Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Valve Selection Guidelines

Caricato da

boom10Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Valve Selection Guidelines

Caricato da

boom10Copyright:

Formati disponibili

Valve Selection Guidelines

CPE10 Valve INTRODUCTION:

When selecting a directional control valve there are 4 main criteria's to look at. The criteria's are the valve function, the type of actuation, the installation options (mounting, wiring, and network), and the required flow rate needed for the application

Valve Function:

The valve function refers to how the valves internal pathways are connected. There are four main valve functions for directional control valves. These valve functions are 2/2, 3/2, 5/2, and 5/3 way valves.

1.1

2/2

All 2-Way valves have a pressure supply port (1) and a working port (2). These valves come in two different variants either Normally Closed (NC) or Normally Open (NO). When a Normally Closed valve is in its initial state, port 1 and 2 are not connected to each other until the valve is actuated. When a Normally Open valve is in its initial state, port 1 and 2 are connected to each other until the valve is actuated. These valves are used when it is not necessary or desirable to exhaust downstream pressure when the valve is closed. These valves are commonly used in applications as blow off or to drive a vacuum nozzle. Most 2way valves have an actuator and a return spring.

1.2

3/2

All 3-Way valves have a supply port (1), working port (2), and an exhaust port (3) . They come in two different variants either Normally Open (NO) or Normally Closed (NC). These two variants are a little different then the same function in the 2/2 valves. When a Normally Closed valve is in its initial state, port 2 and 3 are connected to each other and port 1 is blocked until the valve is actuated. When the valve is actuated port 1 is connected to the port 2 and the port 3 is blocked. When a Normally Open valve is in its initial state, port 1 and 2 are connected to each other and port 3 is blocked until the valve is actuated. When the valve is actuated port 3 is connected to port 2 and port 3 is blocked. These valves are most commonly used when it is necessary to exhaust downstream pressure through the valve. For this purpose, port 3 is usually returned to atmosphere through a pipe port, or an orifice (vent) in the body of the valve. For example, this valve can be used to control single-acting actuators (cylinders, rotary actuators, grippers, etc,,), which must be exhausted to atmosphere in order to return to their un-actuated position. These valves will have an actuator and a mechanical spring or air spring to return the valve to its initial position. If Port 3 is plugged, the 3/2 valve will function identically to a 2/2 valve.

1.3

5/2

All 5/2 Way valves have a supply port (1), 2 working ports (2,4), and 2 exhaust ports (3,5). These valves are most commonly used to control the position of double-acting actuators. For this purpose, the working ports (2, 4) are connected to the actuator, and the exhaust ports (3, 5) are usually returned to atmosphere through pipe ports, or orifices (vents) in the body of the valve. A 5/2 valve always has one of the working ports (2,4) connected to the pressure supply port (1), and the other working port is always connected to an

Valve Selection Guidelines

exhaust port (3,5) which is connected to atmosphere, regardless of the position of the valve. 5/2 valves come in two different configurations single actuated or double actuated valves. Single actuated valves will either have a mechanical spring or an air spring to return the valve to its initial position. A double actuated valve uses two actuators to control the position of the valve. Often double actuated valves are referred to as "Memory" valves because the valve will not return to its initial position until one of the coils are actuated.

1.4

5/3

Like 5/2 way valves 5/3 valves have a supply port (1), 2 working ports (2,4), and 2 exhaust ports. The main difference is that the 5/3 has 3 possible positons.5/3 valves have an additional spring-centered neutral position, which the valve takes when both actuators are not engaged.. In the neutral position, both working ports (2,4) may be blocked (5/3G), pressurized (5/3B), or exhausted (5/3E) depending on the specific type of 5/3 valve. In the blocked version, none of the ports are connected to each other. In the pressurized version, the supply port is connected to both the working ports (2,4) and the exhaust ports are blocked. In the exhausted version, the working ports(2,4) are connected to the exhaust ports(3,5) and the supply port 1 is blocked.

2

2.1

ACTUATOR TYPES:

Solenoid Actuators

2.1.1 Direct-Acting Direct acting solenoid valves are shifted exclusively by the direct mechanical action of a solenoid coil . This means that either the plunger in the coil is used in the valve as poppet or the solenoid plunger is connected to the poppet or spool in the main part of the valve.. These types of valves usually have substantially larger solenoid coils than comparable valves of the Pilot Assist design (see below). The size of the solenoid grows dramatically with increased pressure and flow capacity ratings. This often results in large valves that generate substantial amounts of heat. As a result, some direct-acting solenoid valves are not rated for continuous duty. Direct-acting solenoid valves are used in applications where low-flow switching at high speeds is required. However, while it is true that direct-acting valves shift much faster than Pilot-Assist valves, direct-acting valves have much less flow capacity for an equivalently-sized solenoid. What matters in the end is how quickly can the necessary volume of air, at a given pressure, be delivered to the component or system downstream. For this reason, a slower pilot-assist valve (with a higher flow-rate) can move an actuator much more quickly than a fast direct-acting valve (with a lower flow rate) can. 2.1.2 Pilot-Assist Unlike Direct-Acting solenoid valves, Pilot Assist valves have no mechanical linkage between the solenoid plunger and the main spool of the valve. The shifting of the main spool is, instead, accomplished by air pressure acting on an integral piston or diaphragm. This arrangement can therefore be regarded as two valves in one. A very small Direct-Acting 3/2 solenoid valve controls the pilot air going to a much larger, air-actuated main valve. This is done, even in small valves, to obtain significant reduction in the solenoids size, energy consumption and heat generation. Since the air volume required to shift even a large air-piloted valve is small, a small solenoid-actuated pilot valve will suffice. Most solenoid-operated valves used in todays industrial applications are of the Pilot-Assist design. These units come in two basic configurations; Internal and External Pilot supplies. 2.1.2.1 Internally Piloted

The solenoid actuator of an internal pilot supply valve gets its air from the main working supply port (1). There is an internal connection that diverts a small amount of air from Port 1 up to the solenoid head. This means that there must be a minimum pressure (control pressure) present on Port 1 at all times in order for the valve to work properly. This requirement prevents these valves from being used with low pressures and vacuum, or being used in unconventional supply

Valve Selection Guidelines

pressure arrangement, such as using the working ports as the supply ports and using the supply port as a working port. This is sometimes done so that two different pressures can be selected 2.1.2.2 Externally Piloted External pilot supply valves have an extra connection port(s) for supplying air exclusively to the solenoid actuator (and return air-spring, where applicable). In this case, the supply port (1) is no longer required to have a minimum pressure present. This allows valves of this type to be used for controlling vacuum and low pressure circuits, creating separate pressure zones, and a host of other creative or unconventional applications. Regardless of application, however, there must always be present available supplies of pilot air at no less than the minimum specified (control) pressure.

2.2

Mechanical/Manual Actuation

Another method of valve actuation in which some sort a of lever or push button, or knob is used to change the position of the valve. Mechanically/Manually actuated valves are often used when a machine requires human intervention to run a machine or when an pneumatic output is needed to start another process in a machine.

2.3

Air Piloted Actuation

Air actuated valves are valves which require a pilot pressure so that the valve may be switched. These valves always have external pilot ports on them. They are often used in applications where solenoid valves are not permitted due to safety reasons. These valves get pilot pressure from external valves. They can either be actuated via a manual valve or a solenoid valve, which is connected to its pilot ports.

Installation Options:

How valves are to be installed in the system often drives the selection process. Valves may or may not be easily accessible, the environment may be hostile, or there may be special requirements for maintenance. There are 2 main installation options for valves stand-alone valves and manifold mounted valves.

3.1

Stand Alone

Stand-alone valves can be categorized in 3 different ways In-Line, Semi In-Line, and subbase mounted. Inline refers to a valves where all of the ports are part of the body of the valve. The working ports are usual on the one side of the valve and the exhaust ports and supply port are usually on the side parallel to the working ports. Semi-inline valve refers to valves, which are mounted on a subbase and have the working ports coming out the top of the valve and the other ports being part of the subbase. A subbase valve is a valve where all of the ports are part of the subbase and are not located on the valve external walls. In-line valves are often used for individual installations where the actuator performance can be improved by locating it physically close to the valve. In applications where there are a few widely scattered actuators, in-line installations are usually preferred over manifolds. Sub-base mounted offer the additional benefit of simplified maintenance and system repair, since the system plumbing to the sub-base need not be disturbed when replacing individual valves. Sub-base valves are especially attractive when rigid system piping is used.

3.2

Manifold

Manifold mounted valves are banks of valves that are mounted together and share exhaust channels and supply channels. There are two different types of manifolds, extruded and subbase manifolds. Extruded manifolds are manifolds created from long extrusions where holes are drilled in the manifold for attaching several valves. Subbase manifolds are manifolds which consist of several subbase connected together to create a manifold. Manifolds also come in two sub-divisions Semi-Inline and with the working ports as part of the manifold. One of the more interesting developments in solenoid valve manifold design is the integration of electrical and electronic devices into the manifold assembly. For example, valve manifolds that have plug-in solenoids can have all electrical connections going to a single multi-pin connector, thus simplifying installation. Other integration techniques include the incorporation of various common industrial PLC network transceivers. This technique allows large numbers of solenoids to connect to a

Valve Selection Guidelines

remote PLC using a small two-wire high-speed data cable, thereby drastically reducing the amount of installed system wiring that would otherwise be required. These so-called Fieldbus manifolds can even be fitted with powered electrical receptacles for connecting proximity sensors and low-powered electrical output devices.

FLOW CAPACITY

Once the type of valve is selected, the next most important selection criterion is the valves flow capacity. Flow, which is measured as Volume Coefficient (Cv) or in Liters per Minute of flow, is an indication of the amount of resistance a valve presents to a pneumatic circuit. All devices that conduct air will resist flow to some degree, which causes the pressure drop across the device to increase as the flow increases. The less resistance, the smaller the pressure drop. It must be noted that any device, fitting, or run of tubing can effect the flow rate in a system. In highly time-critical applications, a few extra inches of tubing, or the wrong fitting can mean the difference between a circuit that works and one that does not. For this reason, valve flow ratings alone cannot predict the flow rate through a system branch. In the past, the common practice used in selecting a valve was to match the port size of an actuator and the valve. This is no longer a suggested way of sizing a valve to an actuator. Advancement in technology has allowed smaller valves to have increased flow. Smaller valves tend to have several advantages over larger valves. In general, the advantages of smaller valves are quicker switching time, lower leakage, less expensive and generally lower power consumption since smaller solenoids are generally used. With these advantages, smaller valves will initially save money and then save money due to decreased leakage in a system and decreased power use. In order to select a valve the flow required to move the actuator in the time required by the application. This flow required can be found by using the following equation. US UNITS Q= (Volume x Compression Factor)/(Time x 28.8) SI UNITS Q=(Volume x Compression Factor)/Time Q Volume Time Flow Rate in ft3/min or liter/sec in3 sec

Compression Factor (P1 + Pa)/Pa P1 Pa Inlet Pressure in psi or bar Atmospheric Pressure 14.7psi or 1bar

After the flow is calculated the Cv required can be calculated using the following equations. US UNITS

Cv ( T. G ) Q . . 22.48 P P 2 P a

SI UNITS

Valve Selection Guidelines

Cv ( T. G ) Q . 114.5 P . P 2 P a

T G P P2 Pa EXAMPLE:

Temperature in Rankine or Kelvin Specific Gravity (G=1 for air) Pressure drop across the valve in psi or bar Outlet Pressure in psi or bar Atmosphere Pressure 14.7psi or 1bar

A double acting cylinder with a 25mm bore and 100mm stroke is extended with a pressure of 6 bar. The rod of the cylinder has a 10mm diameter. The cylinder is required to extend in 0.25 seconds and return in 0.2 seconds. What Cv is required to extend cylinder and retract the cylinder? Step 1 : Calculate the areas and volumes

A extend 25 . 2 2

A extend = 490.874 2 2 A retract = 412.334

A retract

25 . 2

10 . 2

V extend

A extend . 100

4 V extend = 4.909 . 10 4 V retract = 4.123 . 10

V retract

A retract . 100

Step 2 : Calculate the Compression Factor

CF 6 1 1

CF = 7

Step 3 : Calculate the flow rate

Q extend V extend . CF ( 0.25 ) V retract . CF ( 0.2 ) Q extend 1.374

Q retract

Q retract

1.443

Step 4 : Calculate the Cv

Cv extend Q extend . 114.5 ( 293. 1 ) ( 0.25 . ( 5.75 1 ) Cv extend = 0.158

Valve Selection Guidelines

Q retract ( 293. 1 ) . ( 0.25 . ( 5.75 1 ) 114.5 Cv retract = 0.166

Cv retract

For the above example, a Cv of 0.158 for the extend and a Cv of 0.166 retract is required to meet the time parameter. Since a valve with the specific flow for both the extend and the retract most likely does not exist, a valve with a larger Cv should be selected. A valve with a Cv of 0.200 should accomplish our parameters. With the larger flowing valve we are also taking into account fittings and tubing lengths, which can effect our time values. If the valve selected causes the cylinder to extend and retract to fast, flow controls can be added to the cylinder to reduce the flow rate going into the cylinder.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- DEPA Air Operated Diaphragm PumpsDocumento6 pagineDEPA Air Operated Diaphragm Pumpsboom10Nessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Spirax Sarco - PRODUCT HANDBOOK AUGUST 2017 PDFDocumento1.900 pagineSpirax Sarco - PRODUCT HANDBOOK AUGUST 2017 PDFboom1086% (7)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- SKF Belt Tension TesterDocumento1 paginaSKF Belt Tension Testerboom10Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- NSB Liquid Ring CompressorDocumento8 pagineNSB Liquid Ring Compressorboom10100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- SHURflo 5904XXX Ficha Despiece enDocumento2 pagineSHURflo 5904XXX Ficha Despiece enboom10Nessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Material Equivalent TableDocumento8 pagineMaterial Equivalent Tableprashantpan1776% (21)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shore Hardness Scale Cross Reference ChartDocumento1 paginaShore Hardness Scale Cross Reference Chartboom10Nessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- VDO Instrument Manual TU00-0755-00000002Documento273 pagineVDO Instrument Manual TU00-0755-00000002boom10100% (1)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- 10 Steps GuideDocumento14 pagine10 Steps GuideUmair Haqqan AminurrahmanNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- Liquid Ring Compressor System PrincipleDocumento3 pagineLiquid Ring Compressor System Principleboom1067% (3)

- Manual - Coupling - Flexibox TSK and TSB Flexible Couplings (From v425)Documento6 pagineManual - Coupling - Flexibox TSK and TSB Flexible Couplings (From v425)anrava100% (1)

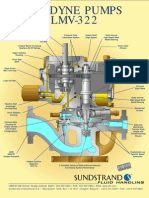

- Lewa Poster LMV 322Documento1 paginaLewa Poster LMV 322boom10Nessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Williams Material Suffix Common Designation Astm Casting Specification Service RecommendationsDocumento2 pagineWilliams Material Suffix Common Designation Astm Casting Specification Service Recommendationsboom10Nessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Screen Openings For Y-StrainersDocumento6 pagineScreen Openings For Y-Strainersboom10Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Marine and Rail Lubricants: Engine OilsDocumento10 pagineMarine and Rail Lubricants: Engine Oilsboom10Nessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- AF Range BrochureDocumento27 pagineAF Range Brochureboom10100% (1)

- DHP-306AV A1 Manual v1.00 (WW)Documento17 pagineDHP-306AV A1 Manual v1.00 (WW)Lip Eang ZhaoNessuna valutazione finora

- Dieselfacts 2006 2Documento16 pagineDieselfacts 2006 2boom10Nessuna valutazione finora

- Wider Choise in Fuel ConsumptionDocumento3 pagineWider Choise in Fuel Consumptionboom10Nessuna valutazione finora

- Flexibox Serie RDocumento5 pagineFlexibox Serie Rboom10Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Flexibox Serie RDocumento5 pagineFlexibox Serie Rboom10Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Jesus - The Creator Unleashes Our Creative PotentialDocumento1 paginaJesus - The Creator Unleashes Our Creative PotentialKear Kyii WongNessuna valutazione finora

- CHB 2Documento15 pagineCHB 2Dr. Guruprasad Yashwant GadgilNessuna valutazione finora

- Storytelling ScriptDocumento2 pagineStorytelling ScriptAnjalai Ganasan100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- D257272 1200 FDD 002 R1 PDFDocumento420 pagineD257272 1200 FDD 002 R1 PDFTap Toan100% (1)

- HU675FE ManualDocumento44 pagineHU675FE ManualMar VeroNessuna valutazione finora

- Caribbean Examinations Council Caribbean Secondary Certificate of Education Guidelines For On-Site Moderation SciencesDocumento9 pagineCaribbean Examinations Council Caribbean Secondary Certificate of Education Guidelines For On-Site Moderation SciencesjokerNessuna valutazione finora

- Mesopotamia CivilizationDocumento56 pagineMesopotamia CivilizationYashika TharwaniNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Fiery Training 1Documento346 pagineFiery Training 1shamilbasayevNessuna valutazione finora

- Call SANROCCO 11 HappybirthdayBramanteDocumento8 pagineCall SANROCCO 11 HappybirthdayBramanterod57Nessuna valutazione finora

- Principles of SamplingDocumento15 paginePrinciples of SamplingziggerzagNessuna valutazione finora

- C11 RacloprideDocumento5 pagineC11 RacloprideAvina 123Nessuna valutazione finora

- All MeterialsDocumento236 pagineAll MeterialsTamzid AhmedNessuna valutazione finora

- Fda PDFDocumento2 pagineFda PDFVictorNessuna valutazione finora

- Philippine College of Northwestern Luzon Bachelor of Science in Business AdministrationDocumento7 paginePhilippine College of Northwestern Luzon Bachelor of Science in Business Administrationzackwayne100% (1)

- Plant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirDocumento20 paginePlant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirSharad KokateNessuna valutazione finora

- Understanding Culture, Society and PoliticsDocumento62 pagineUnderstanding Culture, Society and PoliticsTeds TV89% (84)

- Febrile SeizureDocumento3 pagineFebrile SeizureClyxille GiradoNessuna valutazione finora

- Where On Earth Can Go Next?: AppleDocumento100 pagineWhere On Earth Can Go Next?: Applepetrushevski_designeNessuna valutazione finora

- PGP TutorialDocumento21 paginePGP TutorialSabri AllaniNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- About Version ControlDocumento6 pagineAbout Version ControlMaria Kristina Cassandra HeukshorstNessuna valutazione finora

- Hydrotest CalculationDocumento1 paginaHydrotest CalculationkiranNessuna valutazione finora

- EG-45-105 Material Information Sheet (Textura) V2Documento4 pagineEG-45-105 Material Information Sheet (Textura) V2GPRNessuna valutazione finora

- VNC Function Operation InstructionDocumento11 pagineVNC Function Operation InstructionArnaldo OliveiraNessuna valutazione finora

- E Learning: A Student Guide To MoodleDocumento16 pagineE Learning: A Student Guide To MoodleHaytham Abdulla SalmanNessuna valutazione finora

- CH - 3Documento3 pagineCH - 3Phantom GamingNessuna valutazione finora

- Java MCQ QuestionsDocumento11 pagineJava MCQ QuestionsPineappleNessuna valutazione finora

- Bitcoin MambaDocumento17 pagineBitcoin MambaJean MilenixNessuna valutazione finora

- 01 Design of Flexible Pavement Using Coir GeotextilesDocumento126 pagine01 Design of Flexible Pavement Using Coir GeotextilesSreeja Sadanandan100% (1)

- Practical LPM-122Documento31 paginePractical LPM-122anon_251667476Nessuna valutazione finora

- Application Programming InterfaceDocumento12 pagineApplication Programming InterfacesorinproiecteNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)