Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Geotechnical Risk and Safety

Caricato da

Sergio Echeverría RCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Geotechnical Risk and Safety

Caricato da

Sergio Echeverría RCopyright:

Formati disponibili

GEOTECHNICAL RISK ANDSAFETY

PROCEEDINGS OF THE 2ND INTERNATIONAL SYMPOSIUM ON GEOTECHNICAL

SAFETY & RISK, GIFU, JAPAN, 1112 JUNE, 2009

Geotechnical Riskand

Safety

Editors

Y. Honjo

Department of Civil Engineering, Gifu University, Gifu, Japan

M. Suzuki

Center for Structural Safety and Reliability, Institute of Technology,

Shimizu Corporation, Tokyo, Japan

T. Hara

Department of Civil Engineering, Gifu University, Gifu, Japan

F. Zhang

Department of Civil Engineering, Nagoya Institute of Technology, Nagoya, Japan

Cover photo: Traditional cormorant fishingat theNagaraRiver, GifuCity, J apan

Courtesyof GifuSightseeingAssociation

Taylor & Francis is an imprint of the Taylor & Francis Group, an informa business

2009Taylor & FrancisGroup, London, UK

Typeset byCharonTecLtd(A MacmillanCompany), Chennai, India

PrintedandboundinGreat BritainbyAntonyRowe(A CPI-groupCompany), Chippenham, Wiltshire

All rightsreserved. Nopart of thispublicationor theinformationcontainedhereinmaybereproduced,

storedinaretrieval system, or transmittedinanyformor byanymeans, electronic, mechanical, by

photocopying, recordingor otherwise, without writtenprior permissionfromthepublisher.

Althoughall careistakentoensureintegrityandthequalityof thispublicationandtheinformationherein,

noresponsibilityisassumedbythepublishersnor theauthor for anydamagetothepropertyor

personsasaresult of operationor useof thispublicationand/or theinformationcontainedherein.

Publishedby: CRC Press/Balkema

P.O. Box447, 2300AK Leiden, TheNetherlands

e-mail: Pub.NL@taylorandfrancis.com

www.crcpress.com www.taylorandfrancis.co.uk www.balkema.nl

ISBN: 978-0-415-49874-6(Hbk)

ISBN: 978-0-203-86731-0(eBook)

Geotechnical Risk and Safety Honjo et al. (eds)

2009 Taylor & Francis Group, London, ISBN 978-0-415-49874-6

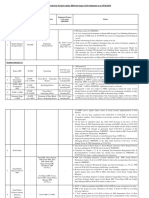

Tableof Contents

Preface IX

Organization XI

Sponsors XIII

Wilson Tang lecture

Reliabilityof geotechnical predictions 3

T.H. Wu

Keynote lectures

Riskassessment andmanagement for geohazards 13

F. Nadim

Riskmanagement anditsapplicationinmountainoushighwayconstruction 27

H.W. Huang, Y.D. Xue &Y.Y. Yang

Recent revisionof J apaneseTechnical Standardfor Port andHarbor Facilitiesbased

onaperformancebaseddesignconcept 39

T. Nagao, Y. Watabe, Y. Kikuchi &Y. Honjo

Special lecture

InteractionbetweenEurocode7 Geotechnical designandEurocode8 Designfor

earthquakeresistanceof geotechnical structures 51

P.S. Sco e Pinto

Special sessions

Reliability benchmarking

Reliabilityanalysisof abenchmarkproblemfor 1-Dconsolidation 69

J.Y. Ching, K.-K. Phoon &Y.-H. Hsieh

Studyondeterminationof partial factorsfor geotechnical structuredesign 75

T.C. Kieu Le &Y. Honjo

Reliabilityanalysesof rockslopestability 83

C. Cherubini & G. Vessia

Reliabilityanalysisof abenchmarkproblemfor slopestability 89

Y. Wang, Z.J. Cao, S.K. Au & Q. Wang

Geotechnical code drafting based on limit state design

and performance based design concepts

DevelopingLRFDdesignspecificationsfor bridgeshallowfoundations 97

S.G. Paikowsky, S. Amatya, K. Lesny &A. Kisse

V

Limit StatesDesignconceptsfor reinforcedsoil wallsinNorthAmerica 103

R.J. Bathurst, B. Huang &T.M. Allen

Lossof staticequilibriumof astructure Definitionandverificationof limit stateEQU 111

B. Schuppener, B. Simpson, T.L.L. Orr, R. Frank &A.J. Bond

Geotechnical criteriafor serviceabilitylimit stateof horizontallyloadeddeepfoundations 119

M. Shirato, T. Kohno & S. Nakatani

Reliability-basedcodecalibrationof pilesbasedonincompleteproof loadtests 127

J.Y. Ching, H.-D. Lin & M.-T. Yen

Sensitivityanalysisof designvariablesfor caissontypequaywall 135

G.L. Yoon, H.Y. Kim, Y.W. Yoon & K.H. Lee

Evaluatingthereliabilityof aleveeagainst seepageflow 141

Y. Shimizu, Y. Yoshinami, M. Suzuki, T. Nakayama & H. Ichikawa

Determinationof partial factorsfor theverificationof thebearing

capacityof shallowfoundationsunder openchannels 147

A. Murakami, S. Nishimura, M. Suzuki, M. Mori, T. Kurata &T. Fujimura

Applicationof concept inGeo-code21 toearthstructures 155

M. Honda, Y. Kikuchi &Y. Honjo

Limit statedesignexample Cut slopedesign 159

W.K. Lin & L.M. Zhang

Probabilisticchartsfor shallowfoundationsettlementsongranular soil 165

C. Cherubini & G. Vessia

Resistancefactor calibrationbasedonFORM for drivensteel pipepilesinKorea 173

J.H. Park, J.H. Lee, M. Chung, K. Kwak & J. Huh

Anevaluationof thereliabilityof verticallyloadedshallowfoundationsand

grouped-pilefoundations 177

T. Kohno, T. Nakaura, M. Shirato & S. Nakatani

Studyonrational groundparameter evaluationmethodsfor thedesignand

constructionof largeearth-retainingwall 185

Y. Yamamoto, T. Hirose, M. Hagiwara, Y. Maeda, J. Koseki, J. Fukui &T. Oishi

Systemreliabilityof slopesfor circular slipsurfaces 193

J.-Y. Ching, Y.-G. Hu & K.-K. Phoon

Correlationof horizontal subgradereactionmodelsfor estimatingresistance

of pilesperpendicular topileaxis 201

Y. Kikuchi & M. Suzuki

Risk management in geotechnical engineering

Thelongandbigtunnel fireevacuationsimulationbasedonanacceptable

level of riskandEXODUSsoftware 211

S.-Q. Hao, H.-W. Huang &Y. Yuan

Riskbaseddecisionsupport systemfor thepumpingprocessincontaminated

groundwater remediation 217

T. Hata &Y. Miyata

VI

A riskevaluationmethodof countermeasurefor slopefailureandrockfall

withaccount of initial investment 221

T. Yuasa, K. Maeda &A. Waku

Riskassessment ontheconstructionof interchangestationof Shanghai metrosystem 229

Z.W. Ning, X.Y. Xie & H.W. Huang

Challengesinmulti-hazardriskassessment andmanagement: Geohazardchain

inBeichuanTowncausedbyGreatWenchuanearthquake 237

L.M. Zhang

General sessions

Design method (1)

A studyof thenewdesignmethodof irrigationpondsusingsheet materials 247

M. Mukaitani, R. Yamamoto, Y. Okazaki & K. Tanaka

Researchonkeytechniqueof double-archtunnel passingthroughwater-erodedgroove 251

Y. Chen & X. Liu

Safetymeasuresbyutilizingtheoldridgeroadandpotential risksof land

near theoldriver alignments 257

M. Okuda, Y. Nakane, Y. Kani & K. Hayakawa

Bearingcapacityof rigidstripfootingsonfrictional soilsunder eccentricandinclinedloads 265

K. Yamamoto & M. Hira

Uncertainty

Reliabilityanalysisof slopestabilitybyadvancedsimulationwithspreadsheet 275

S.K. Au, Y. Wang & Z.J. Cao

Optimal movingwindowwidthinconjunctionwithintraclasscorrelation

coefficient for identificationof soil layer boundaries 281

J.K. Lim, S.F. Ng, M.R. Selamat & E.K.H. Goh

Soil variabilitycalculatedfromCPT data 287

T. Oka & H. Tanaka

Reducinguncertaintiesinundrainedshear strengths 293

J.Y. Ching, Y.-C. Chen & K.-K. Phoon

A casestudyonsettlement predictionbyspatial-temporal randomprocess 301

P. Rungbanaphan, Y. Honjo & I. Yoshida

Construction risk management

Reliabilityanalysisof ahydraulicfill slopewithrespect toliquefactionandbreaching 311

T. Schweckendiek, G.A. van den Ham, M.B. de Groot, J.G. de Gijt, H. Brassinga & P. Hudig

A casestudyof thegeological riskmanagement inmountaintunneling 319

T. Ikuma

Guidelinefor monitoringandqualitycontrol at deepexcavations 327

T.J. Bles, A. Verweij, J.W.M. Salemans, M. Korff, O. Oung, H.E. Brassinga &T.J.M. de Wit

A studyontheempirical determinationprocedureof groundstrengthfor

seismicperformanceevaluationof roadembankments 333

K. Ichii &Y. Hata

VII

GeoRiskScan Gettinggripsongeotechnical risks 339

T.J. Bles, M.Th. van Staveren, P.P.T. Litjens & P.M.C.B.M. Cools

Reductionof landslideriskinsubstitutingroadof Germi-Chaydam 347

H.F. Aghajani & H. Soltani-Jigheh

Risk assessment

Probabilisticriskestimationfor geohazards: A simulationapproach 355

M. Uzielli, S. Lacasse & F. Nadim

A researchproject for deterministiclandslideriskassessment inSouthernItaly:

Methodological approachandpreliminaryresults 363

F. Cotecchia, P. Lollino, F. Santaloia, C. Vitone & G. Mitaritonna

Reliability-basedperformanceevaluationfor reinforcedrailwayembankments

inthestaticloadingcondition 371

M. Ishizuka, M. Shinoda &Y. Miyata

Maximumlikelihoodanalysisof casehistoriesfor probabilityof liquefaction 379

J.Y. Ching, C. Hsein Juang &Y.-H. Hsieh

Suggestionsfor implementinggeotechnical riskmanagement 387

M.Th. van Staveren

Design method (2)

Frameworkfor evaluationof probabilityof failureof soil nail system 397

I.S.H. Harahap &W.P. Nanak

Reliabilityanalysisof embankment damsusingBayesiannetwork 405

D.Q. Li, H.H. Liu & S.B. Wu

Identificationandcharacterizationof liquefactionrisksfor high-speedrailwaysinPortugal 411

P.A.L.F. Coelho &A.L.D. Costa

Fieldcharacterizationof patternsof randomcracknetworksonvertical andhorizontal soil surfaces 419

J.H. Li & L.M. Zhang

Stochasticmethodsfor safetyassessment of aEuropeanpilot site: Scheldt 425

M. Rajabalinejad, P.H.A.J.M. van Gelder & J.K. Vrijling

A report by JGS chapter of TC23 limit state design in

geotechnical engineering practice

Codecalibrationinreliabilitybaseddesignlevel I verificationformat for geotechnical structures 435

Y. Honjo, T.C. Kieu Le, T. Hara, M. Shirato, M. Suzuki &Y. Kikuchi

Author index 453

VIII

Geotechnical Risk and Safety Honjo et al. (eds)

2009 Taylor & Francis Group, London, ISBN 978-0-415-49874-6

Preface

ISGifu(2ndInternational SymposiumonGeotechnical RiskandSafety) whichisheldon11and12J une, 2009

atNagaraInternational ConventionCenter inGifu, J apan, isasymposiumheldaspartof aseriesof conferences

organizedbyagroupof peopleinterestedingeotechnical risk andsafety. TheseconferencesincludeLSD2000

(November 2000, Melbourne, Australia), IWSKamakura(April, 2002, TokyoandKamakura, J apan), LSD2003

(J une, 2003, Cambridge, USA), Georisk 2004 (November, 2004, Bangalore, India), Taipei2006 (November,

2006, Taipei), and the 1st International Symposiumon Geotechnical Risk and Safety (1st ISGSR, October,

2007, Shanghai). Besides theseevents, this grouphas organizedtechnical sessions inmany international and

regional conferencesfromtimetotime.

Themajor themesof thissymposiumare:

Evaluationandcontrol of uncertaintiesconcerninggeotechnical structures.

Performancebasedspecifications, RBDandLSDof geotechnical structures, anddesigncodedevelopments.

Riskassessment andmanagement of geo-hazards.

Riskmanagement issuesconcerninglargegeotechnical constructionprojects.

Repair andmaintenancestrategiesof geotechnical structures.

IS Gifuissponsoredby ISSMGE, J GS andGEOSNet. Twotechnical committeesnowworkinginISSMGE

are taking lead in this symposium, namely, TC 23 Limit state design in geotechnical engineering practice

(chair Y. Honjo) andTC 32Risk assessment and management in geotechnical engineering practice (chair F.

Nadim). Theorganizers greatly appreciatethesupport provided by theJ apaneseGeotechnical Society (J GS)

onthis symposium. ASCE Geo-InstituteRAM (RiskAssessment andManagement Committee) has alsobeen

involvedinpromotingthissymposium.GEOSNet(Geotechnical SafetyNetwork)isatopic-specificinternational

platformtofacilitateandpromoteactiveinteractionontopicsrelatedtogeotechnical safetyandriskamongthe

members, particularlybetweenresearchersandpractitioners. GEOSNetwasformedatTaipei 2006inviewof the

increasinginterest andmomentumtorationalizerisksinnewdesigncodesusingreliabilityandother methods.

GEOSNet isexpectedtotakeover thisactivityandbecomeapermanent bodytoorganizethisseriesof ISGSR

conferences. For thisreason, wecall ISGifualsothe2ndInternational SymposiumonGeotechnical Safetyand

Risk(2ndISGSR).

Oneof theimportant eventsrelatedtoGEOSNet inthissymposiumistheinitiationof WilsonTangLecture

series. Thelectureisnamedtorecognizeandhonour theseminal contributionsof Professor WilsonTang, who

isoneof thefoundingresearchersingeotechnical reliabilityandrisk. GEOSNet planstohost theWilsonTang

Lectureas thekey presentationinfutureISGSR events tohonour distinguishedpeers andtheir achievements.

ThefirstWilsonTanglectureisdeliveredbyProfessorT.H. Wuof OhioStateUniversity, whoisalsooneof the

foundingresearchersinthisdomain.

Finally, theorganizers aregrateful to all thosewho havehelpedandcontributedto theorganizationof this

event.A largepartof thecreditfor theproceedingsgoestotheauthorsandreviewers.Thepublicationcostof the

proceedingsissupportedbyGrantinAidforScientificResearch, ScientificResearch(A) entitledDevelopment

and promotion of performance based design and reliability based design of geotechnical structures (Grant

No. 19206051, Y. Honjoastherepresentativeresearcher). Theorganizersaredeeplyindebtedfor thisfinancial

support.

YusukeHonjo

MakotoSuzuki

Takashi Hara

FengZhang

J une2009, Gifu, J apan

IX

Geotechnical Risk and Safety Honjo et al. (eds)

2009 Taylor & Francis Group, London, ISBN 978-0-415-49874-6

Organization

ISSMGETC23 Limit State Design in Geotechnical Engineering Practice

Honjo,Y. (Chair) Phoon, K.K. (CoreMembers)

Zhang, L.M. (Secretary) Schuppener, B. (CoreMembers)

Becker, D.E. (CoreMembers) Simpson, B. (CoreMembers)

Matsui, K. (CoreMembers) Steenfelt, J. (CoreMembers)

Paikowsky, S. (CoreMembers)

ISSMGETC32 Engineering Practice of RiskAssessment and Management

Nadim, F. (Chair) Leroi, E. (CoreMembers)

Fenton, G.A. (Secretary) ManfredNussbaumer, E.H. (CoreMembers)

Bekkouche, A. (CoreMembers) Pacheco, M. (CoreMembers)

Bolle, A. (CoreMembers) Phoon, K.K. (CoreMembers)

Ho, K. (CoreMembers) Roberds, B. (CoreMembers)

J aksa, M. (CoreMembers)

GEOSNet Board Members

Phoon, K.K. (Chair) Honjo,Y.

Becker, D.E. Horikoshi, K.

Chin, C.T. Huang, H.W.

Faber, M.H. Simpson, B.

Organizing Committee

Honjo,Y. (Chair) Nishimura, S.

Hara, T. Ogura, H.

Honda, M. Oishi, M.

Horikoshi, K. Okumura, F.

Kikuchi,Y. Ohtsu, H.

Kimura, T. Rito, F.

Kobayashi, K. Satake, M.

Kobayashi, S. Shirato, M.

Kusakabe, O. Suzuki, H.

Maeda,Y. Suzuki, M.

Matsui, K. Ueno, M.

Mizuno, H. Yamamoto, K.

Murakami, A. Yamamoto, S.

Nishida, H.

Scientific Committee

Suzuki, M. (Chair) KieuLe, T.C.

Hara, T. Zhang, F.

XI

Local Advisory Committee

Asaoka, A. Ohtani, T.

Daito, K. Okumura, T.

Hara, T. Rokugo, K.

Hinokio, M. Sato, T.

Honjo,Y. Sawada, K.

Itabashi, K. Shibuki, M.

Kamiya, K. Sugii, T.

Kodaka, T. Sugito, M.

Kojima, S. Tsuji, S.

Ma, G. Yamada, K.

Maeda, K. Yashima, A.

Nakai, T. Yasuda, T.

Nakano, M. Yoshimura,Y.

Narita, K. Yoshio, O.

Noda, T. Zhang, F.

Nojima, N.

International Review Panel

Akutagawa, S. Murakami, A.

Becker, D.E. Nadim, F.

Calle, E. Nagao, T.

Ching, J.Y. Nishida, H.

Coelho, P. Nishimura, S.

Cotecchia, F. Notake, H.

Fujita, M. Ohdo, K.

Furuta, H. Orr, T.

Han, J. Otani, J.

Hara, T. Paikowsky, S.

Harahap, I.S.H. Qunfang, H.

Heidari, S. Rajabalinejad, M.

Honda, M. (Makoto) Saito, T.

Honda, M. (Michinori) Scarpelli, G.

Horikoshi, K. Schuppener, B.

Huang, H. Schweckendiek, T.

Ichii, K. Shirato, M.

Karlsrud, K. Staveren, M.

Katsuki, S. Sutoh, A.

Kikuchi,Y. Suzuki, H.

Kitahara, T. Tafazzoli, N.

Kobayashi, A. Taghavi, A.

Kobayashi, S. Takada, T.

Kojima, K. Thomson, R.

Kusakabe, O. Uzielli, M.

Lee, S.R. Vessia, G.

Li, D. Wakai, A.

Li, X.Z. Wang,Y.

Lo, R. Yamaguchi,Y.

Maeda, K. Yamamoto, S.

Maruyama, O. Yoon, G.L.

Miyata,Y. Yoshida, I.

Mori,Y. Yoshinami,Y.

Moriguchi, S. Zhang, J.

Mukaitani, M. Zhang, L.

XII

Geotechnical Risk and Safety Honjo et al. (eds)

2009 Taylor & Francis Group, London, ISBN 978-0-415-49874-6

Sponsors

organizedbytheJ apaneseGeotechnical Society

under theauspicesof theInternational Societyfor Soil

MechanicsandGeotechnical Engineering

withsupport of geotechnical safetynetwork(GEOSNet)

XIII

Wilson Tang lecture

Geotechnical Risk and Safety Honjo et al. (eds)

2009 Taylor & Francis Group, London, ISBN 978-0-415-49874-6

Reliabilityof geotechnical predictions

TienH. Wu

The Ohio State University, Columbus, Ohio, USA

ABSTRACT: Thispaper reviewstheuseof probabilisticandstatistical methodsinreliabilityanalysis. Results

fromreliabilityestimatesarecomparedwithobservedperformancetoprovideameasureof thereliabilityof the

methodsandimproveunderstandingof theparameters. Casehistoriesof failuresinclaysareexaminedindetail.

1 RELIABILITY ANDGEOTECHNICAL

DESIGN

The concepts of risk and uncertainty are familiar

to geotechnical engineers. Since predictions are not

perfect there is always the possibility of failure or

unsatisfactory performance. Structures are designed

sothat theriskof failureisacceptablysmall. Thetwo

principlecomponents of geotechnical design arethe

calculatedrisk (Casagrande1965) andtheobserva-

tional method. Thefirst is described by Casagrande

as(1) theuseof imperfectknowledgetoestimatethe

possibleranges for all pertinent quantities that enter

intoasolution and(2) thedecisiononanappro-

priatemargin of safety, or degreeof risk taking into

considerationlossesthatwouldresultfromfailure.

Wheretheconsequenceof failureis largeandacon-

servativedesign is expensive, Terzaghi proposed the

useof theobservational method, whichisdescribed

byPeck(1969) as, "Basethedesignonwhateverinfor-

mationcanbesecured. Makeadetailedinventory of

all the possible differences between reality and the

assumptions. Then, computeon thebasis of original

assumptions, variousquantitiesthat canbemeasured

inthefield. Onthebasisof theresultsof suchmea-

surements, graduallyclosethegapsinknowledgeand,

if necessary, modify thedesignduringconstruction."

Theseconceptscanbematchedwithwell knownrela-

tions inreliability anddecisionmakingas illustrated

inFigure1and2.

InFigure1, Part(1)estimatethepossiblerange

isrepresentedbytheprobabilitydensityfunctionf (s),

wheres =theshearstrength.InPart(2),thedecision

isbasedonminimizingtheexpectedcost E(C), given

asEq.(1).InPart(3),anappropriatemarginof safety

correspondstoP

f

andlossesthat wouldresult from

failuretoC

f

inPart (4).

Figure2showstherelationshipbetweentheobser-

vational method and Bayes theorem, Eq. (2). Ele-

ment (1), Computeonthebasis of original assump-

tions, various quantities that can bemeasured in the

field, isanalogoustoP[z

i

|x

j

], wherez =performance

and x =soil property. In Element (2), the original

Figure1. Thecalculatedrisk.

assumptions is analogous to P

[x

j

], the prior prob-

ability. Element (3), on the basis of the results

of such measurements, gradually close the gaps in

knowledge, corresponds to P

[x

j

|z

i

], the posterior

probability or updated information. Element (4), if

necessary, modify thedesign, is adecision process

as describedinFig. 1. Thefollowingsections review

methods for estimating the failure probability and

updatingbyBayes theorem.

2 UNCERTAINTIESINGEOTECHNICAL

DESIGN

Uncertaintiesindesignparametersandmethodslead

to errors, which may be randomor systematic. Soil

variability is the most important source of random

error and inaccuracies or simplifications in material

and analytical models are the common sources of

systematicerrors.

Theresult is errors in predictions, represented by

the bias N, which is the ratio of the correct answer

to theprediction. N has mean N, standard deviation

[N] andcoefficient of variationO[N]. Soil variabil-

ity due to spatial variations is represented by O(x),

wherex =property.ThereisawiderangeinO(x),from

O(s

u

)=0.100.50for theundrainedshear strengthto

O(K)=2.03.0 for permeability (Lumb, 1974). The

variabilityof thepermeabilitycoefficientisthelargest

andcanrangeover morethanoneorder of magnitude

withinasoil deposit.

3

Figure2. Theobservational method.

However, in geotechnical engineering practice,

uncertaintyaboutthesubsoil stratificationisoftenthe

major issue. Terzaghis writings (e.g. Terzaghi 1929)

arefull of warnings about complications insitecon-

ditions. A well known exampleis thesoil profileat

Chicopee Dam, MA, shown in Fig. 3a. Much less

known is Fig. 3b, which shows the data Terzaghi

usedto construct Fig. 3a. Theuncertainties involved

intheextrapolationareobvious. Terzaghi recognized

the difficulty of predicting the in-situ permeability

at Chicopee Dam and, in an early example of the

observational method, provided specific instructions

onmeasurement of theseepagefromthedam. Errors

in stratification inferred from site exploration data

canbeconsideredasmappingandclassificationprob-

lems(BaecherandChristian2003).Themajorobstacle

is the difficulty of obtaining the necessary geologic

parameters.

A soil property model is often used to transform

results of laboratory or in-situ tests to the property

used for design to represent in-situ behavior of the

structure. Transformation models, or material mod-

els, are approximate and contain errors. Analytical

modelswhichincludelimit equilibriummethodsand

finite element methods (FEM) also contain errors

becauseof simplifications. Botharemodel errorsand

aresystematic.

Reliability analysis provides arational method of

evaluatingthesafetyof astructurethataccountsforall

theuncertainties.Theoriginof reliability-baseddesign

can betraced to partial safety factors. Taylor (1948)

explainedtheneedtoaccount for different uncertain-

tiesaboutthecohesional andfrictional componentsof

soil strengthandLumb(1970)usedthestandarddevia-

tiontorepresenttheuncertaintyandexpressedthepar-

tial safetyfactorsintermsof thestandarddeviations.

Inreliabilityanalysisthefailureprobabilityis

Freudenthal (1947) may be the first to provide

a comprehensive formulation of P

f

for structures.

Since the functions are complex, numerical integra-

tionisrequired.Theuseof first-order-second-moment

(FOSM) methodismoreconvenient.Animprovement

over FOSM is the use of response surface, or first-

order-reliability method (FORM). More elaborate

are simulation and stochastic methods. Simulation

has been done with stability analysis and FEM and

stochasticFEM. It isinstructivetocompareresultsof

reliabilityanalysiswithobservedperformance.Thisis

presentedinthefollowingsectionsforfailureinclays.

3 FAILURE INCLAYS

Stability of slopes on soft to medium clay under

theundrained condition is awidely studied problem

becauseit is simpleandalso becauseslopes failures

in clay are perhaps the most common among fail-

uresingeotechnical construction. Manycasehistories

areavailableandvariousreliabilityanalyseshavebeen

made.

3.1 Soil Variability

Modelsfor soil variabilityrangefromsimpleparame-

terstostochastic fields. A commonmodel represents

the mean by a trend, usually taken as a function of

depth z, and randomdepartures fromthetrend by a

standarddeviation, (s), or acoefficient of variation

(COV), O(s). Soil variability is spatially correlated

with correlation distances

x

,

z

for horizontal and

vertical directions. To account for spatial correlation

avariancereductionI

A

is usedandtheaverageof s

overaregionA hasmeanandCOV, s

A

=s, O(s

A

)=I

A

O(s), respectively(Vanmarcke1977).

For generic soil types, Rojiani et al (1991) and

PhoonandKulhawy(1999a) havesummarizedknown

data on O(s) and

x

,

z

. There is ample evidence

(Wu 2003, Wang and Chiasson 2006) that the trend

is not constant even within a small region. Exam-

ples of soil variability aregiven inTable1. Thereis

a large range in . One should note that data on

x

and

z

werevery limiteduntil the1980sandTanget

als (1976) estimatewas basedonresults fromblock

samples. If =2m(PhoonandKulhawy1999a), then

O(s

A

)0.10. Also, because of the small number of

samples, thereisanuncertaintyaboutthemeanvalue,

givenas O

o

. Thelarge for theJ ames Bay siteis to

account for thelargesegment of theslipsurfacethat

passes through a layer of lacustrine clay. This illus-

tratesthesignificanceof . Alsoshownarethevalues

4

(a) Permeability Profile at Chicopee Dam, MA. (Terzaghi and

Peck 1948) Reprinted with permission from John Wiley and

Sons.

(b) Data used by Terzaghi to construct (a)

Figure3. ChicopeeDam, MA.

fromPhoonandKulhawy(1999a) forclaysingeneral.

Uncertainty about soil stratification, or the subsoil

model, isnot includedbecauseof inadequatedata.

3.2 Model Errors

Model errorsaresystematic andincludeerrorsinthe

soil propertiesmodel andtheanalytical model. Biasin

thepropertymodel hasbeeninvestigatedbylaboratory

andin-situteststhatcomparedthepropertiesmeasured

bydifferenttests. Examplesincludetheestimateof s

u

fromresults of unconfined compression tests, vane

shear tests or conepenetration tests. Transformation

modelsandtheirreliabilitiesaresummarizedinPhoon

andKulhawy(1999b).Theengineer mustevaluatethe

resultsandexercisejudgment inestimatingthemean

andCOV of themodel error. It issubjective; thetrue

model error isof courseunknown. Table2givessome

examplesof estimatederrorsof strengthmodels. Dur-

ingearlier timestheunconfinedcompressiontestwas

thecommontest usedtomeasuretheundrainedshear

strength of soft to mediumclays. Thetwo estimates

inTable2differ inthefactors consideredandinthe

biasN

m

, andO(N

m

). Theestimatefor vaneshear test

wasbasedonthelaboratorystudiesbyLefebvreet al

(1988) onthesamesoil.

Bias in analytical models has been investigated

by comparison of results of simple models used

in practice with those of more sophisticated ones.

For limit equilibriumanalysis of slope stability, the

simple models range fromthe Fellenius method to

the Morgenstern-Price method. Sophisticated meth-

ods include FEM (Zou et al 1995) and limit anal-

ysis (Yu et al 1998). Examples of estimated model

errors for four sites are given in Table 3. The esti-

matederror for limitequilibriumanalysisisN

a

1.0,

O(N

a

)0.05. If the Fellenius method is included,

a

1.14, O(N

a

)0.05. Another factor is the dif-

ference between the plane-strain analysis and three-

dimensional analysis. The first two cases inTable 3

haveslidemassesof limitedwidth,wherethe3-deffect

is more important, while the embankment at J ames

Bayislongandaplane-strainfailureislikely.Theland-

fill atKettlementHillshasacomplicatedgeometry.A

comparison for an embankment on Bangkok Clay is

giveninCase3,Table4. Despitethedifferentsitecon-

ditions and thetimespan between theestimates, the

estimated model errors arenot very different. There

isverylittledifferencebetweenlimit equilibriumand

limit analysesfor exampleslopeswith30

--45

.

3.3 Combined Uncertainty

Thecombineduncertainty represents theerror of the

predictionmodel

Using theupper and lower limits of thevalues in

Tables13, thecombinedpredictionerrorisestimated

5

Table1. UncertaintiesduetoDataScatter.

Site Soil s kPa O(s) O

0

(m) O(s

A

) Ref.

Chicago upper clay 51.0 0.51 0.083 0.2 0.096 Tanget al.

middleclay 30.0 0.26 0.035 0.2 0.035 1976

lower clay 37.0 0.32 0.056 0.2 0.029

J amesBay lacustrineclay 31.2 0.27 0.045 40

deGroot andBaecher 1993

slipsurface

0.14 24 0.063 Christianet al. 1994

Generic clay 0.100.55 16 PhoonandKulhawy1999

x

,

For circular arcslipsurfaceandH =12m.

Table2. UncertaintiesduetoErrorsinStrengthModel.

Model Errors, N

mi

O(N

mi

) N

m

,

sample stress sample strain progress. O(N

m

)

Site, Test disturbance state anisotropy size rate failure Total Refer.

Detroit unconf. 1.15, 0.08 1.00, 0.03 0.86, 0.09 X X X 0.99, 0.12 Wu& Kraft

clay comp. 1970

Chicago

upper unconf. a) 1.38, 0.024 1.05, 0.03 1.00, 0.03 0.75, 0.09 0.80, 0.14 0.93, 0.03 Tanget al.

clay comp. b) 1.05, 0.02 1976

middle a) 1.38, 0.024 1.05, 0.03 1.00, 0.03 0.93, 0.05 0.80, 0.14 0.97, 0.03

clay b) 1.05, 0.02

lower a) 1.38, 0.024 1.05, 0.03 1.00, 0.03 0.93, 0.05 0.80, 0.14 0.97, 0.03 1.05, 0.17

clay b) 1.05, 0.02

Labrador field X 1.00, X X X X 1.00,0.15 Christian

clay vane 0.15 et al. 1994

(a) stresschange, (b) mechanical disturbance

Table3. ErrorsinAnalytical Model.

Analysis Model Error N

ai

, O(N

i

) N

a

, O(N

a

) Ref.

3-D Slipsurf. Numerical Total

Detroit, Cut =0 1.05,0.03 0.95,0.06 X 1.0, 0.067 WuandKraft 1970

Chicago, cut =0 X X X 0.98, 0.087 Tanget al. 1976

J amesBay, embankment =0 1.1,0.05 1.0,0.05 1.0,0.02 1.0,0.07 Christianet al. (1994)

Kettlement Hills, landfill c

1.1,0.16 X X 1.1,0.16 Gilbert et al. 1998

Example =0 limit eq. limit analysis 0.9, -0.01 Yuet al. 1998

tobeN 1.0, andO(N)=0.130.24forlimitequilib-

riumanalysis withcircular arc slipsurface. For total

stress analysis withs

u

, O(F

s

)=O(N). Notealsothat

soil variabilityisnot theonlysourceof uncertainty.

4 CASE HISTORIESOF FAILURES

Casehistoriesof failuresinclay areusedtocompare

theobservedperformancewithreliabilitypredictions.

This provides some measure of the reliability of

geotechnical predictions.

4.1 Reliability analysis

Table4andFig. 4showtheresultsforanumberof well

documentedcasehistories. Consider first theanalysis

byFOSM andFORM withlimit equilibriumanalysis

andwithFEM,Cases1,5,6and7.Almostall analyses,

exceptCase7,consideronlysoil variability.Thediffer-

encesinP

f

areminor.Whensimulationwasdonewith

arandomtrend, Case8, slightlyhigher failureproba-

bilitiesareobtained.Notethattheauthorscalculations

areapproximatebecauseof varioussimplificationsof

details.

Theresultsof FEM simulationarelessconclusive.

TheP

f

for St. Hilliare, calculated with thecharts of

GriffithandFenton(2004),liesbetween0.02and0.05,

depending on the spatial correlation model. This is

considerably smaller than those fromsimpler mod-

els. For the J ames Bay Dike, the FEM, which does

notincludespatial correlationbetweenelements,gives

P

f

=0.07. This is much larger than that obtained by

6

Table4. SafetyFactorsandFailureProbabilities

ReinforcedEmbankments

Site F

s

P

f

Method Reference

1 Muar Clay 1.22 limit eq. Chai & Bergado

stable 1.29 1.61 0.05 FOSM

c

1993

1.29 1.84 0.03 FORM Low&Tang1997

2 BangkokClay 1.00 limit eq. Bergadoet al 1994a

failure 1.00 limit eq. Low&Tang1997

Embankments

3 BangkokClay 1.03 limit eq. circular, ps Bergadoet al 1994b

failure 1.07 3d

0.98 limit eq. non-circ, ps

1.06 3d

0.60.8 PROBISH, (FOSM?)

dependson

x

4 BangkokClay, 0.96 limit eq. Bergadoet al 1994a

NongNgooHao

failure 1.00 FEM+limit eq. Zouet al 1995

0.99 limit eq. Low&Tang1997

5 J amesBay 1.53 2.60 0.002 limit eq. FOSM, O(j)=0 Christianet al 1994

stable 1.45 2.66 0.009

O(j)=0.07

2.71 0.003 limit eq. FORM, circular Xu& Low2006

1.18 0.12 non-circ.

1.49 0.07 FEM, FORM

1.46 0.005 limit equi. +simulation El-Ramlyet al 2002

6 Example 1.28 1.86 0.03 limit eq. FOSM

c

Low2008

1.96 0.025 FORM

Cut slopes

7 Chicago,

observedfailure 1.18 0.9 0.20 limit eq. FOSM, Tanget al 1976

redesignedslope 1.29 0.05

8 St. Hilliare 1.15

a

0.50

c

0.31

c

limit equi. j=0.85

e

Lafleur et al 1988

failure 1.30

b

0.78

c

0.22

c

FOSM

1.05

a

0.58 Stoch. limit eq. Wang& Chiasson2006

1.14

b

0.44

x

-10m

1.2

c

0.020.05

c

Stoch. FEM Griffith& Fenton2004

=1020m

=reliabilityindex.

a

=45

,

b

=34

,

c

=calculationsbyauthor,

d

correspondsto =20m,

e

j=correctionfor vaneshear test

FOSMandFORM. Also, theslipsurfacedepartscon-

siderably fromthe circular arc used in FOSM and

FORM, andis closer to thenon-circular slipsurface

analyzed by Spencers method, which has F

s

=1.18.

TheestimatedF

s

for theFEM solutionis1.3(Fig. 4).

Inbothcases, onewouldexpectthespatial correlation

distance, especiallyinthehorizontal directiontobean

important factor. At J amesBayalargesegment of the

slipsurfacepassesthroughthecomparativelyweaker

lacustrineclay layer and is agood illustration of the

influenceof subsoil stratification. It shouldbenoted

that theabovecases all havefairly well defined soil

strata. Thestudiesconcentratedontherandomdepar-

turesfromthetrend.Insomecases,uncertaintiesabout

thelayer thicknesswereconsidered.

Fig. 4 shows that generally, P

f

>0.10 for fail-

ures. The uncertainty about soil strength, O(s

A

), for

these sites is approximately 0.01. The largest com-

bineduncertainty O(N)=0.24. Whentheseareused

in the FOSM the calculated range in P

f

versus F

s

is shown by two curves, which includes most of the

case histories. The data in Figure 4 show that the

USArmyCorpsof Engineers (1995) designrequire-

ment that P

f

-310

5

shouldbeadequate. Another

sourceof empirical dataistheestimateof failureprob-

ability based on historic records. Meyerhof (1970)

estimated a range from P

f

=0.05 for O(F

s

)=0.3

to P

f

-10

3

for O(F

s

)=0.1. This includes a wide

rangeof soilsanddesignsbyunknownmethods, with

largely unknown safety factors. If one assumes that

therangeof thesafetyfactorisfrom1.31.5forall the

structures, theestimatedP

f

isshowninFig4.Therela-

tionshipbetweenF

s

andannual failureratehas been

estimatedfromperformancerecordandexpert judg-

ment(Silvaetal 2008).TheareashowninFig. 4isfor

CategoryIII andIV, whichincludefacilitieswith-

outsite-specificdesignandwithlittleornodesign.

Thehistoric records includeall types of failures and

7

Figure4. P

f

versusF

s

soliddotsdenotefailures.

arenot thesameas thecases inTable4, which per-

tainto failureintheundrainedstate, or immediately

or shortlyafter construction.

4.2 Prediction of failures

Therearemanywell-documentedcasehistoriesof fail-

ures, especiallyof slopesonclays.Theobservedfactor

of safetyof afailureis1.Theratioof observedtocalcu-

latedfactorsof safety providesanempirical measure

of the prediction bias N and O(N) is a measure of

uncertainty. A distinctionshouldbemadeonthetype

of prediction as definedby Lambe(1973). TypeA

predictions arethosemadebeforeobservationsType

B predictionsarethosemadeduringobservationsand

TypeC predictionsarethosemadeafter observations.

Consider first Type C predictions. Bishop and

Bjerrum (1960) summarized 27 slope and bearing

capacity failures inclays andvalues of F

s

calculated

with s

u

as measured by theunconfined compression

test. Thepredictionerror or bias, N =1/F

s

, hasmean

andCOV of N =1.01, andO(N)=0.06respectively.

Theprediction error O(N) is much smaller than the

rangegiven in Sec. 3.3. Tavenas and Lerouil (1980)

summarizedalmost 60slopefailures andtheF

s

cal-

culatedwiths

u

measuredbythevaneshear test. Their

results giveN =1.03, O(N)=0.17. Thesearecloser

totherangegiveninSec. 3.3.

Good examples of the reliability of Type A pre-

dictions are the symposia at Massachusetts Institute

of Technology(1975) andat KualaLumpur, Malaysia

(MalaysianHighwayAuthority 1989), 14years later.

Ineachcase, well respectedpredictorswereaskedto

predict theheight H

p

at failureof atest embankment

onclay. Theactual heightatfailure, H

f

, wasunknown

tothepredictors.Theobservedsafetyfactor is1.0and

themodel biasisN =H

f

,H

p

.

The values of N and O(N) for the two symposia

are given in Table 5. There are differences between

Table5. TypeA Predictions

MIT H

p

mean O(H

p

) N O(N)

H

f

=71.7ft 70.6ft 0.10 1.03 0.08

Malaysia

H

f

=5.4m 4.0m 0.14 1.12 0.07

the information given to the predictors at the two

symposia that are worth noting. At the MIT sym-

posium, observed embankment performance during

Stages 1and2wereknownandpredictors usedit to

calibrate their models before making the prediction

of the additional height required to produce failure.

However, theshear strengthat theendof stage2was

not known and had to be estimated. Table 5 shows

the observed and predicted embankment heights at

failure. Only the seven predictions that used ratio-

nal models to estimatetheshear strength areshown

in Table 5. Most predictors used limit equilibrium

analysis andafewusedFEM. Despitedifferent pre-

dictionmodels andassumptions, theresults arevery

consistent withN =1.03andO(N)=0.08. However,

althoughthesiteconditionsareconsideredtobewell

defined, Leonards(1982) suggestedtheprobablepres-

ence of a weak layer. Depending on the strength of

this layer and the failure surface, the safety factor

couldbebetween0.351.20, whichwouldimply that

N 1.3andO(N)0.25. This is onemoreexample

of theimportanceof thesubsoil stratificationandits

influenceonthefailuremode.

IntheMalaysiansymposium, theembankmentcon-

struction took 100 days and this was not known

to the predictors. All predictors used the initial

undrainedshear strengths. Thefiveinvitedpredictors

all predictedheights smaller thantheobserved, with

N =1.12. Theunderestimateof H

f

is likely because

the predictors did not account for the strength gain

duringconstruction. However, O(N)=0.07, whichis

small consideringthedifferent methodsandassump-

tionsused. Thesenumbersmayserveasameasureof

theuncertainty under themost favorabledesignsce-

nario.Thesepredictionerrorsarenotmuchlargerthan

those for Type C predictions and those estimated in

Table3.

Theaboveresults showthat, for thecasehistories

reviewed, thesimplemethodsusedindesignandreli-

ability analysis are generally satisfactory. However,

it must be emphasized that the cases represent very

small spectrumof thoseingeotechnical practiceand

that results fromsimplecases cannot always begen-

eralized. As an example, if oneextends theproblem

to includelong-termstability, thentheporepressure

mustbeestimated. Forslopesonunsaturatedsoils, the

suctionis strongly dependent onthesoil-water char-

acteristics(SWC). StudiesbyChonget al (2000) and

Zhangetal (2005) showthatuncertaintiesaboutSWC

alonecanresultinaO(F

s

) aslargeas0.2.Thisisabout

equal tothecombineduncertaintygiveninSec. 3.3.

8

5 COMPLEX PROBLEMS

Most design problems are far more complex than

thoseexamined in Sec. 3 and 4. Besides thesubsoil

stratification model, boundary conditions are usu-

ally difficult to determine. For slopes onunsaturated

soils, surface infiltration may control stability and

thechangeinporepressuredepends not only onthe

SWCbutalsoonrainfall characteristics.Anothercom-

plex boundary condition is the displacement of the

support systeminbracedexcavations. FEM analyses

canpredict thepressuredistributionwell under ideal-

izedconditions, but detailsof constructionprocesses,

which are difficult to predict, can have important

effect on displacements and stresses. Other complex

boundary conditions include wave loadings on off-

shorestructuresandgroundmotionfromearthquakes.

Evaluationof errorsinmanyof theinputdataisbeyond

thescopeof soil mechanics.

Wheretheuncertaintypredictedbyreliabilitymeth-

odsmaybetoolargetobeuseful for designdecisions,

theobservational methodprovidesanattractivealter-

native to evaluate the safety. There have been many

examples of the successful use of the observational

methodsincetheChicopeeDam.

6 BAYESIANUPDATING

The important role of the observational method in

solving complex design problems has already been

mentioned. Bayesian updating provides a valuable

model toevaluateobservedperformances. Itcancom-

bineinformationfromdifferentsourcesincludingsite

investigationdata, observations, andanalytical results.

EarlyexamplesincludeTang(1971), andMatsuoand

Asaoka (1978). Eq. (2) can be extended to solve

problems with several performance modes (z) and

properties (x) (Wu et al 2007). Two recent applica-

tionsservetoillustratethepotentialsof thisapproach

to complex design problems. Gilbert et al (1998)

usedupdatingtoevaluatethemobilizedshearstrength

of the clay-geosynthetic interface at the Kettlement

Hills landfill. The probability that the strength is x

i

giventhat theslopehas failedis givenby P[x

i

|z

j

] in

Eq(2), Fig. 2, whereP

[x

i

]=prior probabilitythatthe

strength x

i

, P[z

j

|x

i

]=probability that theslopefails

given the strength is x

i

, P[z

i

]=probability that the

slopefails. Theevaluationaccountsfor variousuncer-

taintiesinlaboratoryteststhatcontributetoP

[x

i

] and

inaccuraciesinthestabilityanalysisthat contributeto

P[z

j

|x

i

].

Regional records of slope performance, when

relatedtosomesignificant parameter, suchasrainfall

intensity, arevaluableasaninitial estimateof failure

probability. Cheung and Tang (2005) collected data

on failure probability of slopes in Hong Kong as a

function of age and rainfall. This was used as prior

probabilityinBayesianupdatingtoestimatethefailure

probability for aspecific slope. Thefailureprobabil-

ity based on age is P[x

i

] where i=0 =stable slope

andi =1=failure, P[z

j

|x

i

]=pdf of asdetermined

frominvestigationsfor failedslopes, and =reliabil-

ityindexfor thespecificslopeunder investigation. To

applyBayesianupdating, Eq. (2) isrewrittenas,

Theresults areused to formulateaslopemainte-

nancestrategyfor HongKong.

7 SUMMARY ANDCONCLUSIONS

The review of reliability methods emphasizes the

comparisonof reliability analysis withobservedper-

formance. Failure in soft to mediumclays is exam-

ined in detailed with well documented case histo-

ries. Thecalculatedfailureprobabilities of slopes on

clay with simplesubsoil profiles arein good agree-

ment with observed performance and provide some

confidenceinthemethods. Itisalsoclearthatformore

complex subsoil stratifications, modeling thefailure

mechanismis critical. Complex boundary conditions

wherestatistical dataareofteninsufficientwill require

moreinputintheformof subjectiveprobabilitybased

onjudgment. Foracomprehensivereviewof thistopic,

seeBaecher andChristian(2003).

For very complex design conditions, theobserva-

tional method is often used to achieve a success-

ful design. Bayesian updating provides an analytical

model fortheobservational method.Tworecentexam-

plesaregiventoindicatethepotential applicationsof

Bayesianupdating.

ACKNOWLEDGEMENTS

Theauthor thanks theOrganizingCommitteefor the

opportunity tomakethispresentation, Prof. Y. Honjo

foradviceandhelpinthepreparationof thispaper, and

Prof. B F. LowandProf. G. A. Fentonfor informative

discussionsabout their FEM analyses.

REFERENCES

Baecher,G.B.,andChristian,J.T.2003.Reliability and Statis-

tics in Geotechnical Engineering. Chichester: J ohnWiley

andSons.

Bergado, D. T., Long, P.V., Lee, C.H., Loke, K.H., and

Werner, G. 1994a. Performance of reinforced embank-

ment on soft Bangkok clay with high-strength geotex-

tile reinforcement. Geotextiles and Geomembranes. 13:

403420.

Bergado, D.T., Patron J r, B.C., Youyongwatana, W., Chai,

J -C., and Yudhbir, 1994b. Reliability-based analysis of

embankment on soft Bangkok clay. Structural Safety

13:247266.

Bishop, A. W., and Bjerrum, L. 1960. The relevance of

the triaxial test to the solution of stability problems. In

Proc. Research Conf. on Shear Strength of Cohesive Soils.

437501, NewYork: ASCE.

9

Casagrande, A. 1965. Roleof thecalculatedrisk inearth-

workandfoundationenmgineering. J. Soil Mechanics and

Foundation Division ASCE, 91:140.

Chai, J., and Bergado, D.T. 1993. Performance of rein-

forced embankment on Muar Clay deposiot. Soils and

Foundations, 33(4):117.

Cheung, R. W. M., andTang, W. H. 2005. Realistic assess-

ment of slope stability for effective landslide hazard

management. Geotechnique 55:8594.

Chong, P. C., Phoon, K. K., and Tan, T. S. 2000 Proba-

bilistic analysis of unsaturated residual soil slopes. In

R. E. Melchers andM. G. Stewart (eds.) Applications of

Statistics and Probability, 375382. Rotterdam: Balkema.

Christian, J. T., Ladd, C. C., andBaecher G. B. 1994. Relia-

bilityappliedtoslopestabilityanalysis. J. of Geotechnical

Engineering, 120:21802207.

DeGroot, D. J., and Baecher, G. B. 1993. Estimating auto-

covariance of in-situ soil properties. J. Geotechnical

Engineering, 119:147167.

El-Ramly, H., Morgenstern, N.R., and Cruden, D.M.

2002. Probabilisticslopestabilityfor practice. Canadian

Geotechnical J., 39:665683.

Freudenthal, A.M., 1947. The safety of structures. Trans.

ASCE, 112:125180.

Gilbert, R. B.,Wright, S. G., andLiedke, E. 1998Uncertainty

in back analysis of slopes: Kettleman Hills case his-

tory. J. Geotechnical and Geoenvironmental Engineering,

124:11671176.

Griffith, V. D., and Fenton, G. A. 2004. Probabilistic slope

stability analysisby finiteelements. J. Geotechnical and

Geoenvironmental Engineering, 130:507518.

Lafleur, J., Silvestri, V., Asselin, R., and Soulie, M. 1988.

Behaviourof atestexcavationinsoftChamplainSeaclay.

Canadian Geotechnical J. 25:705715.

Lefebvre, G, Ladd, C.C., and Pare, J -J. 1988. Comparison

of fieldvaneandlaboratoryundrainedshear strengthsin

soft sensitiveclays. InVane Shear Testing in Soils: field

and laboratory studies. STP1014, 233246. Philadelphia:

ASTM.

Lambe,T. W. 1973. Predictionsinsoil engineering. Geotech-

nique, 23:149202.

Leonards, G. A. 1982. Investigationof failures. J. Geotech-

nical Engineering, 108:222283.

Low, B. F. 2008. Practical reliabilityapproachusingspread-

sheet. In K-K. Phoon (ed.) Reliability-Based Design in

Geotechnical Engineering. London: Taylor andFrancis.

Low, B.F., andTang,W.H. 1997. Reliability analysisof rein-

forcedembankment onsoft ground. Canadian Geotech-

nical J. 34:672685.

Lumb, P. 1970. Safetyfactorsandtheprobabilitydistribution

of strength. Canadian Geotechnical J., 7:225242.

Malayasian4HighwayAuthority1989.In(eds.)R.R.Hudson,

C. T. Toh, and S. F. Chan. Proc. Intern. Symp. on

Trial Embankments on Malayasian Marine Clays. Kuala

Lumpur, Malayasia.

Massachusetts Institute of Technology 1975. Proc. Foun-

datiions Deformation Prediction Symp. Washington, DC:

Federal HighwayAdministration.

Matsuo,M.andAsaoka,A.1978.Dynamicdesignphilosophy

of soilsbasedontheBayesianreliabilityprediction. Soils

and Foundations 18(4):117

Meyerhof, G. G. 1970. Safety factors in soil mechanics.

Canadian Geotechnical J. 7:333338.

Peck, R. B. 1969.Advantagesandlimitationsof theobserva-

tional methodinappliedsoil mechanics, NinthRankine

Lecture. Geotechnique, 19:171187.

Phoon, K. K., and Kulhawy, F. H. 1999a. Characterization

of geotechnical variability. Canadian Geotechnical J. 36:

612624.

Phoon, K. K., and Kulhawy, F. H. 1999b. Evaluation of

geotechnical propertyvariability. Canadian Geotechnical

J. 36:625639.

Rojiani, K. B., Ooi, P.S.K., andTan, C.K. (1991) Calibration

of load factor design code for highway bridge founda-

tions, Geotechnical Engineering Congress, Geotechnical

Special Publication No. 217, 2:13531364. NewYork:

ASCE.

Silva, F. Lambe, T.W., andMarr, W.A. 2008. Probabilityand

riskof slopefailure. J. Geotechnical and Geoenvironmen-

tal Engineering, 134:16911699.

Tang, W. H. 1971. A Bayesianevaluationof informationfor

foundation engineering design. In P, Lumb (ed.) Statis-

tics and Probability in Civil Engineering, 173185, Hong

Kong: HongKongUniv. Press.

Tang, W. H. 1971. A Bayesianevaluationof informationfor

foundation engineering design. In P, Lumb (ed.) Statis-

tics and Probability in Civil Engineering, 173185, Hong

Kong: HongKongUniv. Press.

Tang, W. H., Yucemen, M.S., and Ang, A. H-S. 1976.

Probability-basedshort termdesignof soil slopes. Cana-

dian Geotechnical J. 13:201215.

Tavanas, F., andLeroeil, S. 1980. Thebehavior of embank-

ments on clay foundations. Canadian Geotechnical J.

17:236260.

Taylor, D. W. 1948. Fundamentals of Soil Mechanics, New

York: J ohnWileyandSons.

Terzaghi, K. 1929 Effect of minor geologic details on the

safety of dams. Technical Pub. 215, 3144, American

Instituteof MiningandMetallurgical Engineering, New

York.

U.S. Army, Corps of Engineers 1995. Introductionto prob-

ability and reliability methods for use in geotechnical

engineering. Technical letter 1110-2-547, Washington,

DC

Vanmarcke, E. H. 1977. Probabilisic modeling of soil

profiles. J. Geotechnical Engineering Division, ASCE,

103:P1227-1246

Wang,Y-J., andChiasson, P. 2006. Stochasticstabilityanaly-

sisof atestexcavationinvolvingspatiallyvariablesubsoil.

Canadian Getechnical J. 43:10741087.

Wu, T.H. 2003. Variation in clay deposits of Chicago. In

E. VanmarckeandG. A. Fenton, (eds.) Probabilistic Site

Characterization at the National Geotechnical Test Sites.

Geotechnical Special Pub. 121. Reston: ASCE.

Wu, T.H., Kraft, L.M. 1970Safetyanalysisof slopes. J. Soil

Mechanics and Foundations Division,ASCE, 96:609630

Xu, B., andLow, B. F. 2006. andZou, J -Z., Williams, D. J.,

and Xiong, W-L. 1995. Search for critical slip surfaces

basedonfiniteelementmethod. Canadian Getechnical J.

32:233

Yu, H.S., Salgado, R., Sloan, S.W., andKim, J.M. 1998. Limit

Analysis versus limit equilibriumfor slope stability. J.

Geotechnical and Geoenvironmental Eng. 124:111.

Zhang, L. L., Zhang, L. M., and Tang, W. H. (2005)

Rainfall-induced slopefailureconsidering variability of

soil properties, Geotechnique, 55:183188.

Zou, J -Z., Williams, D.J. and Xiong, W-L. 1995. Search

for critical slipsurfacesbasedonfiniteelement method.

Canadian Geotechnical J. 32:233246.

10

Keynote lectures

Geotechnical Risk and Safety Honjo et al. (eds)

2009 Taylor & Francis Group, London, ISBN 978-0-415-49874-6

Riskassessment andmanagement for geohazards

F. Nadim

International Centre for Geohazards (ICG) / Norwegian Geotechnical Institute (NGI), Oslo, Norway

ABSTRACT: Eachyear, natural disasterscausecountlessdeathsandformidabledamagetoinfrastructureand

theenvironment. In20045, morethan300,000peoplelosttheir livesinnatural disasters. Material damagewas

estimatedat USD 300billion. Many lives couldhavebeensavedif morehadbeenknownabout therisks and

possiblerisk mitigationmeasures. Thepaper summarizes thestate-of-the-art intheassessment of hazardand

risk associatedwithlandslides, earthquakesandtsunamis. Theroleof suchassessmentsinarisk management

context is discussed and general recommendations for identification and implementation of appropriaterisk

mitigationstrategiesareprovided.

1 INTRODUCTION

Geohazards, i.e. natural hazards that aredrivenby

geological featuresandprocesses, poseseverethreats

tohumans, propertyandthenatural andbuiltenviron-

ment. During 2005, geohazards accounted for about

100,000 deaths worldwide, of which 84% were due

toOctobersPakistanearthquake. Inthat year, natural

disastersaffected161millionpeopleandcost around

US$160billionoverdoublethedecadesannual aver-

age. HurricaneKatrinaaccountedforthreequartersof

thiscost. Duringtheperiod1996to2005, natural dis-

asters causednearly onemillionlives lost, or double

thefigurefor theprevious decade, affecting 2.5 bil-

lionpeopleacross theglobe(WorldDisaster Report,

2006). Whenthetrendof fatalitiesduetonatural haz-

ardsisstudiedoverthelast100years,itappearsthatthe

increaseintheknownnumber of deathsisduetothe

increaseintheexposedpopulationinthis timescale

and the increased dissemination of the information,

andnottoanincreaseinthefrequencyand/or severity

of natural hazards.

The economic consequences of geohazards show

anevenmoredramatic increasingtrend(MunichRe,

2007). Someof thereasonsfor thisincreaseareobvi-

ous, others less so. The post-disaster effects can be

especially severe in a vast, densely-populated area

wheresewers fail and diseasespreads. Slums spring

upindisaster-proneareassuchassteepslopes, which

arepronetolandslidesor particularly severedamage

in an earthquake. Many of theworlds fastest grow-

ingcities arelocatedoncoastal landor rivers where

climatevariability andextremeweather events, from

cyclones to heat waves to droughts, pose increasing

risksof disaster.

Several well-documented studies have shown

clearly that developing countries are more severely

affectedbynatural disastersthandevelopedcountries,

especially in terms of lives lost (UNDP 2004, ISDR

Table1. Natural disastersintheperiod19912000(Source:

IFRC 2001).

Countryclassification No. of disasters No. of liveslost

Lowandmedium 1838 649,400

developedcountries

Highlydeveloped 719 16,200

countries

2004 and International Federation of Red Cross and

RedCrescent 2004). Table1showsthedatacompiled

by IFRC (2001) for the decade 19912000. Of the

total number of persons killedby natural disasters in

thisperiod, thehighlydevelopedcountriesaccounted

for only 5% of the casualties. In absolute numbers,

thematerial damageandeconomiclossduetonatural

hazards in highly developed countries by far exceed

thoseindevelopingnations. However, thisreflectsthe

grosslydisproportionatevaluesof fixedassets, rather

thanreal economicvulnerability.

Mitigationandpreventionof theriskposedbynatu-

ral hazardshavenotattractedwidespreadandeffective

public support inthepast. However, thesituationhas

changed dramatically during the past decade, and it

is now generally accepted that a proactive approach

toriskmanagementisrequiredtoreducesignificantly

lossof livesandmaterial damageassociatedwithnatu-

ral hazards.Thewidemediaattentiononmajornatural

disasters during the last decade has clearly changed

peoplesmindintermsof acknowledgingriskmanage-

ment as analternativeto emergency management. A

milestoneinrecognitionof theneedfornatural disaster

riskreductionwastheapproval of theHyogoFrame-

work for Action20052015: BuildingtheResilience

of Nations and Communities to Disasters (ISDR

2005). This document, which was approved by 164

UNcountriesduringtheWorldConferenceonDisaster

13

Reduction in Kobe, J anuary 2005, clarifies interna-

tional working modes, responsibilities and priority

actionsfor thecoming10years.

Thefirst step in any decision-making process for

disaster risk reduction is thequantitativeassessment

of the risk. This paper provides an overview of the

state-of-the-art for hazard and risk assessment for

landslides, earthquakes and tsunamis, and discusses

possible risk mitigation strategies for these geohaz-

ards.

2 RISK ASSESSMENT FRAMEWORK

Theterminology usedinthis paper is generally con-

sistent with therecommendations of ISSMGE Glos-

sary of Risk Assessment Terms (listedonTC32web

page: http://www.engmath.dal.ca/tc32/). The impor-

tant termsusedinthecontext of thispaper are:

Danger (Threat): Natural phenomenon that could

lead to damage, described by geometry, mechani-

cal and other characteristics. Description of a threat

involvesnoforecasting.

Hazard: Probabilitythataparticulardanger(threat)

occurswithinagivenperiodof time.

Risk: Measure of the probability and severity

of an adverse effect to life, health, property, or

the environment. Mathematically, risk is defined as

Risk=HazardPotential worthof loss.

Vulnerability: Thedegreeof losstoagivenelement

or setof elementswithintheareaaffectedbyahazard.

Itisexpressedonascaleof 0(noloss) to1(total loss).

InUNISDR terminology onDisaster Risk Reduc-

tion (2009), disaster is defined as a serious dis-

ruptionof thefunctioningof acommunity or asoci-

ety causing widespread human, material, economic

or environmental losses which exceed the ability of

the affected community or society to cope using its

own resources. Thetermnatural disaster is slowly

disappearing fromthedisaster risk management ter-

minology because without the presence of humans,

oneisonlydealingwithnatural processes. Theseonly

becomedisasterswhentheyimpact acommunityor a

society.

Quantitatively risk can beevaluated fromthefol-

lowingexpression:

whereR=riskassociatedwithaparticular danger

H=hazard

V=vulnerabilityof elementsat risk

E=expected cost of total loss of elements at

risk

Several riskassessmentframeworkshavebeenpro-

posed, and Dzgn and Lacasse (2005) list a large

number of these. The frameworks have the com-

mon objective of answering the following questions

(modifiedfromLee& J ones, 2004):

Whataretheprobabledangersandtheirmagnitude?

[Danger Identification]

How often do the dangers of a given magnitude

occur? [HazardAssessment]

What are the elements at risk? [Elements at Risk

Identification]

Whatisthepossibledamagetotheelementsatrisk?

[VulnerabilityAssessment]

What is theprobability of damage? [Risk Estima-

tion]

Whatisthesignificanceof theestimatedrisk?[Risk

Evaluation]

What shouldbedone? [RiskManagement]

In the following sections, the methodologies for

answering one or more of these questions for land-

slides, earthquakes and tsunamis will be discussed.

3 LANDSLIDES

3.1 Landslide threat

Landslides represent a major threat to human life,

propertyandconstructedfacilities, infrastructureand

natural environment in most mountainous and hilly

regions of the world. Statistics fromThe Centre for

Research on theEpidemiology of Disasters (CRED)

showthat landslides areresponsiblefor at least 17%

of all fatalities fromnatural hazards worldwide. The

socio-economic impact of landslides is underesti-

mated because landslides are usually not separated

fromother natural hazard triggers, such as extreme

precipitation,earthquakesorfloods.Thisunderestima-

tioncontributestoreducingtheawarenessandconcern

of bothauthoritiesandgeneral publicabout landslide

risk.

Asaconsequenceof climatechangeandincreasein

exposureinmanypartsof theworld,theriskassociated

withlandslides is growing. Inareas withhighdemo-

graphicdensity, protectionworksoftencannotbebuilt

becauseof economicorenvironmental constraints,and

is it not always possibleto evacuatepeoplebecause

of societal reasons. Oneneeds to forecast theoccur-

renceof landslideandthehazardandrisk associated

with them. Climate change, increased susceptibility

of surface soil to instability, anthropogenic activi-

ties, growingurbanization, uncontrolledland-useand

increased vulnerability of population and infrastruc-

ture as a result, contribute to the growing landslide

risk. According to the European Union Strategy for

Soil Protection (COM232/2006), landslides are one

of themaineight threatstoEuropeansoils.

Water playsamajor roleintriggeringof landslides.

Figure 1 shows the relative contribution of various

landslidetriggeringeventsfactor inItaly. Heavyrain-

fall isthemaintrigger for mudflows, thedeadliestand

most destructiveof all landslides.

Manycoastal regionshavecliffsthataresusceptible

tofailurefromseaerosion(byundercuttingatthetoe)

andtheir geometry (slopeangle), resultinginloss of

agricultural landandproperty. Thiscanhaveadevas-

tatingeffectonsmall communities. Forinstance, parts

of thenorth-eastcoastcliffsof Englandareerodingat

ratesof 1m/yr.

14

Figure1. LandslidetriggersinItaly. Source: CNR-GNDCI

AVI Databaseof areas affected by landslides and floods in

Italy.

As aconsequenceof climatic changes and poten-

tial global warming, anincreaseof landslideactivity

is expected in the future, due to increased rainfalls,

changesof hydrological cycles,moreextremeweather,

concentratedrainwithinshorterperiodsof time, mete-

orological events followed by sea storms causing

coastal erosion and melting of snow and of frozen

soils in high mountain regions liketheAlps and the

Himalayas.Thegrowinglandslidehazardandrisk, the

needtoprotect peopleandproperty, theexpectedcli-

mate change and the need to manage the risk have

contributed to set the agenda for the profession to

assessandmitigatethelandsliderisk.

3.2 Landslide hazard assessment for specific

slopes

Hazard assessment for a specific slope usually

involves a probabilistic analysis of the slope, while

hazardassessment for aregiongenerally requiresthe

computation of frequency of the landslides in the

region. For regional analyses, datatobecollectedare

intheformof maps relatedto geomorphology, geol-

ogy, land-use/cover andtriggers. For specific slopes,

the required data for hazard analysis include slope

geometry such as height, width, inclination of slope

and potential failureplane, shapeand length of fail-

ure plane etc., strength parameters data for possible

trigger suchas rainfall intensity, water level, severity

of dynamic loads e.g. earthquake magnitude, accel-

erationand/or other characteristics. Theprobabilistic

models used for aspecific slopevary depending on

thefailuremechanism(e.g. flows, fallsor slides) and

theslope-formingmaterial (e.g. soil or rock).

Analysesof specific slopesusedeterministic (fac-

tor of safety, numerical analyses) and/or probabilistic

methods, e.g. first order, second-moment (FOSM),

first order reliability method (FORM), point esti-

mate methods, and Monte Carlo Simulation (MCS)

(Ang&Tang1984). Recent trendscombinedifferent

approachesforanimprovedmodel of thehazard(s).An

uncertaintyanalysisisessential priortothecalculation

of slopefailureprobability asit allowsarational cal-

culationof total uncertaintiesassociatedwithdifferent

sourcesof uncertainty(e.g.inparametersandmodels).

Thequantificationandanalysisof uncertaintiesplaya

critical roleintheriskassessment.

The stability situation for natural and man-made

slopes is often expressed by a factor of safety. The

factor of safety is definedas theratio of thecharac-

teristicresistance(resistingforce) tothecharacteristic

load (driving force). The approach does not address

the uncertainty in load and resistance in a consis-

tent manner. The choice of characteristic values

allowstheengineertoimplicitlyaccountforuncertain-

tiesbyusingconservativevaluesof load(highvalue)

andresistanceparameters (lowvalue). Thechoiceis

somewhatarbitrary.Duncan(1992and1996)provided

an overview of deterministic slope stability analysis

method. The overview included the factor of safety

approach, equilibriummethodsof slopestabilityanal-

ysis (J anbus generalized method of slices, Bishops

method, Spencers method, Morgenstern and Prices

method among others), techniques for searching for

thecritical slipsurface, bothcircularandnon-circular,

three-dimensional analyses of slope stability, analy-

ses of thestability of reinforced slopes, drained and

undrained conditions, and total stress and effective

stress analyses. Slopes withnominally thesamefac-

tor of safety couldhavesignificantly different safety

marginsbecauseof theuncertaintiesinvolved. Duncan

(2000) pointedout that Throughregulationor tradi-

tion, thesamevalueof safety factor is oftenapplied

to conditions that involvewidely varying degrees of

uncertainty. Thisisnot logical.

To evaluatethehazard associated with thefailure

of aspecific slope, thestability assessment must be

put into aprobabilistic format usingoneof thetech-

niquesmentionedearlier(FOSM, FORM, MCS, etc.).

Anoverviewof theavailablemethodsfordoingproba-

bilisticslopestabilityassessmentforindividual slopes

isprovidedinNadimet al. (2005).

3.3 Regional landslide hazard assessment

Landslidehazardandriskassessmentisoftenrequired

on a regional or national scale and it would not be

feasible to do a stability assessment for all poten-

tiallyunstableslopesinthestudyarea.Thereforeother

techniquesbasedonGeographical InformationTech-

nology (GIT) are employed in these situations. An

exampleof thistypeof hazardassessmentisthestudy

doneby Nadimet al. (2006) in theGlobal Hotspots

study for the ProVention Consortium. That model,

whichiscurrently beingupdatedfor theGlobal Risk

Updateprojectof ISDR, assessesthelandslidehazard

by considering a combination of the triggering fac-

torsandsusceptibilityindicators.Theprinciplesof the

model aredemonstratedinFigure2.

Inthelatestversionof themodel, alandslidehazard

index was defined using six parameters: slope fac-

tor withinaselectedgridcell, lithology(or geological

conditions), soil moisturecondition, vegetationcover

index, precipitationfactor, andseismicconditions. For

each factor, an index of influence was determined

and the relative landslide hazard level H

landslide

was

obtainedbymultiplyingandsummingtheindices.The

landslidehazardindices werethencalibratedagainst

thedatabases of landslideevents in selected (mostly

European) countries to obtain the frequency of the

15

Figure2. Schematicapproachfor landslidehazardandrisk

evaluation(Nadimet al., 2006).

landslide events, i.e. the landslide hazard. Figure 3

shows the landslide hazard map for parts of Latin

AmericaobtainedbyNadimet al. (2006).

3.4 Landslide risk assessment

Themost completedescriptionof thepossiblelosses

(or risk) is quantitatively in terms of a probability

distribution, whichpresentstherelativelikelihoodof

any particular loss valueor theprobability of losses

being less than any particular value. Alternatively,

the expected value (i.e., the probability weighted

average value) of loss can be determined as a sin-

gle measure of risk. A general scenario-based risk

formulationisgivenbyNadim& Glade(2006):

where C is particular set of losses (of collectively

exhaustive and mutually exclusive set of possible

losses), Sisparticularscenario(of comprehensiveand

mutuallyexclusivediscreteset of possiblescenarios),

P[S]isprobabilityof occurrenceof scenarioS,P[C| S]

is theconditional probability of loss set C giventhat

scenarioShasoccurred, andE[Loss] istheexpected

value of loss. Loss may refer to any undesirable

consequence, such as loss of human life, economic

loss, lossof reputation, etc., intermsof itsdirect and

indirect effects (e.g. local damage of railway tracks

andrelatedinterruptionof industrial traffic), itseffects

on different social groups (e.g. individuals, commu-

nity, insurance, government) as well as its short- and

long-terminfluencesonasociety(e.g. fatalitiescould

includeall childrenof acommunity, thetouristindus-

trymightcollapse). Mostoftenthefocusisontheloss

of humanlife.

Calculationof thetermsintheaboveequationisnot

trivial.Thehazardtermintheaboveequation(i.e.P[S])

isnotconstantwithtime.Moreover,theexpectednum-

ber of fatalitiesdependsonmanyfactors, for example

onwhichweek-dayandwhattimeof thedaytheland-

slideoccurs, whether awarningsystemisinplaceand

working,etc.Thepotentiallyaffectedpopulationcould

bedividedintogroupsbasedonfor examplethetem-

poral exposuretothelandslide: peoplelivinginhouses

Figure3. Landslidehazardmapfor partsof LatinAmerica

(Nadimet al., 2006).

Figure4. Procedurefor riskassessment of slopes.

that arein thepath of thepotential landslide, locals

intheareawho happento bepasser-bys andtourists

and/or workerswhoarecoincidentallyat thelocation

duringcertainperiodsof thedayof theyear.

Figure4 summarizes ageneral procedurefor risk

assessment for slides. The key issue is the identifi-

cation of potential triggers and their probability of

occurrence, the associated failure modes and their

consequences. The triggering mechanisms could be

natural, such as earthquake, tectonic faulting, rain-

fall, temperatureincreasecaused by climatechange,

excess pore pressures or man-made. Generally, one

shouldconsiderseveral scenariosof plausibletriggers,

estimatetherun-out distanceandextent triggeredby

theseevents, andestimatetheupper andlower bounds

on the annual probability of occurrence of the sce-

narios(Roberds, 2005).Thisscenario-basedapproach

involvesthefollowingsteps:

Definescenariosfor landslidetriggering

Computetherun-off distance, volumeandextentof

landslidefor eachscenario

Estimatethelossfor thedifferent landslidescenar-

ios

Estimatetherisk andcompareit withtolerableor

acceptablerisklevels

16

4 EARTHQUAKES

4.1 Earthquake threat

Earthquakescanbeespecially devastatingwhenthey

occur inareas withhighpopulationdensity. Therisk

posedbyearthquakestolargecitiesandother densely

populated areas is by far greater than all other geo-

hazardscombined(Nadim& Lacasse, 2008). Similar

to other natural hazards, the global fatality count

fromearthquakescontinuestorise. Thishasoccurred

despitetheadoptionof earthquake-resistant building

codesinmost countries.

Inthepastfivecenturies, theglobal deathtoll from

earthquakeshasaveraged100,000per year, aratethat

is dominatedby largeinfrequent disasters, mostly in

thedevelopingnations(Bilham, 2004). J ustinthepast

few years, two of themost catastrophic earthquakes

inhistoryhaveoccurredinAsia(PakistaninOctober

2005andSichuan, ChinainMay2008). Theincrease

in earthquake-induced fatalities is mainly dueto the

steadygrowthinglobal population. At thesametime,

there is a decline in the fatality rate expressed as a

percentage of instantaneous population. It is tempt-

ing to attribute this observation to the application

of earthquake-resistant constructioncodeinnewcity

developments.A morepessimistic, andmorerealistic,

interpretationis, however, that theapparent declinein

risk isastatistical anomalyandfutureextremeearth-

quakedisastersinsomeof theworldsmegacitiesmay

arrest, or reverse, thecurrent trend.

4.2 Earthquake hazard assessment

Seismic hazard analysis methods havea widerange

of applications, frombroadly basedzonations aimed

essentiallyonlyatdescribinganddelineatingtheseis-

micity, to site-specific analyses aimed for design of

specific structures. Within both fields the analyses

rangefromrelatively cursory tohighly detailed, with

thelevel of detail fordesignpurposesbeingdependent

onthesensitivityof thestructure.

Prior to 1970, the assessment of seismic hazard

was based on a deterministic approach that consid-

ered the most likely scenarios for earthquakes that

couldaffect aparticular location. Theseminal paper

of Cornell (1968) introducedthemethodologybehind

a Probabilistic Seismic HazardAssessment (PSHA)

changedtheway most engineeringseismologists did

their hazard analyses. Traditionally, thepeak ground

acceleration (PGA) has been used to quantify the

groundmotioninPSHA. Today thepreferredparam-

eter is Response Spectral Acceleration (SA), which

gives the maximum acceleration experienced by a

damped, single-degree-of-freedomoscillator (acrude

representation of building response). The oscillator

periodischoseninaccordancewiththenatural period

of thestructureanddampingvalues aretypically set

at5%of critical. ThePSHA methodologyfor estimat-

ingtheannual probability of occurrenceof aground

motioncharacteristicisthesameforboththePGA and

theSA. Inbothsituations, PSHA involvesthreesteps:

1)specificationof theseismic-hazardsourcemodel;2)

specificationof thegroundmotionmodel (attenuation

relationship); and3) theprobabilisticcalculation.

Theseismic-hazard sourcemodel is adescription

of the magnitude, location, and timing of all earth-

quakes(usuallylimitedtothosethatposeasignificant

threat). For example, asourcemodel might becom-

posed of N total earthquake scenarios, where each

has its own magnitude, location, and annual rate of

occurrence. Thegroundmotionmodel usedinPSHA

consists of thesourcemodel andanattenuationrela-

tionship. Thelatter describeshowrapidlyaparticular

ground motion parameter decays with distancefrom

thesource. Giventhetypicallylargenumber of earth-

quakesandsitesconsideredinananalysis, attenuation

relationships must besimpleand easy to apply. The