Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Instrumentation Procedure ISO

Caricato da

Ahmad Adel El TantawyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Instrumentation Procedure ISO

Caricato da

Ahmad Adel El TantawyCopyright:

Formati disponibili

DOCUMENT NAME DOCUMENT CODE Issue Number INS-P 1

Instruments Procedure

Prepared By Approved By Instruments Manager Chairman

Instrumentation Procedure INS-P

[Type text]

DOCUMENT APPROVAL / REVISION DC-3 Rev. Effective Date Summary of Change 1 2 3 4 6 Rev. Effective Date Summary of change 1 2 3 4 6 Approver's Name / Position Signature Approvers Name/Position Signature

[Type text]

[Type text]

1.0

Purpose A mechanism for establishing the calibration process for all monitoring & measurements devices existed in factory and in instruments lab beginning with planning for that & ending to execution & follow-up. Identifying and controlling the expired monitoring devices.

2.0

Scope This procedure applies to all monitoring devices calibration activities.

3.0

Definitions Calibration

A set of procedures which carried out under specification condition to final a relation between the measured value by the instrument and the standard value Calibration period

The period between two successive calibration which determined by the section who is responsible for calibration Verification

This is a periodic process used to verify the accuracy of the instrument result comparing with that of standard value. Also can be compare with the instrument trend with the previous data for the same result. 4.0 Related Documents Control of non conforming service procedure (NC-P) Devices manuals Standards for calibration tests and results Warehouse Procedure (WH-P) Purchasing Procedure (PR-P) Records control (RC-P)

[Type text]

[Type text]

5.1 5.2

Calibration: Planning for Calibration 5.1.1 The head of planning department shall set a list for all monitoring &measuring devices in the company and send this list to instruments manager via MAXIMO. 5.1.2 In case of any new monitoring & measuring device, planning department responsible shall enter the data of the new devices as mentioned above 5.1.3 Every week, planning department shall send a weekly inspection plan via MAXIMO to instruments manager including work order(s) to all activities should be executed by instruments department

5.2 Establishment & follow-up 5.2.1 Internal Calibration 5.2.1.1. In due date of calibration, the head of instruments department shall establish the checking process according to both Plan and work order(s) 5.2.1.2. According to the check the instruments responsible decide if these devices need to be calibrated or not, if the calibration required the instruments responsible perform the calibration process via the calibration devices in instruments lab and issue calibration report (INS-1) which contains the following data 5.2.1.3 Device name Device code Actual date of calibration Due date of the next calibration process Details of test/s being established to calibrate the device The standard for elected test The reference for controlling the results The actual and acceptable tolerance The conclusion and the final status of calibration If the calibration is not required, instruments responsible fulfill his notes and remarks in work order(s) and send it to Planning department for information

[Type text]

[Type text]

5.2.1.4 After the completion of the calibration process, the instruments responsible shall put a sticker label (INS-2) on the out of use device which to ensure that the device can not be used for another time and to identify the following: Name of device Device code (if exist) Actual date for calibration Reason for exclusion

5.2.1.5 During the checking and/or calibration process if the instruments responsible need any further resources to complete his own job , the required resources should be obtained from warehouses or purchasing departments as mentioned in Warehouse Procedure (WH-P) & Purchasing Procedure (PR-P) 5.2.2 External Calibration of Instruments lab devices: 5.2.2.1 The head of instruments department shall inform the external party with the due date for calibration and the data for the devices that will be calibrated by phone and/or fax before the due date of calibration. 5.2.2.2 In the due date the external party will calibrate the related devices according to their method and supervised by the head of calibration department. 5.2.2.3 5.2.2.4 In case of any delaying in the calibration date the step 5.2.1.2 shall be repeated. After executing the calibration process, the external party shall give a certificate for completion. The certificate should mention the status of device and the standard instrument. 5.2.2.5 All related records such as the calibration certificates shall be controlled according to the record control procedures (RC-P) 5.2.2.6 The instruments responsible shall choose the calibration providers for the approved providers list (INS-3) of service providers is based on certain criteria as follows-but not limited to:

[Type text]

[Type text]

o Reputation o Curriculum vitae o Competence 5.2.2.8Every six months the instruments manager evaluate external calibration parties which offered the calibration service to MOPCOS devices and record the results on calibration provider evaluation (INS-4) form . 5.2.3 Every six months the instruments responsible issuing a report to identify the out of use devices during the last six months this report acts as a historical record the report contains the following data : meetings. Device S.N. Device Name Replacement date

These data will be analyzed periodically and to be discussed during the management review

[Type text]

[Type text]

7. QUALITY RECORDS

Title calibration report sticker label Approved providers list calibration provider evaluation Out of use report 8. APPENDICES

Form # INS-1 INS-2 INS-3 INS-4 ----------

Kept By Instruments manager On device Instruments manager Instruments manager Instruments manager

Where Local Local Local Local Local

Time 3 years 3 years Till it is amended 3 years 3 years

calibration report sticker label Approved providers list calibration provider evaluation

INS-1 INS-2 INS-3 INS-4

[Type text]

[Type text]

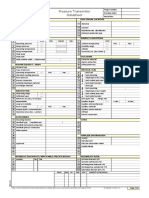

Calibration Report INS-1

DOCUMENTATION TITLE .Report no CALIBRATION REPORT No. Of pages Date

:INSTRUMENT IDENTIFICATION

SECTION/UNIT NAME MANUFACTURE MODEL .S/N

LOACTION

EQUIPMENT/DEVICE

MEASURMENT RANGE RESOULATION CALIBRATION DATE

:CALIBRATION RESULTS .TEST.NO

INSTRUMENT READING DEVIATION

ACCURACY ACCEPTANCE CRITERIA CALIBRATION DUE DATE REPLACEMENT DATE

.TEST.NO

INSTRUMENT READING

DEVIATION

:CONCLUSION

[Type text]

[Type text]

DONE BY

NAME

POSITION

SIGNATURE

DATE

Out of Use INS-2

INSTRUMENT: S/N : EXCLUSION REASON:

SIGNATURE:

[Type text]

[Type text]

[Type text]

[Type text]

Approved providers list INS-3

No. Provider Phone Fax Email Remarks

[Type text]

[Type text]

Calibration Provider Evaluation INS-4

Service provider name: Evaluation criteria

Quality of service (50%) On time delivery (30%)

Administrative

Decision

(%) Sum

issues (20%)

Continue dealing

Warning

Stop dealing

How to decide?

Collect the overall ratio for evaluation on based on the defined weights for evaluation criteria. When the sum is less than 50%, the service provider will be directly removed from the approved providers list When the sum is in the region between 50% and less than 70%, the service providers will be warned, and in case for repeating for 3 times the provider will be removed from the approved providers list When the sum equals 70% or higher and the quality of service criteria is not less than 40% continues dealing with the provider.

[Type text]

Potrebbero piacerti anche

- Instrumentation Work ProcedureDocumento10 pagineInstrumentation Work ProcedureAbdelRhman Elfky100% (1)

- Instrument Loop Check ProcedureDocumento3 pagineInstrument Loop Check ProcedureMiko Quijano100% (1)

- Project Quality Plan and Loop Testing ProceduresDocumento3 pagineProject Quality Plan and Loop Testing ProceduresOwais MalikNessuna valutazione finora

- HandBook Pressure Transmitter-En PDFDocumento32 pagineHandBook Pressure Transmitter-En PDFcarloscieza100% (2)

- 0905.1.0 - Instrument Installation RequirementsDocumento12 pagine0905.1.0 - Instrument Installation RequirementsSaoloan NaiborhuNessuna valutazione finora

- Installation StandardDocumento80 pagineInstallation StandardSukdeb Maity100% (1)

- 3210-8550-FS-0008 Foundation Fieldbus Functional RequrementDocumento34 pagine3210-8550-FS-0008 Foundation Fieldbus Functional Requrementsuhailfarhaan100% (2)

- C InstrumentationDocumento12 pagineC InstrumentationabyzenNessuna valutazione finora

- Inst IndexDocumento3 pagineInst IndexblessonfrancisNessuna valutazione finora

- Earth Testing Results New CCE Office STF AreaDocumento1 paginaEarth Testing Results New CCE Office STF AreaImran Nawaz MehthalNessuna valutazione finora

- UET Lahore Report on Transmitters in Process IndustriesDocumento12 pagineUET Lahore Report on Transmitters in Process IndustriesUmar AdamuNessuna valutazione finora

- MOS For InstrumentationDocumento6 pagineMOS For Instrumentationrenjithv_4100% (1)

- 639-2017 - Forms (ITP)Documento9 pagine639-2017 - Forms (ITP)george stanley paceteNessuna valutazione finora

- Temperature Measuring Instruments Selection & ApplicationDocumento70 pagineTemperature Measuring Instruments Selection & ApplicationIrfan AliNessuna valutazione finora

- SWP InstrumentationDocumento16 pagineSWP InstrumentationMohammad RizwanNessuna valutazione finora

- Loop Check and ValveDocumento1 paginaLoop Check and ValveMohd A IshakNessuna valutazione finora

- P-5000T - Loop Folder PDFDocumento15 pagineP-5000T - Loop Folder PDFSrikant SuruNessuna valutazione finora

- SATR-J-6501 - Rev 0 PDFDocumento5 pagineSATR-J-6501 - Rev 0 PDFAdel KlkNessuna valutazione finora

- 3.4.instrument Location PlanDocumento20 pagine3.4.instrument Location PlanVinitaVartakNessuna valutazione finora

- LADDER AND TRAY SUPPORT CHECK SHEETSDocumento1 paginaLADDER AND TRAY SUPPORT CHECK SHEETSAldeline SungahidNessuna valutazione finora

- LADDER AND TRAY MECHANICAL COMPLETION CHECKLISTDocumento1 paginaLADDER AND TRAY MECHANICAL COMPLETION CHECKLISTAldeline Sungahid100% (1)

- 12-MGDP-I-1024-1 (Spec For General Instrumentation) PDFDocumento23 pagine12-MGDP-I-1024-1 (Spec For General Instrumentation) PDFJairo WilchesNessuna valutazione finora

- 3 Instrumentation PDFDocumento11 pagine3 Instrumentation PDFRakeshNessuna valutazione finora

- Spi FFDocumento17 pagineSpi FFjose_johnNessuna valutazione finora

- Instrument Check ListDocumento19 pagineInstrument Check ListFarhan KhanNessuna valutazione finora

- Hazardous Location Fire Alarm Call PointsDocumento7 pagineHazardous Location Fire Alarm Call PointsKUNONessuna valutazione finora

- Method Statement of Calibration Field Instrument: Rantu Dedap Geothermal Power Plant Project Capacity 220 MWDocumento8 pagineMethod Statement of Calibration Field Instrument: Rantu Dedap Geothermal Power Plant Project Capacity 220 MWsugeng wahyudiNessuna valutazione finora

- SIS ESD SpecificationsDocumento21 pagineSIS ESD SpecificationschatuusumitavaNessuna valutazione finora

- D002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaDocumento38 pagineD002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaSurya Darma100% (1)

- Project number pressure transmitter datasheetDocumento2 pagineProject number pressure transmitter datasheetdiksha surekaNessuna valutazione finora

- SATR-J-6601 Rev 0 PDFDocumento4 pagineSATR-J-6601 Rev 0 PDFAdel Klk100% (1)

- I Et 6000.67 0000 800 Pdy 001 eDocumento178 pagineI Et 6000.67 0000 800 Pdy 001 epitucha_hs100% (1)

- Coriolis Part 1Documento18 pagineCoriolis Part 1yao nestorNessuna valutazione finora

- Saudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestDocumento4 pagineSaudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestRashid Arshad100% (1)

- Field Instrumentation (Oil and Gas)Documento4 pagineField Instrumentation (Oil and Gas)Mohamed RaeesNessuna valutazione finora

- Loop Check Procedure PDFDocumento8 pagineLoop Check Procedure PDFImran Nawaz Mehthal75% (4)

- ITP (Instrumentation)Documento9 pagineITP (Instrumentation)Yaser A. Al-Bustanji100% (1)

- Instrument Designer Job DescriptionDocumento9 pagineInstrument Designer Job DescriptionTimothy LeonardNessuna valutazione finora

- Data Sheet Daniel Model 788 Digital Control Valve en 43714Documento16 pagineData Sheet Daniel Model 788 Digital Control Valve en 43714dreyko77Nessuna valutazione finora

- Loop Checking Procedure IdeasDocumento2 pagineLoop Checking Procedure IdeasJonatas13Nessuna valutazione finora

- Dcs StandardDocumento6 pagineDcs Standardsina20795Nessuna valutazione finora

- KEI Wires & Cables - Instrumentation Cable ManufacturingDocumento1 paginaKEI Wires & Cables - Instrumentation Cable Manufacturingrobinknit2009Nessuna valutazione finora

- Instrumentation Standards ListDocumento45 pagineInstrumentation Standards ListRajeevNessuna valutazione finora

- PROJECT STANDARD AND SPECIFICATIONS Instrumentation Specifications Rev01web PDFDocumento8 paginePROJECT STANDARD AND SPECIFICATIONS Instrumentation Specifications Rev01web PDFMohsin AliNessuna valutazione finora

- SAIC-J - 6501 - Rev 0Documento7 pagineSAIC-J - 6501 - Rev 0Adel KlkNessuna valutazione finora

- CHECKLIST SHEET P & ID PIPING AND INSTRUMENTATION CHART PR-03Documento6 pagineCHECKLIST SHEET P & ID PIPING AND INSTRUMENTATION CHART PR-03Yousef SalahNessuna valutazione finora

- OFFSHORE FUNCTIONAL SPECDocumento35 pagineOFFSHORE FUNCTIONAL SPECjtaylor2k1Nessuna valutazione finora

- Thermowell Temperature Gauge Tag: TUNG1-27-TGDocumento1 paginaThermowell Temperature Gauge Tag: TUNG1-27-TGKenneth EmbeleNessuna valutazione finora

- Instrumentation QuestionsDocumento2 pagineInstrumentation QuestionsBalajirao Samatham100% (1)

- Section C.3 FAT For DCSDocumento11 pagineSection C.3 FAT For DCSChava TejaNessuna valutazione finora

- 26 09 13 Electrical Power Monitoring System - Data CentersDocumento35 pagine26 09 13 Electrical Power Monitoring System - Data CentersHujiLokoNessuna valutazione finora

- Course Title: Basic Instrumentation (Code: 3311701)Documento5 pagineCourse Title: Basic Instrumentation (Code: 3311701)Raja Prathap SinghNessuna valutazione finora

- Fire & Gas Detection Philosophy Part 1 - Fire Detection - Instrumentation and Process ControlDocumento6 pagineFire & Gas Detection Philosophy Part 1 - Fire Detection - Instrumentation and Process ControlAhmed EldosokyNessuna valutazione finora

- Instrument Stand Install Guide PDFDocumento4 pagineInstrument Stand Install Guide PDFChristianNessuna valutazione finora

- Instrument Location PlanDocumento3 pagineInstrument Location PlanNikki Roberts100% (2)

- J1525-HW1-010 SAT Procedure - Rev ADocumento16 pagineJ1525-HW1-010 SAT Procedure - Rev Aluis HernandezNessuna valutazione finora

- 009 04 - Fy14 CH1Documento10 pagine009 04 - Fy14 CH1Brian Joseph MugrageNessuna valutazione finora

- Tandard Perating Rocedure: Authorised by Number Effective Date Pages AuthorDocumento5 pagineTandard Perating Rocedure: Authorised by Number Effective Date Pages Authoryousaf_zai_khan81995Nessuna valutazione finora

- Internal Quality Audit Checklist FOR Control of Monitoring & Measuring DevicesDocumento0 pagineInternal Quality Audit Checklist FOR Control of Monitoring & Measuring DevicesalokjaseNessuna valutazione finora

- Proficiency Testing 17020Documento11 pagineProficiency Testing 17020ss1222100% (1)

- FV-SM Application As FlowmeterDocumento9 pagineFV-SM Application As FlowmeterAhmad Adel El TantawyNessuna valutazione finora

- 0001 Coversheet Operating and Maintenance Manual 814Documento2 pagine0001 Coversheet Operating and Maintenance Manual 814Ahmad Adel El TantawyNessuna valutazione finora

- 0002 General Index 814Documento3 pagine0002 General Index 814Ahmad Adel El TantawyNessuna valutazione finora

- Level MeasurementDocumento48 pagineLevel MeasurementTech and Cool GadgetsNessuna valutazione finora

- Configure/Setup of FT-305401 (IFC 300 Rev. 2) (Historic) 7/10/2008 10:16:00 AMDocumento4 pagineConfigure/Setup of FT-305401 (IFC 300 Rev. 2) (Historic) 7/10/2008 10:16:00 AMAhmad Adel El TantawyNessuna valutazione finora

- Session 1 Chemical Metering and Process Control StrategiesDocumento41 pagineSession 1 Chemical Metering and Process Control StrategiesAhmad Adel El TantawyNessuna valutazione finora

- Intro To Cart ValvesDocumento12 pagineIntro To Cart Valveschandushar1604Nessuna valutazione finora

- Silikometer ManualDocumento147 pagineSilikometer ManualAhmad Adel El TantawyNessuna valutazione finora

- GRUNDFOS ALLDOS ANLEITUNG VACCUPERM VGA-146Documento24 pagineGRUNDFOS ALLDOS ANLEITUNG VACCUPERM VGA-146Ruxandra AdrianaNessuna valutazione finora

- Vle Nim 0001Documento16 pagineVle Nim 0001Ahmad Adel El TantawyNessuna valutazione finora

- A Guide To Manual and Automated Ball ValvesDocumento8 pagineA Guide To Manual and Automated Ball ValvesGohilakrishnan ThiagarajanNessuna valutazione finora

- Control Valve SizingDocumento6 pagineControl Valve SizingSARFRAZ ALINessuna valutazione finora

- D 200064 X 012Documento12 pagineD 200064 X 012Ahmad Adel El TantawyNessuna valutazione finora

- Fisher 3610J and 3620J Positioners Instruction ManualDocumento64 pagineFisher 3610J and 3620J Positioners Instruction ManualAhmad Adel El TantawyNessuna valutazione finora

- D 350365 X 012Documento12 pagineD 350365 X 012Ahmad Adel El TantawyNessuna valutazione finora

- An 460Documento10 pagineAn 460Ahmad Adel El TantawyNessuna valutazione finora

- 10 1 5 1Documento12 pagine10 1 5 1Ahmad Adel El TantawyNessuna valutazione finora

- Industrial Process Control ValvesDocumento36 pagineIndustrial Process Control Valvesffown100% (1)

- Ag 5345492Documento11 pagineAg 5345492Ahmad Adel El TantawyNessuna valutazione finora

- Chevrolet Optra ManualDocumento290 pagineChevrolet Optra Manualleo_j986% (7)

- IDC Technologies - RTGS Details - International TransferDocumento1 paginaIDC Technologies - RTGS Details - International TransferAhmad Adel El TantawyNessuna valutazione finora

- Proof Testing Level Instruments WP01006F24EN0113Documento8 pagineProof Testing Level Instruments WP01006F24EN0113Ahmad Adel El TantawyNessuna valutazione finora

- Full Text 01Documento92 pagineFull Text 01Ahmad Adel El TantawyNessuna valutazione finora

- Emerson-Valve Sizing Calculations (Traditional Method)Documento21 pagineEmerson-Valve Sizing Calculations (Traditional Method)iqtorresNessuna valutazione finora

- Valve Selection Guide: - ContentsDocumento12 pagineValve Selection Guide: - ContentsAhmad Adel El TantawyNessuna valutazione finora

- Control ValveDocumento25 pagineControl ValveAsad RazaNessuna valutazione finora

- FV-SM Application As FlowmeterDocumento9 pagineFV-SM Application As FlowmeterAhmad Adel El TantawyNessuna valutazione finora

- Full Text 01Documento92 pagineFull Text 01Ahmad Adel El TantawyNessuna valutazione finora

- Appendix ADocumento11 pagineAppendix AAhmad Adel El TantawyNessuna valutazione finora

- FV-SM Application As FlowmeterDocumento9 pagineFV-SM Application As FlowmeterAhmad Adel El TantawyNessuna valutazione finora

- Volume Change Apparatus: Product ManualDocumento4 pagineVolume Change Apparatus: Product ManualNelsonPadrónSánchezNessuna valutazione finora

- Hospital Commissioning Checklists: Structural & Operational StandardsDocumento50 pagineHospital Commissioning Checklists: Structural & Operational Standardsmohamed radwan100% (1)

- 8887Documento7 pagine8887Aditya HundekarNessuna valutazione finora

- P and ID HandsbookDocumento30 pagineP and ID HandsbookYohannes GebreNessuna valutazione finora

- 98965-XX CP VersionDocumento53 pagine98965-XX CP VersionJack DanielNessuna valutazione finora

- Catalog Electronic Test Measurement EquipmentDocumento96 pagineCatalog Electronic Test Measurement Equipmentyo6blm12Nessuna valutazione finora

- Protocol For Noise MonitoringDocumento6 pagineProtocol For Noise Monitoringsunil belvekarNessuna valutazione finora

- Official: Á1058Ñ Analytical Instrument QualificationDocumento7 pagineOfficial: Á1058Ñ Analytical Instrument QualificationDilawar BakhtNessuna valutazione finora

- Keithley 775ADocumento132 pagineKeithley 775AboboklaphotoNessuna valutazione finora

- Calibration of Glassware: 1. ScopeDocumento6 pagineCalibration of Glassware: 1. ScopeWaleed MedhatNessuna valutazione finora

- Winch Panel Ops ManualDocumento112 pagineWinch Panel Ops Manualbaggo81Nessuna valutazione finora

- C685-14 Concrete Made by Volumetric Batching and Continous MixingDocumento9 pagineC685-14 Concrete Made by Volumetric Batching and Continous MixingKartika Setia Rini100% (1)

- Entrisii ADocumento251 pagineEntrisii ATimothy RohwedderNessuna valutazione finora

- Gauge BlocksDocumento40 pagineGauge BlocksJean RojasNessuna valutazione finora

- GLIER QSP ManagementrequirementsDocumento72 pagineGLIER QSP ManagementrequirementsMurugan RajaNessuna valutazione finora

- Measurement UncertaintyDocumento140 pagineMeasurement UncertaintyALPER ORHAN100% (1)

- Druck Adts405 ManualDocumento134 pagineDruck Adts405 ManualRodrigo MarinsNessuna valutazione finora

- Produced Water Sampling GuidelinesDocumento91 pagineProduced Water Sampling GuidelinesTaufiq SaidinNessuna valutazione finora

- Pipe Fabrication - Es-32Documento2 paginePipe Fabrication - Es-32My one onlyNessuna valutazione finora

- Horno de Porcelana Jelrus VIP Vision 300 Exclusive 500Documento36 pagineHorno de Porcelana Jelrus VIP Vision 300 Exclusive 500Brevas CuchoNessuna valutazione finora

- Astm D 3999 - 91 R03Documento15 pagineAstm D 3999 - 91 R03AnamulKabirNessuna valutazione finora

- 090 G - Pressure and Leak Testing SafetyDocumento2 pagine090 G - Pressure and Leak Testing SafetyParth Patel100% (1)

- Conductivimetro DDS 12DWDocumento6 pagineConductivimetro DDS 12DWPaola CardozoNessuna valutazione finora

- Iso 17020Documento7 pagineIso 17020Abusaada2012Nessuna valutazione finora

- Incubator Manual Revc2016Documento16 pagineIncubator Manual Revc2016Jhon GalvisNessuna valutazione finora

- Intouch Services: For Ind570 Terminal ApplicationsDocumento2 pagineIntouch Services: For Ind570 Terminal ApplicationsSergio Sosa NavaNessuna valutazione finora

- SKF Eddy Current Probes SystemsDocumento64 pagineSKF Eddy Current Probes SystemsAnonymous Uk3JxlHA100% (1)

- PosiChek3 Troubleshooting GuideDocumento31 paginePosiChek3 Troubleshooting GuideDaniel LagosNessuna valutazione finora

- Blaine Fineness Astm C 204Documento13 pagineBlaine Fineness Astm C 204John Christian PiñonNessuna valutazione finora