Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Os Jaison (Repaired) 2

Caricato da

Arun Sankar PCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Os Jaison (Repaired) 2

Caricato da

Arun Sankar PCopyright:

Formati disponibili

ORGANIZATION STUDY AT KEL LTD

CHAPTER-1 INTRODUCTION

IMK, ALAPPUZHA

Page 1

ORGANIZATION STUDY AT KEL LTD

INTRODUCTION

KERALA ELECTRICAL AND ALLIED ENGINEERING COMPANY LIMITED (KEL) Mamala Unit has a vital share in manufacturing the Distribution Transformers in the market. The electricity is an inevitable factor in the modern world. The distribution transformers help to improve the voltage capacity when the electricity is being distributed. KEL produces these distribution transformers for various electricity boards all over India. KEL has secured 70% of the market in Kerala alone. With foreign collaboration, KEL facilitates the modern technology for producing high quality transformers. The KEL Mamala Unit has two production divisions, namely, Transformer Division and Structural Division. The transformer division has been manufacturing the distribution and medium power transformers. KEL is the largest manufacturers of distribution transformers. The capacity of distribution and medium power transformers is up to 3000 KVA, 33 KV class with an annual production capacity of 600000 KVA. National Test House, various State Electricity Boards and Power Corporations in India have approved the transformers. Structural division is the manufacturers of fabricated hydraulic control gates and hoists. Design fabrication and commissioning of hydraulic gates, hoists and controlling equipment for power and irrigation projects, pressure vessels and other industrial structures are manufactured by structural division of KEL Mamala. The main clients are Indian Railways, Dam projects etc. The concerned clients have inspected these products. An organization study is a study which gains knowledge about the overall working of an organization. An organization study is manly conducted to understand the various activities, departmental structure, functions, previous performance, future plansetc. In an organization study data can be collected through interview, previous records, and direct observation of organization etc. An organizational study involves the study of the structure and functioning of its departments. Organizing is one of the important functions of Management. Almost all the organizations are different but they have certain common features. All are collection of people, linked together by formal and informal relationships. They have hierarchical orders that are engaged in co-operative activities and they all have identical boundaries. So the study of people in organization is important for future managers. Structure of an organisation is very important for its functioning and growth. It provides the basic frame work for its progress and expansion. For future

IMK, ALAPPUZHA

Page 2

ORGANIZATION STUDY AT KEL LTD

managers it is imperative to study the organisational structure and functioning of successful organisations so that they as future managers may guide organisations towards success and profitable functioning

1.1 OBJECTIVES OF THE STUDY

To have an idea about the organizational structure and its levels followed in KEL. To gain practical knowledge of the systems and procedures of various departments in the organization. To enable to create good relation between officials. To know about the quality system prevailing. To know about the product and process. To have an exposure of the work environment. To identify the theory and practical difference in process of an organization. To understand how information is used by the organization for decision making at different levels.

1.2 SCOPE OF THE STUDY

The study is thoro ughly focused on the Organizational performance and understanding about almost all activities of different departments of KEL, the authority responsibility relation and making a clear awareness about the overall environment of organization. The study gives a clear cut picture regarding the customers response in purchasing transformers. The company is very much capable to understand their expectation and needs also.

1.3 METHODOLOGY USED

The entire study is based on two types of data provided by the company and they are mainly: 1. Primary data and 2. Secondary data

IMK, ALAPPUZHA

Page 3

ORGANIZATION STUDY AT KEL LTD

Primary data is obtained through direct observation and direct interview method. The data is collected through the following sources:

Observation

By observing the general environment and day to day operations of the company, many data related to the company were collected.

Interview

Another method used for collecting the primary data is personal interview with the managers and other staff of different departments. The secondary data is obtained from the sources like: Company Annual Reports Company Manuals Company Records Websites Previous Reports Magazines etc

1.4 CHAPTERISATION

Cauterization is done on the basis of grouping of activities of various departments of the organization. The entire project report is divided into seven chapters as described below: CHAPTER 1 The first chapter is the introductory chapter and includes the objectives of the study, scope of the study, methodology, limitations of the study and chapter scheme. CHAPTER 2 The second chapter is about the industrial profile. This chapter include the world, Indian, and state scenario of the industry.

IMK, ALAPPUZHA

Page 4

ORGANIZATION STUDY AT KEL LTD

CHAPTER 3 The third chapter is about the Company profile and it includes business history, competitors, company vision and mission, product profile and organisation structure. CHAPTER 4 The fourth chapter describes departmental details and this chapter includes each Departments Structure, Functions, Procedures and Policies and Programmes. CHAPTER 5 The fifth chapter includes the strength, Weakness, opportunities and Threat of the company. CHAPTER 6 Porter's five forces include - three forces from 'horizontal' competition: threat of substitute products, the threat of established rivals, and the threat of new entrants; and two forces from 'vertical' competition: the bargaining power of suppliers and the bargaining power of customers. CHAPTER 7 The seventh chapter carries the findings and suggestions of the organizational study conducted at Kerala Electricals and Allied Engineering Company Ltd. CHAPTER 8 It also include conclusion, and bibliography

1.5 LIMITATIONS OF THE STUDY

More attention has been taken for analysis but they are subjected to certain limitations also. The main limitations of the study are The time of the study is one of the major limitations. It has only two weeks, which was not sufficient in Study deeply.

IMK, ALAPPUZHA

Page 5

ORGANIZATION STUDY AT KEL LTD

Some of the confidential company files were not shown. Accuracy of data. One of the constraints of this study is non-availability of certain information. Lack of co-operation from certain department due to their work load.

IMK, ALAPPUZHA

Page 6

ORGANIZATION STUDY AT KEL LTD

CHAPTER-2 INDUSTRY PROFILE

IMK, ALAPPUZHA

Page 7

ORGANIZATION STUDY AT KEL LTD

Power is a critical infrastructure on which the socio economic development of the country depends. Recognizing that electricity is one of the key drivers for rapid economic growth and poverty alleviation, after independence Indian government has decided to bring all new power generation, transmission and distribution in rural and urban centre under the purview of state and central government agencies. Accordingly State Electricity Boards were formed in all states. Today SEBs are the major constituents of the power sector. The commercial and industrial distribution transformers market offers a still developing case study in the informal collaborative model for a national market transformation initiative. Despite this large economy wide savings opportunity relatively little attention has been paid to commercial and industrial transformer efficiency. For new facilities, expansion or renovation of existing facilities or the rare transformer failure, choices exist which can provide substantial cost- effective energy savings. By choosing energy efficient transformers, individual commercial and industrial facilities can cut total electricity bills by 0.3% to 1.5% or more with paybacks of three to five years at national average electricity rates. Electrical Manufactures Association, the U.S Environmental Protection Agency federal purchasers represented by the Federal Energy Management Program, utility and regionally-based energy efficiency program, and energy efficiency organization. Each of these market actors has played or will play a critical role in addressing specific market barriers. Transformers A transformer is a voltage changer. Transformer industry is divided in to distribution, power and other type of transformers. The health of transformer industry depends largely on the power generation and transmission sector. The major user of this industry is the State Electricity Boards and Industries. The transformer industry in India has developed for over 50 years and has a well matured technology base. It has the technology to manufacture wide range of power transformers, distribution transformers and special transformers for welding, traction and furnaces etc. Energy efficient transformers with low losses and low noise level are also being developed to meet international requirement.

IMK, ALAPPUZHA

Page 8

ORGANIZATION STUDY AT KEL LTD

Also Indian players in the engineering segment, foraying in to turnkey projects overseas, are further adding to the demand for transformers. The demand is expected to experience double digit growth over the next few years. On other hand the

production numbers indicate a death in supply. Though on a lower base the supply has grown at a rapid rate over a longer period of time, it seems difficult to match the rate of growth in demand for the year ended April 2006, production of distribution transformers was 65131000 KVA and 256585 other transformers were produced. In light of strong demand and stringent supply, the transformer manufactures are expected to enjoy strong order book along with firm margins.

World scenario The growing presence of global participants in the Indian power and distribution transformers market is a concern for local manufactures. Understanding the importance of private participation for the growth of the market, the Indian Govt. is actively taking steps to encourage increased private investment. This report analyses the worldwide markets for Transformers (Electricity) in Millions of US$ and units. The specific product segments analyzed are Power Transformers, Distribution Transformers. One of the most important developments in the global economy in the past half century is the enormous growth in world trade. The growth of the trade share of output is probably the most commonly used piece of evidence to illustrate the increasingly globalize world economy. This growth has been dramatic, averaging 3 % per year for past 50 years. In the time period first focus on 1962-99 the merchandise export share of output tripled. The common wisdom about the cause of this growth focuses on the worldwide reductions in trade barriers brought about by several GATT agreements. This report analyses the worldwide markets for Transformers (Electricity) in Millions of US$. The specific product segments analyzed are Power Transformers, Distribution Transformers, 500-10000 KVA, 100001-30000 KVA, 30001-100000 KVA, and 100001 KVA. The report profiles 195 companies including many key and niche players worldwide such as Areva, Areva T&D, ASEA Brown BAOVERI, ABB

IMK, ALAPPUZHA

Page 9

ORGANIZATION STUDY AT KEL LTD

Powertech Transformers, Bharat Heavy Electrical Limited, Crompton Greaves Ltd, EFACEC, Ekarat Engineering Public Company Ltd, Hammond Power Solutions, Holec Resitra, IMP Power Ltd, Kirlosker Electrical Ltd, Kuhlman Electric Ltd., Nissin Electric Company, Schneider Electric SA, Siemens, Shihlin Electric & Engg Corporation and Waukesha Electric Systems. Rest of World Historic Market Review for Transformers (Electricity) by product group/segment 500-10000 KVA Transformers, 100001-30000 KVA, 30001100000 KVA, and 100001 KVA Transformers Markets Independently analyzed with annual sales figures in units for years 2001.

Indian scenario Heavy electrical company encompasses important industry sectors including power generation, transmission and distribution equipments. This also covers turbo generators, boilers, turbines, transformers, switch gears and relays. The performance of this industry is closely linked to the programmes of the country. The government of the country has an ambitious mission of Power for all 2022 as per working group on the power for 11th plan; a capacity addition of 72000MW is required. To reach wheel power, an expansion of the regional transmission network and inter regional capacity to transfer power would be essential. This will stimulate substantially demand for heavy electrical equipments. There is a strong manufacturing base for the manufacture of heavy electrical equipments in the country. The technology available in India is almost at par with in the international market barring few areas of the high voltage lines. However, items like CRGO steel and amorphous cores for low loss transformers are being important. In India transmission and distribution system is a three tier structure comprising distribution networks, state grids and regional grids. SEBs are vertically integrated as intra state distribution networks and the grids are owned and operated by SEBs. the transmission and sub transmission systems supply power to end consumers. Distribution of power to end consumer is lonely controlled SEBs and licensees in the private sector. Most of the interstate transmission links are owned and operated by power Grid Corporation of India Ltd.

IMK, ALAPPUZHA

Page 10

ORGANIZATION STUDY AT KEL LTD

The present buoyancy in Indian economy would create demand for the electrical product through industrial growth and general economic development. The power sector reforms will create large business for power sector equipment manufacturers and service providers. In the current favourable scenario, the electrical industry certainly looks forward to growth. India has a field-proven technology and capacity to manufacture a wide range of power transformers, distribution transformers and other types of special transformers. For welding, traction, furnace etc. Today, about 95% of the transformers installed in the Indian Power Network are of indigenous origin. Energy efficient transformers with low losses and low noise levels can be available to meet international requirements. The Indian transmission sector has evolved over time mainly on account of improvements in technology and systems. The power sector reforms are on a threshold of major changes that would shape the future of industry. The increased thrust on providing power for all through building additional generation capacities, improving transmission and distribution network would lead to a huge demand for power equipment manufacturers. The transformer market in India is largely unorganized with very few organized players. The key organized players in this segment are: ABB BHEL Bharat Bijlee EMCO Vijay Electricals Crompton Greaves Areva T&D India Indo Tech Transformers limited

State scenario Major players in Kerala are: Intrans Electro Components Pvt. Ltd. is an Electrical equipment manufacturing Private Limited Company, providing the entire range of High Tension 11KV

IMK, ALAPPUZHA

Page 11

ORGANIZATION STUDY AT KEL LTD

equipments for the Industries and other commercial establishments. The products manufactured are Cast Resin Transformers, Unitized Sub Stations, Load Break switch Metering Panels, Epoxy Current Transformers, Potential Transformers and epoxy molded components. The company has a rich heritage of 25 years and is a leading brand in the Kerala Market. The products are manufactured under stringent quality control standards. To diversify the product range, the promoters are putting up the second manufacturing unit at Aluva, Cochin, Kerala, India. To cater to the ever growing demand in other markets an additional Greenfield plant is being established in Tumkur, Karnataka. All the leading construction groups and factories are the esteemed clients of Intrans.

Resi Tech has been in the activity of manufacturing Epoxy resin cast switch gear components, Hi-tension current transformer and potential transformers for more than 20 years and has been enjoying a good reputation among the electrical consultancy, contractors, and industrial establishments. The products manufactured are of high standards and quality and well accepted in the market. The factory is well equipped with the latest machineries vacuum oven material handling facilities to manufacture the above products. Current scenario The Rs55bn Indian transformer industry will benefit from the strong demand expected from reforms in the power sector. We expect the industry to witness a CAGR of 30% plus in value terms over the next five years against approximately 17% CAGR in the past three years. Improved realizations and higher volumes will largely drive this growth. The government intends to add massive capacity to the generation side and create a National Grid for distribution of this power, both of which should boost demand for transformers. The funding issues for the same have been taken care by the World Bank (WB) and Asian Development Bank (ADB).

Indias transformer industry is predominantly unorganized with many small players catering to the smaller distribution transformers market. However, with times changing, many of them have graduated to the medium size category, thereby

IMK, ALAPPUZHA

Page 12

ORGANIZATION STUDY AT KEL LTD

expanding the organized players base. In order to take advantage of on coming demand, a number of companies have initiated capacity addition programs and many new players are venturing into this space.

Annual demand of about 122,679MVA expected for the next five years The countrys installed base for transformers stands at 759,240MVA per annum (till 2004 Source: CMIE). There are about 20 players in the organized segment with nine of them controlling about 60% of it. Installed annual capacity of these nine players will stand at approximately 105,154MVA by end of FY07. Demand for the equipment is expected to remain robust with the XIth Five Year Plan targeting an addition of about 68,000MW to the existing generating capacity. Assuming the historical achievement rate of 60%, we expect 61,050MW of additional generating capacity coming up over the next five years.

Coupled with this, demand will also stem from the replacement market where transformers installed 25-30 years ago will have exceeded the expected life span. In addition, exports to countries where power reforms are underway i.e. Africa and Middle East provide growth opportunity. Also, huge industrial capex lined up in power intensive industries i.e. oil and gas, metals and cement act as a booster.

Based on the above demand factors, we expect a strong annual demand of 122,679MVA for the next five years.

IMK, ALAPPUZHA

Page 13

ORGANIZATION STUDY AT KEL LTD

CHAPTER-3 COMPANY PROFILE

IMK, ALAPPUZHA

Page 14

ORGANIZATION STUDY AT KEL LTD

3.1 HISTORY

The Kerala Electricals and Allied Engineering Company Limited (KEL) were established in 1964 in the state of Kerala, India. It is fully owned by the State Government. The corporate office of the KEL is situated at Panampilly Nagar, Cochin. The company has a wide range of network of regional offices and service centres located in most of the major cities and business centres in India for effective marketing and to provide efficient after sales service for the product. The major regional offices and service centres are at New Delhi, Mumbai, Chennai, Bangalore, Hyderabad, Cochin and Thiruvananthapuram. The company has progressively expanded its range of manufactured goods and services over the years and has strategically broadened its customer base on a global level. KEL offers good quality of products and services through its various manufacturing units and services divisions, with a manpower of over 1200 which includes over 250 highly qualified and well trained professional engineers. The primary interest of a company is in the field of electrical equipment and machinery encompassing areas such as generation transmission, distribution and utilisation of electrical power. In the generating equipment side, KEL is a leading manufacturer of inductor type brushless alternators used for train lighting and airconditioning. In the field of transmission and distribution of electrical power, the companys efforts have been directed in the manufacture of transformers, switchgear, transmission line towers, substations equipment and accessories. KEL is a leading manufacturer and supplier of these items to various State Electricity Boards in India. The KEL is also experienced and competent in the erection, commissioning and maintenance of electrical power transmission and distribution network which includes H.T, L.T substation, both indoor and outdoor type, packages/utilized substations, overhead transmission line and pylons, booster stations, street lights etc. The company has four manufacturing unit located in various Districts of the state, 1. The first plant, Kundara plant in Kollam District, started its operation in the year 1964. It manufactures the inductor type brushless alternators which has been widely acclaimed and accepted by many railway systems around the world. More than 20000 such alternators in operations with the Indian Railways alone. 2. The second plant start began operation in 1968 at Mamala in Ernakulum District with the manufacture of distribution transformers of various capacities. 3. Medium level transformers and distribution transformers- up to 3000 KVA, 33 KV class with an annual production capacity of 600000 KVA.

IMK, ALAPPUZHA

Page 15

ORGANIZATION STUDY AT KEL LTD

4. The third plant at olavakkot in palakkad district, which was formerly known as MENCOS, was taken over by KEL in 1977. It provides HRC fuse and other L.T switchgear items. 5. The fourth plant was commissioned at Kasargod District in the year 1990 for the manufacture of general- purpose brushless a.c.generators; KEL has consolidated its position as a leading manufacturer of electrical equipment in India. This company is equipped with most modern facilities that include computer- aided design centre and the latest CNC machines amongst other hi-tech manufacturing and testing facilities. The KEL has a well organized Research and Development wing. All R&D activities are coordinated from corporate office, Cochin. The R&D wing of KEL has to its credit many special application generators and other products that were indigenously designed and developed. Ground Power Unit for Avro and Dornier Aircrafts 400 Hz alternators of various capacities, brushless alternators for use in automobiles replacing the DC dynamos and conventional alternators for use in automobiles replacing the DC dynamos and conventional alternators are some of the achievements of the companys R&D wing.

3.2 Strategic Intent

MISSION To constantly innovate through value addition for sustainable growth.

VISION To achieve our vision by: Applying state-of-the-art technology, processes and innovative solutions Building long term relationship with stakeholders in an environment of fair business ethics and values Creating value through sustainable and profitable growth Leveraging productivity through highly motivated and empowered team

IMK, ALAPPUZHA

Page 16

ORGANIZATION STUDY AT KEL LTD

QUALITY POLICY OF THE COMPANY Manufacture products to requirements Ensure prompt servicing Achieve continuous improvement.

MARKET POTENTIAL In all India level KEL contributes 2% need when its production is 100%. In the Kerala level KELs market potentiality is around 35 to 40% of the market requirement.

3.3 PRODUCT PROFILE

The company has two divisions, which are Transformer Division and Structural Division. 1. TRANSFORMER DIVISION

The transformer division went on stream in 1968.it has been able to carry a niche for itself in the manufacture of Medium Power Transformer and Distribution Transformers of rating up to 3000 KVA and up to 33KV class. The dual ratio transformer developed by the division has proved that its ability in capacity of product and winner in the market. Versatility is its fortune. It is adaptable to the interchangeable voltage classes, the equipment has found ready acceptance in the market. Utilized substation is another much sought after product evolved by the R&D wing and translated into a roaring success. Integrated and self-contained, the unitized substation saves in terms of space, cabling and installation expenses as well. Transformers from this division come with more special and unique features. On Load tap changers coupled with Automatic Voltage Regulators and Remote Tap Charger Control Cubicle yet another of them. Incorporation of these features has helped to ensure a steady secondary voltage supply. Fluctuations in voltage need not be a matter of concern any more. Voltage drops up to 35% are easily taken care of by these transformers equipped with O.C.T.C that too with seventeen different tap ratios opt for. These transformers have been found indispensable where continuous industrial processing involved and where uninterrupted power supply is to explicitly maintain. The innovative ideas from the Transformers divisions are backed up by a resourceful R&D team helped into small measure by the Design Department. The

IMK, ALAPPUZHA

Page 17

ORGANIZATION STUDY AT KEL LTD

relentless pursuits for perfection and uncompromising quality consciousness have been suitable rewarded by recognition and approval of the Central Power Research Institute for KEL Transformers. 2. STRUCTURAL DIVISION The Structural Fabrication shop was set up in 1967 with an installed capacity of 1200 MT per annum. The main products handled by the division, which caters to the heavy fabrication sector are: Hydraulic control gate and hoists for Power generation/irrigation projects of State Electricity Board/State Irrigation Department. Industrial building structures, Transmission Towers, Switch Yard structures etc. Pressure vessels, process equipment, storage tanks and piping etc. Equipped with sophisticated machinery, the division is competent enough to take up fabrication work of any kind to set standards. There is a centralized planning and Quality Assurance Department directly reporting to the unit head.

IMK, ALAPPUZHA

Page 18

ORGANIZATION STUDY AT KEL LTD

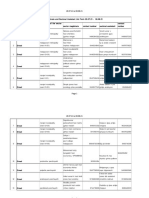

3.4 ORGANISATION STRUCTURE MAMALA UNIT

3.4.1- ORGANISATION CHART- ADMINISTRATIVE OFFICE

IMK, ALAPPUZHA

Page 19

ORGANIZATION STUDY AT KEL LTD

3.4.2- ORGANIZATION CHART- TRANSFORMER DIVISION

GENERAL MANAGER MAMALA

DGM MAINTENANCE

DGM TR DIVISION

DGM QUALITY DESIGN

MANAGER MAINTENANCE

MANAGER PRODUCTION

MANGER DESIGN

ASST. MGR PLANNING

ASST. MGR QUALITY

ASST. MGR DESIGN

ASST. ENGR REPAIR

FOREMAN

IMK, ALAPPUZHA

Page 20

ORGANIZATION STUDY AT KEL LTD

3.4.3- ORGANIZATION CHART- STRUCTURAL DIVISION

GENERAL MANAGER (S-DIV)

DGM- PLANNING & SUBCONTRACT, STR- PROD

DGM- STR- DESIGN

MANAGER DESIGN

ASST. MGR PLAN & SUB

ASST. ENG PL & SUB

ASST. MANAGER PRODUCT

ASST. MANAGER DESIGN

FOREMAN

J.O COMP

IMK, ALAPPUZHA

Page 21

ORGANIZATION STUDY AT KEL LTD

CHAPTER-4 FUNCTIONAL AREAS OF ORGANISATION

IMK, ALAPPUZHA

Page 22

ORGANIZATION STUDY AT KEL LTD

MATERIALS AND STORES DEPARTMENT

IMK, ALAPPUZHA

Page 23

ORGANIZATION STUDY AT KEL LTD

4.1 Material and Stores Department

KEL has a Material and Stores Department which purchases the materials for the companys production. This department is also known as Purchase Department. The main function of this department is to make the purchase that is required for the production and administrative department.

Policy

i. To establish and maintain the process of procurement of right material and services, at right time and at right price from approved vendors as per the production requirement and those of customers.

Objectives

i. ii. To reduce interruption of production due to delay in supply of material. To reduce the purchase cost. The Material Department ensures that good quality materials are purchased at reasonable price. The company has an ideal material control system. KEL follows the ABC analysis for the control of materials. 'A' items are very important, because of the high value and frequent value analysis are required to avoid excess capacity. B items (intergroup items) are less important than A items. C value items are those which require minimum control maintained at the minimum stock level.

Functions of materials and stores department

i. ii. iii. iv. v. vi. vii. Sub-contractors approval and codification Purchase of material Storage and preservation of purchased materials Ensuring re-inspection of store and products Release of purchase order amendments Control receipts and issue of materials Prepare monthly inventory statement

IMK, ALAPPUZHA

Page 24

ORGANIZATION STUDY AT KEL LTD

Functions of Deputy General Manager

i. ii. iii. Receive the Purchase Requisition and initiating enquiries. Verification of sub-contractors evaluation report. Preparing Purchase Committee proposals for items purchased to be approved by Corporate Office. iv. Preparation of purchase orders and verification with the checklist and follow up with supplier. v. vi. vii. Identify the items for cash purchase. Discharge material stores responsibility in his absence. Verification of invoices and bills from suppliers.

Functions of Manager

i. ii. Issue of materials. Counting/weighing of material received/issued.

Functions of Clerk

i. ii. Preparation of enquiries and receiving offers. Preparation of comparative statements, purchase committee proposals for items to be approved by the purchase committee. iii. iv. v. vi. Maintaining Purchase Committee Approval Register. Initiating purchase orders and follows up with the local suppliers. Coordinating with stores. Verification of suppliers invoice/bills and recommending payment.

Functions of Stores in charge

i. Verification of documents such as lorry receipts, invoices transport copies of invoices. ii. iii. iv. v. vi. Receipts of materials. Verification of quantity. Preparation of Goods Received Note. Intimating Quality and Assurance for incoming inspection and testing. Intimate suppliers on rejections/short supply/excess supply.

IMK, ALAPPUZHA

Page 25

ORGANIZATION STUDY AT KEL LTD

vii. viii. ix.

Maintenance of all Stores Registers. Planning storage of materials with proper identification. Identifying shelf life item requiring inspection and preparing report on this for Quality and Assurance inspection.

x.

Correlation of documents in the case of supplier is replacing a rejected lot/supply materials in batches for the same purchase order.

xi.

Preparation of monthly inventory statement.

Programmes and procedure

Purchase procedure

Material purchase 1. Maintenance and structural division maintains and updates a master list of purchased products/services within the scope of this procedure. Such lists are approved by material department. 2. Material department documents and maintain purchasing requirements as guidelines duly approved by the general manager. 3. 4. Purchase is made from sub-contractors approved as per quality specification1. Where purchases are required to be made from sub-contractors not within the approved lists, such lists are approved by the General Manager through waiver notes. 5. Purchase activity is initiated against purchase requisition/purchase notice form user departments. 6. Purchase requisition is raised in respect of requirements specific to the production and purchase notice is raised in respect of standard products for which reorder level are identified. 7. The mode of purchasing such as inviting quotation and bid evaluation or direct purchase is based on the documented purchasing requirements guidelines. 8. Purchase is authorized by a committee consisting of GM, Material Finance and Accounts and the user departments representatives. Depending on the assigned

IMK, ALAPPUZHA

Page 26

ORGANIZATION STUDY AT KEL LTD

authority in relation to value, where required the authorization obtained from the corporate office through Purchase Approval Form. 9. The particulars of purchase committee approval are maintained in the Purchase Committee Approval Register. 10. On finalizing purchase on the basis of guidelines/authorization, purchase order is raised and purchasing data is verified for their correctness by the designed personnel in the department. 11. A purchase order check list is prepared in evidence of verifying the purchasing data. 12. The purchase order is made in 6 copies. The copies are made available to Material, Quality Assurance, and Finance and Accounts Department. Two copies are for retention with Maintenance and Structural division. 13. The purchasing activities such as release of purchase orders, progress in supply of products and results of receiving verification are recorded and monitored with the aid of Purchase Monitoring Register for all purchase made in the structural divisions and for purchase of lamination, conductor and radiator and current Transformer Division. 14. The purchase order is raised in respect of purchase against already made authorization. 15. Cash purchases are made without raising Purchase Orders, limiting value to Rs.5000 on approval of requisition cash purchases by materials. 16. Purchases by sub contracting process are made on the basis of quality specification. 17. Verification of sub contracted jobs items are carried out by the sub contractors premises where so required. 18. The verification of purchased product is carried out as per quality specification and work instructions. When required contractually, customer is provided facility to verify purchased product at sub contractors premises or company premises. 19. The purchase order released to sub-contractors clarify verification requirement either of Quality Assurance or customer or customers agents. It is also clarified to sub contractor that verification by Quality Assurance/customer doesnt absolve the sub-contractor of his responsibility to provide acceptable product as well as companys right and further verify products even after acceptance on receiving inspection and testing. Where purchase order is required to be amended, either a

IMK, ALAPPUZHA

Page 27

ORGANIZATION STUDY AT KEL LTD

purchase order amendment or a superseding purchase order is issued with same number of copies and distribution as in above description.

Material receipt, storage preservation and issue Procedure:1. 2. Stores in charge receive copies of purchase orders from materials. On receiving materials against purchase orders, the accompanying documents such as Lorry Receipt, Invoice, Transport copy of Invoice where applicable, Test certificates and Bill of Entry in case of imports are verified by store keeper and it found in order, items are received and entered in the Goods Receipt Register. 3. Security permits the carriers in to the company premises on verification of document and entering the verified details in the Register. 4. On receiving the Transformer Oil Tanker, the store keeper prepares Goods Received Note (GRN) and passes to Quality Assurance. Only after it is passed by Quality Assurance, the oil is unloaded. 5. 6. 7. In respect of other materials, storekeeper prepares GRN prior to inspection. All received items are accounted as per Goods Receipts Register. GRN prepared in 6 copies. 5 copies will send to Quality Assurance for carrying out inspection and testing and endorsement of results. 8. Quality Assurance endorses the test status; retain 1 copy and forward 4 copies to store in charge. 9. Materials received as barrels/drums, cartons carboys, bag, bundles, rolls, sheets/rods/flats are handled either manually or using cranes. Mechanical handling is controlled with the aid of work instructions. 10. Oil received in tankers is transferred to identify storage tanks by pipelines. 11. All material are secured as per storage plan, updated and authorized by materials. 12. Materials are stored in sub-stores attached to each production area. 13. The storage plan indicates locations of storage area of steel items on open yard, oil in tanks and sub-stores. 14. The identification/status of just received materials, passed/rejected materials and NC procedures are as per quality specification. 15. The non-conforming materials are controlled as per quality specification. 16. Only materials passed in receiving inspection are taken in to KARDEX.

IMK, ALAPPUZHA

Page 28

ORGANIZATION STUDY AT KEL LTD

17. Items held in storage for more than the specified period are subjected to reinspection and testing as per work instructions for re-testing of stored products prepared by materials. 18. The preservation of product in storage is achieved by specifying appropriate controls and application of preservation as documented by Quality Assurance issues of stored items to the user departments/sub-contracted production is made against stores requisition/loan rate. 19. The expiry date, where applicable is verified prior to issue. 20. The quality of Transformer oil held in tanks is assessed referring KARDEX/Stock and Issue Register. 21. Excess quality returns to the stores by used departments are accompanied with Store Return Note, for accounting in the KARDEX. 22. Items taken out for processes are returned and controlled with returnable gate pass/gate pass for lob work. 23. Where stock is held in stores below the minimum/re-order level, purchase activities are initiated by stores in charge. 24. A monthly inventory statement is prepared and sent to

Planning/Production/Finance and Account. 25. The activities of handling, storage, identification, control of non-conforming products and issue of materials under positive recall procedure are carried out as per work instruction

Various records of materials department 1. Purchase Requisition 2. Purchase Notice 3. Purchase Order 4. Purchase Order Checklist 5. Purchase Order Amendments 6. Purchase Approval Form 7. Cash Purchase Approval Register 8. Purchase Committee Approval Register 9. Purchase Monitoring Register

IMK, ALAPPUZHA

Page 29

ORGANIZATION STUDY AT KEL LTD

STRUCTURE OF MATERIALS AND STORE DEPARTMENT

GENERAL MANAGER

DGM-MATERIALS

Asst. Eng. MATERIALS

Asst. Eng. STR-DVN

MANAGER

Asst. Eng. Subcon.

CLERK-1

S.A STR.DVN

CLERK-2, 3

INFERNCE

The stores department in the organization always keep the required amount of raw materials for production. There is no excess investment in stock. Fully computerized record keeping is maintained in this department.

IMK, ALAPPUZHA

Page 30

ORGANIZATION STUDY AT KEL LTD

PRODUCTION DEPARTMENT

IMK, ALAPPUZHA

Page 31

ORGANIZATION STUDY AT KEL LTD

4.2 PRODUCTION DEPARTMENT

The KEL Mamala has one production department. It holds two department section, which are Planning section and Quality Assurance section. The company has two production units which are 1. Transformer Unit and 2. Structural unit PLANNING SECTION Planning section holds the responsibility of planning about the product at their different stage of manufacturing. Planning can be generally made from marketing and design department. The design department designs the stages of production. The materials department provided the materials for production in connection with sales order from marketing department. Thus the production of transformer is done in a highly planned method. POLICIES OF PRODUCTION DEPARTMENT To plan, to organize and to coordinate the activities, to achieve the targeted production, within the time frame to the needs of the organization. Quality Policy of the Company Manufacture product to the requirements, ensure prompt service and achieve continuos improvement: Environment Policy Prevention of pollution Effective utilization of resources to reduce wastage Abide by the environmental laws and regulations Continual improvement of environmental performance

IMK, ALAPPUZHA

Page 32

ORGANIZATION STUDY AT KEL LTD

FUNCTIONS OF PRODUCTION DEPARTMENT Issue work order Coordinate activities of drawing and bill of materials To check work progress Ensuring the proper utilization of resources Maintain the quality of product Carrying out preventive and break down maintenance RESPONSIBILITY OF KEY PERSONNEL Main persons of this department are: 1) Deputy General Manager Receiving work order allocates work to foreman Coordinating planning and design department Achieving production targets Identifying training needs of those reporting to them Assigning personnel process wise Maintaining working environment including safety operations 2) Manager Receiving work order and allocate works to charge in hands. Coordinating with planning and design department to get clarification Achieving production targets 3) Assistant Manager Arranging work shift Monitoring records and upkeep of quality system in the shop Preparation of weekly production report 4) Foreman Effective utilization of men and machinery Drawing of raw material from stores for the work Reporting of daily/ weekly production in time.

IMK, ALAPPUZHA

Page 33

ORGANIZATION STUDY AT KEL LTD

QUALITY POLICY OF THE COMPANY

To establish and maintain a quality system which will ensure incoming materials, in process sub-assemblies and finished products conforming to the specification. FUNCTIONAL OBJECTIVES Reduction in quality related customer complaints after delivery of the product.

STRUCTURE

MGR QA

ASST. MGR

CHARGE IN HAND SUPERVISORS

FUNCTIONS OF THE SECTION Arranging incoming material inspection as per quality plan Arranging in process inspection at the Specified Quality Assurance Checkpoints Arranging testing of finished goods at the factory or at site as and when required Verifying and preparing consignment Audit Report Arrange calibration of equipment either house/with external agencies Accepted and sign Goods Received Note for goods conforming to specification Issue non-conforming reports Sign observation sheets and certificates Sign and issue assembly inspection reported and consigned audit report Incoming materials inspection at the specified Quality Assurance Check points Final testing of transformer

IMK, ALAPPUZHA

Page 34

ORGANIZATION STUDY AT KEL LTD

Conducting consigned audit reports

RESPONSIBILITY OF KEY PERSONNEL

Main persons of this department are: 1) Manager Identifying resources for inspection and testing Planning requirements for quality Planning requirements for inspection and measurement Calibration monitoring, corrective and preventive action Statistical techniques Propose approval of sub-contractors Audit production sub contractors Carry out subcontractor performance evaluation Identifying non conforming products Stop further processing of in process non conforming products Release products to customers 2) Assistant Manager Accept and sign Goods Received Note for goods conforming to specification Issue non conforming reports Sign observation sheets and test certificates Sign and issue assembly inspection reported and consigned report 3) Charge in Hand/ Supervisor Incoming materials inspection as per quality plan In process inspection at the specified Quality Assurance Check points Final testing of transformer Conducting consigned audit reports ISO CERTIFICATION ISO 9001 ISO 14001 Quality Management System Environment Management Section

IMK, ALAPPUZHA

Page 35

ORGANIZATION STUDY AT KEL LTD

SYSTEMS AND PROCEDURES

Refer Goods received note in respect of received products as a call for receiving inspection and testing. Inspection and test requisition is received from materials stores in respect of materials held in store for more than the specified shelf life. On the basis of Goods Received Note requisition, sampling and testing of specific materials are carried out by personnel as assigned by Quality Assurance. The responsible assigned person drawn samples and carries out testing as per work instruction. The extent and nature of receiving inspection and testing is determined on the basis of the class of sub-contractors and availability of test certificates. The result of inspection and testing are recorded in Incoming Inspection report. The sample sizes characterize to be verified and acceptance criteria adopted as per Quality Assurance personnel endorses the results on Goods Received note/Requisition. In case results do not conform to requirements a product non-conformity record is revised in triplicate and 2 copies forwarded to material stores. If required General Manager as per assigned authority at the instance of material stores reviews the nature of non-conformity and permits deviation by endorsing accepted on the Product non-conformity Record. If deviation is not permitted, REJECTED status is assigned and Rejection Note sends to the sub-contractor with a copy to Finance and Accounts Departments. The customer supplied products are subjected to receiving inspection and testing in the same manner as above unsuitable products are returned to customer under intimation. Materials held in storage beyond specified shelf life are re-inspected and tested as per work instructions.

A. TRANSFORMER DIVISION

PLANNING PROCEDURE On the basis of the running contracts in hand and orders received, planning Transformer Division Department prepares a tentative production plan for each month on the basis of priority identified and discussed with General Manager

IMK, ALAPPUZHA

Page 36

ORGANIZATION STUDY AT KEL LTD

indicating production planned cost and due date of delivery in respect of each project. Copies of each plan are made available to GM, Finance and Accounts Department, Production Transformer Division Department, Materials Department and Design Department. On receipt of sale order copy relating to new orders, production plan revise for the month is prepared indicating material quantity and their value copies of the revised monthly plan are made available by the authorities. On receipt of bill of materials (advance information) and drawings from design purchase requisition is prepared as a measure of advance material planning and copy provided to material department. Purchase Requisition follow up Register monitors the flow of purchase. Based on the sale order drawings and bills of materials, work order is prepared indicating particulars of customer sale order number, drawing references operations and work to be completed. The issue of work order is controlled with the aid of Work Order Issue Register. Work order amendments based on material change or other deviations will clear by design department and issued where required and copies distributed. Issue of drawings to shop floor and sub-contract is co-ordinate and controlled by planning with aid of Drawing Issue Register. PRODUCTION PROCEDURE & PROCESS KEL manufactures distribution transformers and medium power

transformers with the capacity of 600000KVA. The works of production department are controlled by Production Manager. For producing a transformer labour will be paid up to 22%, raw material amounts to 63% and other overhead expenses up to 15% of the total cost. Transformer Division has different stages in manufacturing

transformers. In each stage one charge in hand controls the activities in that particular process. The different stages are: Core Building In this stage the frame is cut in the shape of E. Silicon steel is cutting with the E shape for frame fabrication.

IMK, ALAPPUZHA

Page 37

ORGANIZATION STUDY AT KEL LTD

Insulation and Assembly The insulation are done in core building, HV winding and LV winding. The press board is used for insulation work. Insulation helps to overcome the occurrence of short circuit. HV winding The conductors are used for the high voltage coil winding. The conductor is wounded or insulated with Double Paper Grade Strip. HV winding produces high voltage. The high voltage electricity has to be transmitted to distribution. LV winding Here also conductors are used. Low voltage coil are wound with double paper grade strip. This strip reduces the possibility of short circuit. This coil consists of low voltage electricity which comes from outside. In real process the IXth stage is core coil assembly. The core assembly, HV winding and LV winding are assembled in this stage. Terminal Gear Mounting The LV winding terminals are fixed in to a bush. The terminal gear is built with copper or aluminium. Tanking The fabrication tank has been made available through sub-contract or manufacturing the structural unit. The dried TG mounted coils are put in the tank. Then the tank has to be filled with oil. Then tightening take place. Final Testing When the production process is completed, final test conducted by company supervisor. Painting and Dispatching The final stage is painting and dispatching the transformer. Sometimes, in this stage customer can also inspect the transformer. After the payment is made by the customer, dispatching the transformer is done as the specification of the tender.

IMK, ALAPPUZHA

Page 38

ORGANIZATION STUDY AT KEL LTD

TRANSFORMER PRODUCTION PROCESS- FLOW CHART

WINDING CONDUCTOR

LAMINATION INSULATION CUTTING

CORE BUILDING

WINDING

END FRAME FABRICATION

ASSEMBLY

INITIAL DRYING

REBLADING

QA CHECK

TERMINAL GEAR MOUUNTING

QA CHECK

FINAL DRYING

TANKING

TANK

FINAL TESTING

PAINTING

DESPATCH

IMK, ALAPPUZHA

Page 39

ORGANIZATION STUDY AT KEL LTD

PRODUCTION INFRASTRUCTURE The infrastructure needed to design, manufacture and install products as per customer requirements are identified and provided. Infrastructure includes building, utilities, machines, inspection and testing devices, standards and codes, software and supporting devices. Preventive maintenance and upkeep of infrastructure is done for ensuring the capability of the infrastructure to meet the customer requirements. When there is a breakdown occurs, immediate corrective action will take. All statutory and regulatory requirements regarding the manufacturing and installation of products and environmental regulations are duly compiled. Procedure 1. On the basis of production plan for the month initially provided and update from time to time from by Planning Transformer Division based on work orders provided. 2. The materials required for the production held in material stores are drawn by producing the Stores Requisition against work order. 3. The wage of loading of materials and sequence of production operation are carried out as specified in the process sheets/assembly checked sheet. 4. Operations of machine/production process including settings and first of approval are controlled with the work instructions and by utilizing personnel of required skills. 5. Updated master list of personnel with specialized skill are approved by Planning Transformer Division are maintained by Production Transformer Division. 6. Production and labor allocation sheets duplicate are prepared and issue shift wise daily to assign qualified personnel in relation to process. 7. Drawings/specifications based on the work order are drawn from design and referenced during process:. Application codes and standards are referenced and followed. 8. The particulars of shift production are recorded in the production and labor form, indicating the operator, operation carried out and the production output including labor time. A copy of the form is forwarded to Planning Transformer Division for monitoring productivity.

IMK, ALAPPUZHA

Page 40

ORGANIZATION STUDY AT KEL LTD

9.

Stages for in-process inspection and tests are identified and carried out by Quality Assurance against assembly check sheet inspection and test status is assigned.

10. Daily production details are recorded in a daily finished goods register indicating work order wise production figures. 11. Details of monthly production at various stages are recorded in production program for taking corrective action to maintain production. 12. On completion of final assembly testing and painting and on receipt of dispatch advice from Transformer Marketing, products are dispatched by preparing the delivery chelan. 13. Dispatches are accounted and monitored through a Dispatch Register indicating customers name of work order, data and mode of dispatching items authorized by Quality Assurance are dispatched. 14. Achievements of dispatches are received against plans short falls if any analyzed for corrective and preventive action.

B. STRUCTURAL DIVISION

PLANNING PROCEDURE On the basis of running project or hand planning structured document budgetary plan for the year indicating project wise materials and their value for information of GM and Design manager. A tentative production plan is raised in each quarter on the basis of priority identified and discussed with GM. Planning Structural Division made a plan indicating months production are planned, cost and find requirement in respect of each project copies of plan are made available to GM, Finance and Accounts Department, Planning-structural Division and Stores Department. On receipt of sale order copy relating to new projects, production plan for the month is prepared indicating material quantity and the value. On receipt of bill of materials and drawings from design department, Purchase Requisition is prepared as a measure of advance material planning and copy is provided to monitoring through a Purchase Requisition follow up Register. On the basis of sale order, drawings and bill of material and work order is prepared indicating particulars of customer sale order no:, Drawing reference,

IMK, ALAPPUZHA

Page 41

ORGANIZATION STUDY AT KEL LTD

operation and work to be completed. The reverse site of that work order provides facility for production of raw materials from time to time. The issuance of work order is contracted with the width of work order Register. Work order amendments on the basis of material change or other deviations as clearly by design. At the close of each week, a weekly production report is prepared and copies made to planning structural division and Finance and Accounts Department for monitoring. For the purpose of facilitating the financial audit a Register titled Production for the month is prepared by Planning Structural Division, that production information on project use total, quantity and value.. Planning Structural Division documents order position is taken for the whole year in a register. Monthly chart is also prepared for comparative statistical projection of varieties in achievements during different of year. Short falls in achievements again analyzed and inputs provided for corrective and preventive action by Planning Structural Division.

PRODUCTION PROCEDURE & PROCESS

In this division, there are several machines. In each machine one gang is working. One gang contains three workers. These three workers are controlled by one charge in hand. A gang involves one welder, one fitter and one unskilled worker. POLICY To derive customer satisfaction through proper planning, manufacturing, installation and commissioning as per specification The machines and its uses are: 1. Gear Hobbling Machine - It is used for gear cutting. 2. Milling Machine 3. Lath Machine 4. Vending Machine - Slots, plane milling etc used for cutting - For forming thread. - Used for 12 mm pipe bending.

IMK, ALAPPUZHA

Page 42

ORGANIZATION STUDY AT KEL LTD

5. Gillette Machine

- For cutting the plate up to 12 mm.

6. Press Breaker Machine - Plates blending 90 degree the capacity up to 12mm. 7. Drilling Machine 8. Mug welding Process a) Marking b) Cutting c) Drilling d) Bending e) Setting f) Welding g) Surface preparation h) Straightening i) Painting j) keeping - Used for drilling the plates. It is used for welding.

IMK, ALAPPUZHA

Page 43

ORGANIZATION STUDY AT KEL LTD

PRODUCTION PROCESS- FLOW CHART (STRUCTURAL)

MATERIAL PREPARATION

MARKING CUTING STRAIGHTENING

ASSEMBLY

SETTING

WELDING

MACHINING

CLEANING AND PAINTING

INSPECTION

DESPATCH

IMK, ALAPPUZHA

Page 44

ORGANIZATION STUDY AT KEL LTD

Production procedure 1. On the basis of production plan for the month initially provided and update from time to time from by Planning Transformer Division based on work orders provided. 2. The materials required for the production held in material stores are drawn by producing the Stores Requisition against work order. 3. The wage of loading of materials and sequence of production operation are carried out as specified in the process sheets/assembly checked sheet. 4. Operations of machine/production process including settings and first of approval are controlled with the work instructions and by utilizing personnel of required skills. 5. Updated master list of personnel with specialized skill are approved by Planning Transformer Division are maintained by Production Transformer Division. 6. Production and labor allocation sheets duplicate are prepared and issue shift wise daily to assign qualified personnel in relation to process. 7. Drawings/specifications based on the work order are drawn from design and referenced during process:. Application codes and standards are referenced and followed. 8. The particulars of shift production are recorded in the production and labor form, indicating the operator, operation carried out and the production output including labor time. A copy of the form is forwarded to Planning Transformer Division for monitoring productivity. 9. Stages for in-process inspection and tests are identified and carried out by Quality Assurance against assembly check sheet inspection and test status is assigned. 10. Daily production details are recorded in a daily finished goods register indicating work order wise production figures. 11. Details of monthly production at various stages are recorded in production program for taking corrective action to maintain production. 12. On completion of final assembly testing and painting and on receipt of dispatch advice from Transformer Marketing, products are dispatched by preparing the delivery chelan.

IMK, ALAPPUZHA

Page 45

ORGANIZATION STUDY AT KEL LTD

13. Dispatches are accounted and monitored through a Dispatch Register indicating customers name of work order, data and mode of dispatching items authorized by Quality Assurance are dispatched. 14. On the basis of customer specified installation plan indicating the date by which materials including tools and tackles for different stages of erection should reach the site. 15. Copies of the plan are to planning Structural Division, Design Department and Material Department. 16. The tentative installation plan is received at intervals of 6 months the plan updated. 17. The site requirements are identified and documented by planning Structural Division as site requirement document. The document is reviewed and approved. 18. The site required document indicate size of temporary structures, manpower tools and tackles, consumables and sub-contracted workmen/ security personnel required for installation at different frame. 19. Actual movement of tools, tackles and materials for installation is commenced on receipt of confirmation from material stores department about the civil work completion and clearance from customer for commencement of installation work. 20. The materials held at site are adequately protected from deterioration, properly stored and their stock issue is controlled by the site personnel designated by Production Structural Division. 21. Handlings of materials at site are done using validated equipments and observing safety requirements. 22. Site status report is prepared by site engineer and forwarded to Production Structural Division and Material Stores. 23. Installation at each stage is controlled with the aid of installed check sheets. 24. On completion of installation the structure is handed over to customer only after joint inspection by customer designated person/ agency and by site engineer.

IMK, ALAPPUZHA

Page 46

ORGANIZATION STUDY AT KEL LTD

STRUCTURE OF PRODUCTION DEPARTMENT

GENERAL MANAGER

DEPUTY GM TR

DEPUTY GM STR

MANAGER TR

MANAGER STR

Asst. ENGINEER TR

Asst. ENGINEER STR

FOREMAN

FOREMAN

WORKERS

WORKERS

INFERENCE The works in the factory include both skilled and semi- skilled workers. Proper supervision is done for producing quality products and also to reduce wastage of materials

IMK, ALAPPUZHA

Page 47

ORGANIZATION STUDY AT KEL LTD

DESIGN DEPARTMENT

IMK, ALAPPUZHA

Page 48

ORGANIZATION STUDY AT KEL LTD

4.3 DESIGN DEPARTMENT

The design department draws the structural design of the product processes for the production department. Based on this design the transformer is produced with the specification of the customer. POLICIES OF DESIGN DEPARTMENT To establish and maintain a process for an optimum design conforming to customer requirement and relevant standards within a specified time. FUNCTIONS OF DESIGN DEPARTMENT Receipt the sale order from transformer marketing To ensure that the standards of the design Receipt of tender documents from the transformer marketing To ensure that the competition of design work within a specified period of time. To ensure that the changes are adopted from time to time Established and maintain the process for the design work within a specified period of time. Ensure that the feedback forwarded to transformer production section. Design planning, controlling and responsibility assignment, input and design storage reviews. Authorizing, designing, verification and initiating design changes Assign responsibility for designing Approve design outputs

RESPONSIBILITY OF KEY PERSONNEL

Main persons of this department are: 1) General Manager Overall functioning of design department keeping track Ultimate aim to meet customer satisfaction Validation, Verification, and review of product design 2) Deputy General Manager Preparation of estimation and technical details

IMK, ALAPPUZHA

Page 49

ORGANIZATION STUDY AT KEL LTD

Updating, codes, standards and its maintenance Maintenance of quality records 3) Junior Officer Presentation of drawing and specification quoted by design

SYSTEMS AND PROCEDURES DESIGN PROCESS

Obtain tender document from transformer marketing. Obtain estimates and technical specifications from the transformer marketing. Design I stage: Preliminary design for marketing quotation Study the specifications of the product included in specific tender received from the marketing department. Obtain current price of raw materials and components from material department. Make estimates for the product as per the technical specification furnished by the marketing department. Send the cost and guaranteed technical specifications to the marketing department for tendering purposes. Design II stage: Actual design of product Receipt of sale order from transformer marketing department Issue of advance intimation to production planning Make the detailed design of transformers and drawings as per the order Issue of production drawings, specification and list of drawings to planning Feedback from the transformer production section to design on time to time for manufacturing the product with customer specification Feedback of test result from quality assurance test is normally conducted in the presents of the customer consultant or representative. Test results are to be recorded and kept in a file for future reference by the design department. Design change intimation to planning from design

IMK, ALAPPUZHA

Page 50

ORGANIZATION STUDY AT KEL LTD

STRUCTURE OF DESIGN DEPARTMENT

GENERAL MANGER

DGM-Quality Design MGR

DGM-Structure Design (S.DVN)

Asst.MGR Quality

Manager Design

Manager Design

Asst.Mgr Design

Asst.Mgr Design

J.O Com.

INFERENCE Computer aided designing technology is used for producing new designs. They also buy new designs from outside artists. A record of the collection of designs are maintained in this department. .

IMK, ALAPPUZHA

Page 51

ORGANIZATION STUDY AT KEL LTD

PERSONNEL AND ADMINISTRATION DEPARTMENT

IMK, ALAPPUZHA

Page 52

ORGANIZATION STUDY AT KEL LTD

4.4 Personnel and Administration Department

The personnel and administration department is a supporting section which plans and provides manpower to all other subsystems of the organization and to itself by formulating proper recruitment and training programmes. It also monitors the performance of the employees for better direction, promotion and results. The personnel department is responsible for recruitment, selection, placement, training, performance appraisal, welfare compensation and promotion.

Policies

i. To establish and maintain a system for imparting knowledge, skill and motivation ii. Enabling employees to carry out various tasks to achieve organizational objectives. iii. iv. Impart suitable training and development to the employers as well as employees Impart training to optimize their skill and efficiency and to improve quality, productivity and human relations. This procedure covers and action training on the job training, training required for qualifying for process /safe operations, developmental training for job rotation and enlargement/ awareness of new concepts, quality management and quality system techniques, behavioral training and retraining in all these area due to changes in process technology/systems/strategies.

Functions of department

i. ii. iii. iv. v. Arranging preventive maintenance of office activities. Updating data on safely and environment requirement Maintenance of training identification records Procurement of right kind and number of persons Co-ordination with other department/function for sponsoring employees training vi. vii. In-house training management. Employee welfare measures as per approved scheme/agreements

IMK, ALAPPUZHA

Page 53

ORGANIZATION STUDY AT KEL LTD

viii. ix. x. xi. xii. xiii. xiv. xv. xvi. xvii.

Industrial relations Execution of all policies related to personnel function. Manpower planning Maintenance of personal files/records Issue circulation on training and other personnel matters. Correspondence with external bodies on statutory compliance Insurance matters on land, building, materials and products. General insurance including employees medical and accidents insurance Promotion of employees as per policy and as per agreements. Sanctioning of annual increments to employees, keeping records and registers

Functions of Manager

i. ii. iii. iv. Personnel planning for the future Proper utilization of resources Preparation of training schedules Organizing by setting up the structure of relationship among jobs, personnel and physical factors to contribute towards organization goals. v. vi. vii. viii. ix. Mobilization of talented personnel Determination of adequate and equitable compensation to employees. Ensure smooth running of business without any grievance Provide good working conditions and welfare services to employees. Ensure growth and development

Functions of junior officer

i. ii. Legal matters, keeping records of cases at different court etc. Medi claim recording, claim settlement with united India Insurance Company correspondence with insurance department.

IMK, ALAPPUZHA

Page 54

ORGANIZATION STUDY AT KEL LTD

Clerk

i. Time keeping and recording of officers, staff, apprentices and temporary employees ii. iii. iv. v. vi. vii. Arrangements of taxi, preparation of bills etc. Arrangement of remittance of tax, insurance of co-vehicles. Issuing gate passes to contract workers Remittance of contribution, maintenance of all records Reports of accidents, recording, keeping register. Intimation of recovery/ attachment of salary by courts/Kerala State Financial Enterprise/ bank etc. viii. ix. x. xi. Issue of certificates Leave surrendering, keeping records Preparation of alternate bonus Canteen recovery and recording

Programmes and procedure

Recruitment Recruitment is the process of searching for prospective employees and stimulating them to apply for jobs in the organization. For this, the company has adopted different methods. KEL is having a Centralized Recruitment System. The recruitment and selection proceedings are conducted at the head office of the company. The main advantage is i. ii. iii. It ensures effective and suitable placement of candidates The cost of recruitment per candidate Unit managers will not be disturbed by this type of recruitment.

IMK, ALAPPUZHA

Page 55

ORGANIZATION STUDY AT KEL LTD

The company has different methods for recruitment. The main sources are: 1. Advertisement The major recruitment is done through the advertisement. The advertisements are given in local or national press, trade or professional journals. The recruitment of the job is given in the advertisement. Management gets a wider range of candidates for selection through the advertisement.

2.

Employment exchange The company has also recruited employees through this method. The

vacancies may be noticed with the exchange, whenever there is a need. The exchange supplies a list of candidate fulfilling required qualification. 3. Public Service Commission Some of the staffs such as junior assistant, foreman, stenographer, driver etc. are filled through the test conducted by the Public Service Commission among the eligible candidates. Commission notifies specific vacancies by the way of newspapers, employment news.

4.

Trade unions The KEL Mamala has also recruited employees and staff through the mutual

agreement between the trade union and management. There are three recognized unions in KEL, they are KEL Employee Congress, KEL Employees Union and KEL Employee Association.

Selection and training

Selection Selection is the process of differentiating between applicants in order to identify (and hire) those with a greater likelihood of success in a job. The head office of the company selects the right person from the advertisement. The criterion for evaluation is performance, experience and qualification of the candidates. After that the interview is conducted on the basis of the result of interview, the selection is made.

IMK, ALAPPUZHA

Page 56

ORGANIZATION STUDY AT KEL LTD

Training Training is the act of increasing the knowledge and skill of an employee for doing a particular job. In KEL Mamala two types of training are given to employees 1. 2. On the job training: Given to the clerical and other staffs Off the job training: Given to the managerial staff and workers of the production plant.

Transfer and Promotion

Transfer The selected staff can be transferred to different units, where the staff is needed. The transfer does not involve any change in rank. It involves shifting of persons from the present jobs to other similar places or different places in the same job. This does not involve any change in responsibility and prestige. Transfer and promotion are dealt by the head office. Transferred promotions are done on the basis of the mutual agreement between the union and management. Transfer and promotion will be made against vacant posts whenever suitable candidates with the prescribed qualification and experience are available within the organization. But when the suitable candidates are not available, then the post will be filled up from the external source. While offering promotion to higher post, reservations are made for SC/ST. Promotion It involves shifting of persons to position carrying better prestige, higher responsibility and more salaries. The higher positions may be filled up from within the organization. It is purely made on the basis of performance, qualification and experience. Seniority is also an inevitable factor. There is a promotion policy for the company. It is usually for officers.

Performance appraisal system

Performance appraisal includes the identification, measurement and

management of human performance in organization. Assessment and motivation can motivate the workers to improve their performance. But in this organization there is

IMK, ALAPPUZHA

Page 57

ORGANIZATION STUDY AT KEL LTD

no type of performance appraisal system for employees at lower levels. Officers are given promotions according to the promotion policy rather than performance.

Shift timings

The shift timings of employees in KEL are: i. Administration Staff On week days- 9.30 AM 4.30PM On Saturdays 9.30 AM 12.30PM ii. Employees in the production department On week days 12.30 AM - 8.30AM 8.00AM - 4.30PM 4.30 PM - 12.30AM On Saturdays 8.00AM 1.00 PM 1.00 PM 4.30 PM

Punishment and misconduct

An employee guilty of misconduct may given any one of the following punishments depending upon then gravity of the misconduct. i. ii. iii. iv. v. Warning Stoppage of increment Withheld of future promotion or grade Discharge from the service Dismissal

The following shall be the procedure for punishment A charge sheet will be given to the employee concerned and he will be asked to give his explanation in case of alleged misconduct primafacie appears to be of a serious nature, suspension pending enquiry. In other case the management will decide whether a formal enquiry should be conducted, and if the decision is for an enquiry it will be conducted. The management on receipt of the explanation, issue notice to the

IMK, ALAPPUZHA

Page 58

ORGANIZATION STUDY AT KEL LTD

receipt or in the absence of the reply or the expiry of the date by which the reply is called for, the management will pass suitable orders. This process will be applicable only in cases were punishments are either reduction of rank, removal, or dismissal. In other cases, the management shall pass such orders which may be appropriate on receipt of the employees explanation.

Manpower

The company has 101 skilled workers, 52 semi skilled workers, 12 special skilled workers. Staff and security are 44 and 43 managerial persons as on 31st march 2011.

STRUCTURE OF PERSONAL AND ADMINISTRATION DEPARTMENT

GENERAL MANAGER

DGM P & A

J.O(Leg.)

J.O

INFERENCE Majority of the staff in the Personnel and administration department are experienced employees. Computerized record keeping is done in this department. This department also act as an information centre for the employees and suppliers.

IMK, ALAPPUZHA

Page 59

ORGANIZATION STUDY AT KEL LTD

FINANCE AND ACCOUNTS DEPARTMENT

IMK, ALAPPUZHA

Page 60

ORGANIZATION STUDY AT KEL LTD

4.5 Finance and Accounts Department

Finance department regulates the financial transactions of the company. The finance function provides authorization and control to all the subsystem to utilize money more efficiently through a well designed mechanism. The company prepares profit and loss accounts, balance sheet, budgets, financial performance statement, employee cost analysis etc, for the findings of the operating results, financial positions, future prospects and many of other objects. Statement of operating results derives the performance of transactions. This reveals the probability of the concern during the year. The profit of the company increases year after year.

Functions of finance department

Finance department of the company constitute the accounts and administration and cash management. i. Auditing and finalization of works with the assistance of all other members of finance department. ii. iii. iv. v. vi. vii. All the accounts relating to personal. Accounting of purchase bill. Preparation of payrolls. Accounting of bank and cash transactions Calculation of central excise Sales accounting and sales tax matters.

Functions of finance manager

i. ii. iii. iv. v. vi. vii. Estimation of capital requirements Ensuring a fair return to the investors Make sure the suitable availability of funds Laying down the optimum and suitable capital structure for the company Adequate control of cash flows. Preparation, analysis and interpretation of financial statements Facilitate maximum utilization of fund

IMK, ALAPPUZHA

Page 61

ORGANIZATION STUDY AT KEL LTD

viii. ix.

Scrutinize claims and recommend payment Issue of invoices against dispatches

Accounting policies of the company