Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Types of Thermocouples

Caricato da

jordhyyDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Types of Thermocouples

Caricato da

jordhyyCopyright:

Formati disponibili

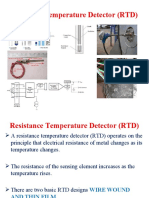

Types of Thermocouples A thermocouple is a temperature sensor that is used to gauge temperatures in manufacturing, machining and scientific applications, as well

as everyday appliances. A thermocouple can be useful to ensure surfaces, like steel or other metals or metal alloys, are appropriately heated for machining, or to gauge when a container or location is too warm and coolants need to be introduced. A thermocouple functions based on differential calculations from a known temperature point, called a cold or reference junction, and a probe, connected to the unit to be measured. Lab conditions allow a natural cold junction, but applied thermocouple conditions often necessitate the use of an artificially generated temperature constant. Because voltages generated by connecting dissimilar metals are known and constant, they are used as reference points based on their relation to the measuring junction. When the machine determines this difference, it calculates the temperature and sends the message to the measuring device. Because different combinations of metals will produce different temperatures, and these different metals have different durability and strength levels, researchers have produced standardized combinations to exploit maximum outcome potential in a standardized set of combinations. There are four different classifications of thermocouple pairings, most distinguished by a capital letter heading. These are the home body class, the upper crust class, the rarified class and the exotic class. The home body class consists of standard or commonly used metals, while the upper crust class represents all platinum combinations. The rarified class consists of refractory metals and the exotic class is much more specific in nature, usually special combinations of rare metals used for specified applications. Thermocouple Type B Composition Platinum 30% Rhodium (+) Platinum 6% Rhodium (-) C W5Re Tungsten 5% Rhenium (+) W26Re Tungsten 26% Rhenium (-) E Chromel (+) Constantan (-) J Iron (+) Constantan (-) Temperature Range 2500-3100 degrees F 1370-1700 degrees C 3000-4200 degrees F 1650-2315 degrees C 200-1650 degrees F 95-900 degrees C 200-1400 degrees F 95-760 degrees C

Chromel (+) Alumel (-)

200-2300 degrees F 95-1260 degrees C 32-2250 degrees F 0-1287 degrees C 1200-2300 degrees F 650 -1260 degrees C 1600-2640 degrees F 870-1450 degrees C 1800-2640 degrees F 980-1450 degrees C negative 330-660 degrees F negative 200-350 degrees C

Nickel (+) Nickel (-)

Nicrosil (+) Nisil (-)

Platinum 13% Rhodium (+) Platinum (-)

Platinum 10% Rhodium (+) Platinum (-) Copper (+)

T Constantan (-)

Rarefied and exotic thermocouples do not have special alpha codes assigned to them, because they are much less frequently used. Some of these combinations have standard temperature ranges listed in technical literature, however. In addition to the numbering system, thermocouples are also generally color coded. The color codings are different from country to country, so it is best to look up the different color coding based on the country from which the material is sourced. Some thermocouple applications include measuring steel during machining. B, K, R, and S type thermocouples are most suited to this job because of their high temperature ranges. This helps the manufacture know when the molten material is melted to a sufficient temperature. Heating appliances also perform well with thermocouples. Gas-fed appliances can get too hot if they are pumped to saturation, which can create dangerous situations where gas is under pressure and high temperatures are present. Thermocouples can read temperatures and activate gas shut off devices when situations get volatile.

Type K

Temperature Temperature Tolerance range C range C class one (continuous) (short term) (C) 0 to +1100 180 to +1300 1.5 between 40 C and 375 C 0.004T

Tolerance class two (C) 2.5 between 40 C and 333 C 0.0075T

IEC Color code

BS Color code

ANSI Color code

0 to +750

180 to +800

0 to +1100

270 to +1300

0 to +1600

50 to +1700

0 to +1600

50 to +1750

between 375 C and 1000 C 1.5 between 40 C and 375 C 0.004T between 375 C and 750 C 1.5 between 40 C and 375 C 0.004T between 375 C and 1000 C 1.0 between 0 C and 1100 C [1 + 0.003(T 1100)] between 1100 C and 1600 C 1.0 between 0 C and 1100 C [1 + 0.003(T 1100)] between 1100 C and 1600 C

between 333 C and 1200 C 2.5 between 40 C and 333 C 0.0075T between 333 C and 750 C 2.5 between 40 C and 333 C 0.0075T between 333 C and 1200 C 1.5 between 0 C and 600 C 0.0025T between 600 C and 1600 C

Not defined.

1.5 between 0 C and 600 C 0.0025T between 600 C and 1600 C

Not defined.

No No 0.0025T standard standard Not between Not +200 to +1700 0 to +1820 use use Available 600 C and defined. copper copper 1700 C wire wire 185 to +300 250 to +400 0.5 1.0 between between 40 C and 40 C and 125 C 133 C 0.004T 0.0075T between between 125 C and 133 C and

0 to +800

40 to +900

Chromel/ 272 to +300 n/a AuFe

350 C 350 C 1.5 2.5 between between 40 C and 40 C and 375 C 333 C 0.004T 0.0075T between between 375 C and 333 C and 800 C 900 C Reproducibility 0.2% of the voltage; each sensor needs individual calibration.

Potrebbero piacerti anche

- INDUSTRIAL INSTRUMENTATION Temperature SensorDocumento75 pagineINDUSTRIAL INSTRUMENTATION Temperature SensorAmna EhsanNessuna valutazione finora

- Various Temperature MeasurementsDocumento3 pagineVarious Temperature MeasurementsPrincess PurnimaNessuna valutazione finora

- Industrial Instrumentation-Lec-04Documento43 pagineIndustrial Instrumentation-Lec-04Haseeb JatoiNessuna valutazione finora

- OIMLDocumento15 pagineOIMLRameshNessuna valutazione finora

- Industrial Instrumentation: Ms. Sobia AnwarDocumento33 pagineIndustrial Instrumentation: Ms. Sobia AnwarAbdullahiNessuna valutazione finora

- InstrumentDocumento42 pagineInstrumentvikash kumarNessuna valutazione finora

- What Is A Thermocouple Sensor?: View A Complete Reference TableDocumento7 pagineWhat Is A Thermocouple Sensor?: View A Complete Reference Tablesankarsuper83Nessuna valutazione finora

- Medicion de TemperaturaDocumento2 pagineMedicion de TemperaturaJavier MartinezNessuna valutazione finora

- Thermocouples: Advantages DisadvantagesDocumento5 pagineThermocouples: Advantages DisadvantagesAffa YogiswaraNessuna valutazione finora

- Experiment ThermocoupleCalibrationUsingPT100Documento6 pagineExperiment ThermocoupleCalibrationUsingPT100Manish RajNessuna valutazione finora

- Thermocouple: VoltageDocumento7 pagineThermocouple: Voltage9897856218Nessuna valutazione finora

- Temperature Sensor: "It Is Time To Turn Up The Heat But First You Must Learn How To Measure It"Documento34 pagineTemperature Sensor: "It Is Time To Turn Up The Heat But First You Must Learn How To Measure It"Mohammad Zohaib AkhterNessuna valutazione finora

- 05 Temp MeasurementDocumento54 pagine05 Temp MeasurementNikhil Kumar - 35Nessuna valutazione finora

- WP 003 Endress TemperatureDocumento17 pagineWP 003 Endress Temperaturevenkatesh425Nessuna valutazione finora

- Temperature MeasurementDocumento35 pagineTemperature MeasurementAlaa Shahwan88% (8)

- Lec One Sensors-1Documento26 pagineLec One Sensors-1Basma EltanekhyNessuna valutazione finora

- Resistance Temperature DetectorDocumento2 pagineResistance Temperature DetectorDebanjana ChowdhuryNessuna valutazione finora

- Lab Report ThermocoupleDocumento8 pagineLab Report ThermocoupleKhalidIqbal100% (2)

- What Is A Thermocouple?Documento9 pagineWhat Is A Thermocouple?Bisma khanNessuna valutazione finora

- R Vs T Relationship of Various Metals: SensorsDocumento6 pagineR Vs T Relationship of Various Metals: SensorsAnbu AyyappanNessuna valutazione finora

- Module 4Documento18 pagineModule 4streetranpuNessuna valutazione finora

- Instrumentation SensorsDocumento145 pagineInstrumentation SensorsGulfam ShahzadNessuna valutazione finora

- Tempsens Product CatalogueDocumento28 pagineTempsens Product CatalogueTempsens InstrumentsNessuna valutazione finora

- Assignment 1 Measurelab 3 FinalDocumento12 pagineAssignment 1 Measurelab 3 FinalMostafa Ahmed ZeinNessuna valutazione finora

- Resistance Thermometer: Resistance Thermometers, Also Called Resistance Temperature Detectors ('RTD'S), AreDocumento10 pagineResistance Thermometer: Resistance Thermometers, Also Called Resistance Temperature Detectors ('RTD'S), AreMac Jayson DiazNessuna valutazione finora

- Specification Data Sheet AISI 304Documento8 pagineSpecification Data Sheet AISI 304Luis Enrique Carreon TorresNessuna valutazione finora

- Thermocouple CalibirationDocumento18 pagineThermocouple CalibirationAnonymous w6v7JWfr5100% (2)

- 3 - 13 Type of RTD ElementsDocumento1 pagina3 - 13 Type of RTD ElementsCharu ChhabraNessuna valutazione finora

- Characteristics of ThermocoupleDocumento6 pagineCharacteristics of ThermocouplekusumgdasNessuna valutazione finora

- ProductCatalog PYROMATIONDocumento212 pagineProductCatalog PYROMATIONDiego John Gavilanes UvidiaNessuna valutazione finora

- RTD, Thermocouple, Thermistors, Manometer, Bourdon TubeDocumento36 pagineRTD, Thermocouple, Thermistors, Manometer, Bourdon TubeDINESH KUMAR DRAVIDAMANI100% (1)

- Above 500 Degrees C A PyrometerDocumento6 pagineAbove 500 Degrees C A PyrometerCharlie Licup100% (2)

- Sensor Catalog 0322 ThermocouplesDocumento50 pagineSensor Catalog 0322 Thermocouplesdominhdung263168Nessuna valutazione finora

- Construction Materials For Pressure Vesel NewDocumento34 pagineConstruction Materials For Pressure Vesel NewArun ArumugamNessuna valutazione finora

- A Woodworker's Guide To Tool Steel and Heat TreatingDocumento7 pagineA Woodworker's Guide To Tool Steel and Heat TreatingCorneliu CarabellaNessuna valutazione finora

- THERMOCOUPLESDocumento3 pagineTHERMOCOUPLESMaintenance Circle100% (1)

- 6.thermo CoupleDocumento30 pagine6.thermo CoupleEZHIL NNessuna valutazione finora

- Metrology 150902141622 Lva1 App6892Documento31 pagineMetrology 150902141622 Lva1 App6892Eng-anwer kadhimNessuna valutazione finora

- CLB21103 Process Instrumentation Experiment 5: Thermocouple RTD MeasurementDocumento9 pagineCLB21103 Process Instrumentation Experiment 5: Thermocouple RTD MeasurementSiti Hajar MohamedNessuna valutazione finora

- Temperature Measurement: Mark Murphy, PE Technical Director, Fluor CorpDocumento35 pagineTemperature Measurement: Mark Murphy, PE Technical Director, Fluor CorpDaniela BustosNessuna valutazione finora

- Temperature Measurement TheoryDocumento5 pagineTemperature Measurement TheoryMarco PlaysNessuna valutazione finora

- ThermocoupleDocumento15 pagineThermocoupleHuzaimah JaiminNessuna valutazione finora

- Application Note: Thermistor - Vs - RTD - Accuracy Rev. 11/09/17Documento5 pagineApplication Note: Thermistor - Vs - RTD - Accuracy Rev. 11/09/17Ndia2007Nessuna valutazione finora

- Thermocouple PiDocumento8 pagineThermocouple PiKamal JoshiNessuna valutazione finora

- What Is A ThermocoupleDocumento10 pagineWhat Is A ThermocoupleKannan RamarajNessuna valutazione finora

- Kaljenje I Drugo Po Boji Teorija MalaDocumento7 pagineKaljenje I Drugo Po Boji Teorija MalaAnonymous dmhNTyNessuna valutazione finora

- MaterialData - 14076 HDS H13Documento2 pagineMaterialData - 14076 HDS H13Amol KulkarniNessuna valutazione finora

- Temperature Measurement PDFDocumento35 pagineTemperature Measurement PDFRavenShieldXNessuna valutazione finora

- 1.2.5 Precision Temperature Sensing Resistor PRC100: Length: 13.5mm (Excl. Leads) Diameter: 5mm RS Stock NumberDocumento12 pagine1.2.5 Precision Temperature Sensing Resistor PRC100: Length: 13.5mm (Excl. Leads) Diameter: 5mm RS Stock NumberEng Bashar MufidNessuna valutazione finora

- Technical News: Engineering Information For The Professional EngineerDocumento3 pagineTechnical News: Engineering Information For The Professional EngineerFelipe GustavoNessuna valutazione finora

- Thermocouples PDFDocumento63 pagineThermocouples PDFkkumar_717405Nessuna valutazione finora

- RTDDocumento4 pagineRTDCss GaneshNessuna valutazione finora

- Temp Wang03 PDFDocumento7 pagineTemp Wang03 PDFJinNessuna valutazione finora

- Types of Thermocouples:: What Is A Thermocouple?Documento13 pagineTypes of Thermocouples:: What Is A Thermocouple?Mark Peter PalayanNessuna valutazione finora

- Temperature Measurement With ThermocouplesDocumento19 pagineTemperature Measurement With Thermocouplessalih dağdurNessuna valutazione finora

- RTD 2022Documento100 pagineRTD 2022Varun VelrajNessuna valutazione finora

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysDa EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysValutazione: 1 su 5 stelle1/5 (1)