Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

4717

Caricato da

immmranCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

4717

Caricato da

immmranCopyright:

Formati disponibili

4717 version 6 Page 1 of 3

Carry out yarn length calculations for warp knitting

Level Credits Purpose 2 4 This unit standard is for warpers and other personnel in a warp-knitting company. People credited with this unit standard are able to calculate the lengths of yarns on yarn packages; and calculate the lengths of warps. Subfield Domain Status Status date Date version published Planned review date Entry information Accreditation Standard setting body (SSB) Industrial Machine Knitting Warp Preparation - Warp Knitting Registered 19 March 2010 19 March 2010 31 December 2015 Open. Evaluation of documentation by NZQA and industry. Plastics and Materials Processing Industry Training Organisation 0030

Accreditation and Moderation Action Plan (AMAP) reference

This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 2 3 This unit standard applies to the calculations associated with warp-preparation. Assessment against this unit standard could be combined with assessment against Unit 4715, Operate warping machinery for warp knitting. Technical aspects that are required to be covered in demonstrating competence in this unit standard include: a Calculations of the lengths of yarns on packages related to the weight of the yarn on the packages and its count; b Calculations of warp lengths.

New Zealand Qualifications Authority 2012

4717 version 6 Page 2 of 3 4 Definitions Technical specifications refer to material such as set-out diagrams or product specifications from either manufacturers or the workplace. This material may be in hard copy or supplied in electronic form. Workplace procedures refer to the verbal or documented procedures for performing activities including health and safety, operational, environmental and quality management requirements. They refer to manuals, manufacturers specifications, codes of practice, or policy statements.

Elements and performance criteria

Element 1 Calculate the lengths of yarns on yarn packages. Performance criteria 1.1 The length of yarn on a package is calculated from the weight of the yarn on the package and the specified yarn count in accordance with workplace procedures. Range Element 2 Calculate the lengths of warps. Performance criteria 2.1 2.2 The required number of ends in a warp is determined from the technical specifications. The number of packages of the yarn available for warping, and the length of yarn on each package, are determined in accordance with workplace procedures. The length of yarn to be warped is calculated in accordance with workplace procedures. direct count and/or indirect count.

2.3

Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards.

New Zealand Qualifications Authority 2012

4717 version 6 Page 3 of 3 Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Plastics and Materials Processing Industry Training Organisation info@pampito.org.nz if you wish to suggest changes to the content of this unit standard.

New Zealand Qualifications Authority 2012

Potrebbero piacerti anche

- CH 14Documento8 pagineCH 14Neeraj NegiNessuna valutazione finora

- Weaving TechnologyDocumento26 pagineWeaving TechnologyimmmranNessuna valutazione finora

- Example Lease Agreement 1Documento8 pagineExample Lease Agreement 1Soundararajan SeeranganNessuna valutazione finora

- How Do You Calculate The Fabric Consumption For Knit GarmentsDocumento3 pagineHow Do You Calculate The Fabric Consumption For Knit GarmentsimmmranNessuna valutazione finora

- Factors Determining The Manufacturing Costs of Lithium-Ion Batteries For PhevsDocumento12 pagineFactors Determining The Manufacturing Costs of Lithium-Ion Batteries For PhevsimmmranNessuna valutazione finora

- How To Perform TahujjadDocumento1 paginaHow To Perform TahujjadimmmranNessuna valutazione finora

- Safety Thermo Forming MachinesDocumento3 pagineSafety Thermo Forming MachinesimmmranNessuna valutazione finora

- SMEDA Animal Feed MillDocumento35 pagineSMEDA Animal Feed Millimmmran80% (5)

- Maxima 1300Documento2 pagineMaxima 1300immmran100% (1)

- Issimo11 Scheda Prodotto EngDocumento2 pagineIssimo11 Scheda Prodotto EngimmmranNessuna valutazione finora

- Company NameDocumento8 pagineCompany NameimmmranNessuna valutazione finora

- SME Policy 2007: SME Led Economic Growth - Creating Jobs and Reducing PovertyDocumento25 pagineSME Policy 2007: SME Led Economic Growth - Creating Jobs and Reducing PovertyimmmranNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Gate Books ListDocumento3 pagineGate Books ListAnonymous peRejuSesXNessuna valutazione finora

- Abhigya Aswal - XI FDocumento1 paginaAbhigya Aswal - XI FAyushi AswalNessuna valutazione finora

- BLESSINGSDocumento38 pagineBLESSINGSleo simporiosNessuna valutazione finora

- Request For Refund or Test Date Transfer Form Restricted 0Documento2 pagineRequest For Refund or Test Date Transfer Form Restricted 0Детелина ХристоваNessuna valutazione finora

- Italy Admision Procedure and Visa GuidanceDocumento4 pagineItaly Admision Procedure and Visa GuidanceSiva Prasad NandyalaNessuna valutazione finora

- Spaced Repetition PDFDocumento42 pagineSpaced Repetition PDFJemart DizonNessuna valutazione finora

- The Skills of Active Listening: Ivey & Ivey, 2007Documento10 pagineThe Skills of Active Listening: Ivey & Ivey, 2007Ahmed ZakariaNessuna valutazione finora

- Letter To School Board Members Supporting LAUSD Superintendent John DeasyDocumento3 pagineLetter To School Board Members Supporting LAUSD Superintendent John DeasyLos Angeles Daily NewsNessuna valutazione finora

- Scribe DeclarationDocumento2 pagineScribe DeclarationMuhammed AmeerNessuna valutazione finora

- Study GuideDocumento12 pagineStudy GuideLuyanda NkambuleNessuna valutazione finora

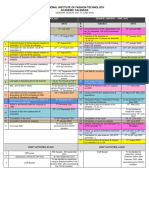

- Academic Calendar 2021-22Documento1 paginaAcademic Calendar 2021-22DÃljït SīñghNessuna valutazione finora

- JQL 2018 For Microsite and AppDocumento2 pagineJQL 2018 For Microsite and Appshadab0123Nessuna valutazione finora

- Applied Linguistics SyllabusDocumento5 pagineApplied Linguistics SyllabusmcdarknightNessuna valutazione finora

- Writing A Formal LetterDocumento11 pagineWriting A Formal LetterImran IbrahimNessuna valutazione finora

- January 30, 2023: University DentistDocumento4 pagineJanuary 30, 2023: University DentistDeneene VillarinNessuna valutazione finora

- Children's Assessments (PPA Presentation)Documento35 pagineChildren's Assessments (PPA Presentation)Samar AljaafaryNessuna valutazione finora

- Nebosh International General CertificateDocumento2 pagineNebosh International General Certificatexeeshan281Nessuna valutazione finora

- Final AP StatsDocumento14 pagineFinal AP StatsJuan MedinaNessuna valutazione finora

- ASNT Catalog 2015 PDFDocumento47 pagineASNT Catalog 2015 PDFAnonymous 4cC6LKBNessuna valutazione finora

- F20 HMGT 6335 OPRE 6332 Spreadsheet Modeling SYLLABUSDocumento9 pagineF20 HMGT 6335 OPRE 6332 Spreadsheet Modeling SYLLABUSAkshat BhatiNessuna valutazione finora

- Foundation Course (FOU) : DescriptionDocumento15 pagineFoundation Course (FOU) : DescriptionVinu VincentNessuna valutazione finora

- Student Handbook PG-RegularDocumento33 pagineStudent Handbook PG-RegularMatin Ahmad KhanNessuna valutazione finora

- Feasibility Study For The Proposed Bachelor of Public AdministrationDocumento5 pagineFeasibility Study For The Proposed Bachelor of Public AdministrationVktoria Halen100% (1)

- Earth & Life WHLP Week 3 & 4Documento1 paginaEarth & Life WHLP Week 3 & 4RICHARD CORTEZNessuna valutazione finora

- Lesson Plans 4Documento1 paginaLesson Plans 4api-368156036Nessuna valutazione finora

- Chapter Three Research MethodologyDocumento5 pagineChapter Three Research MethodologyAdediran Dolapo50% (2)

- Application Form 2016-2017Documento4 pagineApplication Form 2016-2017HR TroikaaNessuna valutazione finora

- IcmapDocumento1 paginaIcmapAsad AliNessuna valutazione finora

- Odia Syllabus For UG HonsDocumento21 pagineOdia Syllabus For UG HonsAadil RazaNessuna valutazione finora

- Emmanuel 101Documento7 pagineEmmanuel 101Khen FelicidarioNessuna valutazione finora