Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

B16-5-2003 24

Caricato da

Shal PanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

B16-5-2003 24

Caricato da

Shal PanCopyright:

Formati disponibili

PIPE FLANGES AND FLANGED FITTINGS

ASME B16.5-2003

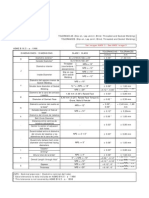

(b) Center-to-End (Ring Joint): NPS 10 1.0 mm (0.03 in.) NPS 12 1.5 mm (0.06 in.) (c) Contact Surface-to-Contact Surface Other Than Ring Joint: NPS 10 2.0 mm (0.06 in.) NPS 12 3.0 mm (0.12 in.) (d) End-to-End (Ring Joint): NPS 10 2.0 mm (0.06 in.) NPS 12 3.0 mm (0.12 in.)

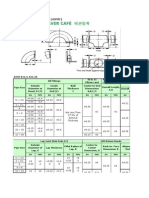

7.5.3 Backing Ring Contact Surface. Required tolerances for the bore of the backing ring contact surface of welding neck flanges, dimension C of Figs. 10 and 11 (Figs. F10 and F11 of Annex F) are as follows. 2 NPS 24 +0.25, 0.0 mm (+ 0.01, 0.0 in.) 7.5.4 Hub Thickness. Despite the tolerances specified for dimensions A and B, the thickness of the hub at the welding end shall not be less than 8712% of the nominal thickness of the pipe, having an under tolerance of 12.5% for the pipe wall thickness to which the flange is to be attached, or the minimum wall thickness as specified by the purchaser.

7.3 Facings

Required tolerances for various flange and flanged fitting facings are as follows: (a) Inside and outside diameter of large and small tongue and groove and female, 0.5 mm (0.02 in.). (b) Outside diameter, 2.0 mm (0.06 in.) raised face, 1.0 mm (0.03 in.). (c) Outside diameter, 7.0 mm (0.25 in.) raised face, 0.5 mm (0.02 in.). (d) Ring joint groove tolerances are shown in Table 5 (Table F5 of Annex F).

7.6 Length Through Hub on Welding Neck Flanges

The required tolerances for the length through hubs on welding neck flanges are as follows. NPS 4 1.5 mm (0.06 in.) 5 NPS 10 +1.5, 3.0 mm (+0.06, 0.12 in.) NPS 12 +3.0, 5.0 mm (+0.12, 0.18 in.)

7.7 Flange Bore

7.7.1 Lapped, Slip-on, and Socket Welding Flange Bores. The required tolerances for lapped, slip-on, and socket welding flange bores are as follows. NPS 10 +1.0, 0.0 mm (+0.03, 0.0 in.) NPS 12 +1.5, 0.0 mm (+ 0.06, 0.0 in.) 7.7.2 Counterbores, Threaded Flanges. The required tolerances for threaded flange counterbores are as follows. NPS 10 +1.0, 0.0 mm (+0.03, 0.0 in.) NPS 12 +1.5, 0.0 mm (+0.06, 0.0 in.) 7.7.3 Counterbores, Socket Welding Flanges. The required tolerances for socket end counterbores is as follows. 1 2 NPS 3 0.25 mm (0.010 in.)

7.4 Flange Thickness

Required tolerances for flange thickness are as follows. NPS 18, +3.0, 0.0 mm (+0.12, 0.0 in.) NPS 20, +5.0, 0.0 mm (+0.19, 0.0 in.) The plus tolerance is applicable to bolting bearing surfaces whether as-forged, as-cast, spot-faced or backfaced. See para. 6.6.

7.5 Welding End Flange Ends and Hubs

7.5.1 Outside Diameter. Required tolerances for the nominal outside diameter dimension A of Figs. 8 and 9 (Figs. F8 and F9 of Annex F) of welding ends of welding neck flanges are as follows: NPS 5 +2.0, 1.0 mm (+0.09, 0.03 in.) NPS 6 +4.0, 1.0 mm (+0.16, 0.03 in.) 7.5.2 Inside Diameter. Required tolerances for the nominal inside diameter of welding ends of welding neck flanges and smaller bore of socket welding flanges (dimension B in the referenced figures) are as follows: For Figs. 8 and 9 (Figs. F8 and F9 of Annex F) the tolerances are NPS 10 1.0 mm (0.03 in.) 12 NPS 18 1.5 mm (0.06 in.) NPS 20, +3.0, 1.5 mm (+0.12, 0.06 in.)

For Fig. 10 (Fig. F10 of Annex F) the tolerances are NPS 10 +0.0, 1.0 mm (+0.0, 0.03 in.) NPS 12 +0.0, 1.5 mm (+0.0, 0.06 in.)

13

7.8 Drilling and Facing

7.8.1 Bolt Circle Diameter. The required tolerance for all bolt circle diameters is 1.5 mm (0.06 in.) 7.8.2 Bolt Hole to Bolt Hole. The required tolerance for the center-to-center of adjacent bolt holes is 0.8 mm (0.03 in.) 7.8.3 Bolt Circle Concentricity. The required tolerances for concentricity between the flange bolt circle diameter and machined facing diameters are as follows. NPS 212 0.8 mm (0.03 in.) NPS 3 1.5 mm (0.06 in.)

Potrebbero piacerti anche

- General Machining TolerancesDocumento6 pagineGeneral Machining TolerancesmanimeczNessuna valutazione finora

- Piping Material Specification Rev CDocumento44 paginePiping Material Specification Rev Cmengelito almonte100% (4)

- Manual of Engineering Drawing: British and International StandardsDa EverandManual of Engineering Drawing: British and International StandardsValutazione: 3.5 su 5 stelle3.5/5 (4)

- MSS SP-118 2007Documento24 pagineMSS SP-118 2007ISRAEL PORTILLONessuna valutazione finora

- PipingDocumento267 paginePipingNurcahyo Djati W100% (1)

- Standardization of Steel Pipe SizesDocumento4 pagineStandardization of Steel Pipe SizesMuhammed Abo-FandoodNessuna valutazione finora

- Jis b1702Documento3 pagineJis b1702Pieyah Chomel75% (4)

- Steelbutt Hinges-Specification (: Pitf CF FFMDocumento8 pagineSteelbutt Hinges-Specification (: Pitf CF FFMSandeep Goud ChatlaNessuna valutazione finora

- ODMEDocumento20 pagineODMEPhilip Kyaw100% (1)

- Block Shear Connection Design Checks PDFDocumento7 pagineBlock Shear Connection Design Checks PDF112160rbc100% (1)

- Analyzing Taper Fits For ManufacturingDocumento7 pagineAnalyzing Taper Fits For Manufacturingsalgado_24Nessuna valutazione finora

- 15801E09 - Manual ValveDocumento390 pagine15801E09 - Manual ValveFAUSTO SAMPIETRO33% (3)

- Beam Desgin SheetDocumento5 pagineBeam Desgin SheetKamYingLamNessuna valutazione finora

- High precision turntables and hobbing machinesDocumento4 pagineHigh precision turntables and hobbing machinesNARENDER SINGH100% (1)

- Drilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsDa EverandDrilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsValutazione: 5 su 5 stelle5/5 (1)

- Piping MaterialDocumento132 paginePiping Materialhamidreza_m85100% (5)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDa EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNessuna valutazione finora

- Original Spare Parts Manual ReferenceDocumento104 pagineOriginal Spare Parts Manual ReferenceJorge Rivera100% (1)

- Broaches - Basic CharacteristicDocumento5 pagineBroaches - Basic CharacteristicDhan CNessuna valutazione finora

- Petronas Technical Standards: Bolted Flange Joint Assembly (Amendments/Supplements To ASME PCC-1)Documento11 paginePetronas Technical Standards: Bolted Flange Joint Assembly (Amendments/Supplements To ASME PCC-1)Agus Marpaung0% (1)

- Interference Fits and PressureDocumento21 pagineInterference Fits and PressurerwmingisNessuna valutazione finora

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Documento9 pagineTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioNessuna valutazione finora

- Tolerancias Ansi b16-5Documento2 pagineTolerancias Ansi b16-5marcoedgNessuna valutazione finora

- Tolerance As Per B16.5Documento1 paginaTolerance As Per B16.5Yogendra KumarNessuna valutazione finora

- ANSI B16.5 Flange ToleranceDocumento2 pagineANSI B16.5 Flange TolerancevmrameshbeNessuna valutazione finora

- ASME B16.5-2003 Annex FDocumento1 paginaASME B16.5-2003 Annex FPanchal ShaileshNessuna valutazione finora

- B16 36 Book PDFDocumento13 pagineB16 36 Book PDFSyed AbudhakirNessuna valutazione finora

- 171CE113-bolted ConnectionDocumento9 pagine171CE113-bolted ConnectionARJUN RNessuna valutazione finora

- Appendix H Sample Calculations For Branch ReinforcementDocumento2 pagineAppendix H Sample Calculations For Branch ReinforcementestudiemosNessuna valutazione finora

- Errata To ASME B18.2.1-2012 Square, Hex, Heavy Hex, and Askew Head Bolts and Hex, Heavy Hex, Hex Flange, Lobed Head, and Lag Screws (Inch Series)Documento2 pagineErrata To ASME B18.2.1-2012 Square, Hex, Heavy Hex, and Askew Head Bolts and Hex, Heavy Hex, Hex Flange, Lobed Head, and Lag Screws (Inch Series)tungxuanbrNessuna valutazione finora

- Gear2 02aDocumento5 pagineGear2 02aΚυριάκος ΒαφειάδηςNessuna valutazione finora

- 2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Documento9 pagine2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Difa LiuNessuna valutazione finora

- BS 4504 FlangeDocumento11 pagineBS 4504 FlangeAlon BalonNessuna valutazione finora

- Structural Design Drawings and Details for Building PlanningDocumento5 pagineStructural Design Drawings and Details for Building PlanningIlham FebriansyahNessuna valutazione finora

- B16 47+book PDFDocumento18 pagineB16 47+book PDFAnonymous K3FaYFlNessuna valutazione finora

- 3500 ENGINE Specifications Pistons and RingsDocumento5 pagine3500 ENGINE Specifications Pistons and RingsVan Phuc ThaiNessuna valutazione finora

- EN 1337-2 (6.9.3) Backing plate stiffnessDocumento1 paginaEN 1337-2 (6.9.3) Backing plate stiffnessMarijanaNessuna valutazione finora

- MS 415 Amen - No - 1Documento5 pagineMS 415 Amen - No - 1priyankaprashaanthNessuna valutazione finora

- Design of Combined Footing : 10Documento5 pagineDesign of Combined Footing : 10PinapaSrikanthNessuna valutazione finora

- Fitting Dimensional TolerancesDocumento13 pagineFitting Dimensional TolerancesJinGuk JangNessuna valutazione finora

- Bearing TolerancesDocumento5 pagineBearing Tolerancesstavros stergiopoulosNessuna valutazione finora

- Tolerence For CouplingsDocumento2 pagineTolerence For CouplingsnagagangNessuna valutazione finora

- Plummer Blocks: Tightening Bolt Oil Fill PlugDocumento30 paginePlummer Blocks: Tightening Bolt Oil Fill Plugmanoj983@gmail.comNessuna valutazione finora

- Plummer en 03-32Documento30 paginePlummer en 03-32refeiNessuna valutazione finora

- Printed in GermanyDocumento8 paginePrinted in Germanyengine wangNessuna valutazione finora

- Structural ConnectionsDocumento26 pagineStructural ConnectionsAlemtsehay ShiferawNessuna valutazione finora

- Standard condenser drawing dimensions and tolerancesDocumento1 paginaStandard condenser drawing dimensions and tolerancesSaravanan VijayanNessuna valutazione finora

- Daniel Senior Orifice Fitting Dimensions and SpecsDocumento2 pagineDaniel Senior Orifice Fitting Dimensions and SpecsEndra BudimansyahNessuna valutazione finora

- Impeder Cores for High Frequency Pipe WeldingDocumento13 pagineImpeder Cores for High Frequency Pipe WeldingАлексей АндрияшNessuna valutazione finora

- Nuts Bolts Screws and WashersDocumento4 pagineNuts Bolts Screws and WashersneevarpsufurNessuna valutazione finora

- Longitud Esparragos - Asme b16.5-2013Documento2 pagineLongitud Esparragos - Asme b16.5-2013andrescortezNessuna valutazione finora

- ASME B16.5 Flange Table NotesDocumento1 paginaASME B16.5 Flange Table NotesPanchal ShaileshNessuna valutazione finora

- APPLICATION: Parker 492620: Form Setup Date: 03/29/2000 Calculation Date: 10/2/2012Documento8 pagineAPPLICATION: Parker 492620: Form Setup Date: 03/29/2000 Calculation Date: 10/2/2012nicoftaNessuna valutazione finora

- Turbocharger NR12/S - New Gaps and Clearances: Application ReasonDocumento3 pagineTurbocharger NR12/S - New Gaps and Clearances: Application ReasonSameer MalikNessuna valutazione finora

- 2 Peso de Bridas Por Cedula o LBSDocumento1 pagina2 Peso de Bridas Por Cedula o LBSjulio cesar arroyoNessuna valutazione finora

- API5LDocumento2 pagineAPI5LSua Vida BrilhaNessuna valutazione finora

- Softening Point of Bitumen (Ring-and-Ball Apparatus) : Aashto Designation: T 53-92Documento1 paginaSoftening Point of Bitumen (Ring-and-Ball Apparatus) : Aashto Designation: T 53-92Evert RiveraNessuna valutazione finora

- Bang Catalog Bac Dan NSKDocumento0 pagineBang Catalog Bac Dan NSKsariobaoNessuna valutazione finora

- Base PLT For IT CentreDocumento13 pagineBase PLT For IT CentreUday UdmaleNessuna valutazione finora

- INFASO 9.4 Example FinalDocumento28 pagineINFASO 9.4 Example Finalpperic13Nessuna valutazione finora

- SRM-51-47-00 Fastener Pitch and Edge Distance DataDocumento13 pagineSRM-51-47-00 Fastener Pitch and Edge Distance DataJelpi Duvan LariosNessuna valutazione finora

- Dimensions: Dimension and Tolerance SymbolsDocumento6 pagineDimensions: Dimension and Tolerance Symbolsjdsa123Nessuna valutazione finora

- Dimensions of Bolts and Nuts BS3692Documento6 pagineDimensions of Bolts and Nuts BS3692azam RazzaqNessuna valutazione finora

- Sec-I 138Documento1 paginaSec-I 138Panchal ShaileshNessuna valutazione finora

- Sec-I 126Documento1 paginaSec-I 126Panchal ShaileshNessuna valutazione finora

- Sec-I 140Documento1 paginaSec-I 140Panchal ShaileshNessuna valutazione finora

- Sec-I 139Documento1 paginaSec-I 139Panchal ShaileshNessuna valutazione finora

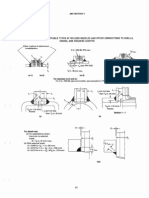

- FIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingDocumento1 paginaFIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingPanchal ShaileshNessuna valutazione finora

- Sec-I 131Documento1 paginaSec-I 131Panchal ShaileshNessuna valutazione finora

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Documento1 paginaTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Panchal ShaileshNessuna valutazione finora

- Table Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsDocumento1 paginaTable Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsPanchal ShaileshNessuna valutazione finora

- Sec-I 136Documento1 paginaSec-I 136Panchal ShaileshNessuna valutazione finora

- Sec-I 130Documento1 paginaSec-I 130Panchal ShaileshNessuna valutazione finora

- Sec-I 133Documento1 paginaSec-I 133Panchal ShaileshNessuna valutazione finora

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Documento1 paginaFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNessuna valutazione finora

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Documento1 paginaTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Panchal ShaileshNessuna valutazione finora

- Sec-I 132Documento1 paginaSec-I 132Panchal ShaileshNessuna valutazione finora

- Sec-I 129Documento1 paginaSec-I 129Panchal ShaileshNessuna valutazione finora

- Sec-I 128Documento1 paginaSec-I 128Panchal ShaileshNessuna valutazione finora

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersDocumento1 paginaFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersPanchal ShaileshNessuna valutazione finora

- Sec-I 127Documento1 paginaSec-I 127Panchal ShaileshNessuna valutazione finora

- FIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IDocumento1 paginaFIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IPanchal ShaileshNessuna valutazione finora

- Sec-I 119Documento1 paginaSec-I 119Panchal ShaileshNessuna valutazione finora

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Documento1 paginaFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNessuna valutazione finora

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Documento1 paginaFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Panchal ShaileshNessuna valutazione finora

- Sec-I 121Documento1 paginaSec-I 121Panchal ShaileshNessuna valutazione finora

- Sec-I 117Documento1 paginaSec-I 117Panchal ShaileshNessuna valutazione finora

- Boiler welding design rules for joints of unequal thicknessDocumento1 paginaBoiler welding design rules for joints of unequal thicknessPanchal ShaileshNessuna valutazione finora

- Sec-I 116Documento1 paginaSec-I 116Panchal ShaileshNessuna valutazione finora

- Sec-I 114Documento1 paginaSec-I 114Panchal ShaileshNessuna valutazione finora

- Sec-I 112Documento1 paginaSec-I 112Panchal ShaileshNessuna valutazione finora

- Sec-I 113Documento1 paginaSec-I 113Panchal ShaileshNessuna valutazione finora

- Horizontal-return tubular boiler locationsDocumento1 paginaHorizontal-return tubular boiler locationsPanchal ShaileshNessuna valutazione finora

- NRC ProposedChanges 2022 NBC NFC NPC NECB Combined 2022-10-24Documento345 pagineNRC ProposedChanges 2022 NBC NFC NPC NECB Combined 2022-10-24AliNessuna valutazione finora

- PN01CA1S01Documento5 paginePN01CA1S01joana ramirezNessuna valutazione finora

- 08 Tombo Naflon Lined Pipe and Fitting PDFDocumento36 pagine08 Tombo Naflon Lined Pipe and Fitting PDFsrikandi marketingNessuna valutazione finora

- Knife Gate Valves, Sizes 2 In. (50 MM) Through 96 In. (2,400 MM)Documento13 pagineKnife Gate Valves, Sizes 2 In. (50 MM) Through 96 In. (2,400 MM)Abhishek Kumar SinhaNessuna valutazione finora

- PIPE SCHEDULE REFERENCE CHARTDocumento3 paginePIPE SCHEDULE REFERENCE CHARTrobbyNessuna valutazione finora

- PipesDN900 PDFDocumento1 paginaPipesDN900 PDFleoscbdNessuna valutazione finora

- NPS Tables For Selected SizesDocumento1 paginaNPS Tables For Selected SizesSanjeewa ChathurangaNessuna valutazione finora

- Inspection 4 Industry LLC: GeneralDocumento31 pagineInspection 4 Industry LLC: GeneralKaliya PerumalNessuna valutazione finora

- PDVSA Engineering Design Manual Piping Fabrication RequirementsDocumento18 paginePDVSA Engineering Design Manual Piping Fabrication RequirementsEdirwinJoseChirinosNessuna valutazione finora

- National UL&FMDocumento28 pagineNational UL&FMAbdulhamit KAYYALINessuna valutazione finora

- NAIMA Facts About Insulation Requirements For Plastic PipingDocumento6 pagineNAIMA Facts About Insulation Requirements For Plastic PipingBryan CarisNessuna valutazione finora

- Allied International - BrochureDocumento24 pagineAllied International - Brochurekhan4luvNessuna valutazione finora

- CPA 55E/65E Type A Flow Conditioner - Raised Face - FOEDocumento1 paginaCPA 55E/65E Type A Flow Conditioner - Raised Face - FOEJerNessuna valutazione finora

- Products Carbon Steel Eccentric ReducerDocumento3 pagineProducts Carbon Steel Eccentric Reducerdcf67myNessuna valutazione finora

- Weldolet and Sockolet ImpDocumento20 pagineWeldolet and Sockolet ImphahrqlNessuna valutazione finora

- A134 PDFDocumento4 pagineA134 PDFالGINIRAL FREE FIRENessuna valutazione finora

- Division 23 - Heating, Ventilating, and Air-Conditioning (Hvac) Section 230529 - Hangers and Supports For Hvac Piping and EquipmentDocumento14 pagineDivision 23 - Heating, Ventilating, and Air-Conditioning (Hvac) Section 230529 - Hangers and Supports For Hvac Piping and EquipmentAhmed EbrahimNessuna valutazione finora

- Api STD 570: Video Training Handout ClassworkDocumento6 pagineApi STD 570: Video Training Handout ClassworkNaresh KumarNessuna valutazione finora

- Spe 77-133 2017Documento7 pagineSpe 77-133 2017윤규섭Nessuna valutazione finora

- Un 3790-44Documento8 pagineUn 3790-44facebookshopNessuna valutazione finora

- Draft Plant Design PaperDocumento65 pagineDraft Plant Design Paper202040336Nessuna valutazione finora