Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Specifications Concrete Products Aug 08

Caricato da

vijvelDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Specifications Concrete Products Aug 08

Caricato da

vijvelCopyright:

Formati disponibili

TITLE: SPECIFICATION FOR CONCRETE PRODUCTS (Hatari Slabs & Stay Blocks)

Doc. No. Issue No. Revision No. Date of Issue Page 1 of 9

FOREWORD This specification lays down requirements for Concrete Products (Hatari Slabs and Stay Blocks). It shall be the responsibility of the manufacturer to ensure adequacy of the design and good engineering practice in the manufacture of the Hatari Slabs and Stay Blocks for KPLC/REA. The manufacturer shall submit information which confirms satisfactory service experience with products which fall within the scope of this specification.

1. 1.1

SCOPE This specification is for Concrete Products Hatari Slabs (concrete cable covers) and Stay Blocks. This specification covers the following sizes: Hatari slab, LV Hatari slab, HT Stay block, 1/2" (12.5mm) Stay block, 3/4" (19mm) Stay block, 1" (25mm)

1.2 1.2.1 1.2.2 1.2.3 1.2.4 1.2.5

2.

REFERENCES The following documents were referred to during the preparation of this specification. In case of conflict, the requirements of this specification shall take precedence. ESI 43 91 IS 5820 BS 2484 Stay Strands and Stay Fittings for Overhead Lines. Indian Standard Specification for Precast Concrete Cable Covers. British Standard Specification for Straight Concrete and Clayware Cable Covers. Steel Fabric for the Reinforcement of Concrete. Kenya Standard Specification for Natural Aggregates for Concrete Kenya Standard Specification for Cement Part1: Composition, Specifications and Conformity Criteria for Common Cement

BS 4483 KS 02-95 KS 1725

3.

TERMS AND DEFINITIONS

TITLE: SPECIFICATION FOR CONCRETE PRODUCTS (Hatari Slabs & Stay Blocks)

Doc. No. Issue No. Revision No. Date of Issue Page 2 of 9

The definitions given in the reference standards shall apply. 4. 4.1 REQUIREMENTS OPERATING CONDITIONS

4.1.1 The concrete products shall be suitable for use in tropical conditions with temperatures of 1 C to 40 C and humi ities of up to 95%. 4.1.2 The stay block shall be buried at depths of up to 1.8m in soils of various types to act as an anchor for stay wire on overhead lines. The concrete stay blocks designated shall be used with stay rod size 6ft x 5/8 & 6ft x of 36.8kN minimum failing load, those designated 3/4" shall be used with stay rod size 8ft x 3/4" of 64kN minimum failing load while those designated 1" shall be used with stay rod size 9ft x 1" of 131.6kN minimum failing load. 4.1.3 The Hatari Slabs (cable covers) shall be laid above power cables buried underground in soils of various types. High voltage cables are buried at depths of up to 1.6m while low voltage cables are buried at depths of 0.5m. The cable covers designated LV shall be used to cover cables operating at 240/415V (low voltage) while those designated HT shall be used to cover cables operating at higher voltages up to 66kV. 4.2. DESIGN AND CONSTRUCTION

4.2.1. General 4.2.1.1 The products shall be made using Portland Cement conforming to KS1725, course aggregates not exceeding 10mm nominal size and conforming to KS0295, clean river sand and drinking quality water free from any visual contamination. The products shall not contain additional admixtures and pigments. The composition of cement, sand and course aggregates shall be such as to satisfy the requirement for transverse strength and ultimate failing load. The concrete stay blocks shall be reinforced while the cable covers shall contain no steel reinforcement. 4.2.1.2 Steel moulds shall be used in the manufacture of the products so as to ensure a smooth texture externally. The mould shall be accurately made to produce units of the dimensions, profiles and shapes shown in the drawings.

TITLE: SPECIFICATION FOR CONCRETE PRODUCTS (Hatari Slabs & Stay Blocks)

Doc. No. Issue No. Revision No. Date of Issue Page 3 of 9

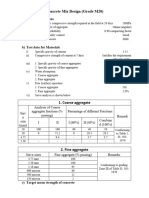

The product shall be vibrated while on mould to ensure a dense mass free from honeycombs or segregation and fill the forms and spaces between reinforcement (for concrete stay blocks) compactly and without voids. The vibrator used shall have a frequency of not less than 5000 cycles/minute and shall not be attached to or allowed to touch reinforcement during compacting. Lettering shown on the drawings (for cable covers) shall be formed using accurately placed formers securely fixed in position. Cutting either uncured or hardened concrete shall not be permitted. 4.2.1.3 Freshly placed concrete shall be suitably protected and shall be kept constantly damp for a period of at least four days after concreting. The concrete shall be allowed to dry slowly over a period of at least three days after wet curing is completed. Steel reinforcement rods shall be welded at all points of crossing and all dimensions shall be as per the drawings. Alternatively, a welded reinforcing fabric of No. 5 SWG x 75mm square with the wires symmetrically placed about the centre would be accepted. The underside of the cable cover and stay block shall be flat while the upper sides shall be peaked as shown on drawings. The concrete cable cover shall have one end concave, the other convex (as shown in drawings) to provide a concave/convex joint resisting lateral displacement. 4.2.2. Dimensions 4.2.2.1 The cable covers are required in two sizes with dimensions as shown in table 1 and drawing SK No. 08424/1 and 2. Tolerances on length (L), width (W) and thickness at outer edges (H) shall be 3mm and 2mm respectively. When tested in accordance with IS5820: 1970 (clause 8.3) the Hatari Slabs (concrete cable covers) shall withstand, without breaking, the loads given in table 1 below. Table 1: Category HT LV 4.2.2.3 Cable Cover Sizes and Transverse Strength Dimensions(LxWxH) Average Breaking mm (kg) 610 x 230 x 50 750 305 x 150 x 40 300

4.2.1.4

4.2.1.5

4.2.2.2

Load

The concrete stay blocks are required in three sizes with dimensions (including hole size) as shown in table 2 and drawing number 3 & 4. Tolerances on length

TITLE: SPECIFICATION FOR CONCRETE PRODUCTS (Hatari Slabs & Stay Blocks)

Doc. No. Issue No. Revision No. Date of Issue Page 4 of 9

(L), width (W) and thickness at outer edges (H) shall be 3mm and 2mm respectively. 4.2.2.4 When tested in accordance with ESI 43 - 91 the concrete stay blocks shall withstand, for a period of 1 minute, the ultimate failing loads given in table 2 below. Table 2: Concrete Stay Blocks- Sizes and Ultimate Failing Load. Category (size Dimensions(LxWxH) Ultimate failing load (kN) of center hole) mm (12.5mm) 500 x 380 x 50, Drg No. 3 65 3/4" (19mm) 500 x 380 x 50, Drg No. 3 65 1" (25mm) 660 x 480 x 60, Drg No. 4 65 5. 5.1 TESTS AND INSPECTION Tests for the concrete stay blocks shall be in accordance with ESI 43-91 while cable covers shall be tested in accordance with IS 5820. Certified true copies of previous test reports by the National Testing/Standards Authority of the country of manufacture shall be submitted with the offer for evaluation (all in English Language). Routine and sample test reports for the concrete products to be supplied shall be submitted to KPLC/REA for approval before delivery of the goods. MARKING AND LABELLING The upper side of each cable cover shall be marked longitudinally by means of impression with the words HATARI REA in accordance with drawing SK No. 08424/1 and 2. The word HATARI shall be impressed on one inclined face and the name REA on the other. The lettering shall be symmetrically spaced, 4mm deep and 20mm minimum height for LV cable covers and 40mm minimum height for HT cable covers. Each cable cover and stay block shall carry an impression or embossment of the manufacturers name or identifying mark. 6.2 The following information shall be marked on the manufacturers certificate supplied with the cable covers and stay blocks: Name or trademark of manufacturer; The number and date of standard to which the concrete product complies; Type of binder constituent (s) used;

5.2

5.3

6. 6.1

TITLE: SPECIFICATION FOR CONCRETE PRODUCTS (Hatari Slabs & Stay Blocks)

Doc. No. Issue No. Revision No. Date of Issue Page 5 of 9

Dimensions of the product; Instructions; (all in English Language)

ANNEX A:

Statement of Compliance and Technical Particulars (to be filled and signed by the Manufacturer for all clauses and submitted for tender evaluation) Reference page on Manufacturers catalogue, drawing, technical data or tests certificate to support the offer.

Clause Number Bidders offer

NB: - This schedule does not in any way substitute for detailed information required elsewhere in the specification.

. Manufacturers Name, Signature, Stamp and Date

TITLE: SPECIFICATION FOR CONCRETE PRODUCTS (Hatari Slabs & Stay Blocks)

Doc. No. Issue No. Revision No. Date of Issue Page 6 of 9

NOTES

1. ALL DIMENSIONS ARE IN mm. 2. WHEN MANUFUCTURING, THE MOULDS ARE TO BE ACCURATELY MADE TO PRODUCE UNITS OF THE DIMENSIONS PROFILES AND SHAPE SHOWN ON THE DRAWINGS. 3. LETTERING SHOWN ON THE DRAWING MUST BE FORMED USING ACCURATELY PLACED FORMERS SECURELY FIXED IN POSITION. CUTTING EITHER UNCURED OR HARDENED CONCRETE WILL NOT BE PERMITTED.

ISOMETRIC VIEW

50 25

50

610

230

SIDE VIEW

END VIEW

HATARI

100 410 610 100

PLAN

FIG :1 CONCRETE HATARI SLAB TO COVER H.T. CABLES

DATE APPROVED CHECKED DRAWN SCALE

26 /03/ 02 17 /11/ 01

SIGN

ISSUE

DESCRIPTION

DATE

SIGN

K. P. & L. Co LTD

S.K.K. J.M.K.

SK. NO. 08424 / 1

115

115

230

K.P.L.C.

115

115 230

75

25

75

TITLE: SPECIFICATION FOR CONCRETE PRODUCTS (Hatari Slabs & Stay Blocks)

Doc. No. Issue No. Revision No. Date of Issue Page 7 of 9

NOTES

1. ALL DIMENSIONS ARE IN mm. 2. WHEN MANUFUCTURING, THE MOULDS ARE TO BE ACCURATELY MADE TO PRODUCE UNITS OF THE DIMENSIONS PROFILES AND SHAPE SHOWN ON THE DRAWINGS. 3. LETTERING SHOWN ON THE DRAWING MUST BE FORMED USING ACCURATELY PLACED FORMERS SECURELY FIXED IN POSITION CUTTING EITHER UNCURED OR HARDENED CONCRETE WILL NOT BE PERMITTED.

ISOMETRIC VIEW

40 25

40

305

150

SIDE VIEW

END VIEW

K.P.L.C. HATARI

75

75

150

150

40

225 305

40

PLAN

FIG: 2 CONCRETE HATARI SLAB TO COVER L.V. CABLES

DATE APPROVED CHECKED DRAWN SCALE

26 /03/ 02 16 /11/ 01

SIGN

ISSUE

DESCRIPTION

DATE

SIGN

75

75

K. P. & L. Co LTD

S.K.K. J.M.K.

SK. NO. 08424 / 2

65

25

65

TITLE: SPECIFICATION FOR CONCRETE PRODUCTS (Hatari Slabs & Stay Blocks)

Doc. No. Issue No. Revision No. Date of Issue Page 8 of 9

REINFORCED CONCRETE STAY BLOCK FOR M.V. O/H LINE

65 65

30 80

80

30 50

50

25

25

Reinforcing Bars

SIDE ELEVATION

65 65

30 80

80

30 50

50

25

25

Reinforcing Bars

FRONT ELEVATION

50 Reinforcing Bars

50

50

90 1

1 90

250 500

250

PLAN VIEW

Not es

1 . All dimensions are in mm. 2.Reinforcement rods should be welded at all point s of point s of crossing. Alt ernat ively a welded reinforcing fabric of No. 5 gauge x 3'' square would be accept ed. 3. C oncret e t o be vibrat ed during manufact ure. 1 /4''

90 1

1 90

SCALE : 1: 5 Drg. No. 3 REINFORCEMENT

NUMBER LENGHT 4 AC ROSS 6 6 .5 KN TONs MANUFAC TURING FAILING LOAD

380

380

TITLE: SPECIFICATION FOR CONCRETE PRODUCTS (Hatari Slabs & Stay Blocks)

Doc. No. Issue No. Revision No. Date of Issue Page 9 of 9

REINFORCED CONCRETE STAY BLOCK FOR H.T. LINE

1 65 75 75 1 65 40 1 00

00 1

mm 25 x 5 x 25mm 25 2 ole h hole

40 60

60

Reinforcing Bars

SIDE ELEVATION

255 75 75 255 40 1 00

00 1

PERSPECTIVE VIEW

40 60

60

Reinforcing Bars

FRONT ELEVATION

Reinforcing Bars

0 1 50

1 0 50

50 380

50

65 1

50 1

60

1 50 1 50

60 60

380

65 1

1 65

50

90

60

255

255

90

50 1 0

1 0

50 50

90

90

60

60

60

90

90

50 50

1 0

56 0 660

0 1

50

50

480

25mm SQ hole

60

90

1 65

90

60 480

SCALE : 1: 5 Not es

1 . All dimensions are in mm. 2.Reinforcement rods should be welded at all point s of point s of crossing. Alt ernat ively a welded reinforcing fabric of No. 5 gauge x 3'' square would be accept ed. 3. C oncret e t o be vibrat ed during manufact ure. 1 /4''

PLAN VIEW

Drg. No. 4 REINFORCEMENT

NUMBER A LENGHT AC ROSS 8 6

Potrebbero piacerti anche

- Testing Aggregates: BS 812: Part 120: 1989Documento10 pagineTesting Aggregates: BS 812: Part 120: 1989AmanNessuna valutazione finora

- MasonDocumento7 pagineMasonMichael Jherome NuqueNessuna valutazione finora

- RMCDocumento2 pagineRMCraju_mantripragadaNessuna valutazione finora

- Mix Design Specification For Low Strength Concretes Containing Recycled and Secondary AggregatesDocumento15 pagineMix Design Specification For Low Strength Concretes Containing Recycled and Secondary AggregatesASearth100% (1)

- BS For Highways TestsDocumento12 pagineBS For Highways Testsdbg2012Nessuna valutazione finora

- DSR PuneDocumento4 pagineDSR PunedigvijayjagatapNessuna valutazione finora

- Setting Time of ConcreteDocumento2 pagineSetting Time of ConcretevempadareddyNessuna valutazione finora

- Concrete Mix DesignDocumento7 pagineConcrete Mix Designtangudusrikanth513gmNessuna valutazione finora

- Final Aac PDFDocumento7 pagineFinal Aac PDFindrajit sodhaNessuna valutazione finora

- Why Do HPC and SCC Require A Longer Mixing Time PDFDocumento7 pagineWhy Do HPC and SCC Require A Longer Mixing Time PDFHuseyin OzturkNessuna valutazione finora

- BricksDocumento15 pagineBricksKeysang WangmoNessuna valutazione finora

- BS 6073-2Documento14 pagineBS 6073-2TAMRAIZNessuna valutazione finora

- Bs en 206Documento13 pagineBs en 206tuyen.nguyenNessuna valutazione finora

- Concrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDocumento5 pagineConcrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDattatreya DattuNessuna valutazione finora

- Sika Carbodur Plate PdsDocumento6 pagineSika Carbodur Plate PdsJesieca SiemaNessuna valutazione finora

- Concrete Mix DesignDocumento21 pagineConcrete Mix DesignIftikhar KamranNessuna valutazione finora

- Design of Block PavementsDocumento12 pagineDesign of Block PavementsPurdiansyahNessuna valutazione finora

- Full FM 5-428 Concrete MasonryDocumento337 pagineFull FM 5-428 Concrete MasonrycitizenkanegNessuna valutazione finora

- 10 - TDS - Emaco S22 NBDocumento3 pagine10 - TDS - Emaco S22 NBaahtagoNessuna valutazione finora

- 480.5-97admixture - Capilary AbsorbtionDocumento10 pagine480.5-97admixture - Capilary AbsorbtionRed FolderNessuna valutazione finora

- Cement Reinforced With Steel FibreDocumento2 pagineCement Reinforced With Steel FibreMaheswara VarmaNessuna valutazione finora

- Flamex Fire ProtectionDocumento4 pagineFlamex Fire ProtectionTori SmallNessuna valutazione finora

- Concrete SpecificationDocumento28 pagineConcrete SpecificationAsad Jamil JawandaNessuna valutazione finora

- Shoring and Purlins Layout PDFDocumento1 paginaShoring and Purlins Layout PDFDexter Lex F. SatanaNessuna valutazione finora

- Conplast SP432MSDocumento2 pagineConplast SP432MSTori Small100% (1)

- Slippage Calculations For Precast Prestressed Hollowcore SlabsDocumento4 pagineSlippage Calculations For Precast Prestressed Hollowcore SlabsAnonymous cG5MyHM100% (1)

- Astm C 618 02 1Documento4 pagineAstm C 618 02 1Ciro Arnold Gonzales PauccarNessuna valutazione finora

- (BS en 678-1994) - Determination of The Dry Density of Autoclaved Aerated Concrete.Documento10 pagine(BS en 678-1994) - Determination of The Dry Density of Autoclaved Aerated Concrete.محمود عبد الحكيم YoungChemistNessuna valutazione finora

- 2918 Mapeproof 1k Turbo UkDocumento4 pagine2918 Mapeproof 1k Turbo UkFloorkitNessuna valutazione finora

- ASTM C 226 Standard Specification For Air-Entraining Additions For Use in The Manufacture of Air PDFDocumento4 pagineASTM C 226 Standard Specification For Air-Entraining Additions For Use in The Manufacture of Air PDFRyan LasacaNessuna valutazione finora

- Allowable Bearing CapacityDocumento6 pagineAllowable Bearing CapacityJomari CapariñoNessuna valutazione finora

- Final PDF of Standard SpecificationDocumento179 pagineFinal PDF of Standard SpecificationabualamalNessuna valutazione finora

- (BS en 12350-5 - 2009) - Testing Fresh Concrete. Flow Table TestDocumento14 pagine(BS en 12350-5 - 2009) - Testing Fresh Concrete. Flow Table TestAdel A. AbdelazizNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento18 pagineDisclosure To Promote The Right To Informationsudhir5441Nessuna valutazione finora

- Concrete Mixed Design Method (BS Method)Documento11 pagineConcrete Mixed Design Method (BS Method)CocoNessuna valutazione finora

- Hot - Weather Creaton 2Documento7 pagineHot - Weather Creaton 2Pankaj PriyadarshiNessuna valutazione finora

- Ccanz tm35 PDFDocumento246 pagineCcanz tm35 PDFcristiano68071Nessuna valutazione finora

- Duracord & Durasheet 40/100: Bond-Breaker and Closed-Cell Back-Up Material For Use With Joint SealantsDocumento2 pagineDuracord & Durasheet 40/100: Bond-Breaker and Closed-Cell Back-Up Material For Use With Joint SealantspbodooNessuna valutazione finora

- BS 8204 BondingDocumento1 paginaBS 8204 BondingNicola BeechNessuna valutazione finora

- Sikatherm® Foam 45 IN: Product Data SheetDocumento4 pagineSikatherm® Foam 45 IN: Product Data SheetTarun KumarNessuna valutazione finora

- C87-C87M - 10Documento4 pagineC87-C87M - 10Jesus Luis Arce GuillermoNessuna valutazione finora

- 09 - PEX20 Screed & Concrete FloorDocumento4 pagine09 - PEX20 Screed & Concrete FloorIbrahim SahinNessuna valutazione finora

- MS - CHRYSO Tapelastic Premia (Kalpitiya)Documento3 pagineMS - CHRYSO Tapelastic Premia (Kalpitiya)Kasun HewagamaNessuna valutazione finora

- R-Kem II Masonry - OptDocumento7 pagineR-Kem II Masonry - OptGnomo GnominNessuna valutazione finora

- Methods of Test For Mortar For Masonry: BSI Standards PublicationDocumento14 pagineMethods of Test For Mortar For Masonry: BSI Standards PublicationbihrajanNessuna valutazione finora

- Repair of Damage With Exposed Steel ReinforcementDocumento4 pagineRepair of Damage With Exposed Steel ReinforcementMohamed NkNessuna valutazione finora

- BS 812-110 1990 AcvDocumento13 pagineBS 812-110 1990 AcvRed FolderNessuna valutazione finora

- ACI Method of Concrete Mix DesignDocumento7 pagineACI Method of Concrete Mix DesignMuhammad Ave SenaNessuna valutazione finora

- Bs 6717 2001 Requirements and Test MethodsDocumento118 pagineBs 6717 2001 Requirements and Test MethodsAamer KhawajaNessuna valutazione finora

- Use of Control Charts in The Production of Concrete: by Ian Gibb and Tom Harrison October 2010Documento55 pagineUse of Control Charts in The Production of Concrete: by Ian Gibb and Tom Harrison October 2010Henock ShewasemaNessuna valutazione finora

- MS005 Block WorkDocumento5 pagineMS005 Block WorkMhando Ignas100% (1)

- Dimensions Tolerance SpecificationDocumento12 pagineDimensions Tolerance SpecificationProfessor Dr. Nabeel Al-Bayati-Consultant Engineer0% (1)

- TDS - IPNet SystemDocumento2 pagineTDS - IPNet SystemRadha KrishnanNessuna valutazione finora

- C 931 - C 931m - 04 Qzkzms9dotmxtqDocumento3 pagineC 931 - C 931m - 04 Qzkzms9dotmxtqHumberto GutierrezNessuna valutazione finora

- MIS GeneralSpecificationCorrugatedContainersComponents en 2010-04-30Documento18 pagineMIS GeneralSpecificationCorrugatedContainersComponents en 2010-04-30Yasser BadrNessuna valutazione finora

- FRP Tank Specifications PDFDocumento5 pagineFRP Tank Specifications PDFRagh100% (1)

- Techinical Specifications Welcome To NescoDocumento54 pagineTechinical Specifications Welcome To NescotejzabNessuna valutazione finora

- API Rev.1Documento36 pagineAPI Rev.1Ismail KarmanaNessuna valutazione finora

- Circuit PlateDocumento8 pagineCircuit PlateMosa Elnaid ElnaidNessuna valutazione finora

- C 1032 - 96 r02 QzewmzitukveDocumento5 pagineC 1032 - 96 r02 QzewmzitukveHumberto GutierrezNessuna valutazione finora

- Vernacular Architecture in KashmirDocumento6 pagineVernacular Architecture in KashmirGUNJAN33% (3)

- Definition of Vessel 10. History: GSK SyllabusDocumento4 pagineDefinition of Vessel 10. History: GSK SyllabusjrnaqviNessuna valutazione finora

- ActiveReport ArCacheItemDocumento204 pagineActiveReport ArCacheItemAnilbishtNessuna valutazione finora

- Discografia Van Halen Live Right Here Right Now 1993Documento6 pagineDiscografia Van Halen Live Right Here Right Now 1993rodrigues_franc1565Nessuna valutazione finora

- Post Tensioned Concrete Case Study PDFDocumento6 paginePost Tensioned Concrete Case Study PDFShaurya Chauhan0% (1)

- Bridges of LoveDocumento4 pagineBridges of LoveRobertKiener100% (2)

- Design of Reinforced Concrete Structures IDocumento5 pagineDesign of Reinforced Concrete Structures IWissam NadirNessuna valutazione finora

- Building Technology (ALE Review 1)Documento1 paginaBuilding Technology (ALE Review 1)Jehan MohamadNessuna valutazione finora

- Design of Steel Footbridges 2005Documento36 pagineDesign of Steel Footbridges 2005Richard FangNessuna valutazione finora

- Report JCBDocumento18 pagineReport JCBAshok KumarNessuna valutazione finora

- Concrete Hollow Block MasonryDocumento15 pagineConcrete Hollow Block MasonryManju Civil PNessuna valutazione finora

- Guide To Choose An Overhead CraneDocumento4 pagineGuide To Choose An Overhead CraneyufeigroupNessuna valutazione finora

- Pavement HistoryDocumento5 paginePavement HistoryHiramNessuna valutazione finora

- HangingDocumento7 pagineHangingCebeiller Sdn BhdNessuna valutazione finora

- NROchre Rad Ban Heavy Aggregate Barite BrochureDocumento2 pagineNROchre Rad Ban Heavy Aggregate Barite BrochureNew Riverside Ochre Company, Inc.Nessuna valutazione finora

- Good Construction Practice Book CBRI 2017Documento36 pagineGood Construction Practice Book CBRI 2017Muhammed NaseefNessuna valutazione finora

- Peri Formwork Scaffolding EngineeringDocumento20 paginePeri Formwork Scaffolding Engineeringfarshan296015100% (3)

- BOQ and MeasurmentDocumento12 pagineBOQ and MeasurmentBipin Ramesh JainNessuna valutazione finora

- Estimate For Proposed Residence Of: Mr. M.P.G. Sanath Wasantha LalDocumento10 pagineEstimate For Proposed Residence Of: Mr. M.P.G. Sanath Wasantha LalchathuragunarathnaNessuna valutazione finora

- Road BOQDocumento129 pagineRoad BOQSunil Kumar GeraNessuna valutazione finora

- Specialty BitsDocumento19 pagineSpecialty BitsEric EngelkeNessuna valutazione finora

- Road StructureDocumento10 pagineRoad StructureMohammed NawzanNessuna valutazione finora

- Tupi NHSDocumento6 pagineTupi NHSRimar LiguanNessuna valutazione finora

- SarfDocumento51 pagineSarfSantosh ThakurNessuna valutazione finora

- Package II Part I.4.1 BOQ SumpDocumento4 paginePackage II Part I.4.1 BOQ Sumpdox4useNessuna valutazione finora

- Kemper Arena CollapseDocumento4 pagineKemper Arena Collapseapi-357035617Nessuna valutazione finora

- BOQ - Al Quoz 4Documento42 pagineBOQ - Al Quoz 4Amy Fitzpatrick100% (2)

- Tyoes of Steel ConstructionDocumento1 paginaTyoes of Steel ConstructionIshwarya SrikanthNessuna valutazione finora

- Reinforced Concrete WorksDocumento5 pagineReinforced Concrete WorksRanjith EkanayakeNessuna valutazione finora

- Sheet PileDocumento20 pagineSheet PileLah HensemNessuna valutazione finora