Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Book Astronomy

Caricato da

sompongtCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Book Astronomy

Caricato da

sompongtCopyright:

Formati disponibili

Appendix E

DUCTILE END-DIAPHRAGM IN GIRDER BRIDGE

E.1 DESIGN PROCEDURE

A seismic design strategy that relies on ductile end-diaphragms inserted in the steel superstructure can be, in some instances, an effective alternative to energy dissipation in the substructure. This could be the case, for example, when stiff wall-piers that can difficulty be detailed to have a stable ductile response are used as a substructure. The ductile diaphragms considered in this Article are therefore those that can be specially designed and calibrated to yield before the strength of the substructure is reached (substructural elements, foundation, and bearings are referred generically as substructure here). Many types of systems capable of stable passive seismic energy dissipation could be used for this purpose. Among those, eccentrically braced frames (EBF) (e.g. Malley and Popov 1983; Kasai and Popov 1986), shear panel systems (SPS) (Fehling et al. 1992; Nakashima 1995), and steel triangular-plate added damping and stiffness devices (TADAS) (Tsai et al. 1993), popular in building applications, have been studied for bridge applications (Zahrai and Bruneau 1999a, 1999b). These are illustrated in Figures E.1-1 to E.1-3. Although concentrically braced frames can also be ductile, they are not admissible in Article 7.7.8.2 or 8.7.8.2 because they can often be stronger than calculated, and their hysteretic curves can exhibit pinching and some strength degradation.

Figure E.1-1

EBF Ductile Diaphragms

Figure E.1-2 SPS Ductile Diaphragms

Figure E.1-3

TADAS Ductile Diaphragms

E-1

E-2

HIGHWAY BRIDGES

APPENDIX E

Note that the plate girders can also contribute to the lateral load resistance, making the end-diaphragm behave as a dual system. Therefore, the lateral stiffness of the stiffened girders, IKg, must be added to the stiffness of the ductile diaphragms, IKDD (usually much larger than the former), to obtain the lateral stiffness of the bridge end-diaphragms (adding the stiffnesses of both ends of the span), Kends, i.e:

K ends K DD Kg

(E.1-1)

The stiffness contribution of a plate girder is obviously a function of the fixity provided to its top and bottom flanges by the deck slab and bearing respectively. If full fixity is provided at both flanges of the plate girder,

12 EI g

3 hg

Kg

(E.1-2)

where Ig is the moment of inertia of the stiffened stub-girder (mainly due to the bearing web stiffeners) in the lateral direction, and hg is its height. If one end is fully fixed, the other one pinned,

3EI g

3 hg

Kg

(E.1-3)

If both ends effectively behave as pin supports, Kg=0. Full fixity at the deck level in composite bridges is possible if shear studs are closely spaced and designed to resist the pull-out forces resulting from the moments developed at the top of the girders under lateral seismic forces. As for fixity at the bearing level, it obviously depends on the type of bearings present. However, even when infinitely rigid bearings are present, full fixity is still difficult to ensure due to flexibility of the girder flanges, as revealed by finite element analyses of subassemblies at the girder-to-bearing connection point. It is the engineers responsibility to determine the level of fixity provided at the ends of the girders. However, contrary to conventional design, the most conservative solution is not obtained when zero fixity is assumed because fixity also adds strength to the diaphragms, and the role of the ductile diaphragms is to limit the magnitude of the maximum forces that can develop in the substructure. The lateral stiffness of the ductile diaphragms, KDD, depends on the type of ductile device implemented. For example, if a ductile SPS is used, the stiffness of one such end-diaphragm in a slab-on-girder bridge, KSPS, can be obtained by:

K SPS E lb 2 Ab cos 2 Ls 4 Abb h 3I l

3 l

2.6hl As ,l

Ls hl d bb / 2 12 I bb

H tan 2 2 Ag

(E.1-4)

where E is the modulus of elasticity, lb and Ab are the length and area of each brace, a is the braces angle with the horizontal, Ls is the girder spacing, dbb, Abb and Ibb are the depth, cross sectional area and moment of inertia for the bottom beam, hl, Il and As,l are the length, moment of inertia and shear area of the link, and H and Ag are the height and area of the stiffened girders. Similarly, lateral stiffness of the EBF and TADAS implemented as end-diaphragms of slab-on-girder bridges, KEBF and KTADAS , can be computed as follows:

APPENDIX E

2001 GUIDELINES AND COMMENTARY

E a e H 2 1.3eH 2 H tan 2 2 Al 12 Ls I l aLs As ,l 2 Ag

2

E-3

K EBF

lb 2 Ab cos 2

(E.1-5)

KTADAS =

E

3 L ( h + dbb / 2 ) lb L H tan 2 a 6hT + s + + s T + 2 3 12 I bb 2 Ag 2 Ab cos a 4 Abb NbT tT 2

(E.1-6)

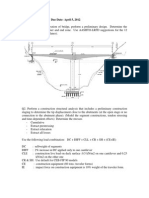

where a is the length of the beam outside the link, e, Il, Al and As,l are the length, moment of inertia, cross sectional and shear areas of the link, N, hT, bT, and tT are the number, height, width and thickness of the TADAS plates, and all other parameters are as defined previously. Note that of the five terms in the denominator of Equations E.1-4 to E.1-6, the second and fifth which account for axial deformations of bottom beam and stiffened girders could be ignored, and the fourth (accounting for the rotation of bottom beam at midspan in SPS and TADAS) could have a small impact if the bottom beam was a deep and stiff beam, which is not however always the case. For a bridge having a given number of girders, ng, number of end-diaphragms implemented at each support, nd, and girder spacing, Ls ,the design procedure for a ductile diaphragm consists of the following steps (illustrated in Figure E..1-4):

Determine M, A, n g, n d, L, K SUB Calculate R Calculate V

W<V inel=V e/R<V subs /2 Vd=(V inel -n gVg)/n d Design link:V l=Vd H/Ls Find V p, M *p e =(1/8 to 1/12)L e <1.6M *p/V p

s

EBF

Vb=0.75V d/cos a SPS Design link: V l=Vd hl=(1/8 to 1/10)H

TADAS

Select t T find h T h T=(1/10 to 1/12)H Select b T (h T/1.2) Find N

Calculate resulting T for bridge Update C s Fix R value

N N

Is C s compatible with obtained T ? Check V g=K gb e and check R

Y Y

Check b max=fb y < e y max (e y maxH/L s for EBF)

Figure E.1-4:

Flow Chart of Design Process for Ductile Diaphragm

E-4

HIGHWAY BRIDGES

APPENDIX E

1) Determine the elastic seismic base shear resistance, Ve, for one end of the bridge (half of equivalent static force). 2) Calculate Vinel = Ve /R, where Vinel is the inelastic lateral load resistance of the entire ductile diaphragm panel at the target reduction factor, and R is the force reduction factor calculated as indicated in Article 7.7.8.2 or 8.7.8.2. Note that f in that equation represents the ductility capacity of the ductile diaphragm as a whole, not the local ductility of the ductile device that may be implemented in that diaphragm. 3) Determine the design lateral load, Vd, to be resisted by the energy dissipation device (e.g. link beam or TADAS) at the target ductility level, by:

Vinel ngVg nd

Vd

(E.1-7)

where Vg is the lateral load resistance of one stiffened girder. Note that in short bridges, Vg can be a dominant factor that could overwhelm the resistance contribution provided by the special ductile diaphragm elements. In that perspective, it is recommended in this procedure that the bearing stiffeners at the support of these girders be trimmed to the minimum width necessary to satisfy the strength and stability requirements. Ideally, the braced diaphragm assembly should also be 5 to 10 times stiffer than the girders with bearing web stiffeners (even though ductility demand tends to be larger in stiffer structures) to prevent, or at least minimize, yielding in the main girders under transverse displacements. Note that in longer bridges, particularly those with a lesser number of girders per cross-section, the contribution of the girders to lateral load resistance is nearly insignificant. 4) Design all structural members and connections of the ductile diaphragm, with the exception of the seismic energy dissipation device, to be able to resist forces corresponding to 1.5Vd to account for potential overstrength of the ductile device due to strain hardening, strain rate effects and higher than specified yield strength. For example, braces should be designed to resist an axial compression force, Vb, equal to:

Vb = 1.5 Vd ( Vd 1 ) = 0.75 2cos a cos a

(E.1-8)

Likewise, for the SPS and TADAS systems, the bottom beam should be designed to resist a moment equal to 1.5 Vd hl or 1.5 Vd hT. Moreover, for a given SPS or TADAS device, it is also advantageous to select a flexurally stiff bottom beam to minimize rigid-body rotation of the energy dissipating device and thus maximize hysteretic energy at a given lateral deck displacement. 5) Design the energy dissipating device. For the link beam in an EBF end-diaphragm, the shear force Vl in the link is:

H Vd Ls

Vl

(E.1-9)

The plastic shear capacity Vp of a wide flange steel beam is given by Equation

E.1-10:

APPENDIX E

2001 GUIDELINES AND COMMENTARY

Vp 0.58 Fy tw dl

(E.1-10)

E-5

where Fy is the yield stress of steel, tw is the web thickness, and dl is the depth of the beam. The moment simultaneously applied to the link must be less than the reduced moment capacity, Mp*, of the link yielding in shear and equal to (Malley and Popov 1983):

M* p t f b f Fy (dl t f )

(E.1-11)

Since shear links are more reliable energy dissipators than flexural links (Kasai and Popov 1986; American Institute 1992), shear links are favored and their length is therefore limited by the equation below:

M* p Vp

e < emax = 1.6

(E.1-12)

A link length, e, of 1/8 to 1/12 of the girder spacing, Ls, is recommended for preliminary design, the less restrictive value preferred for practical reasons (i.e. detailing constraints) in presence of closely spaced girders. Deeper link beams are also preferred as the resulting larger flexural stiffness enhances the overall stiffness of the ductile device, ensuring that its yield displacement is reached much before onset of yielding of the stiffened girders. For a SPS, the above procedure would be followed with the obvious exception that Vl=Vd and the height of panel should be limited to half of the value obtained by the above equation since the yielding link is only in single curvature, as opposed to double curvature for the EBF. A link height of 1/8 to 1/10 of the girder depth is recommended for preliminary design. However, for a TADAS system, replace step 5 with step 6: 6) Select a small plate thickness, tT, based on available plate size. The shear strength, VT, and the stiffness, KT, of a TADAS device can be determined from (Tsai et al. 1993):

2 NbT tT Fy

VT

4ht

(E.1-13)

KT

3 NEbT tT 3 6hT

(E.1-14)

where N, bT, tT and hT are the number, base width, thickness and height of the triangular steel plates. The ratio of the above equations directly provides a relationship between hT and tT :

hT = 2 EtT VT 3Fy KT

(E.1-15)

Here, VT =Vd and a hT of H/10 to H/12 is recommended. Hence, if a reasonable estimate of the desirable KT for the TADAS device is possible, tT can be determined directly from hT. In turn, bT can be chosen

E-6

HIGHWAY BRIDGES

APPENDIX E

knowing that triangular plates with aspect ratio, hT/bT , between 1 and 1.5 are better energy dissipators, based on experimental results (Tsai et al. 1993). Finally, N can then be calculated. Small adjustments to all parameters follow as N is rounded up to the nearest whole number. Incidentally, many different yet appropriate TADAS systems could be designed within these constraints. Systems with thinner steel plates perform better. 7) Calculate the stiffness of the ductile end-diaphragm by using the equation presented earlier in this commentary. Review the assumed lateral period of the bridge, T, and update calculation as necessary. 8) For the maximum lateral drift of the bridge at the diaphragm location, bmax, check that the maximum ductility capacity of ductile device is not exceeded. For shear links, this is commonly expressed in terms of the maximum link deformation angle, Ymax (easily obtained by dividing the maximum relative displacements of link ends by the link length), the maximum drift for the SPS and EBF diaphragms is respectively limited to:

max

max

(E.1-16)

max

eH Ls

max

(E.1-17)

with generally accepted Ymax limits of 0.08 (AISC 1997). Note that, for the SPS diaphragms, the following alternative equation accounting for the rotation of bottom beam at the link connection may be more accurate when this factor has an important impact:

[ V L (h + d bb / 2) ) 6 max < e r max + d s l 12 EI bb

(E.1-18)

Should these limits be violated, modify the links depth and length as well as the stiffness of the EBF or SPS diaphragm as necessary, and repeat the design process. Finally, a maximum drift limit of 2% of the girder height is also suggested here, at least until experimental evidence is provided to demonstrate that higher values are acceptable. Note that the ductile energy dissipating elements should be laterally braced at their ends to prevent out-ofplane instability. These lateral supports and their connections should be designed to resist 6% of the nominal strength of the beam flange, i.e. 0.06Fy tf bf (AISC 1997). In addition, to prevent lateral torsional buckling of beams in the SPS, EBF, and TADAS end-diaphragms, the unsupported length, Lu, of these beams shall not exceed 200bf /iFy where bf is the width of beam flange in metre and Fy is the yield strength of steel in MPa.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Lifting Beam DesignDocumento4 pagineLifting Beam DesignX100% (1)

- Mechanics 01Documento2 pagineMechanics 01sompongtNessuna valutazione finora

- M2A1: Double Taylor Series & The Jacobian Matrix 1 Double Taylor SeriesDocumento2 pagineM2A1: Double Taylor Series & The Jacobian Matrix 1 Double Taylor SeriessompongtNessuna valutazione finora

- Member Z Shear & Y Moment Diagram For Load Condition UlDocumento1 paginaMember Z Shear & Y Moment Diagram For Load Condition UlsompongtNessuna valutazione finora

- Allowableloads Columns10 03Documento1 paginaAllowableloads Columns10 03sompongtNessuna valutazione finora

- Comparison Table2 PT SYPDocumento1 paginaComparison Table2 PT SYPsompongtNessuna valutazione finora

- Addendum: Table 2-Allowable Loads Poly-Classic ColumnsDocumento1 paginaAddendum: Table 2-Allowable Loads Poly-Classic ColumnssompongtNessuna valutazione finora

- HW 4 Solution: Number of Ducts Around 52 To 58 Is OK Estimated Deflection Around 7-8 CM at The TipDocumento1 paginaHW 4 Solution: Number of Ducts Around 52 To 58 Is OK Estimated Deflection Around 7-8 CM at The TipsompongtNessuna valutazione finora

- WSDOT - Glossary of Bridge TermsDocumento2 pagineWSDOT - Glossary of Bridge TermssompongtNessuna valutazione finora

- H 20loadingDocumento1 paginaH 20loadingrey_naldo_gNessuna valutazione finora

- Caltrans H300 LoadsDocumento23 pagineCaltrans H300 Loadstali_bergerNessuna valutazione finora

- Chapter 7 2007Documento23 pagineChapter 7 2007sompongtNessuna valutazione finora

- Allowable Loads Classicast Columns: Table 1Documento1 paginaAllowable Loads Classicast Columns: Table 1sompongtNessuna valutazione finora

- Steel Compl RFDDocumento3 pagineSteel Compl RFDaokankNessuna valutazione finora

- Vol3 Chapter6Documento13 pagineVol3 Chapter6sompongtNessuna valutazione finora

- CE 767 Sample Exam QuestionsDocumento1 paginaCE 767 Sample Exam QuestionssompongtNessuna valutazione finora

- Ce 767 Homework 4Documento1 paginaCe 767 Homework 4sompongtNessuna valutazione finora

- 9 BridgeDesignCriteriaDocumento12 pagine9 BridgeDesignCriteriasompongtNessuna valutazione finora

- Ce 767 Homework 2Documento1 paginaCe 767 Homework 2sompongtNessuna valutazione finora

- Cad Manager Control Utility0Documento20 pagineCad Manager Control Utility0sompongtNessuna valutazione finora

- Anlysis of U Girder Bridge DecksDocumento5 pagineAnlysis of U Girder Bridge DecksFadhilah Muslim100% (1)

- Ce 767 Homework 3Documento1 paginaCe 767 Homework 3sompongtNessuna valutazione finora

- AutoCAD Commands 1 PDFDocumento6 pagineAutoCAD Commands 1 PDFAlvin YanglayNessuna valutazione finora

- Basic Commands of AutoCADDocumento5 pagineBasic Commands of AutoCADMuhammad UmairNessuna valutazione finora

- Auto Cad Certification FAQDocumento2 pagineAuto Cad Certification FAQবহুব্রীহি আর একটা দাঁড়কাকNessuna valutazione finora

- AutoCAD2012 BegDocumento1 paginaAutoCAD2012 BegsompongtNessuna valutazione finora

- Ce 767 Homework 1Documento2 pagineCe 767 Homework 1sompongtNessuna valutazione finora

- Cad ShortcutsDocumento8 pagineCad ShortcutsPrabhat KumarNessuna valutazione finora

- Autocad Design CenterDocumento1 paginaAutocad Design CentersompongtNessuna valutazione finora

- Constr Based CADDocumento15 pagineConstr Based CADviggoNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Handle Properties of FabricDocumento100 pagineHandle Properties of FabricVasant Kothari67% (3)

- Analysis On Laterally Loaded Group PilesDocumento5 pagineAnalysis On Laterally Loaded Group PileschenNessuna valutazione finora

- T000882 PDFDocumento105 pagineT000882 PDFZarr AkshNessuna valutazione finora

- Composite Cover Design PDFDocumento18 pagineComposite Cover Design PDFA.Subin DasNessuna valutazione finora

- Experimental Investigation of Material Properties of Epoxy GraniteDocumento3 pagineExperimental Investigation of Material Properties of Epoxy GranitenikkeNessuna valutazione finora

- Sway BracesDocumento4 pagineSway BracespritamNessuna valutazione finora

- 04 - Analysis Reference - Chapter 4 MaterialsDocumento124 pagine04 - Analysis Reference - Chapter 4 MaterialsSafwat El RoubyNessuna valutazione finora

- Truss ExampleDocumento8 pagineTruss Exampledixn__Nessuna valutazione finora

- Sugar CaneDocumento3 pagineSugar CaneSanjay BaidNessuna valutazione finora

- 2017-Viktoria-Bending Stiffness of CLT-Concrete Composite Member Comparison of Simplified Calculation MethodsDocumento6 pagine2017-Viktoria-Bending Stiffness of CLT-Concrete Composite Member Comparison of Simplified Calculation MethodsSỹ PhạmNessuna valutazione finora

- Dme-22 6 15Documento8 pagineDme-22 6 15VIGNESH L RNessuna valutazione finora

- SSC JE Civil Previous Year Solved PapersDocumento72 pagineSSC JE Civil Previous Year Solved PapersHalf Engr67% (3)

- Can Static Stretching Reduce Stiffness of The Triceps SuraeDocumento7 pagineCan Static Stretching Reduce Stiffness of The Triceps Suraesilvio da costa guerreiroNessuna valutazione finora

- Shaft Design ProjectDocumento7 pagineShaft Design ProjectHiawata Adhya PratamaNessuna valutazione finora

- Group 4 Project ReportDocumento83 pagineGroup 4 Project ReportAmin MemonNessuna valutazione finora

- Formula Student Germany - Chassis Stiffness and Compliance PDFDocumento2 pagineFormula Student Germany - Chassis Stiffness and Compliance PDFAnonNessuna valutazione finora

- Autodesk Nastran 2022 Nonlinear Analysis HandbookDocumento1 paginaAutodesk Nastran 2022 Nonlinear Analysis HandbookDanNessuna valutazione finora

- Rock Mechanics 2Documento6 pagineRock Mechanics 2Carmine TranfaNessuna valutazione finora

- Pile Lateral Load CapacityDocumento18 paginePile Lateral Load CapacityBrhane W YgzawNessuna valutazione finora

- T 321-07 2011Documento11 pagineT 321-07 2011susanaleNessuna valutazione finora

- Advanced Structural Analysis Prof. Devdas Menon Department of Civil Engineering Indian Institute of Technology, MadrasDocumento33 pagineAdvanced Structural Analysis Prof. Devdas Menon Department of Civil Engineering Indian Institute of Technology, MadrasSri DNessuna valutazione finora

- 1st Report Finding Natural Frequency Wind TurbineDocumento7 pagine1st Report Finding Natural Frequency Wind TurbineThanyawut WansuwanNessuna valutazione finora

- Part I - Basics FlexibilityDocumento17 paginePart I - Basics FlexibilityDawit Gebrehana100% (2)

- Lateral Load Capacity of Piles - Short Piles - Davisson - BromsDocumento9 pagineLateral Load Capacity of Piles - Short Piles - Davisson - BromsGeorge KaraspNessuna valutazione finora

- 1 - MOM Lab Manual RevisedDocumento15 pagine1 - MOM Lab Manual RevisedRahman SiddiqueNessuna valutazione finora

- Composite Materials: Design, Analysis & ApplicationsDocumento25 pagineComposite Materials: Design, Analysis & ApplicationsTayyab AttariNessuna valutazione finora

- Broken Wire Condition PDFDocumento16 pagineBroken Wire Condition PDFAmritanshu SrivastavaNessuna valutazione finora

- Additional Objective Type QuestionDocumento32 pagineAdditional Objective Type QuestionThinnai TheniNessuna valutazione finora

- Lab Report 2 - Phyo Paing Soe Chandan Kumar - 450426142Documento10 pagineLab Report 2 - Phyo Paing Soe Chandan Kumar - 450426142Chandan KumarNessuna valutazione finora

- Behaviour of Laterally Loaded Rigid Piles in Cohesive Soils BasedDocumento15 pagineBehaviour of Laterally Loaded Rigid Piles in Cohesive Soils BasedLeo XuNessuna valutazione finora