Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SAIC-A-2009 Rev 0

Caricato da

philipyapDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SAIC-A-2009 Rev 0

Caricato da

philipyapCopyright:

Formati disponibili

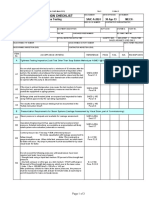

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Verification of Test Preparation and Test Equipment for Pressure Testing

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-A-2009

WBS / BI / JO NUMBER

25-May-05

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A A1 A2

ACCEPTANCE CRITERIA Preparation for Testing Test Pack is available for verification and review. (Refer to SAIC-L-2001). Pre-Test Punchlisting complete and Test Pack Flow Chart signed accordingly. (Refer to SAIC-L-2001). All pre-test punchlist designated as "A" items are cleared. (NOTE: "A"-items are pre-test punchlists required to be completed prior to pressure testing .) Flanges that will not be disturbed after the pressure test are marked/identified and tightened WITH the approved SAIC-L-2014 & SATR-L-2001. Flushing or internal Cleanliness of system is complete. Test Package Flow chart signed-off accordingly. Components which interfere with filling, venting, draining or flushing shall not be installed until after line flushing and pressure testing are completed. These include orifice plates, flow nozzles, sight glasses, venturies, positive displacement and turbine meters and other in-line equipment. Equipment Excluded from Pressure Test The following equipment are excluded from the in-situ pressure testing of the tested system. a) Rotating machinery, such as pumps, turbines and compressors; b) Strainers and filter elements; c) Rupture disks and pressure relief valves; d) Locally mounted indicating pressure gauges, where the test pressure will exceed their scale range; e) Equipment that cannot be drained; f) Instrument Devices. Temporary supports are installed if they were determined to be required per SAES-L-150. Expansion joints and spring hangers or spring supports are provided with temporary restraints where needed to prevent excessive travel or deformation under the test loads.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

Best Practice Best Practice

A3

Best Practice

A4

Best Practice SAES-A-004, Para. 7.1.2

A5

A6

SAES-A-004, Para. 7.1.4

A7

SAES-A-004, Para. 7.2

A8

SAES-A-004, Para. 7.5.2 SAES-L-150, Para. 6.4

A9

All joints including welded joints are left exposed for visual leak detection A10 during the strength test. (NOTE: This excludes joints that will be subject to 24-hr recorded test. ) Work permit is obtained for all pressure testing and associated work within restricted areas as covered in G.I. 2.100, Work Permit System. Equipment and appurtenances that are not adequate for test pressures are isolated.

SAES-L-150, Para. 7.3

A11

G.I.-2.102, Para. 5.6 G.I.-2.102, Para. 5.7

A12

Page 1 of 3

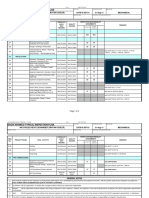

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Verification of Test Preparation and Test Equipment for Pressure Testing

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-A-2009

WBS / BI / JO NUMBER

25-May-05

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

If isolation valves are used in lieu of blinds, provisions are A13 made to ensure that no overpressuring can occur in equipment that is not being tested, due to possible valve leak. Materials Safety Data Sheets or Chemical Hazard Bulletins are reviewed for all chemicals handled such as corrosion inhibitor, bactericide, chlorine, and oxygen scavenger, and a written procedure to safely handle A14 chemicals during testing, and proper disposal of the chemicals after testing, is approved prior to start of the work. Personal protective equipment shall be utilized as shown on these sheets and bulletins. A15 The test areas are marked and warning signs posted to alert approaching personnel. Where a road parallels within 30 m (100 ft.) of an aboveground pipeline being tested, traffic shall be diverted or stopped during the test. If this is not practical, the area Loss Prevention offices should be contacted to confirm that the test can be conducted safely.

G.I.-2.102, Para. 5.7

G.I.-2.102, Para. 5.9

G.I.-2.102, Para. 5.11

A16

G.I.-2.102, Para. 5.11

If non-Saudi Aramco facilities will be exposed in a pressure test of Saudi Aramco facilities, the proponent organization of the test shall so inform A17 the Saudi Aramco Affairs representative prior to the test. B B1 Test Piping and temporary appurtenances: Test piping, fittings and hoses are designed or have pressure rating that matched or exceed the system test pressure. Paddle blinds or spectacle blinds used to isolate the test sections are of the same class rating of the system or may be fabricated based on appropriate calculations. Test Manifold The pressure testing manifold was separately pressure tested to at least 1.2 times the system test pressure. Pressure rating or design of test manifold components, ie: isolation valves, pipe nipples, are not less than 20% above the system test pressure. A blow down valve of adequate pressure rating is installed to depressurize the system. An isolation valve of adequate pressure rating is installed to isolate the test piping manifold from the system under test. Test Relief Valve(s) Relief valve(s) of adequate capacity are set to relieve at 5% above the hydrotest pressure. The relief valve(s) are tested, dated, and tagged within one week prior to the pressure testing. Isolation valves installed on the inlet and outlet of the relief valve are sealed open during the test. The relief valve is located in the system under test and near the test pump.

G.I.-2.102, Para. 5.12

G.I.-2.102, Sec.4 SAES-A-004 Para. 7.3

B2 C C1

SAES-A-004 Para 5.5.4 G.I.-2.102, Para. 5.5 G.I.-2.102, Para. 5.5 G.I.-2.102, Para. 5.5

C2

C3

C4 D D1 D2 D3

SAES-A-004 Para 5.5.1 SAES-A-004 Para 5.5.1 G.I.-2.102, Para. 5.5 G.I.-2.102, Para. 5.5

D4

Page 2 of 3

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Verification of Test Preparation and Test Equipment for Pressure Testing

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-A-2009

WBS / BI / JO NUMBER

25-May-05

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. E

ACCEPTANCE CRITERIA Pressure Gages and Recorders A minimum of two pressure gages are required for the test system. Their accuracy shall be within 5% of one another. (NOTE: When large systems are tested, Inspection personnel will determine the need for additional gages. ) Pressure gages and pressure recorders are calibrated within one (1) month prior to the test. Stickers shall be applied indicating the latest calibration date. A Test gauge is located at the bottom of the equipment to inable the reading of the test pressure, including the head of test water. All gages have a range such that the test pressure is within 30% to 80% of the full range. Temperature Gages (when required, ie: 24-hr recorded test) Thermocouples are installed to obtain accurate pipe metal temperature measurements and to determine the acceptance of the pressure test where pressure variations due to test water temperature changes occur, such as in cross-country pipelines.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

E1

SAES-A-004 Para 7.1.5

E2

SAES-A-004 Para 7.1.5 G.I.-2.102, Sec.4 SAES-A-004 Para 7.1.5

E3

E4

F1

SAES-L-150, Para. 11.3

REMARKS:

REFERENCE DOCUMENTS: 1. SAES-A-004, General Requirements for Pressure Testing, (30 April, 2002) 2. GI-2.102, Saudi Aramco General Instruction-Pressure Testing Safely , (22 July, 2001) 3. SAES-L-150, Pressure Testing of Plant Piping and Pipelines, (30 September, 2003)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 3 of 3

Potrebbero piacerti anche

- SAIC-A-2015 Rev 7Documento8 pagineSAIC-A-2015 Rev 7Bebin Mathew0% (1)

- Saic A 2011Documento5 pagineSaic A 2011Anonymous 4e7GNjzGWNessuna valutazione finora

- SAUDI ARAMCO PNEUMATIC TEST CHECKLISTDocumento3 pagineSAUDI ARAMCO PNEUMATIC TEST CHECKLISTரமேஷ் பாலக்காடுNessuna valutazione finora

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005Documento3 pagineSaudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005ரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)Documento15 pagineSAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)imrankhan2250% (2)

- SAIC-A-2009 Rev 2Documento5 pagineSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- SAIC-A-2016 Rev 0Documento2 pagineSAIC-A-2016 Rev 0philipyapNessuna valutazione finora

- Saic A 2011Documento8 pagineSaic A 2011jerinNessuna valutazione finora

- 00 Saip 06Documento4 pagine00 Saip 06Selvakpm06Nessuna valutazione finora

- SATR-J-6512 - Rev 0 PDFDocumento5 pagineSATR-J-6512 - Rev 0 PDFAdel KlkNessuna valutazione finora

- SAIC-A-2023 Rev 6 Prssure Test Air GasDocumento5 pagineSAIC-A-2023 Rev 6 Prssure Test Air Gaspookkoya thangalNessuna valutazione finora

- SAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGDocumento3 pagineSAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGpookkoya thangalNessuna valutazione finora

- Satip A 004 03Documento3 pagineSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocumento2 pagineSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saic L 2008 PDFDocumento4 pagineSaic L 2008 PDFHesham HelalNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento8 pagineSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Air Cooled Heat Exchanger Inspection PlanDocumento2 pagineSaudi Aramco Air Cooled Heat Exchanger Inspection PlanAnonymous S9qBDVkyNessuna valutazione finora

- SATIP B 019 01 (Revision 4)Documento2 pagineSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWNessuna valutazione finora

- SAIC-L-2014 Flange Joint Insp PDFDocumento7 pagineSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyNessuna valutazione finora

- SAIC-A-2008 Rev 0Documento3 pagineSAIC-A-2008 Rev 0Kristine Caye DatarioNessuna valutazione finora

- Materials System SpecificationDocumento7 pagineMaterials System Specificationaanouar77Nessuna valutazione finora

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Documento2 pagineSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento6 pagineSaudi Aramco Inspection ChecklistAnonymous 4e7GNjzGWNessuna valutazione finora

- Seat Leak Test For Contrl ValvesDocumento19 pagineSeat Leak Test For Contrl ValvesAdeel Qaiser100% (1)

- Receiving Inspection of Pressure VesselsDocumento5 pagineReceiving Inspection of Pressure Vesselsரமேஷ் பாலக்காடுNessuna valutazione finora

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Documento2 pagineSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNessuna valutazione finora

- Saudi Aramco Reinstatement Procedure ChecklistDocumento5 pagineSaudi Aramco Reinstatement Procedure ChecklistpravinNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento3 pagineSaudi Aramco Inspection ChecklistDilshad AhemadNessuna valutazione finora

- SAIC-L-2136 Rev 0Documento3 pagineSAIC-L-2136 Rev 0philipyapNessuna valutazione finora

- Satip e 007 01Documento2 pagineSatip e 007 01Anonymous 4e7GNjzGWNessuna valutazione finora

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Documento2 pagine1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyNessuna valutazione finora

- Saudi Aramco Pressure Testing ProcedureDocumento21 pagineSaudi Aramco Pressure Testing ProcedureDilshad AhemadNessuna valutazione finora

- 04 Samss 055Documento42 pagine04 Samss 055nadeem shaikh100% (1)

- SAIC-A-2005 Rev 5 Leak TestDocumento4 pagineSAIC-A-2005 Rev 5 Leak Testpookkoya thangalNessuna valutazione finora

- Satip D 001 01Documento11 pagineSatip D 001 01Rijwan Mohammad0% (1)

- Saudi Aramco Inspection ChecklistDocumento3 pagineSaudi Aramco Inspection ChecklistAbdul HannanNessuna valutazione finora

- 34 Samss 711Documento25 pagine34 Samss 711naruto256Nessuna valutazione finora

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento2 pagineInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNessuna valutazione finora

- Saudi-Arabian-Engineering-Standardssaes-J-001 PDFDocumento11 pagineSaudi-Arabian-Engineering-Standardssaes-J-001 PDFsalasineNessuna valutazione finora

- Control Valve Test ProcedureDocumento5 pagineControl Valve Test ProcedureMark Haizlip100% (2)

- 04 Samss 035Documento28 pagine04 Samss 035SamiNessuna valutazione finora

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocumento2 pagineSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNessuna valutazione finora

- Factory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: DDocumento6 pagineFactory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: Dbayu dewantoNessuna valutazione finora

- Dokumen - Tips Saep-1135pdfDocumento12 pagineDokumen - Tips Saep-1135pdfArsalan HaiderNessuna valutazione finora

- 32 Samss 005Documento33 pagine32 Samss 005naruto256100% (1)

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14Documento10 pagineSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14pravinNessuna valutazione finora

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocumento8 pagineSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289Nessuna valutazione finora

- 175-Ir171300, (850146), 11.30.2015Documento2 pagine175-Ir171300, (850146), 11.30.2015Rami ELLOUMINessuna valutazione finora

- Saep 35Documento6 pagineSaep 35hendraox3996Nessuna valutazione finora

- SATIP-A-004-01 Rev 7Documento2 pagineSATIP-A-004-01 Rev 7Bebin Mathew100% (1)

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDocumento2 pagineSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanNessuna valutazione finora

- 175 000003 PDFDocumento1 pagina175 000003 PDFSohail TisekarNessuna valutazione finora

- SAIC L 2031 (Comments)Documento2 pagineSAIC L 2031 (Comments)Anton Thomas PunzalanNessuna valutazione finora

- SAIC-A-2013 Rev 0Documento2 pagineSAIC-A-2013 Rev 0philipyapNessuna valutazione finora

- SAIC-A-2015 Rev 2Documento9 pagineSAIC-A-2015 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Pressure Testing SafelyDocumento18 paginePressure Testing SafelyHaleem Ur Rashid Bangash100% (1)

- SAIC-A-2023 Rev 0Documento2 pagineSAIC-A-2023 Rev 0philipyapNessuna valutazione finora

- SAIC-A-2015 Rev 0Documento1 paginaSAIC-A-2015 Rev 0philipyapNessuna valutazione finora

- Saudi Aramco Piping ChecklistDocumento3 pagineSaudi Aramco Piping ChecklistphilipyapNessuna valutazione finora

- SATR-J-6001 Rev 0 PDFDocumento5 pagineSATR-J-6001 Rev 0 PDFAdel KlkNessuna valutazione finora

- Saudi Aramco Tent Structure SpecificationsDocumento5 pagineSaudi Aramco Tent Structure SpecificationsphilipyapNessuna valutazione finora

- Sealant and CaulkingDocumento8 pagineSealant and CaulkingphilipyapNessuna valutazione finora

- Piping and Ducting SupportDocumento7 paginePiping and Ducting SupportphilipyapNessuna valutazione finora

- Panel BoardDocumento7 paginePanel BoardphilipyapNessuna valutazione finora

- Fire Protection SysytemDocumento5 pagineFire Protection SysytemphilipyapNessuna valutazione finora

- Finish CarpentryDocumento17 pagineFinish CarpentryphilipyapNessuna valutazione finora

- Low Voltage Wires and Cables SpecificationDocumento9 pagineLow Voltage Wires and Cables SpecificationphilipyapNessuna valutazione finora

- Raceway Selection GuideDocumento10 pagineRaceway Selection GuidephilipyapNessuna valutazione finora

- Resilent FlooringDocumento7 pagineResilent FlooringphilipyapNessuna valutazione finora

- Exterior LightingDocumento8 pagineExterior LightingphilipyapNessuna valutazione finora

- DuctworksDocumento7 pagineDuctworksphilipyapNessuna valutazione finora

- Saudi Aramco Tent Structure SpecificationsDocumento5 pagineSaudi Aramco Tent Structure SpecificationsphilipyapNessuna valutazione finora

- Sheet Membrance Water ProofingDocumento6 pagineSheet Membrance Water ProofingphilipyapNessuna valutazione finora

- Saudi Aramco Ductwork SpecificationsDocumento5 pagineSaudi Aramco Ductwork SpecificationsphilipyapNessuna valutazione finora

- FanDocumento7 pagineFanphilipyap100% (1)

- DuctworksDocumento7 pagineDuctworksphilipyapNessuna valutazione finora

- Chilled Water PumpDocumento6 pagineChilled Water PumpphilipyapNessuna valutazione finora

- SignageDocumento4 pagineSignagephilipyapNessuna valutazione finora

- Fan Coil UnitsDocumento3 pagineFan Coil UnitsphilipyapNessuna valutazione finora

- Variable Air UnitDocumento4 pagineVariable Air UnitphilipyapNessuna valutazione finora

- Metal FramesDocumento4 pagineMetal FramesphilipyapNessuna valutazione finora

- Control SystemDocumento21 pagineControl SystemphilipyapNessuna valutazione finora

- 03210-Epoxy Coated Conc ReoDocumento7 pagine03210-Epoxy Coated Conc ReophilipyapNessuna valutazione finora

- Metal FramesDocumento4 pagineMetal FramesphilipyapNessuna valutazione finora

- G.furniture & FixturesDocumento2 pagineG.furniture & FixturesphilipyapNessuna valutazione finora

- Plumbing SpecialitiesDocumento4 paginePlumbing SpecialitiesphilipyapNessuna valutazione finora

- Floor MatsDocumento3 pagineFloor MatsphilipyapNessuna valutazione finora

- Roof and Deck InsulationDocumento3 pagineRoof and Deck InsulationphilipyapNessuna valutazione finora

- Swimming PoolDocumento4 pagineSwimming PoolphilipyapNessuna valutazione finora

- Glass and GlazingDocumento8 pagineGlass and GlazingphilipyapNessuna valutazione finora

- Marketing Strategies of Olper's.....Documento15 pagineMarketing Strategies of Olper's.....don_zed_420100% (6)

- Pran Lukas TDocumento2 paginePran Lukas TmisanthropoNessuna valutazione finora

- Key Officers On This ProjectDocumento6 pagineKey Officers On This ProjectNnaa Kalu NtoNessuna valutazione finora

- Catalogo Balanzas andDocumento40 pagineCatalogo Balanzas andMauricioTeranAguilarNessuna valutazione finora

- REST, dojo, JavaFX: Catalog App</TITLEDocumento45 pagineREST, dojo, JavaFX: Catalog App</TITLEnaresh921Nessuna valutazione finora

- SSP Nfra BDT1 Jind MST 00032Documento42 pagineSSP Nfra BDT1 Jind MST 00032Zulhazmi ZulkafliNessuna valutazione finora

- Municipal Profile of Umingan, PangasinanDocumento51 pagineMunicipal Profile of Umingan, PangasinanGina Lee Mingrajal Santos100% (1)

- Jota EP15P 快干环氧底漆EP15P(0XT) (United Kingdom - English)Documento5 pagineJota EP15P 快干环氧底漆EP15P(0XT) (United Kingdom - English)long chanNessuna valutazione finora

- Customs Reviewer 2018 (Final)Documento25 pagineCustoms Reviewer 2018 (Final)Mamerto Egargo Jr.Nessuna valutazione finora

- Antique Maps Sale During The International ExhibitionDocumento148 pagineAntique Maps Sale During The International ExhibitionVu Nguyen100% (1)

- Student Project Titles and DetailsDocumento2 pagineStudent Project Titles and DetailsPidikiti Surendra BabuNessuna valutazione finora

- Soering v. UK PDFDocumento32 pagineSoering v. UK PDFAnica GNessuna valutazione finora

- Stone Enterprises - QUALITY REPLACEMENT PARTS & CUSTOM EQUIPMENTDocumento28 pagineStone Enterprises - QUALITY REPLACEMENT PARTS & CUSTOM EQUIPMENTMallikharjuna Reddy GogireddyNessuna valutazione finora

- Principles of Semiconductor Devices ZeghbroeckDocumento692 paginePrinciples of Semiconductor Devices ZeghbroeckAlim Mohammad AbdulNessuna valutazione finora

- Eia AbudabiDocumento173 pagineEia AbudabiAdministracion BucareNessuna valutazione finora

- Tim CookDocumento15 pagineTim CookHoang AnhNessuna valutazione finora

- Automatic Congestion Handler (RAN19.1 - 01)Documento604 pagineAutomatic Congestion Handler (RAN19.1 - 01)anthonyNessuna valutazione finora

- Pharmacy Management SoftwareDocumento7 paginePharmacy Management SoftwareShirely MansellNessuna valutazione finora

- ECTE323/8323 Synchronous Machines GuideDocumento28 pagineECTE323/8323 Synchronous Machines GuideFUCKYOUNessuna valutazione finora

- Data Sheet - Nvidia Jetson Tx2 System-On-moduleDocumento61 pagineData Sheet - Nvidia Jetson Tx2 System-On-moduleDeepak RajamohanNessuna valutazione finora

- Civil Constraction Method - DrainaseDocumento7 pagineCivil Constraction Method - DrainaseIrvan MaulaNaNessuna valutazione finora

- Motion to Compel Discovery in Personal Injury LawsuitDocumento6 pagineMotion to Compel Discovery in Personal Injury LawsuitAmanda ZelinskyNessuna valutazione finora

- Report On RERA ImpactsDocumento30 pagineReport On RERA ImpactsEmperor MinatiNessuna valutazione finora

- Issues, Concerns and Prospects: Teacher Training Institutions' Views On K-12Documento16 pagineIssues, Concerns and Prospects: Teacher Training Institutions' Views On K-12rrNessuna valutazione finora

- NITI Policy-Paper BMID 2023-MayDocumento20 pagineNITI Policy-Paper BMID 2023-MayAmardeep RavalNessuna valutazione finora

- SBI PO Syllabus PDFDocumento2 pagineSBI PO Syllabus PDFDeepak KumarNessuna valutazione finora

- Programming: Hardware & SoftwareDocumento18 pagineProgramming: Hardware & SoftwaresantoshNessuna valutazione finora

- T&B WorksheetDocumento11 pagineT&B WorksheetAmir ZeidabadiNessuna valutazione finora

- R410A GMV Multi VRF Installation ManualDocumento28 pagineR410A GMV Multi VRF Installation ManualRahul DubeyNessuna valutazione finora

- 1 ZzfeDocumento8 pagine1 ZzfeScuderia Redin100% (1)