Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Scaba Kevero en

Caricato da

Suphi YükselDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Scaba Kevero en

Caricato da

Suphi YükselCopyright:

Formati disponibili

OPTIMAL MIXING WITHIN THE PROCESS INDUSTRY.

Scanpump Solutions for Process Industry.

www.scanpump.com

1

SCANPUMP SCABA agitators

System DA - Degree of Agitation

Application Know-how for Optimal Mixing

What is the aim of agitation? For Scanpump it is To attain the customers wanted process result by the most costeffective solution. Choosing and designing agitators is related to the process in which they will operate. Many factors affect the process and mechanical aspects of the design procedure. Important considerations are type of process, type of liquid, volume, the shape of the tank etc. In some applications the density, viscosity and solid content are the dominant factors. Our long experience, our knowledge of the processes and the ability to use this knowledge in our own design programme have given even more effective agitators for all kinds of mixing. The demand to acheive a perfect result is to get an optimal liquid motion for the specic process. Through research and theoretical calculations we have developed a correlation between the liquids surface velocity and what we call Degree of Agitation - DA. This and the choice of impeller is the foundation to decide the demand of the mixing for different processes.

Benets

Process guarantee: Desired mixing result obtained Cost effective: Minimum power needed Easy service: Designed for minimised downtime and maintenance Support: Our specialists will ensure best mixing result

Technical Features

High Flow Propellers: Better mixing, less vibrations, minimises forces and power consumption Sealing: Maintenance work without emptying the tank Modular system: Same Modular System for all agitators No bottom bearing: Minimises maintenance

Design Criteria

Depending on the medias involved, they can be classied into three groups: liquid/liquid, liquid/particles and liquid/gas. Other kinds of application are also available but not presented here.

Liquid / Liquid Miscible liquids

For the liquid/liquid processes the design criteria is a certain amount of Liquid Motion. The suitable impeller is the patented SCABA High ow Propeller type 3SHP. It revolutionised the market by its ability to lower the power need drastically. It suits both to side and top entry agitators. Further development of the original 3SHP1 has given 3SHP18 mainly used in low viscosity medias and 2SHPD for high viscosity.

High Flow Propeller 3SHP1 - Keeping liquid homogeneous / Blending Viscosity 1-5000 mPas.

High Flow Propeller 3SHP18

Double acting High Flow propeller 2SHPD

- Keeping liquid homogeneous - Blending Viscosity 1-10 000 mPas. Chemicals, Juice, Milk, Sugar, Oils, Soap, Plastics,Paint, Latex, Lime, Sugar solutions, pH-adjustment, Wastewater... 2

- Keeping liquid homogeneous Viscosity 10 000 - 1 milj. mPas or up to paste consistency. Oils, Latex, Lime slurry, Cream, Paint, Glue, Grease, Youghurt...

- Heat transfer Heating or cooling Viscosity 1-5000 mPas Heating of Fats, Veg. oil & food, Glue, Cooling of cream, ethanol...

SCANPUMP SCABA agitators

SCABA Degree of Agitation - DA

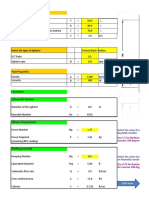

Degree of Agitation 1 Mild Weak Flocculation Keeping liquid homogeneous Flotation 2 3 Medium Visible Keeping liquid homogeneous Blending 4 Good Good Blending Heat transfer 6 Strong Strong Blending Heat transfer Solids suspension Dissolving Leaching Polymerisation Crystallisation 8 Very strong Very strong Blending Solids suspension Dissolving Leaching Poymerisation Dispersion Fermentation 10 Violent Violent Solids suspension Dissolving Leaching Description Very mild Surface velocity Process Invisible Flocculation Flotation

Liquid / Particles

Suspensions of particles For the liquid/particles processes the design criteria is a certain amount of Liquid Motion. The suitable impeller is the patented SCABA High ow Propeller type 3SHP.

Degree of suspension 1 2 3 Description Most particles off bottom All particles off bottom Full suspension Homogeneity ~ 30% ~ 50% ~ 90%

Liquid / Gas

Design criteria in these processes are Shear forces and Liquid Motion. The patented special turbine SRGT with its unique properties is the optimal impeller. This turbine disperses more gas before ooding which generates higher masstransfer. Furthermore, no power drop occurs when gased.

Gas Dispersing Turbine SRGT

High Flow Propeller 3SHP1

High Flow Propeller 3SHP18

- Solids suspension and slurries - Dissolving - Crystallisation and polymerisation - Leaching Viscosity 1 - 10 000 mPas Basic chemicals, Lime, Sugar and other crystals, Iron ore, Copper ore, Dressed ore...

- Powder draw down Viscosity 1 - 10 000 mPas Lime, Aluminium sulphate, Soda ash, Urea, Starch, Magnesium sulphate, CMC, Bentonite, Polymers...

- Gas dispersion - Fermentation - 3-phase system Viscosity of liquids 1 - 5000 mPas CO2 in CaCO3 slurry, Mash solution, H2 in veg. oil, Gypsum, Basic chemicals...

SCANPUMP SCABA agitators

Process Guarantee, Service, Maintenance and Local Support

Process Guarantee

Every agitator sold by Scanpump comes with a process guarantee, which means that you will achieve your desired results or we will x or replace your agitator at our expense. The guarantee is based on mutually understood and agreed upon terms in accordance with design specications. The benet to our customers is total satisfaction with absolutely no risk!

Service

Scanpump has an extensive service network so when your agitator requires service, Scanpump will be there to get it up and running again.

Maintenance

Proper maintenance is critical to the life of any product. Scanpump's factory trained service representatives can keep your agitator running like new.

Local Support

All Scanpump's products are sold through a world-class sales and service organization. Local support is always available to help you with your needs.

Main ofce Sweden ABS Scanpump AB Tel. +46 31 83 63 00 Fax +46 31 16 79 14 info@scanpump.com www.scanpump.com Subsidiaries, ABS Group Austria Tel. +43 2236 642 61 Fax +43 2236 642 66 www.absgroup.com

Subsidiaries Denmark ABS Scanpump A/S Tel. +45 48 17 11 10 Fax+45 48 17 19 11 info@scanpump.com www.scanpump.com

France ABS Scanpump AB Tel. +33 4 72 31 00 06 Fax +33 4 78 05 57 74 info@scanpump.com www.scanpump.com

Germany ABS Scanpump AB Tel. +49 6257 9317 0 Fax +49 6257 9317 99 info@scanpump.com www.scanpump.com Norway Tel. +47 67 55 47 00 Fax +47 67 55 47 50 www.absgroup.com

Great Britain ABS Scanpump AB Tel. +44 1293 744 836 Fax +44 1293 543 392 info@scanpump.com www.scanpump.com Group head ofce ABS Group Tel. +46 40 35 04 70 Fax +46 40 30 50 45 info@absgroup.com www.absgroup.com

Finland Tel. +358 7 5324 0300 Fax +358 9 55 80 53 www.absgroup.com

Netherlands Tel. +31 30 242 56 78 Fax +31 30 241 03 46 www.absgroup.com South and North America Brazil Tel. +55 41 3227 8100 Fax +55 41 3348 1879 www.absgroup.com

USA Tel. +1 203 238 2700 Fax +1 203 238 0738 www.absgroup.com

230213 GB 09.05

Asia Pacic China Singapore Tel. +86 21 68882900 Tel. +65 6463 3933 Fax +86 21 58826708 Fax +65 6462 2122 wwww.abspumps.comQui pati facissederae hor www.absgroup.com www.absgroup.com

Scanpump reserves the right to alter specifications due to technical developments.

| Pumps | Mixers | Aeration | Controls | Services |

SCANPUMP SCABA AGITATORS. TOP-MOUNTED AND SIDE-MOUNTED AGITATORS FOR INDUSTRIAL PROCESSES.

www.scanpump.com

SCANPUMP SCABA AGITATORS

Scanpump is a specialist in stirring applications for the process, water and waste, and paper industry, wherever a liquid is to be mixed with another liquid, or with particles or gas. We have been supplying agitators to all corners of the world and for a wide variety of stirring processes. The inhouse calculation programs that we have developed have made us known for our ability to produce a reliable solution to virtually any type of stirring problem. The software, in combination with our patented agitator impellers, enable us to offer economically benecial process solutions. Our experience and expertise enables us to offer process guarantees, which we have been doing for many years. Scanpump conforms to the ISO9001 quality assurance standard, which ensures reliable reli deliveries and high quality. Our salesmen offer a comprehensive service including advise on selections prior to order placement and a good after sales service.

In consultation with your specialists, our highly trained salesmen analyze your basic conditions and needs. Alternative solutions are then discussed.

Our calculation programs allow for unlimited variation of tank sizes, media data, agitator impellers, speeds and shaft combinations.

In order to maintain the necessary high standard of our process expertise, we continually run research projects in our laboratory. We also undertake tests on customer products.

Modern computerized machine tools are used in the production of our agitators.

SCANPUMP SCABA TOP ENTERING AGITATORS.

The agitators are of a robust, modular design and can be combined with various types of drive units, seals and impellers. Due to this exibility, the agitators can be adapted optimally to the needs of the process.

Drive unit

The drive unit selected is determined by the pro- Power ratings: 0.12 kW - 250 kW cess requirements and the customers wishes. The agitator can be equipped with gears, paral- Electric Hydraulic lel shaft gears, bevel gears or V-belt drives. Pneumatic

Motor

Pedestal modul

The shaft coupling in the pedestal module provides the connection between the drive and the agitator shaft. Sleeve and ange couplings are standard. Radially split couplings are used for special applications. The pedestal module is equipped with a double spherical roller bearing with adapter sleeve. For a V-belt drive and certain special applications, an extra shaft bearing is built into the pedestal module. The SCABA shaft bearing can be used as an alternative. This enables the bearing to be changed without the need for removing the shaft.

Flange coupling Sleeve coupling Radially split coupling

Double spherical roller bearings Patented bearing for simplied bearing change

Housing for shaft seal

This is equipped with a suitable seal. The con- Stufng box necting ange of the housing can be supplied Single mechanical seal Double mechanical seal in different sizes. TH and TS seals Labyrinth seal

Shaft coupling

The agitator shaft is equipped with one or more Flange coupling shaft couplings, if necessary. The couplings are Threaded coupling of ange type, although if the hygienic requirements are strict, threaded shaft couplings can be supplied instead.

Agitator impeller

To suit specic applications we offer a wide range of agitator impellers.

Series VP

Series KP

Series VVP

Series VVT

Shaft seals for top entering agitators

The shaft seals are designed to maintain the required pressure in the tank or to prevent leakage through the shaft entry. Seals are also used to prevent impurities from entering the tank, or to prevent damage to the agitator by splashing or by vapour from the process liquid.

Mechanical seal

Adapted to meet the customers requirements on performance and the preferred seal supplier. The seal housing can be designed to allow the seal to be changed without removing the agitator from the tank.

Double or single design Dry or liquid lubricated Split seal Liquid-cooled seal housing Cartridge seal

Stufng box seal

The lantern ring, usually included, serves as a gliding bearing and increases the useful life of the seal. The shaft is often equipped with a wear sleeve.

2 - 5 packing plaits Liquid or grease lubricated

TH seal

Hygienic seal designed to prevent the ingress of oil and impurities into the process liquid. Has a labyrinth function.

TS seal

Lip seal designed to prevent the ingress of impurities into the process liquid. Protects the agitator from splashing and from attack by the vapour in the tank.

Labyrinth seal

Seal for low-pressure processes. Particularly suitable for digesters. The height of the water trap is determined by the pressure inside the tank.

Can be equipped with level control in the labyrinth. With or without facilities for changing the shaft bearing with the agitator remaining on the tank.

Scanpump Scaba impellers

Scaba uses their own patented or designed registered impellers. Combined with our extensive design knowhow, these impellers produce the best possible process results at the lowest possible energy cost. The widespanning range of impellers enable us to select the optimum element for each individual application.

SHP1

Our high-ow propeller which is acknowledged for its energy-efciency and effectiveness. It is just as effective on difcult suspensions and reactions as it is on homogenizing and mixing. Intended for viscosities up to 50 000 mPas.

Applications

Mixing Homogenizing Suspensions Reactions Medium-high viscosities

SHP18

A registered-design development of the SHP1. Offers better effectiveness at lower viscosities. Low weight allows for lighter shaft design.

Mixing Homogenizing Suspensions Low viscosities

SHPD

Double-acting propeller for high viscosities, up to paste consistency. Also suitable for very gentle stirring. Due to the double-acting function, the liquid is pumped both downwards and upwards.

Mixing Homogenizing Very high viscosities Gentle stirring

SRGT

Gas dispersion Patented turbine intended for gas Three-phase systems dispersion. Due to its design, the power demand is constant at varying gas ows. Performs very well also on three-phase systems comprising liquid - gas - particles.

Other agitator elements

Our range also includes impellers of conventional type.

Supplement to our own impellers

SCANPUMP SCABA SIDE ENTERING AGITATORS

The agitators are of a robust modular design and can be combined with various types of drive units, seals and impellers.This exibility enables the agitator to be adapted optimally to the process requirements.

Housing with shaft bearing

A range of housings are used, and these can be adapted to most drive units.

Housing for shaft seal

Side entering agitators are always equipped with shaft seals. The housing is designed to accommodate either a stufng box or a variety of optional mechanical seals. The connecting ange of the housing can be delivered in different dimensions.

Agitator propeller

The SCABA SHP1 or SHP18 high-ow propeller is used to generate good axial ow.

Gear-driven agitator series

Designed for heavy duty as well as light duty. The gear boxes are of standard brand, which simplies service and ensures good availability of spare parts. The gear boxes, seals and bearings can be serviced and maintained with the agitator remaining the tank.

One double spherical roller bearing with adapter sleeve. The shaft bearing has a theoretical operating life of 100 000 hours. Designed for power ratings ranging from 0.12 kW to 110 kW. Can also be equipped with standard IEC foot-mounted or ange motors.

Series SVPT

Series SVVPT

Series SFVPT

Scanpump Scaba SKPT series of V-belt driven agitators

Specially designed for heavy duty. Seals and bearings can be serviced and maintained with the agitator remaining in the tank. Two double spherical roller bearings with adapter sleeve with a theoretical operating life of 100 000 hours. Standard type of V-belt drive which is easily adjustable. Designed for power ratings ranging from 2.2 kW to 250 kW.

Shaft seals for side entering agitators

The shaft seals are designed to maintain the required pressure in the tank or to prevent leakage through the shaft entry.

Stufng box

Double mechanical seal

Single mechanical seal

SERVICE, MAINTENANCE AND RELIABLE DELIVERIES

Scanpump Scaba agitators are in service in many types of industrial processes in most of the worlds countries. The agitators are designed to simplify service and maintenance. As a result, the work is easy to plan and execute. The procedure is described in detail in our service instructions. Quality assurance, dynamic testing and pre-delivery inspection are included as natural elements in our efforts to maintain our leading position as supplier of agitators for optimized process economy.

Main ofce Sweden ABS Scanpump AB Tel. +46 31 83 63 00 Fax +46 31 16 79 14 info@scanpump.com www.scanpump.com

Subsidiaries Denmark ABS Scanpump A/S Tel. +45 48 17 11 10 Fax+45 48 17 19 11 info@scanpump.com www.scanpump.com

France ABS Scanpump AB Tel. +33 4 72 31 00 06 Fax +33 4 78 05 57 74 info@scanpump.com www.scanpump.com

Germany ABS Scanpump AB Tel. +49 6257 9317 0 Fax +49 6257 9317 99 info@scanpump.com www.scanpump.com

Great Britain ABS Scanpump AB Tel. +44 1293 744 836 Fax +44 1293 543 392 info@scanpump.com www.scanpump.com

The Netherlands ABS Scanpump AB Tel. +31 651 08 21 25 Fax +31 523 27 04 71 info@scanpump.com www.scanpump.com

Subsidiaries, ABS Group Austria Finland Tel. +43 2236 642 61 Tel. +358 7 5324 0300 Fax +43 2236 642 66 Fax +358 9 55 80 53 www.absgroup.com www.absgroup.com Asia Pacic China Singapore Tel. +86 21 68882900 Tel. +65 6463 3933 wwww.abspumps.comQui pati facissederae Faxhor +86 21 58826708 Fax +65 6462 2122 www.absgroup.com www.absgroup.com

Norway Tel. +47 67 55 47 00 Fax +47 67 55 47 50 www.absgroup.com South and North America Brazil Tel. +55 41 2108-8100 Fax +55 41 3348 1879 www.absgroup.com

USA Tel. +1 203 238 2700 Fax +1 203 238 0738 www.absgroup.com

231634 GB 01.06

Scanpump reserves the right to alter specifications due to technical changes.

Potrebbero piacerti anche

- SAP MM Organization Structure and Master DataDocumento3 pagineSAP MM Organization Structure and Master Datanbhaskar bhaskar100% (2)

- Concrete Offshore Gravity StructuresDocumento38 pagineConcrete Offshore Gravity StructuresVlad Kudryavtsev100% (1)

- ECI CLP3 Pricing System For PipingDocumento133 pagineECI CLP3 Pricing System For PipingWajdi MansourNessuna valutazione finora

- Reactor DesignDocumento27 pagineReactor Designcheckmeout803100% (3)

- SolutionGuidesSales PDFDocumento472 pagineSolutionGuidesSales PDFSourabh BhardwajNessuna valutazione finora

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineDa EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineValutazione: 5 su 5 stelle5/5 (1)

- Sizing ImpellersDocumento7 pagineSizing ImpellerskaramniaNessuna valutazione finora

- Survey Welding-Standards 09-09-2013Documento0 pagineSurvey Welding-Standards 09-09-2013Ioana-Andreea GoagășNessuna valutazione finora

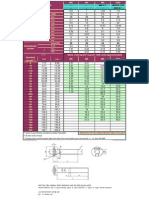

- M8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Documento1 paginaM8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Suphi YükselNessuna valutazione finora

- Rheology - Viscosity - Article - A Fluid's Resistance To FlowDocumento3 pagineRheology - Viscosity - Article - A Fluid's Resistance To FlowmariandreadeaNessuna valutazione finora

- Spray Drying Technology ReviewDocumento46 pagineSpray Drying Technology Reviewedison58Nessuna valutazione finora

- GB 02 Mixing Process DesignDocumento28 pagineGB 02 Mixing Process DesignRamakrishna Somu100% (3)

- Excel - TCDDocumento159 pagineExcel - TCDKouameBecantyArthurNessuna valutazione finora

- IKA Magic PLANT en ScreenDocumento16 pagineIKA Magic PLANT en Screenkishor sutharNessuna valutazione finora

- Agitator Power Requirement and Mixing Intensity CalculationDocumento26 pagineAgitator Power Requirement and Mixing Intensity CalculationChemical Engineering100% (2)

- Agitation of Non-Newtonian FluidsDocumento8 pagineAgitation of Non-Newtonian FluidsandresjypNessuna valutazione finora

- Agitiation and Mixing Liquids To StudentsDocumento30 pagineAgitiation and Mixing Liquids To StudentsAkshay dev100% (1)

- Mixing Succeed at Scale UpDocumento9 pagineMixing Succeed at Scale Upicingrock100% (1)

- 2015-Tackling Difficult Mixing ProblemsDocumento8 pagine2015-Tackling Difficult Mixing Problemsjuan sepulvedaNessuna valutazione finora

- CHE 503 Agitation LiquidsDocumento33 pagineCHE 503 Agitation LiquidsNurtasha Atikah100% (1)

- Section 06B - PumpsDocumento62 pagineSection 06B - PumpsRajesh KumarNessuna valutazione finora

- Spraydrying PDFDocumento4 pagineSpraydrying PDFagrocel_bhv5591Nessuna valutazione finora

- August 2013Documento62 pagineAugust 2013ceshesolNessuna valutazione finora

- RV Series ViscometerDocumento1 paginaRV Series Viscometerain kamarudinNessuna valutazione finora

- Atomization For Spray Drying Unanswered Questions and Industrial NeedsDocumento6 pagineAtomization For Spray Drying Unanswered Questions and Industrial NeedsNicolas Pardo AlvarezNessuna valutazione finora

- Brosjyre ChemineerDocumento14 pagineBrosjyre ChemineerRaul DiazNessuna valutazione finora

- WCB Waukesha U1 Instruction Manual PDFDocumento106 pagineWCB Waukesha U1 Instruction Manual PDFJojaca Xencillo CaqueNessuna valutazione finora

- Dec06feature PDFDocumento4 pagineDec06feature PDFAmgad_SNessuna valutazione finora

- Silverson Bottom Entry MixerDocumento5 pagineSilverson Bottom Entry MixerDiego ArroyaveNessuna valutazione finora

- Fluids HandlingDocumento234 pagineFluids HandlingVenkatesh GangadharNessuna valutazione finora

- Silverson Lab MixerDocumento6 pagineSilverson Lab MixerSandip MehtaNessuna valutazione finora

- Pumps Maintenance and Mechanical SealsDocumento5 paginePumps Maintenance and Mechanical Sealskarioke mohaNessuna valutazione finora

- Product Design & Development Final ExamDocumento1 paginaProduct Design & Development Final ExamGood Guy80% (5)

- Expansion Joint Manual 12654Documento321 pagineExpansion Joint Manual 12654Suphi YükselNessuna valutazione finora

- Raven 3800 MixerDocumento3 pagineRaven 3800 Mixersantosh kumar100% (1)

- SAP SecurityDocumento20 pagineSAP SecurityNasir Gondal100% (2)

- Spray Drying Small Scale Pilot Plants Gea Tcm11 34874Documento20 pagineSpray Drying Small Scale Pilot Plants Gea Tcm11 34874gonzalo torresNessuna valutazione finora

- LIGHTNIN Top Entry Mixers Agitadores ImpellersDocumento12 pagineLIGHTNIN Top Entry Mixers Agitadores ImpellersJosue QuirozNessuna valutazione finora

- DickeyD-Mixing Scale-Up PDFDocumento39 pagineDickeyD-Mixing Scale-Up PDFSteve Wan100% (1)

- Oracle SCM Cloud Securing SCM 19CDocumento154 pagineOracle SCM Cloud Securing SCM 19CJose LaraNessuna valutazione finora

- Mixing With Helical Ribbon AgitatorsDocumento9 pagineMixing With Helical Ribbon AgitatorsWilson Agudelo CatañoNessuna valutazione finora

- Agitation and MixingDocumento77 pagineAgitation and MixingKolliparaDeepak100% (1)

- Agitator and MixerDocumento6 pagineAgitator and MixerCik MinnNessuna valutazione finora

- Decanter PDFDocumento14 pagineDecanter PDFDedi Mulyadi50% (2)

- Pumps & Systems - August 2015Documento116 paginePumps & Systems - August 2015Dragan Belcovski100% (1)

- The Unexpected Rewards of Testing A MixerDocumento4 pagineThe Unexpected Rewards of Testing A MixerJoshua JohnsonNessuna valutazione finora

- Bubble Wake Dynamics in Liquids and Liquid-Solid SuspensionsDa EverandBubble Wake Dynamics in Liquids and Liquid-Solid SuspensionsNessuna valutazione finora

- Chem September 2013Documento84 pagineChem September 2013Orlando BarriosNessuna valutazione finora

- MixerDocumento48 pagineMixerzueklateNessuna valutazione finora

- VSL Post Tensioning SolutionsDocumento28 pagineVSL Post Tensioning SolutionskmabdNessuna valutazione finora

- May 2016 - International PDFDocumento104 pagineMay 2016 - International PDFBánh Cuốn Tôm ThịtNessuna valutazione finora

- PED TrainingDocumento52 paginePED TrainingSuphi YükselNessuna valutazione finora

- Goulds Pump Curves 3175Documento3 pagineGoulds Pump Curves 3175RichNessuna valutazione finora

- Outokumpu Stainless Steel HandbookDocumento92 pagineOutokumpu Stainless Steel HandbookcutefrenzyNessuna valutazione finora

- Review of The Main Mathematical ModelsDocumento37 pagineReview of The Main Mathematical Modelsgrincheu70Nessuna valutazione finora

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Da EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Nessuna valutazione finora

- SLA TemplateDocumento4 pagineSLA Templatebenfitz123100% (3)

- Westinghouse-Design Steam Chest PowerGen-2012FinalDocumento0 pagineWestinghouse-Design Steam Chest PowerGen-2012FinalSuphi YükselNessuna valutazione finora

- Chemical Reactor Analysis and Applications for the Practicing EngineerDa EverandChemical Reactor Analysis and Applications for the Practicing EngineerNessuna valutazione finora

- Rheology: Dairy Processing Handbook/chapter 3Documento8 pagineRheology: Dairy Processing Handbook/chapter 3Margo SmithNessuna valutazione finora

- NEW - Granulation Technology Scale Up by Diosna - June 2021Documento4 pagineNEW - Granulation Technology Scale Up by Diosna - June 2021BlueSagaNessuna valutazione finora

- Industrial Centrifuge: The OptionsDocumento8 pagineIndustrial Centrifuge: The OptionsSam PanNessuna valutazione finora

- More Solutions PDFDocumento59 pagineMore Solutions PDFleopardo7Nessuna valutazione finora

- Guide To Pump Types - PumpScoutDocumento8 pagineGuide To Pump Types - PumpScoutmohdazanNessuna valutazione finora

- Agitation&MixingDocumento2 pagineAgitation&Mixingdaniel191286Nessuna valutazione finora

- LR / LM Side - Entry Agitators: Installation, Service and Maintenance InstructionsDocumento22 pagineLR / LM Side - Entry Agitators: Installation, Service and Maintenance InstructionsPetros IosifidisNessuna valutazione finora

- Instruction Manual Alfa Laval Agitator Alt Altb Ese03504enDocumento112 pagineInstruction Manual Alfa Laval Agitator Alt Altb Ese03504ennqh2009Nessuna valutazione finora

- Steam Jet Ejector: Can A Fit Your Vacuum Process?Documento5 pagineSteam Jet Ejector: Can A Fit Your Vacuum Process?Tiến Mạnh NguyễnNessuna valutazione finora

- 59E Agitator Seals in Chemical-En-18.09.2008Documento24 pagine59E Agitator Seals in Chemical-En-18.09.2008Daniel CostaNessuna valutazione finora

- sb25 100 PDFDocumento8 paginesb25 100 PDFkumar_chemicalNessuna valutazione finora

- Mixing V3: Theory and PracticeDa EverandMixing V3: Theory and PracticeVincent W. UhlNessuna valutazione finora

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDa EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNessuna valutazione finora

- Simulated Moving Bed Technology: Principles, Design and Process ApplicationsDa EverandSimulated Moving Bed Technology: Principles, Design and Process ApplicationsNessuna valutazione finora

- Fiberli Flanşli Altiköşe İnce Diş Somunlar With Flange and With Non-Metallic Insert With Metric Fine Thread Prevaling Torque Type Hexagon Nuts EN 1666Documento1 paginaFiberli Flanşli Altiköşe İnce Diş Somunlar With Flange and With Non-Metallic Insert With Metric Fine Thread Prevaling Torque Type Hexagon Nuts EN 1666Suphi YükselNessuna valutazione finora

- DIN 982 Fiberli Altiköşe Yüksek Somunlar Prevaling Torque Type Hexagon Nuts With Nonmetallic InsertDocumento1 paginaDIN 982 Fiberli Altiköşe Yüksek Somunlar Prevaling Torque Type Hexagon Nuts With Nonmetallic InsertSuphi YükselNessuna valutazione finora

- Einschlaganker Drop in Anchor: Çakma DübelDocumento16 pagineEinschlaganker Drop in Anchor: Çakma DübelSuphi YükselNessuna valutazione finora

- Gupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Documento108 pagineGupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Suphi YükselNessuna valutazione finora

- EN ISO 10513 Sikmali Altiköşe İnce Diş Stil 2 Somunlar All-Metal Prevailing Torque Type Hexagon Nuts Style 2 With Metric Fine ThreadDocumento1 paginaEN ISO 10513 Sikmali Altiköşe İnce Diş Stil 2 Somunlar All-Metal Prevailing Torque Type Hexagon Nuts Style 2 With Metric Fine ThreadSuphi YükselNessuna valutazione finora

- DIN 985 Fiberli Altiköşe Somunlar Prevaling Torque Type Hexagon Thin Nuts With Nonmetallic InsertDocumento1 paginaDIN 985 Fiberli Altiköşe Somunlar Prevaling Torque Type Hexagon Thin Nuts With Nonmetallic InsertSuphi YükselNessuna valutazione finora

- DIN 928 Kare Kaynak Somunlari Square Weld Nuts: (D) M5 M6 M8 M10 M12 Thread Size (D XP)Documento1 paginaDIN 928 Kare Kaynak Somunlari Square Weld Nuts: (D) M5 M6 M8 M10 M12 Thread Size (D XP)Suphi YükselNessuna valutazione finora

- DIN 6926 Fiberli Flanşli Altiköşe Somunlar Prevaling Torque Type Hexagon Nuts With Flange and With Non-Metallic InsertDocumento1 paginaDIN 6926 Fiberli Flanşli Altiköşe Somunlar Prevaling Torque Type Hexagon Nuts With Flange and With Non-Metallic InsertSuphi YükselNessuna valutazione finora

- DIN 929 Altiköşe Kaynak Somunlari Hexagon Weld Nuts: - M8 X 1 M10 X 1,25 M12 X 1,25 - M10 X 1 M12 X 1,5Documento1 paginaDIN 929 Altiköşe Kaynak Somunlari Hexagon Weld Nuts: - M8 X 1 M10 X 1,25 M12 X 1,25 - M10 X 1 M12 X 1,5Suphi YükselNessuna valutazione finora

- DIN 6915 High-Strenght Hexagon Nuts With Large Widths Across Flats Geniş Anahtar Ağizli Altiköşe SomunlarDocumento1 paginaDIN 6915 High-Strenght Hexagon Nuts With Large Widths Across Flats Geniş Anahtar Ağizli Altiköşe SomunlarSuphi YükselNessuna valutazione finora

- P (Auxiliary Dimension) C: Min. Max. Max. Max. Max. Nominal SizeDocumento1 paginaP (Auxiliary Dimension) C: Min. Max. Max. Max. Max. Nominal SizeSuphi YükselNessuna valutazione finora

- A Max. P: - M8 X 1 M10 X 1,25 - M10 X 1Documento1 paginaA Max. P: - M8 X 1 M10 X 1,25 - M10 X 1Suphi YükselNessuna valutazione finora

- M12 M16 M20 Thread Size (D) )Documento1 paginaM12 M16 M20 Thread Size (D) )Suphi YükselNessuna valutazione finora

- P B Ref.: Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinDocumento1 paginaP B Ref.: Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinSuphi YükselNessuna valutazione finora

- Ref. Max. Theor - Max. Actual Min. Max. Min. Min. Max. Max. Min. Nom. Max.) Max.) Min. Min. MinDocumento1 paginaRef. Max. Theor - Max. Actual Min. Max. Min. Min. Max. Max. Min. Nom. Max.) Max.) Min. Min. MinSuphi YükselNessuna valutazione finora

- Max. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinDocumento1 paginaMax. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinSuphi YükselNessuna valutazione finora

- M5 M6 M8 M10 M12 (M14) M16 Thread Size (D) ) : Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinDocumento1 paginaM5 M6 M8 M10 M12 (M14) M16 Thread Size (D) ) : Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinSuphi YükselNessuna valutazione finora

- Mass (7,85 KG/DM: Products in The Green Region Are Available As Full ThreadDocumento1 paginaMass (7,85 KG/DM: Products in The Green Region Are Available As Full ThreadSuphi YükselNessuna valutazione finora

- InTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsDocumento19 pagineInTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsSiap SiapNessuna valutazione finora

- Tozalti Crushed FluxDocumento5 pagineTozalti Crushed FluxSuphi YükselNessuna valutazione finora

- Welding Expert EnglishDocumento6 pagineWelding Expert EnglishSuphi YükselNessuna valutazione finora

- Nükleer Tesi̇s DenetlemeDocumento276 pagineNükleer Tesi̇s DenetlemeSuphi YükselNessuna valutazione finora

- Solar System Bill of MaterialsDocumento4 pagineSolar System Bill of Materialsapi-646171646Nessuna valutazione finora

- Keynote Steve Elliott, Doing Business With The VA (It's Different Than The DoD), VA SAME Brief FinalDocumento22 pagineKeynote Steve Elliott, Doing Business With The VA (It's Different Than The DoD), VA SAME Brief FinalSAMETampaBayNessuna valutazione finora

- WWE Filter Press OperationDocumento4 pagineWWE Filter Press OperationMf LuiNessuna valutazione finora

- RES23 Rules For Commercial Yachts 2023 - Part B 1.1.2023Documento297 pagineRES23 Rules For Commercial Yachts 2023 - Part B 1.1.2023aryopangestu.navalarchitectNessuna valutazione finora

- Rajasthan's Secondary Board's Free Laptop Distribution SchemeDocumento68 pagineRajasthan's Secondary Board's Free Laptop Distribution Schemeneeraj meenaNessuna valutazione finora

- Nuevo Ajuste de Valvulas 1 PDFDocumento9 pagineNuevo Ajuste de Valvulas 1 PDFroyert80100% (1)

- EN 10025: 2004 Is The New European Standard For Structural SteelDocumento6 pagineEN 10025: 2004 Is The New European Standard For Structural Steelvimalkumar_trjNessuna valutazione finora

- 1338 X 175 XCD 419Documento1 pagina1338 X 175 XCD 419pendexxNessuna valutazione finora

- Formula Sae Series Cost Module OperationsDocumento35 pagineFormula Sae Series Cost Module OperationsMateus FlausinoNessuna valutazione finora

- Supply-Chain and SOA Camerinelli-ToulemondeDocumento4 pagineSupply-Chain and SOA Camerinelli-ToulemondeMarcos Mangione PassarelloNessuna valutazione finora

- VP Operations Manufacturing Food Production in Philadelphia PA Resume Harmeet SandhuDocumento2 pagineVP Operations Manufacturing Food Production in Philadelphia PA Resume Harmeet SandhuHarmeet SandhuNessuna valutazione finora

- Basic Ship HandlingDocumento1 paginaBasic Ship HandlingCostisNessuna valutazione finora

- Company ProfileDocumento8 pagineCompany ProfileD Wahyu Bawono0% (1)

- Introduction To CASE TOOLS: Sheet No: - 1Documento35 pagineIntroduction To CASE TOOLS: Sheet No: - 1Srimanik KamarapuNessuna valutazione finora

- openSAP dscm1 Week 1 Unit 1 CDPR PresentationDocumento11 pagineopenSAP dscm1 Week 1 Unit 1 CDPR PresentationPritishNessuna valutazione finora

- 100 Daily Job 02mar2021Documento35 pagine100 Daily Job 02mar2021Himanshu VyasNessuna valutazione finora

- Catalog 2017 Winter Spring PDFDocumento52 pagineCatalog 2017 Winter Spring PDFLhagva DalaibatNessuna valutazione finora

- Transaction Processing RulesDocumento319 pagineTransaction Processing RulesmanishNessuna valutazione finora

- Alarm ManagementDocumento4 pagineAlarm Managementashraf1971Nessuna valutazione finora

- Clever Pathway Havells Motors SuppliersDocumento12 pagineClever Pathway Havells Motors SuppliersClever Chemicals Ltd.Nessuna valutazione finora