Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

The Nimble Lancair Legacy: Zu-Fcy

Caricato da

aerogem618Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

The Nimble Lancair Legacy: Zu-Fcy

Caricato da

aerogem618Copyright:

Formati disponibili

The nimble Lancair Legacy ZU-FCY

By Athol Franz

The story of the Lancair began in 1985 with the revolutionary Lancair 200, an aircraft so technically advanced that it is now part of the Experimental Aircraft Associations (EAA) museum collection. The Lancair 200 revolutionised the flying experience, offering pilots outstanding performance, more freedom, increased satisfaction and better value than any other piston-engine general aviation aircraft at that time. Never content to rest on their laurels, Lance Neibauer and the Lancair team continued to push the envelope of the worlds finest two-place experimental kit-built plane. The result was the Lancair 320/360, an aircraft so beautiful and unprecedented in design that it hung on display in New York Citys Metropolitan Museum of Art. Swift, stable, tight and responsive, the Lancair 200s evolutionary heir again shook up the general aviation industry. Some 15 years after the Lancair revolution began the history of unparalleled innovation and the heritage of record-setting performance continued with the Lancair Legacy. The successor to Lancairs legendary two-place aircraft, the Legacy represents the culmination of more than a decade of research, testing and invaluable input from Lancair builders and pilots. Redesigned from the tail forward, this plane is larger, faster and easier to build. Wing Design When the Lancair team went to work designing a new wing plan form, high expectations were set. This wing had to perform up to the tremendous top speeds that pilots expect from Lancair aircraft. However, a higher emphasis was placed on low speed handling. To keep area to a minimum, the wing has a unique double taper to maximise the lift distribution from root to tip. This also allowed the designers to eliminate all washout, which can compromise efficiency. This new airfoil creates extensive laminar flow across more than 50% of the surface. The low-drag laminar bucket is also wider than before, further increasing overall performance. The result is a very carefully tuned wing design, which enhances overall aircraft performance. Roll control had to remain light, snappy and balanced. In addition, a relatively thick cord was employed, which aids strength whilst providing room for adequate fuel (up to 66 US gallons). This wing also had to swallow the new larger 5.00 x 5 main gear tyres without gear door modifications. Lancairs designers are pleased that the new Legacy wing exceeds all design expectations, with lower stall speed, better roll rate, improved low speed handling and higher top speeds. Ultra-high-speed cruise with a nimble roll rate of 150 degrees/second and solid, comfortable control stick forces are the result of an intense design process. At the other end of the performance spectrum, the Legacys low-speed roll control is remarkable and the stall behaviour is straight ahead. The addition of simplified fowler flaps further increases the wings maximum lift coefficient to enhance low speed handling. This translates into the safety of slower approaches and shorter landing distances. Increased cabin comfort Inside the cabin, creature comforts, ergonomics and luxury were foremost customer considerations. A wider and taller cabin offers more shoulder and headroom. In addition, the larger canopy affords unobstructed visibility and outstanding views in all directions, which is another safety feature. The roomier baggage area makes it possible to comfortably stow everything Every aspect of the Legacy has been methodically designed and engineered, from the kit assembly process to flight characteristics. Detachable wing panels are just one example. To trailer the aircraft to an airport or to the paint shop, the wings can be removed whilst the aircraft remains on its landing gear. Lancair also works closely with the engineers at Teledyne Continental Motors and Textron Lycoming, Hartzell and MT-Propellers to refine the power plant installation and to perfect the union of engine and propeller to the airframe. Several engine options from 160 hp to 310 hp can be accommodated including the Lycoming 1O-360 and the Continental 1O-550. Fuel The fuel tanks are integrated within the wing bays. Standard fuel tanks have a 66 US gallon (250 litre) capacity. The fuel selector is designed per FAA standards, allowing for either left, right or off. As a safety feature, each wing tank incorporates a slosh bay to prevent un-porting of the fuel pickup in the event of uncoordinated manoeuvres such as during slips. The fuel valve (for Continental engines) also returns vapour, or return fuel, back to the fuel tank in use, which tremendously simplifies management. Custom fuel quantity monitoring systems are available as options. Advanced landing gear Three inches taller than the 320/360 for improved ground and propeller clearance, the Legacys main landing gear incorporates premium air/oleo struts with the larger 5.00 x 5 main gear tyres for better landing characteristics. The nose gear is also the premium air/oleo strut with unique internal viscous shimmy dampening. Protected from the environment, the internalised dampening system provides longer service life and there are no scissor links that wear out. Steering is easily accomplished using differential braking, permitting tight-radius turns and the rudder becomes effective at taxi speeds as low as 20 mph. A tyre guide strap ensures proper retraction of the nose wheel into the gear well. The gear retraction method is Lancairs well proven, extremely reliable and simple, electro/hydraulic system. required for a cross-country trip, including golf bags and fishing rods. Unlike most fast singles, pilot and passenger sit in a normal upright position with headroom to spare. Fastest in the air The Legacys spacious new fuselage did not come at the expense of speed. The type is able to accommodate a larger engine. With a 310 hp Continental 1O-550, the Legacy achieves stellar performance, by cruising at 280 mph (243 knots) at 10 000 feet. In addition the Legacys climb rate of +2 200 fpm will outperform most aircraft types in its class. Design

98

African Pilot

February 2010

Materials Like every Lancair, the Legacys major airframe is constructed of advanced composite materials. Cured at 270 degrees Fahrenheit under vacuum pressure, these NASA tested, epoxy based composites are among the lightest, strongest, stiffest materials known. The high-temperature, pre-impregnated carbon fibre and/or fibreglass systems combined with Nomex/honeycomb core materials are considered the supreme composite airframe materials of choice worldwide. This combination allows compound aerodynamic shapes, such as the Legacys sculptured fuselage and double-taper wing whilst there are no drag-producing rivets or lap joints. Corrosion resistant, a nearly infinite fatigue life and virtually non-flammable, composite materials also extend the life of the aircraft. When correctly maintained, Lancair airframes will easily outlive any aluminium airframe, whilst composites are easier with which to work and considerably easier to repair. Testing

at the factory, the builder will not only learn the basics of advanced composite construction, but also completely close both wings, including flaps and ailerons as well as complete the horizontal stabiliser and elevators in the first week. If a builder decides to stay for another week, he will finish the canopy as well as fit and finish the rudder. Lancair supplies the fixtures, tools, supplies and guidance. A builder will head home with not only much accomplished, but also the knowledge and confidence to quickly and accurately complete the airframe build process. Free technical assistance When a builder decides to purchase a Lancair he/she will receive unlimited, free technical assistance, five days a week, eight hours a day forever. Lancairs staff members are available to advise on all aspects of the assembly and final systems installations, from spinner to tail. Free guidance also includes optional installations such as autopilots, new avionics and system accessories. Specifications

Component parts are rigorously tested during aircraft development and throughout the manufacturing process. Lancair engineers are committed to the ideas that perfection of the whole can be accomplished only through perfection of the smallest details. For example, in addition to computer analysis, a full flutter test programme was conducted on actual aircraft components beginning with an extensive Ground Vibration Survey (GVS), which is utilised over forty accelerometers covering all points of the airframe. In environmental testing chambers, Lancair engineers simulated extreme natural conditions to which the aircrafts materials might be exposed during their long life. Samples are tested at room temperature and in extreme hot/wet conditions. During this testing phase, the incredible strength and stiffness of the fibreglass and carbon fibre materials becomes most evident. Finally to confirm materials and engineering data, a complete static load-testing programme is conducted for the wing and other specific load bearing areas. Kit preassembly In order to make wing assemblies simpler and more manageable, the main spars and the ribs are pre-installed into the wing skins. In addition, wing attachments bushings that accurately establish the wing dihedral are pre-installed. Flaps and ailerons are completed and most of the control systems are also installed. The remaining installations and assemblies are simple and very straightforward. Lancair invented the fast-build kit and the Legacy kit is the result of more than ten years of fast-build kit developments. Lancair builder assist programme Nothing beats having experienced technical assistance during the early stages of a Lancair Legacy assembly. In the Lancair builder assist programme, conducted

Engine: Continental IO-550-N: 310 hp at 2 700 rpm or Lycoming IO-540: 260 hp at 2 700 rpm Propeller: three-blade constant speed Length: 22 ft (6.71 m) Wingspan: 25.5 ft (7.77 m) Wing area: 82.5 sq ft (7.66 sq m) Wing loading: 23 lbs/sq ft Aspect ratio: 7.95:1 G loading: +4.4, -2.2 Gs (utility) +3.8, -2.0 Gs (normal) Empty weight: 1 500 lbs (680 Kg) Gross weight: 2 200 lbs (998 Kg) Fuel capacity: 66 US gallons (250 litres) Useful load: 700 lbs (318 Kg) Baggage Capacity: 90 lbs (41 Kg) Cockpit seats two: length 63 in (1.6m) width 43.5in (1.1m) and height 44.5 in (1.11m) Performance Typical cruise 276 mph (240 knots) at 8 000 ft Stall speed: 65 mph (56 knots) in the landing configuration Service ceiling: 18 000 feet Take-off distance: 850 feet (260 m) gross at sea level Landing roll: 900 feet (274 m) Cross wind landing: 21 mph component Fuel consumption: 13.5 to15 US g/h (51 to 56 lit) typical Maximum range: 1 150 statute miles (1 448 Km) with reserves at 8 000 ft Rate of climb: 2 700 fpm (solo IO-550) and 2 000 fpm at gross weight

February 2010 African Pilot

99

Constructing my Lancair Legacy

By Jack Onderstall

The aerodynamic efficiency of the Lancair design is incredible, but with a few more horses up front and a modification or two on the airframe, the type will go much faster. I had hands on experience flying in Dieter Bocks Lancair 320 hp where we tried our utmost to catch Dave Mandels Lancair which had twenty more horsepower and winglets. The Lancair Legacys legacy is the fact that the designer incorporated the best aspects of the original 320 design through its various stages of development over the years to eventually produce the ultimate, two seat, high speed cruiser in the form of the Legacy. The lines and form are similar to the original aircraft, but many changes actually took place. The most significant design changes have been: The engine power was raised from 160 hp to 310 hp The entire airframe produced from carbon fibre Ram air induction system in flight Standard electric slotted flap system Clean aerodynamic canopy design with lift producing engine compartment cowlings Being a speed junkie and having some experience flying the type I decided to build a Lancair Legacy. As I have built several other aircraft types and have all the necessary tools, I set up a small assembly factory on a farm just outside Bloemfontein where the Legacy and a Sonex aircraft were built. This was stage one of the home building plan and at the time of writing the Sonex is waiting to be test flown. I spent two weeks in the Lancair factory in Redmond Oregon. Home builders receive a dust coat, safety glasses along with a lockable tool chest and innovative cupboard in which you store your kit inventory. You get to know these dedicated, hard working, enthusiastic, energetic men of all ages who do not arrive at work late, leave early or steal time on a tea break. Becoming used to this worker attitude took some getting used to. I invited two of the staff members to lunch one day and they accepted as I had made sure it was okay with their boss. The restaurant was pretty busy and it took for ever to be served. It thus seemed unlikely that my guests would make it back to the workshop floor in time when we were eventually served, so they excused themselves and went back to work. What a wonderful attitude. What is it like building the Lancair Legacy? The Legacy goes together like a walk in the park. As with most kit planes, they come with plenty of options that generate more profit for the company and although most are good to have, there are some that I would say are essential. Essential options I would suggest are Centre section bonding with fuselage: Use the factory jig, because you do not want to build your own Closing of the wings and building in the canopy glass: This means you get a good looking canopy. Your wings are closed in the factory jigs and tested by a team of enthusiastic and capable people Innovative design features of the type The Legacy comes with removable wing sections that split just outboard of the gear. This is a great concept because it facilitates the process The Legacy remains on the step and has a slight nose down attitude in flight. This should take most pilots into a world unknown to many, as they gaze out and appreciate panoramic visibility through the incredible low of building the aircraft. Also means that moving it around the workshop, turning it over on the supplied steel rotisserie, getting it to the spray booth and eventually the airport are easily manageable because of the removable wings.Two people can de-rig the Legacy in about an hour. The most difficult operation is to get the bolts undone as the space inside the wing access is restricted - smaller hands and long arms are required Slotted flaps provide good runway visibility on final approach to actual touch down Large forward hinged bubble canopy provides for easy access and one can stand outside the aircraft whilst working on the back of the instrument panel by simply removing the glare shield Adjustable rudder pedals are essential offering four positions. A retrofit model available from a vendor in the USA produces a top hung set of adjustable rudder pedals that appear to offer greater leg length than the option offered by Lancair. I have found that anyone taller than six foot two inches has difficulty in fitting his knees under the panel. The seating position is extremely comfortable - laid back like a high performance sports car. The seats are even better if you use the memory foam and layer your seats in with ergonomic shaping into the seatback and bottom shape. Flying this amazing aircraft Two experienced airshow rated pilots have flown my Legacy. My friends Chris Briers and Johnnie Smit. Both were extremely impressed with the handling characteristics of the Legacy and both found the control harmony comfortable and predictable. Joining overhead at full power means you have to get rid of 80 to 100 knots before lowering the gear. Losing height on final approach is all a matter of throttle position. I try to maintain steep approaches that would enable you to reach the runway in the event of a loss of power. This equates to about 100 knots on finals maintaining adequate runway visibility with about 13 to 15 inches of manifold pressure. A slower approach means less runway visibility and an attitude that takes some adjustment. I believe that high performance aircraft were not designed for low and slow approaches. Holding off at about 90 knots with touch down one third into the runway at Tempe, Bloemfontein comfortably allows the Legacy to run to the end of the runway without excessive braking. Gear deployment is super fast and emergency extension of the gear relies on three gas struts to lock the gear into over centre position. The standard Legacy kit comes with main gear inner doors. The gear system is well designed and operates like a dream. The cockpit is fairly noisy with the gear out, but once you are in the cruise phase and trim the aircraft with the provided rudder aileron and elevator tabs, she sits comfortably with an incredibly light touch in the palm of your hand.

100

African Pilot

February 2010

slung canopy of the Legacy. The standard Continental IO 550 can operate fuel efficiently at lower power settings. I have seen the figures recorded in the US as low as 43 litres per hour whilst achieving 190 knots indicated. The Legacy has incredibly good looks and with the correct decals or striping she becomes a real eye catcher. Dieter Bock and I flew this Legacy to the SAAF Test Flight and Development Centre, Overberg in just two hours and seven minutes in cruise mode from Bloemfontein. If you fit the optional adjustable sun shades on to the canopy you will have an incredibly comfortable, economical high performance sporty aircraft that will give you the ride of your life every time you take her out of the hangar. The Legacy is well designed and built from the best, air and navy standardaircraft grade materials available today. If you treat her with respect and a fair amount of discipline there is no reason to think that this aircraft will bite you. The test flight on ZU FCY was undertaken by Gideon Langeveld and there was no question about whether I was going to go with him on the test flight. Gideon spent quality time, meticulously checking through the airframe, noticing build quality and attention to detail. He remained calm throughout the inspection process, showing no tendency to rush at all. He asked questions about certain choices I had made in assembling the plane and offered advice on possible negative issues around these choices. Finally it was his decision to climb on board and start the engine, based on his careful evaluation of the build quality of the aircraft. I was in the right seat for this incredible moment, where I experienced the acceleration down the runway as the engine was opened up for the first time. Getting to know and appreciate Gideon under these circumstances was an enormous pleasure. Arrival of Legacy and tools

Chris Briers and Jack Onderstal

February 2010 African Pilot

101

Potrebbero piacerti anche

- Flying the Light Retractables: A guided tour through the most popular complex single-engine airplanesDa EverandFlying the Light Retractables: A guided tour through the most popular complex single-engine airplanesNessuna valutazione finora

- Advanced Light HelicopterDocumento20 pagineAdvanced Light HelicopterChandrashekar HiremathNessuna valutazione finora

- British Aerospace Hawk: Armed Light Attack and Multi-Combat Fighter TrainerDa EverandBritish Aerospace Hawk: Armed Light Attack and Multi-Combat Fighter TrainerNessuna valutazione finora

- Hawker 900XP Review Flight Global 2008Documento10 pagineHawker 900XP Review Flight Global 2008albucurNessuna valutazione finora

- Long-EZ POHDocumento72 pagineLong-EZ POHDonald Foulk100% (4)

- Northrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Da EverandNorthrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Valutazione: 5 su 5 stelle5/5 (2)

- Description and Operation of A320 Engine (Iae v2500)Documento149 pagineDescription and Operation of A320 Engine (Iae v2500)Anirudh Reddy75% (12)

- Natural Stability and the Parachute Principle in AeroplanesDa EverandNatural Stability and the Parachute Principle in AeroplanesNessuna valutazione finora

- Lancair Evolution AircraftDocumento10 pagineLancair Evolution Aircraftaerogem618Nessuna valutazione finora

- An Aviator's Field Guide to Middle-Altitude Flying: Practical skills and tips for flying between 10,000 and 25,000 feet MSLDa EverandAn Aviator's Field Guide to Middle-Altitude Flying: Practical skills and tips for flying between 10,000 and 25,000 feet MSLValutazione: 4.5 su 5 stelle4.5/5 (2)

- SWMDocumento24 pagineSWMRaj DhuriNessuna valutazione finora

- Range & Endurance: Fuel-Efficient Flying in Light AircraftDa EverandRange & Endurance: Fuel-Efficient Flying in Light AircraftNessuna valutazione finora

- Cobalt Aircraft Industries Airparc 6 Avenue de L'europe 78117 Toussus Le Noble, FRANCEDocumento21 pagineCobalt Aircraft Industries Airparc 6 Avenue de L'europe 78117 Toussus Le Noble, FRANCECamilo MartinezNessuna valutazione finora

- Helicopter Flying Handbook (2024): FAA-H-8083-21BDa EverandHelicopter Flying Handbook (2024): FAA-H-8083-21BValutazione: 4.5 su 5 stelle4.5/5 (3)

- A ViatorDocumento37 pagineA ViatorMontse Gazquez FernandezNessuna valutazione finora

- A600 Talon Info Pac PDFDocumento12 pagineA600 Talon Info Pac PDFRuham Pablo ReisNessuna valutazione finora

- Bell 412EP DataBrochureDocumento6 pagineBell 412EP DataBrochureNash7777Nessuna valutazione finora

- Brosura AeroplaneDocumento25 pagineBrosura AeroplaneCristian AlbuNessuna valutazione finora

- Extra300 88 ManualDocumento39 pagineExtra300 88 ManualCarlos NakagawaNessuna valutazione finora

- Brochure SkyRangerDocumento4 pagineBrochure SkyRangerbestoff82Nessuna valutazione finora

- Q2 PohDocumento44 pagineQ2 PohjambojeefNessuna valutazione finora

- Tejas RadianceDocumento13 pagineTejas RadianceAdventurous AviatorNessuna valutazione finora

- Multiplex ProductsDocumento32 pagineMultiplex Productsteste41Nessuna valutazione finora

- 78" EXTRA 300 ARF: Instruction ManualDocumento27 pagine78" EXTRA 300 ARF: Instruction Manualsimonthierryhotmail.comNessuna valutazione finora

- Eurocopter E-C225Documento20 pagineEurocopter E-C225Tam Argento100% (1)

- VLJ Industry ReportDocumento16 pagineVLJ Industry ReportRobert KazmiNessuna valutazione finora

- Flight TestDocumento36 pagineFlight TestJUAN MALDONADO100% (2)

- Faster. More Powerful. Better Than Ever.: We Build Aircraft You Can Believe inDocumento2 pagineFaster. More Powerful. Better Than Ever.: We Build Aircraft You Can Believe inmarciowiliamNessuna valutazione finora

- Body AW119Kx Executive TransportDocumento16 pagineBody AW119Kx Executive TransportLee Jihoon100% (1)

- ASW28Documento4 pagineASW28Marco OlivettoNessuna valutazione finora

- C208BTechnical BriefingDocumento94 pagineC208BTechnical BriefingEvans Ev100% (1)

- BLR 212Documento8 pagineBLR 212Karadias100% (1)

- En 412EP DataBrochureDocumento6 pagineEn 412EP DataBrochureLavern P. SipinNessuna valutazione finora

- C208B Groundschool - SolentaDocumento94 pagineC208B Groundschool - SolentaMuhammad Ihsan Nur100% (1)

- King Air BrochureDocumento40 pagineKing Air BrochureFran Garita100% (1)

- Snu Worm GearDocumento29 pagineSnu Worm Gearmarisamy_lntNessuna valutazione finora

- 2017 Equator P2Documento3 pagine2017 Equator P2Grizz LyNessuna valutazione finora

- Hawker 900XP Review BJT 2009 BriefDocumento3 pagineHawker 900XP Review BJT 2009 BriefalbucurNessuna valutazione finora

- B 757 General Familiarisation in MaintenanceDocumento167 pagineB 757 General Familiarisation in MaintenanceManish Mishra100% (8)

- 3 - Idt Af - BKMDocumento106 pagine3 - Idt Af - BKMVishnuNessuna valutazione finora

- FLYER EurofoxDocumento6 pagineFLYER EurofoxMashrekin HossainNessuna valutazione finora

- Brochure NynjaDocumento4 pagineBrochure Nynjabestoff82Nessuna valutazione finora

- Spitfire Ultralight SpecificationsDocumento3 pagineSpitfire Ultralight SpecificationsKamini DudetNessuna valutazione finora

- Brochure Cavalon ENG PDFDocumento20 pagineBrochure Cavalon ENG PDFfjfluzNessuna valutazione finora

- Ec360c Eu EngDocumento24 pagineEc360c Eu Engdalibor_bogdanNessuna valutazione finora

- Issue 31754Documento13 pagineIssue 31754jose_jara_12Nessuna valutazione finora

- A Project By: Darshak BhuptaniDocumento32 pagineA Project By: Darshak BhuptaniDarshak BhuptaniNessuna valutazione finora

- FLYFokker Fokker 100 Leaflet - 1Documento4 pagineFLYFokker Fokker 100 Leaflet - 1FredyBrizuelaNessuna valutazione finora

- Albatross Flying SystemDocumento50 pagineAlbatross Flying SystemDarshak BhuptaniNessuna valutazione finora

- Brochure PDFDocumento7 pagineBrochure PDFJonni WillsNessuna valutazione finora

- LSCTDocumento32 pagineLSCTafdsfagadgNessuna valutazione finora

- Bloodhound SSC: RolexDocumento44 pagineBloodhound SSC: Rolexprof585Nessuna valutazione finora

- Autoclave 2016 PDFDocumento20 pagineAutoclave 2016 PDFekmedzicNessuna valutazione finora

- Nacelles With Plenty of PanacheDocumento1 paginaNacelles With Plenty of PanacheMohammadNessuna valutazione finora

- Aero At-3Documento17 pagineAero At-3sidplanNessuna valutazione finora

- Thoikol Final BXDocumento91 pagineThoikol Final BXDenis CNessuna valutazione finora

- Adp 1 FinalDocumento43 pagineAdp 1 Finalrahul_vh100% (1)

- Dhruv: Advanced Light HelicopterDocumento4 pagineDhruv: Advanced Light HelicopterSubhasish HoreNessuna valutazione finora

- Extra 260Documento26 pagineExtra 260andres silvestreNessuna valutazione finora

- Flat and Curved PlatesDocumento4 pagineFlat and Curved Platesaerogem618Nessuna valutazione finora

- Lesson AerodynamicsDocumento113 pagineLesson AerodynamicsShermeen Khan100% (1)

- Section 1.15 Flow ConditionsDocumento2 pagineSection 1.15 Flow Conditionsaerogem618Nessuna valutazione finora

- Shear and Bending Moment in BeamsDocumento2 pagineShear and Bending Moment in Beamsaerogem618Nessuna valutazione finora

- Section 1.2 Hydraulic System Principle and OperationDocumento4 pagineSection 1.2 Hydraulic System Principle and Operationaerogem618Nessuna valutazione finora

- Section 1.7 Pressurized ReserviorsDocumento2 pagineSection 1.7 Pressurized Reserviorsaerogem618Nessuna valutazione finora

- Section 1.3 Hydraulic System Power RequirementDocumento4 pagineSection 1.3 Hydraulic System Power Requirementaerogem618Nessuna valutazione finora

- Section 1.13 Hydraulic System Hand PumpsDocumento4 pagineSection 1.13 Hydraulic System Hand Pumpsaerogem618Nessuna valutazione finora

- Section 1.8 Aircraft Hydraulic System Power PumpsDocumento5 pagineSection 1.8 Aircraft Hydraulic System Power Pumpsaerogem618100% (1)

- Section 1.14 Flow ControlDocumento4 pagineSection 1.14 Flow Controlaerogem618Nessuna valutazione finora

- Section 1.1 Introduction To Aircraft HydraulicsDocumento2 pagineSection 1.1 Introduction To Aircraft Hydraulicsaerogem6180% (1)

- 9/27/01 AC 43.13-1B CHG 1: Figure 12-5. Pitot/static System For A Small AircraftDocumento5 pagine9/27/01 AC 43.13-1B CHG 1: Figure 12-5. Pitot/static System For A Small Aircraftaerogem618Nessuna valutazione finora

- 2-Sheet Metal Structures TextDocumento29 pagine2-Sheet Metal Structures Textaerogem618Nessuna valutazione finora

- Flight Mechanics: 1 Two-Dimensional AirfoilsDocumento4 pagineFlight Mechanics: 1 Two-Dimensional Airfoilsaerogem618Nessuna valutazione finora

- Chapter 6: Conic Sections: NotesDocumento26 pagineChapter 6: Conic Sections: Notesaerogem618Nessuna valutazione finora

- Jet Engine Propulsion Systems ReviewDocumento137 pagineJet Engine Propulsion Systems Reviewaerogem618Nessuna valutazione finora

- Lecture Notes, M261-004, Conic Sections: 1 ParabolasDocumento4 pagineLecture Notes, M261-004, Conic Sections: 1 Parabolasaerogem618Nessuna valutazione finora

- "-C.osine 1 - '': 2.A+B+C 180o A+B 90o l2Documento3 pagine"-C.osine 1 - '': 2.A+B+C 180o A+B 90o l2aerogem618Nessuna valutazione finora

- Related RatesDocumento3 pagineRelated Ratesaerogem618Nessuna valutazione finora

- L18 - Masts, Towers, Chimneys PDFDocumento48 pagineL18 - Masts, Towers, Chimneys PDFsrvshNessuna valutazione finora

- 5 Experimental Measurement of MT Coefficients PDFDocumento20 pagine5 Experimental Measurement of MT Coefficients PDFYee LingNessuna valutazione finora

- SAMPLE Critical Thinking 3Documento7 pagineSAMPLE Critical Thinking 3liuqiong1011Nessuna valutazione finora

- Barrackpore DivisionDocumento5 pagineBarrackpore Divisionsamima khatunNessuna valutazione finora

- MV RescuerDocumento2 pagineMV RescuerselleriverketNessuna valutazione finora

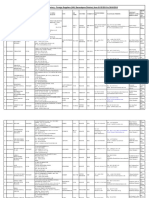

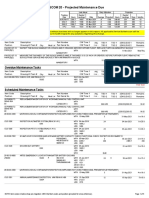

- CESCOM 20 - Projected Maintenance Due: New Requirements/Action ItemsDocumento5 pagineCESCOM 20 - Projected Maintenance Due: New Requirements/Action ItemsAndré CarneiroNessuna valutazione finora

- 2011 SRM Winter2011 9 WebDocumento36 pagine2011 SRM Winter2011 9 Webgalaxie1968Nessuna valutazione finora

- Delta Ops 4Documento1 paginaDelta Ops 4schussel2Nessuna valutazione finora

- Boroscope Inspection Procedure 7th Stage StatorDocumento15 pagineBoroscope Inspection Procedure 7th Stage StatorAPU SHOP BTH MS100% (2)

- kc10143 Muskie Mic Eval BDDocumento12 paginekc10143 Muskie Mic Eval BDambet TayloNessuna valutazione finora

- Synopsis of Midway PaperDocumento6 pagineSynopsis of Midway Paperknowme73Nessuna valutazione finora

- Wind Load AS1170.2Documento25 pagineWind Load AS1170.2kusumoaji100% (2)

- Research ProposalDocumento3 pagineResearch ProposalPhilip ShamouNessuna valutazione finora

- A320 Family PDFDocumento23 pagineA320 Family PDFbarbarbiroUNessuna valutazione finora

- ADP ReportDocumento56 pagineADP ReportsanjayNessuna valutazione finora

- Module 11A.7 (A) L2 2016-08-16Documento44 pagineModule 11A.7 (A) L2 2016-08-16Abdul Aziz KhanNessuna valutazione finora

- Chapter 8 Flow in Conduits: Entrance and Developed FlowsDocumento43 pagineChapter 8 Flow in Conduits: Entrance and Developed FlowsRicardo ACNessuna valutazione finora

- Master Caution SystemDocumento50 pagineMaster Caution SystemAloizio SilvaNessuna valutazione finora

- CFM Technical Training Course Catalog 2019Documento22 pagineCFM Technical Training Course Catalog 2019Ibnu Ahmad33% (3)

- Project GlyncoDocumento193 pagineProject GlyncoLcousins7961100% (1)

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) DoorsDocumento84 pagineSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) DoorsjuanNessuna valutazione finora

- Structural Analysis at Aircraft Conceptual Design StageDocumento127 pagineStructural Analysis at Aircraft Conceptual Design StageYvessNessuna valutazione finora

- Book Sent To Publishers On The Vulcan B.1-2 Production, History and SQN List (Updated) PDFDocumento63 pagineBook Sent To Publishers On The Vulcan B.1-2 Production, History and SQN List (Updated) PDFPhillip EvansNessuna valutazione finora

- Installation and Inspection of Screw Jacks, LeverDocumento7 pagineInstallation and Inspection of Screw Jacks, LeverazrulafifNessuna valutazione finora

- PART 4 Aircraft Registration and MarkingDocumento20 paginePART 4 Aircraft Registration and MarkingPROJECT INFINITE COMMANDERNessuna valutazione finora

- Bxa 185063 12CF 2Documento1 paginaBxa 185063 12CF 2jorgeNessuna valutazione finora

- CMH-17 Priorities and Topics For Chapter 12 Rev. H (NSE)Documento19 pagineCMH-17 Priorities and Topics For Chapter 12 Rev. H (NSE)Lukas GneistNessuna valutazione finora

- Bombardier: The C-Series Dilemma: OpportunityDocumento8 pagineBombardier: The C-Series Dilemma: OpportunityAtsushiNessuna valutazione finora

- Early Aviation History (1909)Documento184 pagineEarly Aviation History (1909)CAP History Library100% (8)

- Tail StrikeDocumento5 pagineTail StrikeKuro ShiroNessuna valutazione finora

- Eat & Run: My Unlikely Journey to Ultramarathon GreatnessDa EverandEat & Run: My Unlikely Journey to Ultramarathon GreatnessNessuna valutazione finora

- The Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsDa EverandThe Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsValutazione: 4 su 5 stelle4/5 (49)

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthDa EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthValutazione: 4 su 5 stelle4/5 (59)

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveDa EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveNessuna valutazione finora

- Elevate and Dominate: 21 Ways to Win On and Off the FieldDa EverandElevate and Dominate: 21 Ways to Win On and Off the FieldValutazione: 5 su 5 stelle5/5 (8)

- The Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItDa EverandThe Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItNessuna valutazione finora

- Merle's Door: Lessons from a Freethinking DogDa EverandMerle's Door: Lessons from a Freethinking DogValutazione: 4 su 5 stelle4/5 (326)

- Life Is Not an Accident: A Memoir of ReinventionDa EverandLife Is Not an Accident: A Memoir of ReinventionValutazione: 3.5 su 5 stelle3.5/5 (7)

- Crazy for the Storm: A Memoir of SurvivalDa EverandCrazy for the Storm: A Memoir of SurvivalValutazione: 3.5 su 5 stelle3.5/5 (217)

- Becky Lynch: The Man: Not Your Average Average GirlDa EverandBecky Lynch: The Man: Not Your Average Average GirlValutazione: 4.5 su 5 stelle4.5/5 (18)

- Body Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialDa EverandBody Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialValutazione: 4 su 5 stelle4/5 (2)

- Bloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyDa EverandBloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyValutazione: 4 su 5 stelle4/5 (8)

- Patriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionDa EverandPatriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionValutazione: 3.5 su 5 stelle3.5/5 (30)

- The TB12 Method: How to Achieve a Lifetime of Sustained Peak PerformanceDa EverandThe TB12 Method: How to Achieve a Lifetime of Sustained Peak PerformanceValutazione: 3.5 su 5 stelle3.5/5 (21)

- Can't Nothing Bring Me Down: Chasing Myself in the Race Against TimeDa EverandCan't Nothing Bring Me Down: Chasing Myself in the Race Against TimeValutazione: 4 su 5 stelle4/5 (1)

- Badasses: The Legend of Snake, Foo, Dr. Death, and John Madden's Oakland RaidersDa EverandBadasses: The Legend of Snake, Foo, Dr. Death, and John Madden's Oakland RaidersValutazione: 4 su 5 stelle4/5 (15)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsDa EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNessuna valutazione finora

- Peak: The New Science of Athletic Performance That is Revolutionizing SportsDa EverandPeak: The New Science of Athletic Performance That is Revolutionizing SportsValutazione: 5 su 5 stelle5/5 (97)

- Earnhardt Nation: The Full-Throttle Saga of NASCAR's First FamilyDa EverandEarnhardt Nation: The Full-Throttle Saga of NASCAR's First FamilyValutazione: 3.5 su 5 stelle3.5/5 (7)

- Relentless: From Good to Great to UnstoppableDa EverandRelentless: From Good to Great to UnstoppableValutazione: 5 su 5 stelle5/5 (788)

- What Winners Won't Tell You: Lessons from a Legendary DefenderDa EverandWhat Winners Won't Tell You: Lessons from a Legendary DefenderValutazione: 4.5 su 5 stelle4.5/5 (7)

- Showing Up: Get Comfortable Being UncomfortableDa EverandShowing Up: Get Comfortable Being UncomfortableValutazione: 5 su 5 stelle5/5 (2)

- The Inner Smile: Increasing Chi through the Cultivation of JoyDa EverandThe Inner Smile: Increasing Chi through the Cultivation of JoyValutazione: 5 su 5 stelle5/5 (18)

- The Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerDa EverandThe Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerValutazione: 4 su 5 stelle4/5 (23)

- Summary: Range: Why Generalists Triumph in a Specialized World by David Epstein: Key Takeaways, Summary & Analysis IncludedDa EverandSummary: Range: Why Generalists Triumph in a Specialized World by David Epstein: Key Takeaways, Summary & Analysis IncludedValutazione: 4.5 su 5 stelle4.5/5 (6)