Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Disi Qa Mos El Ms CNX 001 Rev 0 Ms For Temporary CP

Caricato da

Amer Y KTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Disi Qa Mos El Ms CNX 001 Rev 0 Ms For Temporary CP

Caricato da

Amer Y KCopyright:

Formati disponibili

THE HASHEMITEKINGDOM OF JORDAN MINISTRY OF WATER AND IRRIGATION

DISI WATER COMPANY

Gama G Sistemleri Mhendislik ve Taahht A.. Gama Power Systems Engineering and Contracting Inc. Project Title:

DISI-MUDAWARRA TO AMMAN WATER CONVEYANCE SYSTEM PROJECT

Document Title:

METHOD STATEMENT FOR CATHODIC PROTECTION SYSTEM INSTALLATION (Temporary)

Document Number:

DISI-QA-MOS-EL-MS-CNX-001

Issue Date:

14 25 OCTOBER 2010

Construction Experts Company )ConEx)

THE HASHEMITEKINGDOM OF JORDAN MINISTRY OF WATER AND IRRIGATION

DISI WATER COMPANY

Gama G Sistemleri Mhendislik ve Taahht A.. Gama Power Systems Engineering and Contracting Inc.

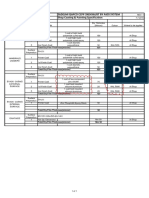

INDEX SHEET FOR REVISIONS

Document Title: Document Number:

DISI-QA-MOS-EL-MS/CNX-001

Gama GucSistemleri:

METHOD STATEMENT FOR CATHODIC PROTECTION SYSTEM INSTALLATION )Temporary)

APPROVED BY: DATE:

REVISION HISTORY REV NO A DESCRIPTIONS/ REASON FOR ISSUE Issued for Approval CHECKED BY K.M APPROVED BY G.S

DATE

PREPARED BY M.TH

1425/10/2010

Disi-Mudawarra to Amman Water Conveyance System Project

HashemiteKingdom of Jordan Ministry Of Water And Irrigation Disi Water Company

METHOD STATEMENT FOR CATHODIC PROTECTION SYSTEM INSTALLATION -Temporary Doc .No:

DISI-QA-MOS-EL-MS/CNX001

CONSTRUCTION EXPERTS COMPANY

Rev 0

1 of 128

TABLE OF CONTENTS

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. SCOPE .............................................................................................................2 PURPOSE .........................................................................................................2 DEFINITION .....................................................................................................2 REFERENCES ....................................................................................................2 ROLES & RESPONSIBILITIES .......................................................................... 223 TOOLS &EQUIPMENTS: .................................................................................. 445 MANPOWER ......................................................................................................5 ENGINEERING AND RESPONSIBILITIES ........................................................... 556 MATERIALS ACQUISITION AND AVAILABILITIES ...................................................6 Method of Construction -Cathodic Protection System -Sacrificial type-Temporary. .......7 TESTING & INSPECTIONS ..................................................................................8

DISI-QA-MOS-EL-MS/CNX-001 Rev 0

Disi-Mudawarra to Amman Water Conveyance System Project

HashemiteKingdom of Jordan Ministry Of Water And Irrigation Disi Water Company

METHOD STATEMENT FOR CATHODIC PROTECTION SYSTEM INSTALLATION -Temporary Doc .No:

DISI-QA-MOS-EL-MS/CNX001

CONSTRUCTION EXPERTS COMPANY

Rev 0

2 of 128

1.

SCOPE

The scope of this method statement is to detail the sequence and activities followed during the construction and installation of the cathodic protection system temporary where needed and define the responsibilities of the construction team

2.

PURPOSE

The purpose of this method statement is to ensure that the cathodic protection installation team is familiar with the minimum guidelines and measures to be followed during construction and installation of the proposed temporary cathodic protection system.

3.

DEFINITION

Contractor Sub-Contractor Project :Gama G Sistemleri Mhendislik ve Taahht A. . :Construction Experts Company).CNX( :Disi Water Conveyance Project )DISI(

4.

REFERENCES

J08086FDSPCENV-03 Rev 1 :Datasheet for Temporary CP. J08086-GEN-DET-FD-ENV-DT-20 :Typical Details Temporary CP System. J08086-GEN-DET-FD-ENV-DT-21 :Typical Details CP standard Test facility. Subcontract agreement PRICE SCHEDULE -Encl_4C_Description_of_Prices_Rev_1

5.

ROLES & RESPONSIBILITIES

The following are job descriptions of the principal Project Field Staff personnel utilized construction of the DISI Water Conveyance System Project of Jordan. Project Construction Manager Construction Superintendents, (Civil, Mechanical, Electrical, Instrumentation) Field HSE Coordinator/Safety Designate or Safety Man Field Quality Assurance / Quality Control Manager

5.1

Project Construction Manager

DISI-QA-MOS-EL-MS/CNX-001 Rev 0

Disi-Mudawarra to Amman Water Conveyance System Project

HashemiteKingdom of Jordan Ministry Of Water And Irrigation Disi Water Company

METHOD STATEMENT FOR CATHODIC PROTECTION SYSTEM INSTALLATION -Temporary Doc .No:

DISI-QA-MOS-EL-MS/CNX001

CONSTRUCTION EXPERTS COMPANY

Rev 0

3 of 128

Reports to the Project Manager and/or Manager of Construction. His responsibilities include the supervision of the entire field organization including field staff and subcontractors. He has the overall responsibility for the execution of all contract commitments relating to the field construction activities in accordance with specific project plans, schedules, and budgets. He has the authority to administer all field office activities and direct assigned personnel in meeting company and project objectives. His specific duties includes planning, organizing, and directing all field work to a successful conclusion of the project, meeting contractual obligations and the Client's expectations while maintaining the company's best interests. He will establish a site office, personnel camps and any additional structures required to accomplish project goals and administer all field activities in accordance with company and departmental policies and procedures and project specifications. He will direct material control activities and all QA/QC and survey activities. He will administer all subcontracts and participate in all subcontract negotiations and submit subcontractors, including any third party NDE companies for approval to the client prior to signing contracts with subcontractors. Additionally, he will provide jobsite interface with the Client, maintaining close liaison at all times and attend project meetings with the client on a regular basis He will also be responsible to provide a copy of all field reports, inspection documents, and procedures including project activities to the client upon an agreed timeline. He will perform any additional project related duties as required and be responsible for all project documentation which includes document Turn-Over-Packages and OEM Manuals.

5.2

Construction Superintendents The Construction Superintended reports to the Project Construction Manager. His responsibilities include the supervision of, filed supervisors, Craft Personnel and Subcontractors. He is responsible for the day to day coordination of all construction activities related to physical progress and productivity. Specific Duties includes but not limited to organizing and directing all construction activities, supervising assigned staff personnel and establish daily productivity goals, monitor productivity and initiate remedial action where required. He will assist in preparation of reports; participate in all coordination, scheduling, safety and progress review meeting. He is responsible for interfacing with engineering and assuring that the latest drawing and document revisions are circulated to project personnel. He will also be responsible for interpreting drawings and specifications for field personnel and subcontractors and coordinates resolution of engineering problems with the appropriate engineering staff and the client. He will also notify QA/QC personnel in all QA/QC activities including any deficiencies found during construction. He is also responsible for development of field test data and punch lists.

DISI-QA-MOS-EL-MS/CNX-001 Rev 0

Disi-Mudawarra to Amman Water Conveyance System Project

HashemiteKingdom of Jordan Ministry Of Water And Irrigation Disi Water Company

METHOD STATEMENT FOR CATHODIC PROTECTION SYSTEM INSTALLATION -Temporary Doc .No:

DISI-QA-MOS-EL-MS/CNX001

CONSTRUCTION EXPERTS COMPANY

Rev 0

4 of 128

5.3

Field HSE Coordinator The Safety Coordinator reports to the Project Construction Manger and is responsible for Project Safety and the implementation of an effective safety program, including initiating a daily Job Safety Analysis (JSA). Where the Clients safety re quirements are more stringent that the contractors safety program, the clients safety program will be met. He is responsible for establishing first aid facilities and the requisition of all necessary safety, first aid and fire prevention equipment required to have an effective project safety system in place. He is responsible for maintaining a continuous inspection of the jobsite and report any unsafe acts or conditions to the responsible supervisor. Serious violations must be reported immediately to the Project Construction Manager and the client. He will preview and monitor all subcontractor safety programs and provide assistance upon request. He will also organize, train and attend weekly safety meetings for all levels of supervision and investigate all accidents and submit accident reports as required by law and client safety policy. He will maintain all safety records and issue Monthly safety reports.

. 5.4

QA/QC Coordinator The QA/QC Manager is responsible to the Project Manager in all activities pertaining to quality. He is responsible for the daily activities and supervision of filed QC Inspectors. He will supervise and/or perform inspections of work, in progress and completed to conform to project drawings, specifications, applicable Codes and Standards and keeping with the requirements of good industry practices. QA/QC Coordinator is responsible for technical aspects on site and coordination with client inspections, witness and hold points. He is responsible for performing audit of subcontractor's inspection reports, logs and other documentation to assure conformance with Project Specifications. He will review all NDE records and radiographs of weldments, coating applications, trenching and any additional requirements to meet project quality assurance goals and practices. He will monitor and inspect diverse segments of work, including, but not limited to surveying, soils, concrete, structural steel, equipment, piping, electrical and instrumentation. Perform hands on inspections and witness tests and keep documents in an organized fashion for final turn-over of project documentation. Be prepared for client audits which can be performed without audit notification. Maintain master files containing all inspection and test documents.

6.

TOOLS &EQUIPMENTS:

Tools &equipments to be used during installation work DISI-QA-MOS-EL-MS/CNX-001 Rev 0

Disi-Mudawarra to Amman Water Conveyance System Project

HashemiteKingdom of Jordan Ministry Of Water And Irrigation Disi Water Company

METHOD STATEMENT FOR CATHODIC PROTECTION SYSTEM INSTALLATION -Temporary Doc .No:

DISI-QA-MOS-EL-MS/CNX001

CONSTRUCTION EXPERTS COMPANY

Rev 0

5 of 128

Description Excavator Water Tank Pickup Pin Brazing Machine Hand Tool Kit Safety PPE AVO Meter Megger

Role and usage area Widening the pipe trench where anode bed exists-part time for anode bed preparation-Part Time Materials and tools delivery-Fully Dedicated Prepare and accomplish pin welding on the pipe work as required. For fastening, cable tightening, etc ... For all personnel For testing (continuity, Voltage, Ampere, etc) For Insulation Test -applied for multi core cables only

7.

MANPOWER

Description Electrical Site Engineer Cathodic system Foreman Technician Un-skilled labor Driver NO. 1 1 2 4 1

8.

ENGINEERING AND RESPONSIBILITIES

Gama responsibility is to identify the location where the temporary cathodic protection is required based on the soil resistivity test which will be performed by Gama contractor. All installation shall be as per J08086-GEN-DET-FD-ENV-DT-20 and J08086FDSPCENV-03 Rev 1 Datasheet for Temporary CP.

DISI-QA-MOS-EL-MS/CNX-001 Rev 0

Disi-Mudawarra to Amman Water Conveyance System Project

HashemiteKingdom of Jordan Ministry Of Water And Irrigation Disi Water Company

METHOD STATEMENT FOR CATHODIC PROTECTION SYSTEM INSTALLATION -Temporary Doc .No:

DISI-QA-MOS-EL-MS/CNX001

CONSTRUCTION EXPERTS COMPANY

Rev 0

6 of 128

SHOP DRAWINGS As long as the design drawings are comprehensive in enough manners but the following shop drawings maybe generated to detail the work and assure the quality of work: Shop drawings for the location of the system )survey plan (will show the coordinates of all items which will be installed underground. Shop drawings for the Test Post foundation Reinforced concrete. Shop drawing for above ground marker )temporary.(

9.

MATERIALS ACQUISITION AND AVAILABILITIES

Since all materials will be supplied by Gama and the sub-contractor role is to install the system under supervision of Main contractor's experts; the Materials to be used shall have to be cross checked between the sub-contractor and contractor prior commencing the installation and assure the followings: All materials required are available at site )storage.( All materials required have been inspected and checked against the validity for installation .

MATERIALS USAGE )LIST AND DESCRIPTION) With reference to project contractual documents the Materials to be used shall be as the following List:

ID 001 002 003 004 005 006 007

Description Pre-packed Magnesium Anode Anode cable line tap C/W self-amalgamating Tape 1 cm2 Coupon 10mm2 XLPE/PVC Single Core Multiple Stand cable. M8X10mm2 Pin Brazing Cable Lug MCL Polyurethane Cable Lugs/Ties/Markers,

Supplied By GAMA GAMA GAMA GAMA GAMA GAMA GAMA

Installed By CNX CNX CNX CNX CNX CNX CNX

Quantity )Tentative( 4 4 1 ~=60 Meter 3 2LIT As required

DISI-QA-MOS-EL-MS/CNX-001 Rev 0

Disi-Mudawarra to Amman Water Conveyance System Project

HashemiteKingdom of Jordan Ministry Of Water And Irrigation Disi Water Company

METHOD STATEMENT FOR CATHODIC PROTECTION SYSTEM INSTALLATION -Temporary Doc .No:

DISI-QA-MOS-EL-MS/CNX001

CONSTRUCTION EXPERTS COMPANY

Rev 0

7 of 128

008 009

etc Reed Switch Test Post

GAMA GAMA

CNX CNX

1 1

10.

Method of Construction -Cathodic Protection System -Sacrificial typeTemporary .

After identifying the location of the temporary cathodic protection system the following procedures will take place sequentially. 1. Check the readiness of the site for installation. 2. Marking the location of system installation on site and to be inspected by contractor )Gama.) 3. Widening the trench of pipe line at the area marked above as per drawings J08086-GENDET-FD-ENV-DT-20A. 4. Identify the location of the TCPS )Temporary Cathodic Protection Station(as per site condition. 5. Deliver the materials to site which inspected under clause 9 above. 6 Area of attachment to the pipe shall be ground to bright metal and pins shall be attached within the ground area. Prior to attaching pins, a test plate shall have 5 pins welded to the test plate. The pins shall then be bent or hammered to a 90angle. No pins shall be welded to the pipe until a successful test has been performed. 5.6. Pipe surface preparation to attach cable(s )to the pipe using pin brazing technology (Conex will provide only the tools )the following to be supplied by GAMA: a. Brazing Pins.

b. Cable Lugs as required. c. Cables as required.

DISI-QA-MOS-EL-MS/CNX-001 Rev 0

Disi-Mudawarra to Amman Water Conveyance System Project

HashemiteKingdom of Jordan Ministry Of Water And Irrigation Disi Water Company

METHOD STATEMENT FOR CATHODIC PROTECTION SYSTEM INSTALLATION -Temporary Doc .No:

DISI-QA-MOS-EL-MS/CNX001

CONSTRUCTION EXPERTS COMPANY

Rev 0

8 of 128

d. Coating repair patch/mastic filler. 6.7. Magnesium anodes to be installed as per J08086-GEN-DET-FD-ENV-DT-20A. 7.8. Cables to be installed with identifications and tagging. 8.9. Cables to be tested )continuity, megge.( 9.10. Coating and repairing for the brazing location on pipe. 10.11. Initial backfill over anode installation.

Notes: All installation above to be done before pipes testing (hydrostatic, holiday, etc All installation above to be done by Contractor witnessed by GGS. TCPS to be installed after completing full backfill at that area of system installation and land re instating.

11.

TESTING & INSPECTIONS

Testing Testing & commissioning shall be performed by Contractor experts. Subcontractor is responsible to install the system as per Drawings, Project documents and procedures in project tender documents; where CNX will not be responsible about the system performance and design deliverables.

Inspections Refer to ITP plan Ref# )DISI-QA-EL-CNX-016 )

Comment [b1]: Please submit the mentioning ITP.

DISI-QA-MOS-EL-MS/CNX-001 Rev 0

Disi-Mudawarra to Amman Water Conveyance System Project

HashemiteKingdom of Jordan Ministry Of Water And Irrigation Disi Water Company

METHOD STATEMENT FOR CATHODIC PROTECTION SYSTEM INSTALLATION -Temporary Doc .No:

DISI-QA-MOS-EL-MS/CNX001

CONSTRUCTION EXPERTS COMPANY

Rev 0

9 of 128

DISI-QA-MOS-EL-MS/CNX-001 Rev 0

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Quality Assurance Quality Control Manual PDFDocumento76 pagineQuality Assurance Quality Control Manual PDFCarl Williams50% (2)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- ITP PaintingDocumento1 paginaITP PaintingAmer Y KNessuna valutazione finora

- KornFerry and Peoplescout JobsDocumento994 pagineKornFerry and Peoplescout JobsDeepak PasupuletiNessuna valutazione finora

- 017 Summary Tech Report NI43101 RDocumento185 pagine017 Summary Tech Report NI43101 RmefkuregamzekurkcuNessuna valutazione finora

- Bridge EngineerDocumento171 pagineBridge EngineerChu Do HuuNessuna valutazione finora

- Awwa C208-17Documento32 pagineAwwa C208-17Pablo DM100% (1)

- Daikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFDocumento2 pagineDaikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFAmer Y KNessuna valutazione finora

- Key 2Documento18 pagineKey 2Amer Y KNessuna valutazione finora

- Key 2Documento17 pagineKey 2Amer Y KNessuna valutazione finora

- Key 2Documento17 pagineKey 2Amer Y KNessuna valutazione finora

- Daikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFDocumento2 pagineDaikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFAmer Y KNessuna valutazione finora

- Ansi b36.10 Pipe SizeDocumento9 pagineAnsi b36.10 Pipe SizeSpoonful BurnsideNessuna valutazione finora

- KeyDocumento18 pagineKeyAmer Y KNessuna valutazione finora

- Structural Steel Painting DFT Inspection Record (Beams) : Readings ( )Documento5 pagineStructural Steel Painting DFT Inspection Record (Beams) : Readings ( )Amer Y KNessuna valutazione finora

- CO2Documento2 pagineCO2Amer Y KNessuna valutazione finora

- TANK-01 Layout1Documento1 paginaTANK-01 Layout1Amer Y KNessuna valutazione finora

- Diesel CoolerDocumento1 paginaDiesel CoolerAmer Y KNessuna valutazione finora

- Advance Steel AttributesDocumento2 pagineAdvance Steel AttributesAmer Y KNessuna valutazione finora

- 1 Software / Instruction Manuals: A. Communications & NetworkingDocumento2 pagine1 Software / Instruction Manuals: A. Communications & NetworkingAmer Y KNessuna valutazione finora

- Avikote AV 800-7Documento2 pagineAvikote AV 800-7Amer Y KNessuna valutazione finora

- 1 Software / Instruction Manuals: A. Communications & NetworkingDocumento2 pagine1 Software / Instruction Manuals: A. Communications & NetworkingAmer Y KNessuna valutazione finora

- UL Certificate of Compliance MK6s 05-02-16Documento1 paginaUL Certificate of Compliance MK6s 05-02-16Amer Y KNessuna valutazione finora

- TCV Modification PlanDocumento1 paginaTCV Modification PlanAmer Y KNessuna valutazione finora

- Advance Steel AttributesDocumento2 pagineAdvance Steel AttributesAmer Y KNessuna valutazione finora

- Stack Painting SpecsDocumento1 paginaStack Painting SpecsAmer Y KNessuna valutazione finora

- Avikote AV 650-5 PDFDocumento2 pagineAvikote AV 650-5 PDFAmer Y KNessuna valutazione finora

- Silicone SealantDocumento2 pagineSilicone SealantAmer Y KNessuna valutazione finora

- Gantt Project Planner1Documento1 paginaGantt Project Planner1Amer Y KNessuna valutazione finora

- Avikote AV 650-5Documento2 pagineAvikote AV 650-5Amer Y KNessuna valutazione finora

- Pipe Identification ModelDocumento1 paginaPipe Identification ModelAmer Y KNessuna valutazione finora

- Monokote MK 6s 17Documento2 pagineMonokote MK 6s 17Amer Y KNessuna valutazione finora

- ASME B16.4 Example 1Documento8 pagineASME B16.4 Example 1Amer Y KNessuna valutazione finora

- Zamil Airconditioning Delivery - 9-8-2015Documento3 pagineZamil Airconditioning Delivery - 9-8-2015Amer Y KNessuna valutazione finora

- NFPA Fire Code ListDocumento8 pagineNFPA Fire Code ListAnindito NurprabowoNessuna valutazione finora

- Assignment On QualityDocumento83 pagineAssignment On QualityPradip SigdelNessuna valutazione finora

- Statistical Process ControlDocumento29 pagineStatistical Process ControlTushar NaikNessuna valutazione finora

- Lecture Computer Aided Software Engineering LectureDocumento26 pagineLecture Computer Aided Software Engineering LectureJooo loNessuna valutazione finora

- Outsource It!Documento246 pagineOutsource It!Andrew Berezovskiy100% (2)

- Internal Blasting and Painting Procedure For Storage TankDocumento31 pagineInternal Blasting and Painting Procedure For Storage TankMathias Onosemuode100% (3)

- Papers 2022Documento3 paginePapers 2022MDrakeNessuna valutazione finora

- Workbookand Study GuideDocumento50 pagineWorkbookand Study GuideAnton_Young_1962Nessuna valutazione finora

- POCT ManualDocumento120 paginePOCT ManualAbdulrahman M Alharbi100% (1)

- Applying Quality STANDARDS (Part 2)Documento16 pagineApplying Quality STANDARDS (Part 2)Mary Grace OribelloNessuna valutazione finora

- H.M.C. MOHIDEEN (Bsc. Eng.) : Personal InformationsDocumento7 pagineH.M.C. MOHIDEEN (Bsc. Eng.) : Personal InformationsmohideenNessuna valutazione finora

- 6172011416Documento235 pagine6172011416Cristina SolisNessuna valutazione finora

- Directorate General OF Supplies & DisposalsDocumento49 pagineDirectorate General OF Supplies & DisposalsimshwezNessuna valutazione finora

- 01 - Basics of Project Management - Part IDocumento34 pagine01 - Basics of Project Management - Part IKavidu KrishenNessuna valutazione finora

- Software Test TypesDocumento15 pagineSoftware Test TypesMEHJABEEN SAYYEDNessuna valutazione finora

- Ensuring Suplly Chain QualityDocumento5 pagineEnsuring Suplly Chain QualityJohn MwangiNessuna valutazione finora

- Holistic Approach To Quality Management - TQMDocumento21 pagineHolistic Approach To Quality Management - TQMADEFIOYE AdeniyiNessuna valutazione finora

- Sitra News Jan 13Documento23 pagineSitra News Jan 13Venkat PrasannaNessuna valutazione finora

- Advances in Ground Improvement _ Research to Practice in the United States and China _ Proceedings of the US-China Workshop on Ground Improvement Technologies, March 14, 2009, Orlando, Florida ( PDFDrive )Documento335 pagineAdvances in Ground Improvement _ Research to Practice in the United States and China _ Proceedings of the US-China Workshop on Ground Improvement Technologies, March 14, 2009, Orlando, Florida ( PDFDrive )flashtronNessuna valutazione finora

- Kinjal Patel Resume,.,.,.Documento2 pagineKinjal Patel Resume,.,.,.Angela FrenchNessuna valutazione finora

- ConquasDocumento18 pagineConquasSyahir AzhariNessuna valutazione finora

- Summer Internship Project Report - A Study On Job Satisfaction at CompanyDocumento62 pagineSummer Internship Project Report - A Study On Job Satisfaction at CompanyKushagra purohitNessuna valutazione finora

- Quality Assurance Plan (Template)Documento16 pagineQuality Assurance Plan (Template)Sajeel ZamanNessuna valutazione finora

- 6 Jim Travis Quality AssuranceDocumento58 pagine6 Jim Travis Quality AssuranceKY PengNessuna valutazione finora

- FMRC 7710Documento14 pagineFMRC 7710berkayNessuna valutazione finora

- Pmbok Vs Prince2 DetailDocumento21 paginePmbok Vs Prince2 DetailAlessandro Balotta100% (1)

- Procedure For Traffic Light Quality System-LibreDocumento8 pagineProcedure For Traffic Light Quality System-LibreAnonymous wA6NGuyklDNessuna valutazione finora