Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SAIC-A-2016 Rev 0

Caricato da

philipyapDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SAIC-A-2016 Rev 0

Caricato da

philipyapCopyright:

Formati disponibili

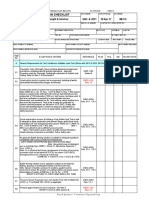

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Visual Inspection of Pneumatic Test for Reinforcing Pads, Sleeves, or Weld-Plus-Ends Couplings

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-A-2016

WBS / BI / JO NUMBER

25-May-05

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No.

ACCEPTANCE CRITERIA Reinforcing Pads or Sleeves (NOTE: A separate test is not required if the reinforcing pads or sleeves are installed before pressure testing of the piping. Test is required for pads or sleeves installed in hot tap installation.) Re-inforcing pads that will require pneumatic test are provided with at least a 1/4" tapped vent hole. A pneumatic test of 173 kPa (ga) (25 psi) shall be applied to the reinforcing pad or ring after installation. The test pressure is then be reduced to 21 - 35 kPa (ga) (3 - 5 psi) for a tightness test using a soap solution. Weld-Plus-Plus Ends Coupling (SAEP-310)

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A1 A2 A3 B

Best Practice SAEP-311, Para. 3.8.8 SAEP-311, Para. 3.8.8

B1

Both ends of the weld-Plus-Ends coupling are welded to the pipe.

SAEP-312, Para. 3.4.13 (Step 2) SAEP-312, Para. 3.4.13 (Step 2) SAEP-312, Para. 3.4.13 (Step 5)

B2

All of the thrust screw ends are welded over. Apply a pneumatic test at 5 to 10 psig at each end of the coupling through the top clamping screw holes, apply soap solution over all the welds and check for leaks. (NOTE: Test Relief valve is not requirede for this test per G.I.-2.102, Para. 5.5 ) Inspection for leaks All joints including welded shall be left exposed for visual leak detection during the strength test. Visual examination is done with sufficient safe access such that the component to be inspected is in close proximity to the eye(24"). (ASME Sec V, Article 10, Para. I-1075 & Article 9, Para. T-952) The joint/area to be inspected is properly illuminated by natural or supplemental white light. (ASME Sec V, Article 10, Para. I-1075 & Article 9, Para. T-952) The bubble forming solution is compatible with the temperature of the test conditions. (NOTE: As a standard technique, the temperature of the surface of the part to be examined shall not be below 40F (4C) nor above 125F (52C) throughout the examination.) (ASME Sec V, Article 10, Para. I-1032 b & I-1072)

B3

C1

SAES-L-150, Para. 7.3 SAES-A-004, Para. 6.3.2 SAES-A-004, Para. 6.3.2

C2

C3

C4

SAES-A-004, Para. 6.3.2

Page 1 of 2

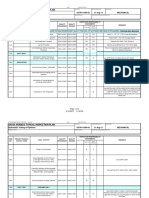

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Visual Inspection of Pneumatic Test for Reinforcing Pads, Sleeves, or Weld-Plus-Ends Couplings

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-A-2016

WBS / BI / JO NUMBER

25-May-05

WELD-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

C5

The bubble forming solution is applied to the surface to be tested by flowing, spraying, or brushing the solution over the examination area. (NOTE: The number of bubbles produced in the solution by application should be minimized to reduce the problem of masking bubbles caused by leakage. ) (ASME Sec V, Article 10, Para. I-1073)

SAES-A-004, Para. 6.3.2

C6

After application of bubble forming solution, there is no presence of continuous bubble growth on the surface of the material in the region under examination. (ASME Sec V, Article 10, Para. I-1076) Pressure gages showed no loss in pressure.

SAES-A-004, Para. 6.3.2 SAES-L-150, Para. 5.2

C7

REMARKS:

REFERENCE DOCUMENTS: 1. 2. 3. 4. 5. SAES-A-004, General Requirements for Pressure Testing, (30 June, 2003) SAEP-312, PLIDCO Weld+Ends Couplings, (31 January, 2005) SAEP-311, Installation of Hot Tapped Connections, (29 January, 2003) SAES-L-150, Pressure Testing of Plant Piping and Pipelines, (30 September, 2003) ASME Sec V, Nondestructive Examination, (July 1, 2001)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 2 of 2

Potrebbero piacerti anche

- SAIC-L-2035 Rev 6Documento2 pagineSAIC-L-2035 Rev 6biplabpal2009Nessuna valutazione finora

- Saep 321Documento25 pagineSaep 321AbdullahNessuna valutazione finora

- SignageDocumento4 pagineSignagephilipyapNessuna valutazione finora

- Swimming PoolDocumento4 pagineSwimming PoolphilipyapNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocumento4 pagineSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289Nessuna valutazione finora

- SAIC-H-2014 Rev 7Documento3 pagineSAIC-H-2014 Rev 7mohammed siddiqNessuna valutazione finora

- Materials System SpecificationDocumento7 pagineMaterials System Specificationaanouar77Nessuna valutazione finora

- SAIC-W-2084 Buttering or Build-Up of JointsDocumento1 paginaSAIC-W-2084 Buttering or Build-Up of Jointskarioke mohaNessuna valutazione finora

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocumento3 pagineSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNessuna valutazione finora

- Satip A 004 03Documento3 pagineSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- SAIC-L-2136 Rev 0Documento3 pagineSAIC-L-2136 Rev 0philipyapNessuna valutazione finora

- 175 091300Documento2 pagine175 091300Abu Anas M.SalaheldinNessuna valutazione finora

- 175-Ir171300, (850146), 11.30.2015Documento2 pagine175-Ir171300, (850146), 11.30.2015Rami ELLOUMINessuna valutazione finora

- SAIC-A-2008 Rev 0Documento3 pagineSAIC-A-2008 Rev 0Kristine Caye DatarioNessuna valutazione finora

- SAIC-A-2003 Rev 0Documento3 pagineSAIC-A-2003 Rev 0bluelions_19Nessuna valutazione finora

- Satip F 001 04Documento4 pagineSatip F 001 04Anonymous 4e7GNjzGWNessuna valutazione finora

- Saic L 2003Documento9 pagineSaic L 2003MAZHARULNessuna valutazione finora

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechDocumento2 pagineSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishNessuna valutazione finora

- Saudi Aramco Typical Inspection PlanDocumento2 pagineSaudi Aramco Typical Inspection PlanMAZHARULNessuna valutazione finora

- Schedule B - Attachment IVDocumento29 pagineSchedule B - Attachment IVAbdul Ahad LoneNessuna valutazione finora

- SATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsDocumento2 pagineSATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsAbdul HannanNessuna valutazione finora

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocumento2 pagineSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- Saic L 2007 PDFDocumento7 pagineSaic L 2007 PDFHesham HelalNessuna valutazione finora

- Saic L 2008 PDFDocumento4 pagineSaic L 2008 PDFHesham HelalNessuna valutazione finora

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDocumento12 pagineSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadNessuna valutazione finora

- Satr-W-2010Documento1 paginaSatr-W-2010Joni Carino SuniNessuna valutazione finora

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Documento2 pagineSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNessuna valutazione finora

- SAIC L 2031 (Comments)Documento2 pagineSAIC L 2031 (Comments)Anton Thomas PunzalanNessuna valutazione finora

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Documento2 pagineSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNessuna valutazione finora

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocumento8 pagineSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289Nessuna valutazione finora

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento1 paginaInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento5 pagineSaudi Aramco Inspection ChecklistManoj KumarNessuna valutazione finora

- Saudi Aramco Test ReportDocumento7 pagineSaudi Aramco Test ReportziaNessuna valutazione finora

- Ai Hempadur 87540 EnglishDocumento2 pagineAi Hempadur 87540 EnglishAmilcar BolagNessuna valutazione finora

- Saic-L-2010 Pmi Testing PDFDocumento5 pagineSaic-L-2010 Pmi Testing PDFkarioke mohaNessuna valutazione finora

- Saic K 4010Documento3 pagineSaic K 4010mohamadNessuna valutazione finora

- Saic A 2001Documento21 pagineSaic A 2001Dilshad AhemadNessuna valutazione finora

- SAEP-379 Quality Issues NotificationDocumento4 pagineSAEP-379 Quality Issues NotificationMusic And FunNessuna valutazione finora

- 175 000003Documento1 pagina175 000003zhangNessuna valutazione finora

- Saudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Documento1 paginaSaudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Zia ur RehmanNessuna valutazione finora

- Saep 324Documento13 pagineSaep 324Up WeldNessuna valutazione finora

- SAES-W-012 - Google Search3Documento1 paginaSAES-W-012 - Google Search3fayceal0% (1)

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocumento5 pagineSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNessuna valutazione finora

- Saudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalDocumento11 pagineSaudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalSasi Head OfficeNessuna valutazione finora

- Saic A 2013Documento6 pagineSaic A 2013jerinNessuna valutazione finora

- QMIS RFI RaisedDocumento2 pagineQMIS RFI RaisedSulman YounasNessuna valutazione finora

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento2 pagineInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocumento2 pagineSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Satip Q 001 03Documento10 pagineSatip Q 001 03munnaNessuna valutazione finora

- SATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementDocumento2 pagineSATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementAbdul HannanNessuna valutazione finora

- SATIP-T-492-01 Ver 08Documento1 paginaSATIP-T-492-01 Ver 08thezaidNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento2 pagineSaudi Aramco Inspection Checklistkarthi51289Nessuna valutazione finora

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocumento2 pagineSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNessuna valutazione finora

- Saudi Aramco Test ReportDocumento2 pagineSaudi Aramco Test ReportEswari AnandNessuna valutazione finora

- Saudi Aramco Test ReportDocumento4 pagineSaudi Aramco Test Reportkarthi51289Nessuna valutazione finora

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocumento3 pagineSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNessuna valutazione finora

- Saudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechDocumento1 paginaSaudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechphilipyapNessuna valutazione finora

- SAIC-A-2021 Rev 6 Pnematic Test - 3Documento4 pagineSAIC-A-2021 Rev 6 Pnematic Test - 3pookkoya thangalNessuna valutazione finora

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocumento2 pagineSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNessuna valutazione finora

- SAIC-A-2023 Rev 0Documento2 pagineSAIC-A-2023 Rev 0philipyapNessuna valutazione finora

- SAIC-A-2010 Rev 0Documento3 pagineSAIC-A-2010 Rev 0philipyapNessuna valutazione finora

- Saic A 2011Documento5 pagineSaic A 2011Anonymous 4e7GNjzGWNessuna valutazione finora

- Bazaar Tent StructureDocumento5 pagineBazaar Tent StructurephilipyapNessuna valutazione finora

- Resilent FlooringDocumento7 pagineResilent FlooringphilipyapNessuna valutazione finora

- Wire, Cable and Low VotageDocumento9 pagineWire, Cable and Low VotagephilipyapNessuna valutazione finora

- DuctworksDocumento7 pagineDuctworksphilipyapNessuna valutazione finora

- Fire Protection SysytemDocumento5 pagineFire Protection SysytemphilipyapNessuna valutazione finora

- Panel BoardDocumento7 paginePanel BoardphilipyapNessuna valutazione finora

- Piping and Ducting SupportDocumento7 paginePiping and Ducting SupportphilipyapNessuna valutazione finora

- Sealant and CaulkingDocumento8 pagineSealant and CaulkingphilipyapNessuna valutazione finora

- Finish CarpentryDocumento17 pagineFinish CarpentryphilipyapNessuna valutazione finora

- Exterior LightingDocumento8 pagineExterior LightingphilipyapNessuna valutazione finora

- Saudi Aramco Oil Company: SECTION 16110 RacewaysDocumento10 pagineSaudi Aramco Oil Company: SECTION 16110 RacewaysphilipyapNessuna valutazione finora

- Chilled Water PumpDocumento6 pagineChilled Water PumpphilipyapNessuna valutazione finora

- Bazaar Tent StructureDocumento5 pagineBazaar Tent StructurephilipyapNessuna valutazione finora

- FanDocumento7 pagineFanphilipyap100% (1)

- Sheet Membrance Water ProofingDocumento6 pagineSheet Membrance Water ProofingphilipyapNessuna valutazione finora

- Duct Works & AccessoriesDocumento5 pagineDuct Works & AccessoriesphilipyapNessuna valutazione finora

- Variable Air UnitDocumento4 pagineVariable Air UnitphilipyapNessuna valutazione finora

- Metal FramesDocumento4 pagineMetal FramesphilipyapNessuna valutazione finora

- Fan Coil UnitsDocumento3 pagineFan Coil UnitsphilipyapNessuna valutazione finora

- DuctworksDocumento7 pagineDuctworksphilipyapNessuna valutazione finora

- Control SystemDocumento21 pagineControl SystemphilipyapNessuna valutazione finora

- Metal FramesDocumento4 pagineMetal FramesphilipyapNessuna valutazione finora

- G.furniture & FixturesDocumento2 pagineG.furniture & FixturesphilipyapNessuna valutazione finora

- Plumbing SpecialitiesDocumento4 paginePlumbing SpecialitiesphilipyapNessuna valutazione finora

- 03210-Epoxy Coated Conc ReoDocumento7 pagine03210-Epoxy Coated Conc ReophilipyapNessuna valutazione finora

- Roof and Deck InsulationDocumento3 pagineRoof and Deck InsulationphilipyapNessuna valutazione finora

- Floor MatsDocumento3 pagineFloor MatsphilipyapNessuna valutazione finora

- Glass and GlazingDocumento8 pagineGlass and GlazingphilipyapNessuna valutazione finora