Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Design Example - Workshop

Caricato da

laichmailCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Design Example - Workshop

Caricato da

laichmailCopyright:

Formati disponibili

Design Example - Workshop

Design a ventilation system for the building shown below. The building is a small workshop used for general metal fabrication and welding. No welding booths are installed. If the building gets too warm the door may be opened for free cooling. DATA: Building dimensions : 15.0 metres long x 7.0 metres wide x 5.0 metres high to eaves. Roof ridge height is 7.5 metres. The air change rate for mechanical ventilation is to be 6 air changes per hour.

Roller Shutter door

WORKSHOP

PLAN

Scale 1:100

The building volume may be calculated from: V = ( L x W x H to eaves ) + ( 0.5 x W x perpendicular height from eaves to ridge x L ) V = ( 15 x 7 x 5 ) + ( 0.5 x 7 x 2.5 x 15 ) V = 525 + 131.25 = 656.25 m3. DESIGN METHODOLOGY 1. What areas need ventilation? Answer: The total area of the workshop. The contaminants are welding fumes and heat. What type of system should be used, supply, extract or balanced? Answer: Extract. Are there any alternative systems to consider? Answer: No, supply air is not required. Is air conditioning necessary in the building? Answer: No, external door to be opened. Where should the fan(s) and plant be installed? Answer: On the roof. What type of fan(s) and plant should be used? Answer: Roof mounted units with weatherproof cowl. Anti-backdraught shutters on each fan. No ductwork. Is a separate heating system necessary? Answer: No, not for extract only. What type of control system should be used? Answer: Variable speed fan(s) for a flexible system. What type of air distribution system should be used, upward or downward? Answer: Upward for extract systems, with duct mounted extract grilles. Have I considered what will happen in the event of a fire in the building? Answer: The fans could remove smoke in the event of a fire. Have I considered the noise from fans? Answer: In a workshop, fan noise is not a problem.

2. 3. 4. 5. 6.

7. 8. 9. 10. 11.

SIZING The sizing procedure is as follows: 1. Calculate Ventilation rates. 2. Decide on number of fans and grilles/diffusers. 3. Draw scale layout drawing: Position fan(s). Lay out ductwork. Lay out grilles and diffusers. Indicate flow rates on drawing. 4. Size ductwork 5. Size fan 6. Size grilles and diffusers.

1. VENTILATION RATES

For Extract ventilation systems the rate in air changes per hour is obtained for some buildings in Table 3.1. There is no explicit rate given for Factories and warehouses or Industrial ventilation due to the variations in building design and usage. The rate for this example is given in the question as 6 air changes per hour. The following formulae may be used: FOR GENERAL MECHANICAL VENTILATION

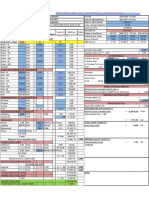

Ventilation rate (m3/h) = Air Change Rate (/h) x Room Volume (m3) = 6 x 656.25 = 3937.5 m3/h Ventilation rate (m3/s) = Ventilation rate (m3/h) / 3600 = 3937.5 m3/h / 3600 3 = 1.094 m /s. Three extract roof units are used so each will remove 1.094 / 3 = 0.365 m3/s. The resistance to air flow is negligible since there is no ductwork or grilles connected to the fans. It is a good idea to look at several types of extract unit to ascertain the best option for the job. A typical unit is shown below.

CHOOSING A FAN To choose a suitable fan one must look at the performance curves. These curves show the pressure developed by a fan at a given flow rate.

The operating point of the system is marked as a point on the curve. To accurately establish a fan size the air flow resistance would have to be calculated (see DUCT SIZING).

In the absence of duct resistance data we can look at typical fans for the job. There are several options to choose from, for example, from the Woods Air Movement Ltd catalogue:

SIZE Dia. (mm) 315 330 250 315 VOLUME FLOW RATE (m3/s) 0.37 0.37 0.37 0.37 SOUND LEVEL (dB) 48 57 51 49

REF.

FAN TYPE

PRESSURE (Pa) 32 230 135 55

SPEED (rpm) 1420 1300 1350 1420

Woods DSP 315 Woods DSM 330 Woods DSC 250 Woods DSJ 315

Propeller Mixed flow Centrifugal Axial flow

From the above table, the propeller type fan and the axial flow fan produce 32Pa and 55 Pa pressure which is sufficient for the proposed system.

The noise output from both fans is similar. I would choose the DSP 315 propeller type unit since a speed controller is available. The ductwork resistance can be calculated later to ascertain an accurate fan size.

3No. fan speed controllers

3No. Roof mounted extract units

0.182 m3/s.

0.182 m3/s.

0.182 m3/s.

PLAN

Scale 1:100

Potrebbero piacerti anche

- 4 ACMV SystemsDocumento293 pagine4 ACMV SystemsMorgan HengNessuna valutazione finora

- Heating and Cooling Load CalculationDocumento7 pagineHeating and Cooling Load Calculationirsalan_shahidNessuna valutazione finora

- The Equal Friction Method of Sizing Ducts Is Easy and Straightforward To UseDocumento8 pagineThe Equal Friction Method of Sizing Ducts Is Easy and Straightforward To UseRamil BelmonteNessuna valutazione finora

- Base Plate Design For Fixed BaseDocumento59 pagineBase Plate Design For Fixed Basemoneoffice100% (2)

- The Good Ventilation of Switchgear and Transformer RoomsDocumento8 pagineThe Good Ventilation of Switchgear and Transformer RoomsjayamenggalaNessuna valutazione finora

- Shubharambh Banquets HL - All Halls 26-5-2017Documento5 pagineShubharambh Banquets HL - All Halls 26-5-2017calvin.bloodaxe4478Nessuna valutazione finora

- Refrigeration Heat Load EstimatingDocumento17 pagineRefrigeration Heat Load EstimatingAnonymous 1gbsuaafddNessuna valutazione finora

- 12 Cooling Load CalculationsDocumento61 pagine12 Cooling Load Calculationssp suNessuna valutazione finora

- Ahu & Chiller OkDocumento40 pagineAhu & Chiller OkAndy DwiNessuna valutazione finora

- R&AC Lecture 30Documento17 pagineR&AC Lecture 30Denise Koh Chin HuiNessuna valutazione finora

- Transient Thermal Conduction ExampleDocumento14 pagineTransient Thermal Conduction ExampleDevendra BangarNessuna valutazione finora

- Tema & Asme Section Viii Div1 Section UhxDocumento20 pagineTema & Asme Section Viii Div1 Section UhxEmad A.Ahmad100% (1)

- Hydraulic Fracturing in Soil During HDDDocumento12 pagineHydraulic Fracturing in Soil During HDDamir_hayfaNessuna valutazione finora

- UFAD PresentationDocumento42 pagineUFAD Presentationsenthilarasu5Nessuna valutazione finora

- Air Changes Per HourDocumento2 pagineAir Changes Per HourjjzoranNessuna valutazione finora

- Catalogue Water Cooled Scroll Uwl b5 1Documento48 pagineCatalogue Water Cooled Scroll Uwl b5 1rajeshwar sriramNessuna valutazione finora

- ASHRAE - HVAC-HospitalBook - Room Design PDFDocumento4 pagineASHRAE - HVAC-HospitalBook - Room Design PDFalialavi2Nessuna valutazione finora

- HAP Thermal Load Cal - FormulaDocumento19 pagineHAP Thermal Load Cal - Formulamajortay100% (1)

- Cooling Load EstimationDocumento37 pagineCooling Load EstimationHazem MohamedNessuna valutazione finora

- Air Diffuser Architecture PDFDocumento28 pagineAir Diffuser Architecture PDFBranislavPetrovicNessuna valutazione finora

- EC Fan Application Note - EMERSONDocumento8 pagineEC Fan Application Note - EMERSONlouie mabiniNessuna valutazione finora

- Proper Engine Room VentilationDocumento2 pagineProper Engine Room VentilationAsok AyyappanNessuna valutazione finora

- Psychrometry Part-2Documento11 paginePsychrometry Part-2Tushar Sharma100% (1)

- Nuaire Commercial Useful InfoDocumento10 pagineNuaire Commercial Useful InfoYaser AkarNessuna valutazione finora

- Price UfadDocumento8 paginePrice UfadbarelihbNessuna valutazione finora

- SKM FCU High Static DetailDocumento28 pagineSKM FCU High Static DetailInzamamNessuna valutazione finora

- SR Steel Design Check Limit State Design of Steel Structure (SK Duggal) )Documento67 pagineSR Steel Design Check Limit State Design of Steel Structure (SK Duggal) )ShaileshRastogi100% (1)

- Equations: Hvac Equations, Data, and Rules of ThumbDocumento21 pagineEquations: Hvac Equations, Data, and Rules of ThumbzodedNessuna valutazione finora

- Heat Recovery Units RangeDocumento35 pagineHeat Recovery Units RangeGabetsos KaraflidisNessuna valutazione finora

- Cooling Load1111 PDFDocumento43 pagineCooling Load1111 PDFJason PaquibulanNessuna valutazione finora

- Geothermal HVAC: Shifting Performance Risk From Buyer To SellerDocumento5 pagineGeothermal HVAC: Shifting Performance Risk From Buyer To SellerKagitha TirumalaNessuna valutazione finora

- HVAC Thermal Load EstimatingDocumento28 pagineHVAC Thermal Load EstimatingIntisar Ali SajjadNessuna valutazione finora

- Application of Hydronic Radiant & Beam SystemsDocumento86 pagineApplication of Hydronic Radiant & Beam SystemsDhirendra Singh RathoreNessuna valutazione finora

- Is Required To: Maintain Adequate Indoor Air Quality by Removing And/or Diluting Pollutants From Occupied SpaceDocumento41 pagineIs Required To: Maintain Adequate Indoor Air Quality by Removing And/or Diluting Pollutants From Occupied SpaceTsz ching YipNessuna valutazione finora

- Fan BasicsDocumento6 pagineFan BasicsPankaj Patil100% (1)

- AAF CatalogueDocumento40 pagineAAF CatalogueArshavin Watashi Wa100% (2)

- Battery RoomDocumento2 pagineBattery RoomMohammed IqbalNessuna valutazione finora

- Technical Handbook Air CurtainsDocumento13 pagineTechnical Handbook Air Curtainsaca111111Nessuna valutazione finora

- Small Absorption ChillersDocumento2 pagineSmall Absorption ChillersAdil AbdoNessuna valutazione finora

- Meteorology: Background ConceptsDocumento98 pagineMeteorology: Background ConceptsPuja Kadam Ghadi100% (1)

- Combining DOAS and VRF, Part 2 of 2Documento9 pagineCombining DOAS and VRF, Part 2 of 2miniongskyNessuna valutazione finora

- Assigment 1Documento18 pagineAssigment 1Kolos Char YiuNessuna valutazione finora

- PRICE - Air Distribution GuideDocumento5 paginePRICE - Air Distribution Guidenvenkat.narayan100% (1)

- Air WashersDocumento7 pagineAir WashersimshubhamlackNessuna valutazione finora

- CO2 Sensor RoomDocumento8 pagineCO2 Sensor RoomTrần Khắc ĐộNessuna valutazione finora

- Advanced Air Duct Design Part 2Documento29 pagineAdvanced Air Duct Design Part 2Timothy Bryant100% (1)

- Project: FT Catcher Fpso Feed: Hvac - Heater Load CalculationDocumento7 pagineProject: FT Catcher Fpso Feed: Hvac - Heater Load CalculationinstrengNessuna valutazione finora

- Engine Room Ventilation - Necesar AerDocumento1 paginaEngine Room Ventilation - Necesar AerBirshopulosNessuna valutazione finora

- Saiver AHUDocumento12 pagineSaiver AHUNorsyafiqah RoziNessuna valutazione finora

- HVAC Useful Conversions ChartDocumento2 pagineHVAC Useful Conversions ChartdheerajdorlikarNessuna valutazione finora

- Daikin VRV IV CatalogueDocumento46 pagineDaikin VRV IV CatalogueNathan Vo100% (5)

- AHU Catalogue enDocumento68 pagineAHU Catalogue enTRISTIANDINDA PERMATANessuna valutazione finora

- Convention Hall at CRP - BOQ - StageDocumento2 pagineConvention Hall at CRP - BOQ - Stagegowrish80_bmsNessuna valutazione finora

- VRV SystemDocumento152 pagineVRV SystemKHA120096 StudentNessuna valutazione finora

- ASHRAE62.1 and FAQsDocumento18 pagineASHRAE62.1 and FAQsols3dNessuna valutazione finora

- Encon Basement VentilationDocumento15 pagineEncon Basement VentilationcyruskuleiNessuna valutazione finora

- 02 Cooling Load Calculation - HAPDocumento2 pagine02 Cooling Load Calculation - HAPU DEEPAKNessuna valutazione finora

- Power, Heat and CoolingDocumento12 paginePower, Heat and CoolingJayanth MandalgiriNessuna valutazione finora

- Biddle - VRVDocumento31 pagineBiddle - VRVutzu_yooNessuna valutazione finora

- Oxycom IntrCool Brochure (2019) enDocumento20 pagineOxycom IntrCool Brochure (2019) enAnkit JainNessuna valutazione finora

- Heat Wheel: Mohammad Yusuf 13PKB380Documento10 pagineHeat Wheel: Mohammad Yusuf 13PKB380Haider Ali100% (1)

- Project Name: Doc No: Air System Name: Rev: Equipment Type: Date: Space Used For: Sheet No: Floor: Reference: ClientDocumento10 pagineProject Name: Doc No: Air System Name: Rev: Equipment Type: Date: Space Used For: Sheet No: Floor: Reference: ClientMukti WibowoNessuna valutazione finora

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Da EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Nessuna valutazione finora

- Course Title: Thermal System DesignDocumento27 pagineCourse Title: Thermal System DesignhailemebrahtuNessuna valutazione finora

- Assignment Ac-System1Documento12 pagineAssignment Ac-System1Akatew Haile MebrahtuNessuna valutazione finora

- Ventilation SystemDocumento10 pagineVentilation SystemAkhileshkumar PandeyNessuna valutazione finora

- Borrower SlipsDocumento5 pagineBorrower SlipsGokuNessuna valutazione finora

- Finite Element Analysis of Cable Stayed Bridge ModelDocumento5 pagineFinite Element Analysis of Cable Stayed Bridge ModelSukrit GhoraiNessuna valutazione finora

- 1 s2.0 S0267726123000192 MainDocumento14 pagine1 s2.0 S0267726123000192 Mainlx nieNessuna valutazione finora

- 321aquatech Heat Pump CatalogueDocumento8 pagine321aquatech Heat Pump CatalogueMohammad ZeeshanNessuna valutazione finora

- Slope-Deflection Method (With Side Sway)Documento22 pagineSlope-Deflection Method (With Side Sway)عمر حسن محمدNessuna valutazione finora

- Infiltration 1Documento13 pagineInfiltration 1Abdulelah AlhamayaniNessuna valutazione finora

- Fatigue Crack Propagation: George TottenDocumento3 pagineFatigue Crack Propagation: George TottenDida KhalingNessuna valutazione finora

- Cross Bracing Design PDFDocumento5 pagineCross Bracing Design PDFVictor Miranda AcuñaNessuna valutazione finora

- Steam Mains and Drainage: Piping LayoutDocumento11 pagineSteam Mains and Drainage: Piping Layouthej hejNessuna valutazione finora

- S TN Rcs General 001 1Documento9 pagineS TN Rcs General 001 1Hamed RoshanaeiNessuna valutazione finora

- 2000 The Adavantages and Disadvantages of Dynamic Load Testing and Statnamic Load Testing Middendorp Ginneken enDocumento8 pagine2000 The Adavantages and Disadvantages of Dynamic Load Testing and Statnamic Load Testing Middendorp Ginneken enJorge Eduardo Pérez LoaizaNessuna valutazione finora

- Thermodynamics 2 E7Documento41 pagineThermodynamics 2 E7taya699Nessuna valutazione finora

- FluidDocumento5 pagineFluidMohammed SobhiNessuna valutazione finora

- Pressure, Temperature, and Law of Conservation of MassDocumento20 paginePressure, Temperature, and Law of Conservation of MassCarla Francheska CalmaNessuna valutazione finora

- Measurement of Creep Crack Growth Times in Metals: Standard Test Method ForDocumento25 pagineMeasurement of Creep Crack Growth Times in Metals: Standard Test Method ForCristian DíazNessuna valutazione finora

- Prismatic Beam Design: C 11 D B SDocumento8 paginePrismatic Beam Design: C 11 D B SChristian Jay GamboaNessuna valutazione finora

- Netcol 5000Documento2 pagineNetcol 5000febripepNessuna valutazione finora

- Fatigue Tutorial v81Documento11 pagineFatigue Tutorial v81cooljovinNessuna valutazione finora

- ME PHD Handbook 3 18Documento42 pagineME PHD Handbook 3 18SamsonNessuna valutazione finora

- Behavior of Members Subjected To Axial LoadsDocumento21 pagineBehavior of Members Subjected To Axial LoadsAhmad Faraz JuttNessuna valutazione finora

- 4 - ENS6148 - Descriptive Practice QuestionsDocumento3 pagine4 - ENS6148 - Descriptive Practice QuestionssatheeswaranNessuna valutazione finora

- Experiment 1-Vapour Pressure and Enthalpy of VaporisationDocumento5 pagineExperiment 1-Vapour Pressure and Enthalpy of VaporisationStefani KavangoNessuna valutazione finora

- Lecture 5 - Work, Energy & Power (Part 2)Documento54 pagineLecture 5 - Work, Energy & Power (Part 2)Alya Afiqah Junaidi0% (1)

- Shuttleless Weaving (MCQ: SECTION - 3.1) : Question 1: Match The PairsDocumento15 pagineShuttleless Weaving (MCQ: SECTION - 3.1) : Question 1: Match The PairsIT'S Fake IDNessuna valutazione finora