check any damage or weld shear off support 12) Check any bolt/ nuts loose for impeller blade 13) Check any sign of lining/ cladding failure 14) Obtain thickness for shell/ nozzles and dead legs area 15) Check any insulation damage / CUI/ external corrosion 16) Check foundations/ support condition 17) Check platform, ladders, handrails and davis condition 18) Check any painting damage 19) Perform hydro test for external/ internal coil 20) Check all internal apparatus like thermo well, etc condition NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA

Others Comment.

Rev.5 / Sept 2011

Page 22 of 22

Potrebbero piacerti anche

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersDa EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersValutazione: 3.5 su 5 stelle3.5/5 (19)

- TUV India HEAT EXCHANGER InspectionDocumento43 pagineTUV India HEAT EXCHANGER InspectionParthiban NCNessuna valutazione finora

- Feild Inspection of Shell and Tube Heat ExchangersDocumento4 pagineFeild Inspection of Shell and Tube Heat ExchangersMatthew BennettNessuna valutazione finora

- Inspection of Unfired Pressure Vessel Std-128Documento34 pagineInspection of Unfired Pressure Vessel Std-128dyke_engg100% (1)

- CML Optimization FinalDocumento31 pagineCML Optimization FinalFatemeh SaadatmandNessuna valutazione finora

- Heat Exchanger InspectionDocumento7 pagineHeat Exchanger InspectionHamid Albashir100% (1)

- Inspection of Heat ExchangersDocumento20 pagineInspection of Heat Exchangersadel100% (1)

- Maintenanc and Repair of Pressure VesselsDocumento93 pagineMaintenanc and Repair of Pressure VesselsVimin Prakash100% (12)

- Heat Exchanger InspectionDocumento9 pagineHeat Exchanger Inspectionpstechnical_43312697Nessuna valutazione finora

- 00 Saip 74 - CuiDocumento8 pagine00 Saip 74 - CuiAbdelrahman HosnyNessuna valutazione finora

- Pressure Vessel Repair ProcedureDocumento7 paginePressure Vessel Repair ProcedureAndy UgohNessuna valutazione finora

- 10.400.413 Unfired Pressure Vessel Inspection ProcedureDocumento17 pagine10.400.413 Unfired Pressure Vessel Inspection ProcedureedwinsazzzNessuna valutazione finora

- Itp Existing Pressure VesselDocumento3 pagineItp Existing Pressure Vesselmuhammad afrizal100% (1)

- Guide For Insepction For Installed Fired HeatersDocumento35 pagineGuide For Insepction For Installed Fired HeatersColoLatino100% (7)

- Heat Exchanger InspectionDocumento43 pagineHeat Exchanger Inspectionabdul aziz100% (6)

- Boilers InspectionDocumento62 pagineBoilers Inspectionrty288% (16)

- Hydrotest ProcedureDocumento12 pagineHydrotest Procedurealex_feryando42100% (1)

- F.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselDocumento7 pagineF.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselIksan Adityo MulyoNessuna valutazione finora

- Maintaining and Repairing Heat Exchanger TubesDocumento14 pagineMaintaining and Repairing Heat Exchanger TubesMicheal Brooks100% (1)

- Boiler Inspection Report TemplateDocumento7 pagineBoiler Inspection Report TemplateE. Niem86% (7)

- 6 Inspection Report - LP Heater 7 - PMT 4004 - MIOV 2019Documento4 pagine6 Inspection Report - LP Heater 7 - PMT 4004 - MIOV 2019zaihasrenNessuna valutazione finora

- Report No. TA-V-1456Documento2 pagineReport No. TA-V-1456u04ajf3Nessuna valutazione finora

- Heat Exchanger Inspection Checklist - QC, Inspection & Testing Engineering - Eng-TipsDocumento2 pagineHeat Exchanger Inspection Checklist - QC, Inspection & Testing Engineering - Eng-TipsdileepNessuna valutazione finora

- Pressure VesselDocumento80 paginePressure Vesselkart_rl75% (4)

- Fired Heater Inspection Manual PDFDocumento35 pagineFired Heater Inspection Manual PDFBalaji Narasimhan100% (1)

- Heat Exchanger InspectionDocumento11 pagineHeat Exchanger InspectionVivek Bhangale100% (1)

- Inspection of Unfired Pressure VesselsDocumento35 pagineInspection of Unfired Pressure Vesselstbmari100% (7)

- Process Piping Inspection Procedure Rev.2 PDFDocumento34 pagineProcess Piping Inspection Procedure Rev.2 PDFLevi Porter100% (6)

- STS Qac Sop 002 Heat Exchanger Retubing ProcedureDocumento4 pagineSTS Qac Sop 002 Heat Exchanger Retubing Proceduremohd as shahiddin jafri50% (2)

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDocumento13 pagineJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNessuna valutazione finora

- Vessel Cleaning ProcedureDocumento6 pagineVessel Cleaning ProcedureZool HilmiNessuna valutazione finora

- Maintenance and Repair of Pressure VesselsDocumento81 pagineMaintenance and Repair of Pressure Vesselsjishnunelliparambil100% (3)

- Heat Exchanger Inspection Procedure PDFDocumento33 pagineHeat Exchanger Inspection Procedure PDFshakeelahmadjsr67% (3)

- F.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselDocumento6 pagineF.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselIksan Adityo MulyoNessuna valutazione finora

- Corrosion Modelling.: Piping Corrosion Circuit or Corrosion Loop / Piping Circuitization andDocumento4 pagineCorrosion Modelling.: Piping Corrosion Circuit or Corrosion Loop / Piping Circuitization andOussama radikiNessuna valutazione finora

- Pressure Testing of Pressure VesselDocumento3 paginePressure Testing of Pressure VesselAriq FauzanNessuna valutazione finora

- 32 Saip 11Documento9 pagine32 Saip 11Jam100% (2)

- Pressure VesselDocumento31 paginePressure VesselCkaal74Nessuna valutazione finora

- (PDF) API-571-Damage-mechanisms-Affecting-Fixed-Equipment-in-the-Refining-IndustryDocumento5 pagine(PDF) API-571-Damage-mechanisms-Affecting-Fixed-Equipment-in-the-Refining-Industrysabari ramasamyNessuna valutazione finora

- Pressure Equipment IMDocumento43 paginePressure Equipment IMInspection EngineerNessuna valutazione finora

- Mechanical Integrity Management of Bulk Storage TanksDocumento84 pagineMechanical Integrity Management of Bulk Storage Tanksjimmytry100% (1)

- Generic Repair Procedure For Grinding and Build-UpDocumento8 pagineGeneric Repair Procedure For Grinding and Build-UpRafiqKuNessuna valutazione finora

- Pressure Vessel Inspection Procedure Rev.2Documento24 paginePressure Vessel Inspection Procedure Rev.2Ariq Fauzan100% (7)

- On-Stream Leak Repair Techniques - Part 2Documento2 pagineOn-Stream Leak Repair Techniques - Part 2qaisarabbas9002100% (1)

- F.sq-wI.008 Procedure For Inspection of Existing Storage TankDocumento17 pagineF.sq-wI.008 Procedure For Inspection of Existing Storage TankIksan Adityo MulyoNessuna valutazione finora

- CHE Retubing ReportDocumento29 pagineCHE Retubing ReportRajesh KtrNessuna valutazione finora

- EG 19-2-1.1 Strip Lining of Pressure Vessels: ScopeDocumento6 pagineEG 19-2-1.1 Strip Lining of Pressure Vessels: ScopeaminNessuna valutazione finora

- TUV India COLUMN InspectionDocumento21 pagineTUV India COLUMN InspectionParthiban NC100% (1)

- Mechanical Interview Rev 1Documento86 pagineMechanical Interview Rev 1Syed Mohamed Gani GaniNessuna valutazione finora

- Sample NTD Inspection ReportDocumento127 pagineSample NTD Inspection ReportGeorge NicolaidesNessuna valutazione finora

- Piping Inspector Questions 1Documento6 paginePiping Inspector Questions 1Badiuzzama786100% (1)

- Aramco Q&aDocumento5 pagineAramco Q&aEzhil Arasan100% (2)

- Piping InterviewDocumento9 paginePiping Interviewsatyammmishra0101Nessuna valutazione finora

- TUV India STORAGE TANK InspectionDocumento20 pagineTUV India STORAGE TANK Inspectionneelapu mahesh reddyNessuna valutazione finora

- Manual-Trunnion Ball ValvesDocumento12 pagineManual-Trunnion Ball ValvesTrinh DungNessuna valutazione finora

- ASME CODE Requirements - Heat ExchangerDocumento9 pagineASME CODE Requirements - Heat ExchangerJithin FrancizNessuna valutazione finora

- Vendor Drawing Review VDR Valve Specific RequirementsDocumento5 pagineVendor Drawing Review VDR Valve Specific Requirementsthuyenquyen_vtNessuna valutazione finora

- Work Procedure For ColumDocumento9 pagineWork Procedure For ColumShams TabrezNessuna valutazione finora

- Vibration of Cooling Tower Fans 2015Documento37 pagineVibration of Cooling Tower Fans 2015fazzlie100% (1)

- Ea230 - Astm E2357 - E331Documento11 pagineEa230 - Astm E2357 - E331Deco DluxeNessuna valutazione finora

- Eat Right For Your Blood TypeDocumento5 pagineEat Right For Your Blood Typekingcobra00791% (58)

- FMC Network Uae Jafza List - November 2013Documento489 pagineFMC Network Uae Jafza List - November 2013rtrajan_mech5408Nessuna valutazione finora

- Vibration Failure of HE TubeDocumento1 paginaVibration Failure of HE Tubertrajan_mech5408Nessuna valutazione finora

- Job Applicant Questionnaire UAE & IraqDocumento1 paginaJob Applicant Questionnaire UAE & Iraqrtrajan_mech5408Nessuna valutazione finora

- CV FormatDocumento2 pagineCV FormatnidaahmedNessuna valutazione finora

- MD PV ASME v0.1Documento35 pagineMD PV ASME v0.1rtrajan_mech5408Nessuna valutazione finora

- PV Newsletter - August2014Documento20 paginePV Newsletter - August2014rtrajan_mech5408Nessuna valutazione finora

- Whats New in Asme A 2010Documento19 pagineWhats New in Asme A 2010Sudhanshu ShekharNessuna valutazione finora

- Interpretation: 'VIII-78-149Documento1 paginaInterpretation: 'VIII-78-149rtrajan_mech5408Nessuna valutazione finora

- Interpretation: VIII-78-142Documento1 paginaInterpretation: VIII-78-142rtrajan_mech5408Nessuna valutazione finora

- Interpretation: VIII-79-02Documento1 paginaInterpretation: VIII-79-02rtrajan_mech5408Nessuna valutazione finora

- Interpretation: VIII-78-145Documento1 paginaInterpretation: VIII-78-145rtrajan_mech5408Nessuna valutazione finora

- Interpretation: VIII-79-02Documento1 paginaInterpretation: VIII-79-02rtrajan_mech5408Nessuna valutazione finora

- Interpretation: VIII-78-135Documento1 paginaInterpretation: VIII-78-135rtrajan_mech5408Nessuna valutazione finora

- 864 74Documento1 pagina864 74rtrajan_mech5408Nessuna valutazione finora

- Interpretation: VIII-78-138Documento1 paginaInterpretation: VIII-78-138rtrajan_mech5408Nessuna valutazione finora

- 864 77Documento1 pagina864 77rtrajan_mech5408Nessuna valutazione finora

- 864 77Documento1 pagina864 77rtrajan_mech5408Nessuna valutazione finora

- Interpretation: VIII-78-112Documento1 paginaInterpretation: VIII-78-112rtrajan_mech5408Nessuna valutazione finora

- Interpretation: VIII-78-135Documento1 paginaInterpretation: VIII-78-135rtrajan_mech5408Nessuna valutazione finora

- 864 76Documento1 pagina864 76rtrajan_mech5408Nessuna valutazione finora

- 864 73Documento1 pagina864 73rtrajan_mech5408Nessuna valutazione finora

- AttentionDocumento1 paginaAttentionrtrajan_mech5408Nessuna valutazione finora

- 864 72Documento1 pagina864 72rtrajan_mech5408Nessuna valutazione finora

- 864 68Documento1 pagina864 68rtrajan_mech5408Nessuna valutazione finora

- 864 66Documento1 pagina864 66rtrajan_mech5408Nessuna valutazione finora

- Interpretation: VIII-78-107Documento1 paginaInterpretation: VIII-78-107rtrajan_mech5408Nessuna valutazione finora

- 864 70Documento1 pagina864 70rtrajan_mech5408Nessuna valutazione finora

- Interpretation: VIII-78-101Documento1 paginaInterpretation: VIII-78-101rtrajan_mech5408Nessuna valutazione finora

- Interpretation: VIII-78-94Documento1 paginaInterpretation: VIII-78-94rtrajan_mech5408Nessuna valutazione finora

- HY-TB3DV-M 3axis Driver PDFDocumento10 pagineHY-TB3DV-M 3axis Driver PDFjoelgcrNessuna valutazione finora

- Earth Sciences Notes Csir-Ugc Net JRFDocumento57 pagineEarth Sciences Notes Csir-Ugc Net JRFmanas773Nessuna valutazione finora

- Pre RmoDocumento4 paginePre RmoSangeeta Mishra100% (1)

- Sw34 Religion, Secularism and The Environment by NasrDocumento19 pagineSw34 Religion, Secularism and The Environment by Nasrbawah61455Nessuna valutazione finora

- Chemical Bonds WorksheetDocumento2 pagineChemical Bonds WorksheetJewel Mae MercadoNessuna valutazione finora

- Donna Hay Magazine 2014-10-11 PDFDocumento172 pagineDonna Hay Magazine 2014-10-11 PDFlekovic_tanjaNessuna valutazione finora

- Intel Stratix 10 Avalon - MM Interface For PCI Express Solutions User GuideDocumento173 pagineIntel Stratix 10 Avalon - MM Interface For PCI Express Solutions User Guideenoch richardNessuna valutazione finora

- Propert 447-445Documento11 paginePropert 447-445LUNA100% (1)

- #Dr. Lora Ecg PDFDocumento53 pagine#Dr. Lora Ecg PDFمحمد زينNessuna valutazione finora

- (G. Lakshmi Narasaiah) Finite Element Analysis PDFDocumento349 pagine(G. Lakshmi Narasaiah) Finite Element Analysis PDFmoljaime1326Nessuna valutazione finora

- Book BindingDocumento14 pagineBook Bindingpesticu100% (2)

- Disectie AnatomieDocumento908 pagineDisectie AnatomieMircea SimionNessuna valutazione finora

- Binder 3 of 4 Dec-2018Documento1.169 pagineBinder 3 of 4 Dec-2018Anonymous OEmUQuNessuna valutazione finora

- Easergy PS100 48VDC Power SupplyDocumento2 pagineEasergy PS100 48VDC Power SupplyRichard SyNessuna valutazione finora

- BS746 2014Documento22 pagineBS746 2014marco SimonelliNessuna valutazione finora

- Vallarpadam Terminal ChallengesDocumento3 pagineVallarpadam Terminal Challengespriya rajeev100% (1)

- History and Philo of ScienceDocumento5 pagineHistory and Philo of ScienceJan Oliver YaresNessuna valutazione finora

- TS SR Chemistry Imp Questions PDFDocumento5 pagineTS SR Chemistry Imp Questions PDFUnknown Khan100% (3)

- Is 4031 Part 4 - ConsistencyDocumento4 pagineIs 4031 Part 4 - ConsistencyCrypto AbhishekNessuna valutazione finora

- Product Recommendation Hyster Forklift Trucks, Electric J1.60XMTDocumento1 paginaProduct Recommendation Hyster Forklift Trucks, Electric J1.60XMTNelson ConselhoNessuna valutazione finora

- Material Requirement Planning (MRP)Documento55 pagineMaterial Requirement Planning (MRP)Lisa CarlsonNessuna valutazione finora

- Salem RPGDocumento16 pagineSalem RPGabstockingNessuna valutazione finora

- Cac de Luyen ThiDocumento18 pagineCac de Luyen ThiVinh Dao CongNessuna valutazione finora

- Final Thesis - Aris PotliopoulosDocumento94 pagineFinal Thesis - Aris PotliopoulosCristinaNessuna valutazione finora

- Differential Geometry of Curves and Surfaces 3. Regular SurfacesDocumento16 pagineDifferential Geometry of Curves and Surfaces 3. Regular SurfacesyrodroNessuna valutazione finora

- YellowstoneDocumento1 paginaYellowstoneOana GalbenuNessuna valutazione finora

- Contact Inform 2002 PDFDocumento24 pagineContact Inform 2002 PDFFrank AlmeidaNessuna valutazione finora

- History of Flash Part - 2Documento7 pagineHistory of Flash Part - 2YOGESHWER NATH SINGHNessuna valutazione finora

- Mpfic54 PDFDocumento201 pagineMpfic54 PDFAmy100% (1)