Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

14382

Caricato da

Muhammad AwaisCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

14382

Caricato da

Muhammad AwaisCopyright:

Formati disponibili

Radiant Flux Measurements in the Pilot-Scale IFRF-NFA Burner Operating in a High CO2 Environment at Different Swirl Settings

O.B. Ramadan, C.S. Lam, P.M. Hughes, P. Gogolek, and J. Wong CanmetENERGY, Natural Resources Canada, 1 Haanel Drive, Ottawa, Ontario K1A 1M1

Corresponding author: Cecilia Lam CanmetENERGY, Natural Resources Canada 1 Haanel Drive, Ottawa, Ontario, Canada K1A 1M1 Tel: +1 613-996-2759 Fax: +1 613-992-9335 Email: Cecilia.Lam@NRCan-RNCan.gc.ca

ABSTRACT The thermal environment produced by the IFRF Near Field Aerodynamics burner under O2/CO2 combustion and different swirl settings (0-90%) was examined. A comparison case involving air combustion under a single swirl setting of 70% was also included. As the swirl setting was increased from 0 to 70% under O2/CO2 combustion, furnace temperatures and radiant heat flux to the wall increased by 5% and 20-25%, respectively. For the same swirl setting of 70%, air combustion resulted in up to 15% higher temperatures and 20-24% higher levels of radiant heat flux than O2/CO2 combustion. This implies that a higher O2 to CO2 ratio is needed in order to obtain levels of heat flux and temperature similar to those experienced in air combustion. KEYWORDS Swirl burner, O2/CO2 combustion, temperature, radiant heat flux

1. INTRODUCTION Experimental studies show that rotating flow (i.e. swirl) has an important influence on flow field characteristics such as jet growth, entrainment and decay for inert jets, as well as flame size, flame shape, flame stability, and combustion intensity for reacting flows [1-3]. Swirlers are static mixing devices used to impart swirl to the flow. Different swirler types can exhibit varying mixing profiles and reverse flow characteristics. Existing swirler designs for gas turbine combustors and industrial burners have been reviewed [4, 5]. The degree of swirl is typically characterized by the swirl number. The swirl number is a non-dimensional characteristic of the rotating flow and describes how fast the tangential momentum flux decays relative to the axial momentum flow [6]. The presence of swirl in combusting flows not only enhances entrainment and mixing, but also induces an internal recirculation zone that transports hot combustion products back into the flame region and helps to stabilize the flame [1-3]. Higher levels of swirl tend to increase the recirculation intensity [7]. An ongoing project at CanmetENERGY involves characterizing the performance of different pilot-scale burners (including a swirl burner) in direct fuel-fired furnaces in a high CO2 environment. Such an environment would allow implementation of technologies appropriate for carbon capture and storage. Some of the experimental results from this project have already been reported [8-11]. The present paper is focussed on results from the swirl burner in particular, thermal measurements made using conventional water-cooled probes under different swirl settings and O2/CO2 combustion.

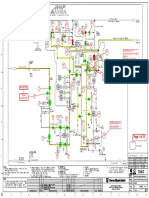

2. EXPERIMENTAL SETUP All the experiments reported in this work were performed at the CanmetENERGY facilities in Ottawa, Canada. This section briefly describes the furnace, burner and instrumentation used in the tests. 2.1 Furnace The Research Tunnel Furnace (RTF) at CanmetENERGY is intended for the study of combustion aerodynamics, burner performance, pollutants in relation to flame properties and heat transfer from flames. The RTF has a cylindrical cross-section and operates with a single burner fired along the horizontal axis (Fig. 1). The furnace is designed for a thermal input of 700 kW and can be fired on natural gas, oil or coal. The RTF has an overall length of 4.25 m. The first 0.9 m defines the near burner region (NBR) (Fig. 1). This section has an inner diameter of 0.9 m and is refractory-lined to provide heat feedback to the incoming reactants. The NBR is the measurement region of interest in this study. Measurement ports accessing this region are labelled P1 to P4; see Fig. 1 and Table 1 for the port locations. In combination, the four ports form an opening of 0.66 m total length and 0.10 m height in the wall of the furnace. All tests were performed using natural gas fired at 200 kW. Two different oxidizers, air (at 3% above stoichiometric) and a combination of oxygen (O2) and carbon dioxide (CO2), were used. The ratio of O2 to CO2 was selected to represent the case in which all the nitrogen in the air is replaced on a volume basis by CO2. Table 2 provides details of the firing conditions.

Figure 1: The CanmetENERGY Research Tunnel Furnace Table 1: Measurement Positions on the RTF

Table 2: Furnace Operating Conditions

Oxidizer Air O2/CO2 Oxidizer Flow Rate [kg/h] 263.4 60.5 / 301.74 NG Flow Rate [kg/h] 13.86 13.84 Firing Rate [kW] 200 200

2.2 Burner The Near Field Aerodynamics (NFA) burner of the International Flame Research Foundation (IFRF) is a research-type burner with a moveable block swirl generator and is designed for studying near-burner aerodynamics. This burner was used in the wellknown Scaling 400 study, which focussed on scaling characteristics of the near-burner aerodynamics and NOx emissions of industrial natural gas burners [12]. In the NFA burner, parameters such as swirl intensity, stoichiometric ratio and degree of premix of the natural gas-air mixture can be controlled. Figure 2 shows a schematic drawing of the

burner, along with basic dimensions. The burner contains a swirl generator and quarl joined together via a cylindrical tube. Swirl in the incoming flow is generated by means of a moveable block swirler, which is installed upstream of the tube. The swirl generator consists of a number of alternately placed fixed and moveable blocks (Fig. 2). Inside the cylindrical tube, an adjustable fuel rod is maintained in the frontmost position, as shown in Fig. 2. Hence, an annular channel is formed between the tube and fuel rod. The fuel rod conducts natural gas to the burner mouth, where it is radially injected into the swirling combustion air through a ring set of 30 holes. Expansion of the flow is accommodated by the quarl. During the present investigation, the swirl setting (which controls the swirl intensity) was varied between 0 and 90% by adjusting the control wheel on the swirl generator (Fig. 2).

Figure 2: Schematic of the IFRF-NFA burner with the moveable block swirl generator.

2.3 Heat Transfer Measurements The incident radiant heat flux to the inside wall of the furnace was measured using a water-cooled, ellipsoidal radiometer. Figure 3 shows the radiometer used in this investigation. The working part of the radiometer is a thermopile situated at one end of the ellipsoidal cavity at the probe tip. The cavity is lined with a gold coating. The incident radiation enters the ellipsoidal cavity through a 3.18 mm hole and is concentrated onto the thermopile detector [13, 14]. The cavity is constructed such that the entrance acceptance angle is almost 2 steradians; therefore, the radiation incident at the entrance of the cavity from almost all directions is captured and focussed onto the detector. Through calibration with a black body source, the temperature measured by the thermopile can be related to the amount of thermal energy entering the cavity. The black body source used in the present tests for the calibration of the radiometer was the MIKRON M300, which has a temperature range of 200C to 1100C. The ellipsoidal cavity is continuously purged with nitrogen gas (at a flow rate of 0.6 L/min) to apply a quantifiable convective condition and to avoid deposition of combustion particles or condensation on the cavity surface. The manufacturer-specified uncertainty of the ellipsoidal radiometer is 3% [14].

Figure 3: Schematic and photograph of the water-cooled ellipsoidal radiometer 2.4 Gas Temperature Measurements A water-cooled suction pyrometer was used to estimate the temperature of the combustion gases inside the furnace. This instrument is designed to increase the convective part of the heat transfer from the gases to the sensor while minimizing radiation between the sensor and the surroundings. The tip of the suction pyrometer (Fig. 4) has an entry nozzle through which combustion gases are sampled with high velocity. The gases are drawn into the probe and pass over a thermocouple bead. Ceramic tubes and an end cap provide a radiation shield to prevent radiant heat exchange between the bead and furnace walls. When an increase in the suction rate of the gases through the probe no longer gives an increase in bead temperature, the bead is assumed to be at the temperature of the gases being drawn through the probe. A Type S (Platinum vs. Platinum-10% Rhodium) thermocouple in the suction pyrometer enables temperature measurements up to 1500C.

In addition to the suction pyrometer, a Type K (Chromel-Alumel) thermocouple, protected in a ceramic tube, was located at a distance of approximately 0.30 m from the burner face and 0.35 m from the furnace wall to monitor the temperature inside the combustion chamber.

Figure 4: Schematic of Tip of Suction Pyrometer 2.5 Visual Imaging A progressive scan, RGB color camera (model CV-M9-CL, manufactured by JAI Inc. of San Jose, CA) was used to capture images inside the combustion chamber through the access ports (Fig. 1). The camera has 3 CCD sensors (each based on a 1/3" image format) and a sensitivity of 1034 (h) by 779 (v) pixels. A shutter speed of 1/500 s was used for all images presented in this paper.

3. RESULTS This section presents results for O2/CO2 combustion under swirl settings of 0, 30, 50, 70 and 90% and, for comparison, air combustion under a single swirl setting of 70%. The swirl settings of 30, 50, 70 and 90% correspond to swirl numbers of 0.09, 0.27, 0.50 and 0.80, respectively, as estimated using data taken from the Scaling 400 study (see reports referenced by Weber [12]). Figures 5 to 9 show typical images of the burner flame under O2/CO2 combustion and different swirl settings, captured using the camera described in Section 2.5. The camera is looking through the access ports P1 to P3. The refractory bricks and insulation on the opposite side of the furnace can be seen, in addition to the thermocouple monitoring the chamber temperature (located near the centre of the image). The exit of the burner quarl is visible on the right side of the image.

Figure 5: Image inside combustion chamber, 0% swirl setting, O2/CO2 combustion

Figure 6: Image inside combustion chamber, 30% swirl setting, O2/CO2 combustion

Figure 7: Image inside combustion chamber, 50% swirl setting, O2/CO2 combustion

Figure 8: Image inside combustion chamber, 70% swirl setting, O2/CO2 combustion

Figure 9: Image inside combustion chamber, 90% swirl setting, O2/CO2 combustion In all of the images, a bluish flame is evident. As the swirl setting increases, the combustion chamber appears to glow, indicating increasing temperatures inside the furnace. At the 70% swirl setting (Fig. 8), a distinct yellow region can be seen at the quarl exit on the right side of image; this is a reflection off the quarl wall. At the 90% swirl setting (Fig. 9), all the walls glow a bright orange colour, indicating very high chamber temperatures.

The above is corroborated by measurements from the Type K thermocouple monitoring the chamber temperature (Section 2.4). Figure 10 shows the temperature measurements corresponding to swirl settings between 0 and 70% (no data were available for the 90% swirl setting). Error bars indicate the 0.75% standard calibration uncertainty for Type K thermocouples [15]. As the swirl setting increased from 0 to 30%, the temperature increased by 6C, or 0.6%. As the swirl setting then increased up to 70%, the furnace temperature increased almost linearly by a further 46C, or 4.8% of the temperature at the 30% swirl setting.

1020 1010

Furnace temperature [C]

1000 990 980 970 960 950 940 0 10 20 30 40 Swirl setting (%) 50 60 70 80

Figure 10: Effect of swirl setting on furnace temperature (measured with thermocouple) For air combustion, Fig. 11 shows a typical image of the burner flame under a swirl setting of 70%. This may be compared with Fig. 8 for O2/CO2 combustion, although it should be noted that Fig. 11 was taken from a different angle and covers a smaller region of the flame and furnace. (The thermocouple monitoring the chamber temperature is visible on the left side of Fig. 11, as opposed to the middle of Fig. 8.) The air combustion condition appeared to involve higher furnace temperatures than O2/CO2 combustion under the same swirl setting, as evident from the greater glow of the furnace

walls in Fig. 11. This was confirmed by measurements taken with the suction pyrometer, as indicated in Fig. 12. The plots show that temperatures under air combustion were up to 15% higher than those under O2/CO2 combustion.

Figure 11: Image inside combustion chamber, 70% swirl setting, air combustion

Figure 12: Radial temperature profiles across the furnace at port locations P1, P2 and P3 (measured with suction pyrometer), 70% swirl setting

Further to the above, Fig. 13 shows heat flux data measured by the ellipsoidal radiometer at different axial locations along the inside wall of the furnace. Data are plotted for O2/CO2 combustion and swirl settings from 0 to 70%, as well as for air combustion at a swirl setting of 70%. Consistent with the temperature results discussed previously, Fig. 13 shows an overall trend of increasing radiant heat flux with higher swirl settings under O2/CO2 combustion. The heat flux levels for the 70% swirl setting were 20-25% higher than those for the 0% swirl setting. Similar to the temperature curve in Fig. 10, only a small increase in heat flux (0-4%) was observed when the swirl setting was increased from 0 to 30%. Meanwhile, the heat flux increased by a larger amount when the swirl setting was increased from 30 to 50% (8-11% increase in heat flux), and subsequently to 70% (6-10% increase in heat flux). In three of the four O2/CO2 tests, the maximum heat flux for a particular swirl setting was measured at a distance of 0.54 m from the burner face (P3). The only test in which this trend did not occur was that for the 30% swirl setting, in which the maximum heat flux was measured at 0.70 m from the burner face (P4). Although reasons for this shift in peak heat flux are unclear, it may be noted that the heat flux levels measured from 0.38 to 0.70 m downstream of the burner face (i.e. from P2 to P4) under the 30% swirl setting increased with distance by only 2%, well within the 3% measurement uncertainty of the ellipsoidal radiometer. Thus, more measurements would be needed to verify the observations at the 30% swirl setting.

20 19

Radiant Heat Flux [W/cm 2]

18 17 16 15 14 13 12 11 10 0.1 0.2 0.3 0.4 0.5 0.6 0.7 O2/CO2

70% (Air)

Swirl setting 70% 50% 30% 0%

0.8

Distance from burner face [m]

Figure 13: Longitudinal variation in radiant heat flux to inside wall of furnace Comparing the tests for air versus O2/CO2 combustion at the 70% swirl setting, the radiant flux levels measured under air combustion were between 20 and 24% higher than those measured under O2/CO2 combustion. This is consistent with the temperature data in Fig. 12 and the visual images in Figs. 8 and 11. Also, under air combustion, higher levels of heat flux were measured with increasing distance from the burner face, with a 5% increase in heat flux measured between distances of 0.38 and 0.70 m and the peak heat flux occurring at the 0.70 m distance. This suggests that combustion reactions, and therefore heat release, under air combustion occurred over a greater distance from the burner face than in the test with O2/CO2 combustion. It is consistent with previously reported measurements of carbon monoxide (CO) concentrations [8], which indicated faster consumption of CO in the O2/CO2 conditions than in air.

4. CONCLUSIONS Under O2/CO2 combustion, increases in the swirl setting resulted in higher gas temperatures and higher radiant heat flux to the furnace wall. Between swirl settings of 0 and 70%, measured temperatures increased by 5% (52C), while heat flux at a given location increased by 20-25%. A similar trend was seen in both parameters: first, a small increase occurred as the swirl setting increased from 0 to 30%; then larger increases of similar extent were observed as the swirl setting increased from 30 to 50% and from 50 to 70%. The increases in temperature and heat flux were likely caused by enhanced combustion resulting from increased entrainment and mixing of furnace gases with incoming fuel and oxidizer under higher swirl. For a fixed swirl setting of 70%, air combustion resulted in higher temperatures and radiant heat flux levels than O2/CO2 combustion. The heat flux levels were 20-24% higher, while the temperatures were up to 15% higher. This was likely due to the ability of CO2 to absorb more radiation than nitrogen. The results imply that a higher O2 to CO2 ratio is needed in order to obtain levels of heat flux and temperature that are similar to those experienced in air combustion. REFERENCES [1] [2] [3] [4] [5] [6] Lilley, D.G., AIAA Journal, 15(8) 1063-1078, 1977. Ber, J.M. and Chigier, N.A., Combustion Aerodynamics, Applied Science Publishers Ltd., London, 1972. Syred, N. and Ber, J.M., Combustion and Flame, 23(2) 143-201, 1974. Gupta, A.K., Lilley, D.G. and Syred, N., Swirl Flows, Abacus Press, Tunbridge Wells, England, 1984. Basu, P., Kefa, C. and Jestin, L. in Boilers and Burners: Design and Theory (Ed. F. Ling), Springer, New York, 212-241, 2000. Weber, R. and Dugu, J., Progress in Energy and Combustion Science, 18(4) 349367, 1992.

[7] [8]

Fudihara, T.J., Goldstein Jr., L. and Mori, M., Brazilian Journal of Chemical Engineering, 24(2) 233-248, 2007. Hughes, P.M., Ramadan, O., Lam, C., Gogolek, P., Wong, J., Lacelle R. and Lycett, R., Industrial Furnace Performance Under Carbon Capture Operation, 2010 Pacific Rim Symposium, IFRF-AFRC, Maui, Hawaii, September 26-29, 2010.

[9]

Lam, C.S., Ramadan, O., Wong, J., Lycett, R. and Hughes, P.M., Heat Flux Measurement in Industrial Furnaces, 2010 Spring Technical Meeting, Combustion Institute - Canadian Section, Ottawa, Ontario, May 9-12, 2010, pp. 415-420.

[10] Ramadan, O.B., Hughes, P.M., Lam, C.S., Lacelle, R.J., Wong, J. and Lycett, R., Incident Radiant Flux Measurements in Pilot-Scale Burners Operating in a High CO2 Environment, 9th European Conference on Industrial Furnaces and Boilers (INFUB), Estoril, Portugal, April 26-29, 2011. [11] Ramadan, O., Hughes, P., Lam, C., Gogolek, P., Wong, J. and Topping, J., Temperature and Radiant Flux Measurements in Pilot-Scale Combustion of Natural Gas in a High CO2 Environment, 17th International Member Conference, IFRF, Paris, France, June 11-13, 2012. [12] Weber, R., Twenty-Sixth Symposium (International) on Combustion, The Combustion Institute, Pittsburgh, 3343-3354, 1996. [13] Chedaille, J. and Braud, Y., Industrial Flames, Vol. 1, Measurements in Flames, Edward Arnold, London, 1972. [14] Operating Instructions for the Land 2 Ellipsoidal Radiometer (Type B Axial), Land Combustion Ltd., Chesterfield, England, 1977. [15] OMEGA Engineering, Inc., The Temperature Handbook, Stamford, CT, 2nd edition, 2000.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Solar Water Heating Slope Roof and CoilDocumento1 paginaSolar Water Heating Slope Roof and CoilMuhammad AwaisNessuna valutazione finora

- EXAMPLE 8.1-2: Conductance of A Cross-Flow Heat Exchanger (Revisited)Documento1 paginaEXAMPLE 8.1-2: Conductance of A Cross-Flow Heat Exchanger (Revisited)Muhammad AwaisNessuna valutazione finora

- LLL LLL: Mazdon HP200 - 20 Tube Manifold Mazdon HP200 - 30 Tube ManifoldDocumento5 pagineLLL LLL: Mazdon HP200 - 20 Tube Manifold Mazdon HP200 - 30 Tube ManifoldMuhammad AwaisNessuna valutazione finora

- 1761 Performance Aspen SeriesDocumento2 pagine1761 Performance Aspen SeriesMuhammad AwaisNessuna valutazione finora

- View A-A: Part No. Ordering InformationDocumento2 pagineView A-A: Part No. Ordering InformationMuhammad AwaisNessuna valutazione finora

- 1 s2.0 S0017931005003005 MainDocumento9 pagine1 s2.0 S0017931005003005 MainMuhammad AwaisNessuna valutazione finora

- Transient Conduction and Lumped Capacitance MethodDocumento15 pagineTransient Conduction and Lumped Capacitance MethodMuhammad Awais100% (1)

- In-Situ Gas AnalyzrDocumento4 pagineIn-Situ Gas AnalyzrMuhammad AwaisNessuna valutazione finora

- Portable Flue Gas Analyzer: Tempest 50Documento7 paginePortable Flue Gas Analyzer: Tempest 50Muhammad AwaisNessuna valutazione finora

- Emissions Incinerator Plants - Application Note (2006) ... FtirDocumento3 pagineEmissions Incinerator Plants - Application Note (2006) ... FtirMuhammad AwaisNessuna valutazione finora

- RP338 Flue Gas Flow EN-12952-15Documento81 pagineRP338 Flue Gas Flow EN-12952-15Muhammad AwaisNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- MSS SP 75 WPHY Pipe Fittings: Product CategoriesDocumento2 pagineMSS SP 75 WPHY Pipe Fittings: Product CategoriesBenaknaik S GajannavarNessuna valutazione finora

- C ProfileDocumento16 pagineC ProfileResky Ervaldi SaputraNessuna valutazione finora

- Sample of P&ID Marked Up DrawingDocumento11 pagineSample of P&ID Marked Up DrawingToniNessuna valutazione finora

- Liquid DetergentDocumento6 pagineLiquid DetergentAshu GargNessuna valutazione finora

- Alkylation Complex Start Up Plan: ObjectivesDocumento10 pagineAlkylation Complex Start Up Plan: ObjectivesBikas SahaNessuna valutazione finora

- SM Nissan T31 X Trail Body Repair ManualDocumento64 pagineSM Nissan T31 X Trail Body Repair ManualOvidiu IancuNessuna valutazione finora

- Silicon Wafer and Ingot Preparation PDFDocumento23 pagineSilicon Wafer and Ingot Preparation PDFprinceNessuna valutazione finora

- 1 Toth Opt SecDocumento12 pagine1 Toth Opt SeccoolerthanhumphreyNessuna valutazione finora

- Spheroidal Graphite (SG) Acicular / MartensiticDocumento2 pagineSpheroidal Graphite (SG) Acicular / MartensiticTarun ChakrabortyNessuna valutazione finora

- Aux Electrical PDFDocumento137 pagineAux Electrical PDFmahi9892100% (1)

- Grapa Tipo Pistola - MACLEAN AR-A0930Documento1 paginaGrapa Tipo Pistola - MACLEAN AR-A0930RogerNessuna valutazione finora

- Arihant Brochure 2016 PDFDocumento148 pagineArihant Brochure 2016 PDFSachinNessuna valutazione finora

- FRACCIONAMIENTO de Aceite de PalmaDocumento8 pagineFRACCIONAMIENTO de Aceite de PalmaJame QFNessuna valutazione finora

- JSA-009a Drilling and Mon Well Construction-SonicDocumento4 pagineJSA-009a Drilling and Mon Well Construction-SonicDedi Apriadi86% (7)

- Manual Generador ENGGADocumento20 pagineManual Generador ENGGAmanuel100% (2)

- Fs-1030 Quick G... R Jam (Eng)Documento1 paginaFs-1030 Quick G... R Jam (Eng)paliouras11Nessuna valutazione finora

- Air, Combustion, Fire Fighting-Topic 7 ChemistryDocumento6 pagineAir, Combustion, Fire Fighting-Topic 7 ChemistryAlberto De SafariNessuna valutazione finora

- SOUDAL Product Catalogue 2016 129171Documento68 pagineSOUDAL Product Catalogue 2016 129171Candice Diaz100% (1)

- Large Engine Lubricants: OutlineDocumento17 pagineLarge Engine Lubricants: OutlineJahmia CoralieNessuna valutazione finora

- Steel Plates For Offshore StructuresDocumento8 pagineSteel Plates For Offshore StructuresYiengeChanYeeNessuna valutazione finora

- Ring Joint GasketsDocumento5 pagineRing Joint GasketsBahman Matouri100% (1)

- Te 710 WebDocumento57 pagineTe 710 WebRoman KrautschneiderNessuna valutazione finora

- Airflow Pattern StudiesDocumento18 pagineAirflow Pattern Studiessainath_84100% (1)

- Yamaha Ef2800iDocumento45 pagineYamaha Ef2800ik barron0% (1)

- Gas Springs1Documento32 pagineGas Springs1GLADWIN PAUL SIM 16-18Nessuna valutazione finora

- Final Report 3D Chocolate PrintingDocumento20 pagineFinal Report 3D Chocolate PrintingPrathamesh PatilNessuna valutazione finora

- DIN 18800-02 - Structural Steelwork Design Construction - DIN (1990)Documento41 pagineDIN 18800-02 - Structural Steelwork Design Construction - DIN (1990)rapaig100% (4)

- Epocem PrimerDocumento2 pagineEpocem PrimerAnonymous v1blzDsEWANessuna valutazione finora

- BO1001-41120-EEC102 - 448220633 - Cable Trays and Conduits Technical Specification - ESEDocumento31 pagineBO1001-41120-EEC102 - 448220633 - Cable Trays and Conduits Technical Specification - ESEfernando romeroNessuna valutazione finora

- Replacing Downdraft Kiln With Chamber Kiln in A Refractory IndustryDocumento2 pagineReplacing Downdraft Kiln With Chamber Kiln in A Refractory IndustryKauser ImamNessuna valutazione finora