Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Astm C90

Caricato da

Jairo MendezDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Astm C90

Caricato da

Jairo MendezCopyright:

Formati disponibili

4.2.1. ASTM C-90 Northwest Modifications.

The typical concrete masonry unit manufactured in the Northwest is a Grade N block, Grade N units require a minimum compressive strength of 1000 p.s.i., average (3 units) gross area. This equates to a net concrete strength of over 2000 psi. since the block is approximately 50 % void area. Some confusion arises over the compressive strength portion of the specification. Many specs call for the compressive strength of the concrete masonry unit to be 1350 p.s.i. rather than 1000 p.s.i. This is improper as 1350 p.s.i. is the wall design strength allowable with Grade N units. This value incorporates the strengths of the mortar and grout as well as the block into one design value based on net area. Another ASTM C-90 requirement that stirs up much controversy, misunderstanding and wrong application is that concerning the type classification of concrete masonry units. C-90 states that there are two types of units for each grade: Type I, Moisture- Controlled Units, which shall conform to the moisture content requirements of Table I, and Type II, Non Moisture-Controlled Units, which need not conform to the moisture content requirement shown in Table 1. ASTM C-90 Table 1 Moisture-Content Requirements for Type 1 Units Moisture Content, max, % of Total Absorption (Average of 3 Units) Humidity Conditions at Job Site or Point of Use Humida Intermediateb Aridc 45 40 35 35 30 30 25

Linear Shrinkage

0.03 or less From 0.03 to 40 0.045 0.045 to 0.065, 35 max

a

Average annual relative humidity above 75 % Average annual relative humidity 50 to 75 % c Average annual relative humidity less than 50 %

b

Table 2 Strength and Absorption Requirements Note -- To prevent water penetration protective coating should be applied on the exterior face of basement walls and where required on the face of exterior walls above grade.

Compressive Strength min, psi (MPa) Average Gross Area Grade

Water Apsorption, max lb/ft3 (kg/m3) (Average of 3 units) with Ovendry Weight of Concrete, lb/ft3 (kg/ m3) Weight Classification

Light weight Medium weight Less than Average Individual Less Less of 3 than than 125 to Unit Units 85 105 105 (1362) (1682) (2002 to 1682) 1000 800 (5.5) (6.9) 700 600 (4.1) (4.8) -20 (320)

Normal weight 125 (2002) or more

N-1 N-11 S-1a S-11a

a

18 15 (240) 13 (208) (288) ----

Limited to use above grade in exterior walls with weather-protective coatings and in walls not exposed to the weather

Table 3 Minimum Thickness of Face-shell and Webs Web Thickness (WT) Equivalent Web Webs,a min, Thickness, min. in. (mm) in./linear ftb (mm/linear m)b 3/4 (19) 1 (25) 1 (25) 1 1/8 (29) 1 1/8 (29) 1 5/8 (136) 2 1/4 (188) 2 1/4 (188) 2 1/2 (209) 2 1/2 (209)

Face-Shell Nominal Thickness Width (W) of (FST) min, in. Units, in. (mm) (mm)a 3 (76.2) and 3/4 (19) 4 (102) 6 (152) 1 (25) 8 (203) 1 1/4 (32) 1 3/8 (35) 10 (254) 1 1/4 (32)c 1 1/2 (38) 12 (305) 1 1/4 (32)c

Average of measurements on 3 units taken at the thinnest point, when measured as described in Methods C 140, Sections 15 and 17.2.

b

Sum of the measured thickness of all webs in the unit, multiplied by 12, and divided by the length of the unit.

c

This face-shell thickness (FST) is applicable wher allowable design load is reduced in proportion to the reduction in thickness from basic face-shell thickness shown.

Moisture content requirements are included to con trol the amount of shrinkage that can occur in a concrete masonry unit. There are three facets to consider in evaluating moisture content and shrinkage. 1. What are the humidity conditions at the jobsite or point of use? In an area that is continually damp, rainy and very humid, masonry would not tend to dry out and shrink. Shrinkage takes place when excessive water leaves the unit through evaporation or drying. Arid or desert area will cause the excessive moisture in the unit to leave rapidly and thus shrink more than in a humid area. Accordingly, in humid areas, the moisture content of the block can be higher than the moisture content in arid areas. The humidity conditions are defined as follows: Humid, when the average humidity is above 75 %; Intermediate, when the average annual humidity is between 50 % and 75 %; Arid, when the average annual humidity is less than 50 %. This average annual humidity is generally obtained from the local weather bureau, which may or may not have the same condition as the jobsite. 2. What is the absorption of the masonry units? The heavier the unit, the less water it is permitted to absorb. 3. What is the total shrinkage of the units from saturated wet to oven dry? Table 1 gives three ranges of shrinkage: 1. 0.03 % or less 2. from 0.03 % to 0.045 % 3. from 0.045 % to 0.065 % max. Masonry units that have very little shrinkage, 0.030 % or less, can have higher moisture content because the loss of water will not create excessive shrinkage in the block. Units

with high shrinkage, 0.065 % may have excessive movement or shrinkage if the units are very wet and they dry out in an arid climate. The total linear shrinkage of the unit will be a governing factor in determining how much moisture may be in the block. With the materials used in the manufacturing of block in the NW., it is recommended that the shrinkage requirement be specified as 0.045 % - 0.065 % maximum. In Seattle for example, the maximum moisture content would then be 35%, as taken from Table I 4.2.2. Basic Use. 1) Reinforced structural walls. 4.2.3. Grades. There are two grades of hollow concrete block: N and S. The grade N unit is for general use in exterior walls above and below grade and for interior walls. The Grade S unit is limited to use above grade in exterior walls with weather protective coating and in walls not exposed to the weather. 4.2.4. Compression. This is the vertical load applied upon a block unit in its normal position in accordance with ASTM specification. Block shall develop not less than 700 p.s.i. grade S, and 1000 p.s.i. for Grade N over the average gross area with an average of three units, Higher strength block are available. Consult with local manufacturer when desired. 4.2.5. Moisture Control. Two types of hollow concrete block are covered as follows: TYPE I: Moisture controlled units shall conform to a maximum moisture content requirement dependent upon the linear shrinkage properties of the block and the humidity conditions at the jobsite. Block with less shrinkage potential are permitted to have higher moisture contents. TYPE II: Non-moisture controlled units are not required to meet a moisture content requirement. 4.2.6. Dimension. No overall dimension (width height, and length) shall differ by more than 1/8 inch from the specified standard dimensions.

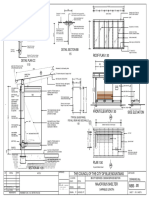

Configurations and dimensions of a typical 8x8x16 unit 4.3. Solid Load-Bearing Units. This section covers solid concrete block (units with 75% or more solid area) ASTM C-145 is the most widely used solid block specification. 4.3.1. Basic Use. 1) Veneer, 2) Cavity walls, 3) Multi-wythe reinforced walls. 4.3.2. Grades. There are two grades of solid load-bearing concrete block "N and S". The grade N unit is for general use in exterior walls above and below grade and for interior walls. The Grade S unit is limited to use above grade in exterior walls with weather protective coating and in walls not exposed to the weather. 4.3.3. Compression. Block shall develop not less than 1200 p.s.i. for grade S units, and 1800 p.s.i. for grade N over the average gross area with an average of three units. 4.3.4. Moisture Content. Two types of solid concrete block are covered as follows: NOTE: Same info as 4.2.5. 4.3.5. Dimension. Two types of hollow concrete block are covered as follows: NOTE: Same info as 4.2.6.

Gross and net CMU area

Concrete Masonry Unit interior wall

Next page

The NW Masonry Guide Table of Contents Masonry Institute of Washington Washington State Conference of Mason Contractors

This site created by Paragraphics

1998 - 2000 Paragraphics all rights reserved

Potrebbero piacerti anche

- Mitigating The Effect of Clay Content of Sand On Concrete StrengthDocumento7 pagineMitigating The Effect of Clay Content of Sand On Concrete Strengthbpkndl7943Nessuna valutazione finora

- Guidance Document Bakery Sector 24-10-2017Documento84 pagineGuidance Document Bakery Sector 24-10-2017R dhawan100% (1)

- 2124R 04Documento13 pagine2124R 04Cynti DZNessuna valutazione finora

- Astm A 185-97Documento5 pagineAstm A 185-97MiguelitovskyNessuna valutazione finora

- Concrete Surface Profile Visual Scale PDFDocumento1 paginaConcrete Surface Profile Visual Scale PDFdang2172014Nessuna valutazione finora

- Structural SpecificationDocumento40 pagineStructural SpecificationBharatharunSaravanakumarNessuna valutazione finora

- Guide To Standards and Tolerances 2017Documento72 pagineGuide To Standards and Tolerances 2017Jill Jim Livestock100% (1)

- Adhesives For Construction. Classification of AdhesivesDocumento8 pagineAdhesives For Construction. Classification of AdhesivesEmma BrunoNessuna valutazione finora

- Highway SpecificationDocumento85 pagineHighway SpecificationAkaninyeneNessuna valutazione finora

- Petrographic Methods of Examining Hardened Concrete: A Petrographic ManualDocumento353 paginePetrographic Methods of Examining Hardened Concrete: A Petrographic ManualTom RewertsNessuna valutazione finora

- Master Deed SampleDocumento29 pagineMaster Deed Samplepot420_aivan0% (1)

- TechnicalGuidelines - Connell WagnerDocumento36 pagineTechnicalGuidelines - Connell WagnerJpver1000Nessuna valutazione finora

- BS en 1996 1 2 2005Documento20 pagineBS en 1996 1 2 2005Meganathan MegaNessuna valutazione finora

- GFRCDocumento11 pagineGFRCMhmd AbdoNessuna valutazione finora

- 100032012Documento8 pagine100032012Nadim527Nessuna valutazione finora

- Aci-211.2 (1998) PDFDocumento18 pagineAci-211.2 (1998) PDFFernando HerediaNessuna valutazione finora

- M 80-87 (2003) Coarse Aggregate For PCCDocumento5 pagineM 80-87 (2003) Coarse Aggregate For PCCWalticoZegarraHerrera100% (1)

- Aashto T 112-2021Documento5 pagineAashto T 112-2021reza acbariNessuna valutazione finora

- Astm C 90 PDFDocumento4 pagineAstm C 90 PDFsumeshmhrNessuna valutazione finora

- TT S 00230CDocumento33 pagineTT S 00230CAnjali AnjuNessuna valutazione finora

- Steel - and Synthetic Fibre ReinforcedDocumento12 pagineSteel - and Synthetic Fibre ReinforcedMangisi Haryanto ParapatNessuna valutazione finora

- NHBC Standards 2008Documento388 pagineNHBC Standards 2008Euan GeddesNessuna valutazione finora

- ACPA City Street Pavement DesignDocumento8 pagineACPA City Street Pavement DesignFelipe Fernández100% (1)

- Precast Concrete - Sandwich Panel ConstructionDocumento16 paginePrecast Concrete - Sandwich Panel Constructionalberto5791Nessuna valutazione finora

- BS 6076.1996Documento19 pagineBS 6076.1996Yaser Al ShabasyNessuna valutazione finora

- Structural Analysis 1: Statically Determinate StructuresDa EverandStructural Analysis 1: Statically Determinate StructuresNessuna valutazione finora

- Astm A762 PDFDocumento10 pagineAstm A762 PDFCristian OtivoNessuna valutazione finora

- ASTM C881 SummaryDocumento1 paginaASTM C881 SummaryRodrigo GarcíaNessuna valutazione finora

- Evaluating The Effect of Asphalt Binder Modification 2019 Case Studies in CDocumento13 pagineEvaluating The Effect of Asphalt Binder Modification 2019 Case Studies in CAmin ZuraiqiNessuna valutazione finora

- Aggregates and Their Properties in Concrete Presentation - Mark Alexander PDFDocumento75 pagineAggregates and Their Properties in Concrete Presentation - Mark Alexander PDFharold romuald Lele FotsoNessuna valutazione finora

- Testing Aggregates: BS 812: Part 120: 1989Documento10 pagineTesting Aggregates: BS 812: Part 120: 1989AmanNessuna valutazione finora

- Fire Protection 5.2 Klemenz Fire ResistanceDocumento80 pagineFire Protection 5.2 Klemenz Fire ResistanceaswathiNessuna valutazione finora

- Installation Guide CINEO C2060Documento196 pagineInstallation Guide CINEO C2060iguzina100% (1)

- Mix Design Specification For Low Strength Concretes Containing Recycled and Secondary AggregatesDocumento15 pagineMix Design Specification For Low Strength Concretes Containing Recycled and Secondary AggregatesASearth100% (1)

- North American Standard For Cold-Formed Steel Framing - GeneralDocumento49 pagineNorth American Standard For Cold-Formed Steel Framing - GeneralNishan GajurelNessuna valutazione finora

- Investigate The Combination of Coconut Shell and Grained Palm Kernel To Replace Aggregate in Concrete: A Technical ReviewDocumento10 pagineInvestigate The Combination of Coconut Shell and Grained Palm Kernel To Replace Aggregate in Concrete: A Technical ReviewKhan BrothersNessuna valutazione finora

- BS 729-1Documento17 pagineBS 729-1Hari GopalNessuna valutazione finora

- C847Documento2 pagineC847reefreefNessuna valutazione finora

- Hilti HCC-B For Concrete Overlays: Fastening Technology ManualDocumento39 pagineHilti HCC-B For Concrete Overlays: Fastening Technology ManualPablo Martinez FesserNessuna valutazione finora

- PavementDocumento11 paginePavementJus CamungaoNessuna valutazione finora

- CR 408 Ceramic TilesDocumento1 paginaCR 408 Ceramic TilesYuri ValenciaNessuna valutazione finora

- Chloride ResistanceDocumento37 pagineChloride ResistanceCarlos Augusto Sánchez Rondón100% (1)

- BarChip Fibres Replace Steel in Chilean HousingDocumento2 pagineBarChip Fibres Replace Steel in Chilean HousingPedro Augusto Delgado NascimentoNessuna valutazione finora

- 2015.10.24, Rock Durability Tests (DMI TEST Etc) PDFDocumento31 pagine2015.10.24, Rock Durability Tests (DMI TEST Etc) PDFkyuguNessuna valutazione finora

- Geotextile FIBERTEXDocumento2 pagineGeotextile FIBERTEXdanfaurNessuna valutazione finora

- When To Challenge Petrographic Reports - tcm45-347346Documento4 pagineWhen To Challenge Petrographic Reports - tcm45-347346Dan TranNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento17 pagineDisclosure To Promote The Right To InformationIndira MukherjeeNessuna valutazione finora

- Astm C 936-2007Documento2 pagineAstm C 936-2007Nikolay DrumevNessuna valutazione finora

- Testing AggregatesDocumento36 pagineTesting AggregatesCodrut RomanNessuna valutazione finora

- Astm C307Documento2 pagineAstm C307John Pink0% (1)

- Specification For Highway Works UK - SERIES 1900Documento78 pagineSpecification For Highway Works UK - SERIES 1900Kévin JacobNessuna valutazione finora

- Ultra High Performance Fiber Reinforced Concrete Mixture DesignDocumento3 pagineUltra High Performance Fiber Reinforced Concrete Mixture DesignShaker QaidiNessuna valutazione finora

- Delta Waterproofing - Method StatementDocumento2 pagineDelta Waterproofing - Method Statementbilly wuNessuna valutazione finora

- Energy TestDocumento19 pagineEnergy TestDataNessuna valutazione finora

- Curing In-Place ConcreteDocumento2 pagineCuring In-Place ConcreteaaNessuna valutazione finora

- AquaMarine Foul Release Vs Antifoul CoatingsDocumento9 pagineAquaMarine Foul Release Vs Antifoul CoatingsA MarineNessuna valutazione finora

- DSR PuneDocumento4 pagineDSR PunedigvijayjagatapNessuna valutazione finora

- Cyclone-Brochure PubDocumento2 pagineCyclone-Brochure Pubsk lukoNessuna valutazione finora

- European International Geotextilestandards Shortguide2010Documento25 pagineEuropean International Geotextilestandards Shortguide2010Michael HarnackNessuna valutazione finora

- Is 5512 1983 PDFDocumento17 pagineIs 5512 1983 PDFBijaya RaulaNessuna valutazione finora

- Influence of Fiber Type and Fiber Orientation On Cracking and Permeability of Reinforced Concrete Under Tensile Loading 2017 Cement and Concrete ReseaDocumento12 pagineInfluence of Fiber Type and Fiber Orientation On Cracking and Permeability of Reinforced Concrete Under Tensile Loading 2017 Cement and Concrete ReseaKaio OliveiraNessuna valutazione finora

- BS 6717 - 2001Documento34 pagineBS 6717 - 2001Ahmad Khreisat100% (1)

- Is-2386-Part-8-1963-R-2002-Method of Tests For Photographic Examination of Aggregates For ConcreteDocumento23 pagineIs-2386-Part-8-1963-R-2002-Method of Tests For Photographic Examination of Aggregates For ConcreteSachin PawarNessuna valutazione finora

- Standard Specification For Masonry CementDocumento4 pagineStandard Specification For Masonry CementJoseph Cloyd LamberteNessuna valutazione finora

- BS 6750 1986 Modular Coordination in Building XDocumento28 pagineBS 6750 1986 Modular Coordination in Building XDaniel CheungNessuna valutazione finora

- BS 6319-4-1984 - (2017-07-27 - 07-49-45 AM) Bond Strength - Slant Shear MethodDocumento16 pagineBS 6319-4-1984 - (2017-07-27 - 07-49-45 AM) Bond Strength - Slant Shear MethodmargarethsmNessuna valutazione finora

- Mechanical and Physcial Properties of Fibre Cement Board PDFDocumento5 pagineMechanical and Physcial Properties of Fibre Cement Board PDFanhnguyenhaiNessuna valutazione finora

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionDa Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNessuna valutazione finora

- CH 1Documento49 pagineCH 1Gurinder PalsinghNessuna valutazione finora

- Non-Loadbearing Steel Stud Partitions: National GypsumDocumento10 pagineNon-Loadbearing Steel Stud Partitions: National GypsumGerald De OcampoNessuna valutazione finora

- TB 08 Building Envelope - CompressedDocumento63 pagineTB 08 Building Envelope - CompressedNraisyahaldaf100% (1)

- Missel Product List GB 2017 02 Fire Protection PDFDocumento36 pagineMissel Product List GB 2017 02 Fire Protection PDFHakkı YılmazNessuna valutazione finora

- WS18-Chapter 23 Roof Plan LayoutDocumento2 pagineWS18-Chapter 23 Roof Plan LayoutJCNessuna valutazione finora

- Technical Submittal - Sika's Passive Fire Protection Solutions - RemovedDocumento65 pagineTechnical Submittal - Sika's Passive Fire Protection Solutions - Removedsamoeel2010Nessuna valutazione finora

- Presentation Masonry & FinishingDocumento36 paginePresentation Masonry & Finishingfrancis_chokiNessuna valutazione finora

- TechnicalDrawing - MAJOR BUS SHELTERDocumento3 pagineTechnicalDrawing - MAJOR BUS SHELTERyoudhffgNessuna valutazione finora

- Bridgeport Connecticut New Zoning Regulations 2010Documento206 pagineBridgeport Connecticut New Zoning Regulations 2010BridgeportCTNessuna valutazione finora

- Building Jali Detail-Layout1Documento1 paginaBuilding Jali Detail-Layout1SUMIT SHARMA100% (1)

- Jablite Basement BoardDocumento7 pagineJablite Basement BoardalokNessuna valutazione finora

- University of East London, Barking Campus, Greater London - Building RecordingDocumento71 pagineUniversity of East London, Barking Campus, Greater London - Building RecordingWessex Archaeology100% (2)

- European Commission: 04/33 External Walls (Including Cladding), Internal Walls and PartitionsDocumento14 pagineEuropean Commission: 04/33 External Walls (Including Cladding), Internal Walls and PartitionsСтанислав ПодольскийNessuna valutazione finora

- Product Sheet SKJ 80-EngDocumento2 pagineProduct Sheet SKJ 80-EngEduardo CarcelenNessuna valutazione finora

- Pages From UBC 1997 - Uniform Building Code 12Documento1 paginaPages From UBC 1997 - Uniform Building Code 12danieldumapitNessuna valutazione finora

- Fischer Firestop Catalog Aug2019Documento73 pagineFischer Firestop Catalog Aug2019ArunKumar RajendranNessuna valutazione finora

- NAA Standard For The Storage of Archival RecordsDocumento17 pagineNAA Standard For The Storage of Archival RecordsickoNessuna valutazione finora

- Besta Board: ... Building ResponsiblyDocumento2 pagineBesta Board: ... Building ResponsiblyWhite RabbitNessuna valutazione finora

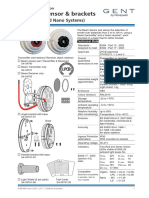

- 4188-969 - New GENT Beam PDFDocumento22 pagine4188-969 - New GENT Beam PDFCherif TharwatNessuna valutazione finora

- 2016CA IBC Vol1Documento120 pagine2016CA IBC Vol1Mich DeesNessuna valutazione finora

- Case Study Design 6 PDFDocumento5 pagineCase Study Design 6 PDFHadeelNessuna valutazione finora

- BASF Styrodur Basement Insulation PDFDocumento20 pagineBASF Styrodur Basement Insulation PDFakajsiNessuna valutazione finora