Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Proper and Efficient Work Procedures: 1. Removal

Caricato da

diemnganDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Proper and Efficient Work Procedures: 1. Removal

Caricato da

diemnganCopyright:

Formati disponibili

IN-12

INTRODUCTION

PROPER AND EFFICIENT WORK PROCEDURES

Body Measument Diagrams

1.

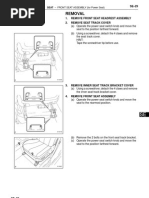

REMOVAL

(a) PRE-REMOVAL MEASURING (1) Before removal or cutting operations, take measurements in accordance with the dimensions diagram. Always use a puller to straighten a damaged body or frame.

F33020

Cutting Okay

(b) CUTTING AREA (1) Always cut in a straight line and avoid cutting reinforced areas.

Corners Reinforcement

F33021

(c)

PRECAUTIONS FOR DRILLING OR CUTTING (1) Check behind any area to be drilled or cut to ensure that there are no hoses, wires, etc., that may be damaged. HINT: See Handling Precautions on Related Components on page IN-17.

WRONG

F33022

(d) REMOVAL OF ADJACENT COMPONENTS (1) When removing adjacent components, apply protective tape to the surrounding body and your tools to prevent damage. HINT: See Handling Precautions on Related Components on page IN-17.

F33007

INTRODUCTION

IN-13

2.

Less than 3 mm

PREPARATION FOR INSTALLATION

(a) SPOT WELD POINTS (1) When welding panels with a combined thickness of over 3 mm (0.12 in.), use a MIG (Metal Inert Gas) welder for plug welding. HINT: Spot welding does not provide sufficient durability for panels with a combined thickness of over 3 mm (0.12 in.)

F10011A

(b) APPLICATION OF WELD-THROUGH PRIMER (SPOT SEALER) (1) Remove the paint from the portion of the new parts and body to be welded, and apply weld-through primer.

F33008

(c)

MAKING HOLES FOR PLUG WELDING (1) For areas where a spot welder cannot be used, use a puncher or drill to make holes for plug welding. REFERENCE: mm (in.)

Thickness of welded portion 1.0 (0.04) under 1.0 (0.04) 1.6 (0.06) Size of plug hole 5 (0.20) over 6.5 (0.26) over 8 (0.31) over 10 (0.39) over

Puncher

F33009

1.7 (0.07) 2.3 (0.09) 2.4 (0.09) over

(d) SAFETY PRECAUTIONS FOR ELECTRICAL COMPONENTS (1) When welding, there is a danger that electrical components will be damaged by the electrical current flowing through the body. (2) Before starting work, disconnect the negative terminal of the battery and ground the welder near the welding location of the body.

F33023

Air Saw

20 30 mm Overlap

(e) ROUGH CUTTING OF JOINTS (1) For joint areas, rough cut the new parts, leaving 20 30 mm (0.79 1.18 in.) of overlap.

F33024

IN-14

INTRODUCTION

3.

INSTALLATION

(a) PRE-WELDING MEASUREMENTS (1) Always take measurements before installing underbody or engine components to ensure correct assembly. After installation, confirm proper fit.

F33025

(b) WELDING PRECAUTIONS (1) The number of welding spots should be as follows. Spot weld: 1.3 X No. of manufacturers spots. Plug weld: More than No. of manufacturers plugs. (2) Plug welding should be done with a MIG (Metal Inert Gas) welder. Do not gas weld or braze panels at areas other than where specified.

WRONG

F10017A

(c)

POST-WELDING REFINISHING (1) Always check the welded spots to ensure that they are secure. (2) When smoothing out the weld spots with a disc grinder, be careful not to grind off too much as this will weaken the weld.

CORRECT

WRONG

F10018A

Old Spot Locations

(d) SPOT WELD LOCATIONS (1) Avoid welding over previously welded areas.

New Spot Locations

F33010

Tip Cutter

F10019A

(e) SPOT WELDING PRECAUTIONS (1) The shape of the tip point of the spot welder significantly affects the strength of the weld. Therefore, maintain the tip point in the proper shape, and allow it to cool after every five or six spots. (2) Completely remove the paint from the areas to be spot welded, including the seams and the surfaces that come in contact with the welding tip. (3) Use a sander to remove any burrs that are created during spot welding.

INTRODUCTION

IN-15

Sealer Gun

4.

ANTI-RUST TREATMENT AFTER INSTALLATION (BEFORE PAINTING PROCESS)

(a) BODY SEALER APPLICATION (1) For water-proofing and anti-corrosion measures, always apply the body sealer to the body panel seams and hems of the doors, hood, etc.

F33011

(b) UNDERCOAT APPLICATION (1) To prevent corrosion and protect the body from damage by flying stones, always apply sufficient under coating to the bottom surface of the under body and inside of the wheel housings.

F33012

5.

ANTI-RUST TREATMENT AFTER INSTALLATION (AFTER PAINTING PROCESS)

(a) ANTI-RUST AGENT (WAX) APPLICATION (1) To preserve impossible to paint areas from corrosion, always apply sufficient anti-rust agent (wax) to the inside of the hemming areas of the doors and hood, and around the hinges, or the welded surfaces inside the box-shaped cross sections of the side members, body pillars, etc.

F33013

IN-16

INTRODUCTION

6.

ANTI-RUST TREATMENT BY PAINTING

REFERENCE:

Painting prevents corrosion and protects the sheet metal from damage. In this section, anti-chipping paint only for anti-corrosion purposes is described. (a) ANTI-CHIPPING PAINT (1) To prevent corrosion and protect the body from damage by flying stones, etc., apply anti-chipping paint to the rocker panel, wheel arch areas, balance panel, etc. HINT: Depending on the model or the application area, there are cases where the application of anti-chipping paint is necessary before the second coat or after the top coat.

S Apply the anti-chipping paint after the top coat. Anti-Chipping Paint Top Coat Second Coat Under Coat (ED Primer) Steel Metal Anti-Chipping Paint Under Coat (ED Primer) Steel Metal

F10024A

S Apply the anti-chipping paint before the second coat. Top Coat Second Coat

Potrebbero piacerti anche

- Proper work procedures for vehicle body repair and installationDocumento5 pagineProper work procedures for vehicle body repair and installationMilton Poma CabasNessuna valutazione finora

- A70 Chassis Collision Repair Manual PDFDocumento79 pagineA70 Chassis Collision Repair Manual PDFstevencychenNessuna valutazione finora

- Proper and Efficient Work Procedures: 1. RemovalDocumento5 pagineProper and Efficient Work Procedures: 1. RemovalmaximchacaNessuna valutazione finora

- Use Again: Thrust Washer ReusabilityDocumento19 pagineUse Again: Thrust Washer ReusabilityGanbat JargalNessuna valutazione finora

- Main Rotor Hub InspectionDocumento21 pagineMain Rotor Hub InspectionJessie DinoyNessuna valutazione finora

- Ribe-SubCon Connector CatalogDocumento203 pagineRibe-SubCon Connector CatalogBurghelea Ovidiu-GabrielNessuna valutazione finora

- Drill 32: Instructions Manual Drilling RigDocumento20 pagineDrill 32: Instructions Manual Drilling RigPungan IonNessuna valutazione finora

- Sect 29 Preventive MaintenanceDocumento6 pagineSect 29 Preventive MaintenancezfiyldvmNessuna valutazione finora

- AA01042A Fisura Horse CollarDocumento5 pagineAA01042A Fisura Horse CollarSebastiánRodrigoPérezHenríquezNessuna valutazione finora

- LG Wheels and BrakesDocumento34 pagineLG Wheels and Brakesmarcos torresNessuna valutazione finora

- ML B 200 b200fmm1035Documento11 pagineML B 200 b200fmm1035Marco Antonio PrietoNessuna valutazione finora

- Design Principle of Jig and Fixture: Prepared by Federick Anak Mydin Register No: 05Dtp09F2036Documento14 pagineDesign Principle of Jig and Fixture: Prepared by Federick Anak Mydin Register No: 05Dtp09F2036Ritesh PatelNessuna valutazione finora

- InstallationInstructions RLK603Documento6 pagineInstallationInstructions RLK603Shantanu DuttaNessuna valutazione finora

- Preventive maintenance tips for thermoset molds and pressesDocumento6 paginePreventive maintenance tips for thermoset molds and pressesAnurag SrivastavaNessuna valutazione finora

- Paint CoatingDocumento11 paginePaint CoatingMirceaNessuna valutazione finora

- 70.00.00 Standard Practices - InspectionDocumento2 pagine70.00.00 Standard Practices - InspectionTimoteo Molina RomeroNessuna valutazione finora

- (D-301) General Requirement in Equipment Installation - Rev.4 PDFDocumento11 pagine(D-301) General Requirement in Equipment Installation - Rev.4 PDFmihir_jha2Nessuna valutazione finora

- TL245 English 2004Documento8 pagineTL245 English 2004Elliott RussellNessuna valutazione finora

- Rubber Joint ManualDocumento5 pagineRubber Joint ManualKAY UNANessuna valutazione finora

- Repair Manual HS 1.5 Thru HS 015Documento12 pagineRepair Manual HS 1.5 Thru HS 015Mahesh NanayakkaraNessuna valutazione finora

- Design Principle of Jig and Fixture: Prepared by Federickanakmydin Register No: 05Dtp09F2036Documento14 pagineDesign Principle of Jig and Fixture: Prepared by Federickanakmydin Register No: 05Dtp09F2036Bong ThoNessuna valutazione finora

- Structural Repair Manual Guide to Fastener Preparation and InstallationDocumento18 pagineStructural Repair Manual Guide to Fastener Preparation and InstallationRobert KrižanovićNessuna valutazione finora

- 52 013Documento4 pagine52 013Jung CalangNessuna valutazione finora

- Motor 60Z02152 - 02 (1) CAT 3306Documento4 pagineMotor 60Z02152 - 02 (1) CAT 3306Ismael De Jesus Andrade50% (2)

- Trimo 2967 Trimo Assembly SNVDocumento14 pagineTrimo 2967 Trimo Assembly SNVBogdan RuxandaNessuna valutazione finora

- ATA70standard Practice EngineDocumento24 pagineATA70standard Practice EnginearunNessuna valutazione finora

- Repair Instruction For Engine Repair Manual (1Az-Fe) : PrecautionDocumento3 pagineRepair Instruction For Engine Repair Manual (1Az-Fe) : PrecautionichamoNessuna valutazione finora

- TVF2100NH - 09 008 432 1R2 PDFDocumento39 pagineTVF2100NH - 09 008 432 1R2 PDFEfra Lan PeñaNessuna valutazione finora

- Repair Instruction For Engine Repair Manual: PrecautionDocumento3 pagineRepair Instruction For Engine Repair Manual: PrecautionHenry SilvaNessuna valutazione finora

- Montagem e Desmontagem Da Camisa 3306Documento3 pagineMontagem e Desmontagem Da Camisa 3306Lucas ApostoloNessuna valutazione finora

- 2.3.2 Procedure For Mounting MoldDocumento4 pagine2.3.2 Procedure For Mounting MoldMuhammad JohariNessuna valutazione finora

- Manual de Armado HD785-7 - Compressed (1) - Compressed-201-216Documento16 pagineManual de Armado HD785-7 - Compressed (1) - Compressed-201-216Gustavo RolongNessuna valutazione finora

- 2005-2010 Tacoma Bed Extender PT329-35050 Rev. A - PT329-35050Documento8 pagine2005-2010 Tacoma Bed Extender PT329-35050 Rev. A - PT329-35050kylemac123Nessuna valutazione finora

- Main Rotor Blade Inspection and MaintenanceDocumento13 pagineMain Rotor Blade Inspection and MaintenanceEirick Wayne Zuñigga De-ItzelNessuna valutazione finora

- 1.0 Maintenance (Worker Unit, Wh4)Documento13 pagine1.0 Maintenance (Worker Unit, Wh4)Mauricio PauloNessuna valutazione finora

- Diagram of Vitamix Blade Blade Assembly: InstructionsDocumento5 pagineDiagram of Vitamix Blade Blade Assembly: InstructionsRenato PurcinoNessuna valutazione finora

- Service Manual: Color TelevisionDocumento21 pagineService Manual: Color TelevisionLuis MorenoNessuna valutazione finora

- Body Repair Manual 1463KBDocumento25 pagineBody Repair Manual 1463KBjason_meyer_14100% (1)

- Rear Door Outer Panel (Cut) : Double Cab: Body Panel Replacement BP-31Documento2 pagineRear Door Outer Panel (Cut) : Double Cab: Body Panel Replacement BP-31Osmar AugustoNessuna valutazione finora

- Shaft Seal Installation GuideDocumento11 pagineShaft Seal Installation GuideMachineryengNessuna valutazione finora

- General Notes 1 Steel WorkDocumento18 pagineGeneral Notes 1 Steel Workmaga2292Nessuna valutazione finora

- 3406 Crankshaft Front Seal and Wear SleeveDocumento4 pagine3406 Crankshaft Front Seal and Wear Sleevemanu luvungaNessuna valutazione finora

- TV-C1421 C1422Documento43 pagineTV-C1421 C1422gusy180662Nessuna valutazione finora

- Bearing Clearance - CheckDocumento3 pagineBearing Clearance - CheckchanlinNessuna valutazione finora

- Series: Compact SlideDocumento17 pagineSeries: Compact SlideluisenriqueruizNessuna valutazione finora

- Model 172 Maintenance Manual Safetying - Maintenance Practices 1. GeneralDocumento3 pagineModel 172 Maintenance Manual Safetying - Maintenance Practices 1. Generalraj mohanNessuna valutazione finora

- E Locking Cessna 172Documento3 pagineE Locking Cessna 172RAJ MOHANNessuna valutazione finora

- Printed in GermanyDocumento222 paginePrinted in GermanyGilberto GonzalezNessuna valutazione finora

- Con Eng f4sDocumento13 pagineCon Eng f4scristian.rodriguezNessuna valutazione finora

- Printed in GermanyDocumento11 paginePrinted in GermanyEdson CarvalhoNessuna valutazione finora

- 1.2m Installation ManualDocumento19 pagine1.2m Installation ManualJeremy Lee100% (1)

- TITLE Engine Assembly Guide: 12V140E-3 Series Cylinder Liner InstallationDocumento39 pagineTITLE Engine Assembly Guide: 12V140E-3 Series Cylinder Liner InstallationЕгорNessuna valutazione finora

- 2001 Oldsmobile Aurora 2000 Pontiac Bonneville 2000 Buick Lesabre Collision Repair ManualDocumento25 pagine2001 Oldsmobile Aurora 2000 Pontiac Bonneville 2000 Buick Lesabre Collision Repair ManualPedro Angel Alvarez NarvaezNessuna valutazione finora

- Bearing Clearance - ChecksDocumento3 pagineBearing Clearance - ChecksPutra JawaNessuna valutazione finora

- DX 6550Documento45 pagineDX 6550victorino2009Nessuna valutazione finora

- 7 14mmDocumento18 pagine7 14mmR. MondeNessuna valutazione finora

- TV-CN202 Service ManualDocumento33 pagineTV-CN202 Service Manualjama35Nessuna valutazione finora

- FRONT SEAT ASSEMBLY (For Power Seat) : ComponentsDocumento4 pagineFRONT SEAT ASSEMBLY (For Power Seat) : ComponentsdiemnganNessuna valutazione finora

- Rear Seat Assembly: ComponentsDocumento6 pagineRear Seat Assembly: ComponentsdiemnganNessuna valutazione finora

- Removal: Seat Belt - Rear Seat Inner Belt AssemblyDocumento2 pagineRemoval: Seat Belt - Rear Seat Inner Belt AssemblydiemnganNessuna valutazione finora

- Lumbar Support Adjuster Assembly: ComponentsDocumento2 pagineLumbar Support Adjuster Assembly: ComponentsdiemnganNessuna valutazione finora

- Installation: SB-34 23. Remove Rear Seat Inner With Center Belt Assembly LHDocumento3 pagineInstallation: SB-34 23. Remove Rear Seat Inner With Center Belt Assembly LHdiemnganNessuna valutazione finora

- Child Restraint Seat Tether Anchor: ComponentsDocumento3 pagineChild Restraint Seat Tether Anchor: ComponentsdiemnganNessuna valutazione finora

- Removal: Seat Belt - Rear Seat Outer Belt AssemblyDocumento4 pagineRemoval: Seat Belt - Rear Seat Outer Belt AssemblydiemnganNessuna valutazione finora

- Reassembly: Seat - Front Seat Assembly (For Power Seat)Documento5 pagineReassembly: Seat - Front Seat Assembly (For Power Seat)diemnganNessuna valutazione finora

- Deploy Front Seat Belt Pretensioner Before DisposalDocumento5 pagineDeploy Front Seat Belt Pretensioner Before DisposaldiemnganNessuna valutazione finora

- FRONT SEAT ASSEMBLY (For Manual Seat) : ComponentsDocumento3 pagineFRONT SEAT ASSEMBLY (For Manual Seat) : ComponentsdiemnganNessuna valutazione finora

- Front Seatback Heater: ComponentsDocumento2 pagineFront Seatback Heater: ComponentsdiemnganNessuna valutazione finora

- Removal: (A) Remove The 3 Screws. (B) Disconnect The Connector and Remove The Power Seat SwitchDocumento4 pagineRemoval: (A) Remove The 3 Screws. (B) Disconnect The Connector and Remove The Power Seat SwitchdiemnganNessuna valutazione finora

- Front Seat Cushion Heater: ComponentsDocumento2 pagineFront Seat Cushion Heater: ComponentsdiemnganNessuna valutazione finora

- Rear Seat Inner Belt Assembly Removal and InstallationDocumento3 pagineRear Seat Inner Belt Assembly Removal and InstallationdiemnganNessuna valutazione finora

- Removal: Seat - Front Seat Assembly (For Manual Seat)Documento2 pagineRemoval: Seat - Front Seat Assembly (For Manual Seat)diemnganNessuna valutazione finora

- Seat Heater Switch Testing and Replacement GuideDocumento4 pagineSeat Heater Switch Testing and Replacement GuidediemnganNessuna valutazione finora

- Removal: Seat - Front Seat Assembly (For Power Seat)Documento2 pagineRemoval: Seat - Front Seat Assembly (For Power Seat)diemnganNessuna valutazione finora

- Rear Seat Outer Belt Assembly Removal and InstallationDocumento3 pagineRear Seat Outer Belt Assembly Removal and InstallationdiemnganNessuna valutazione finora

- Removal: Seat - Front Seat Assembly (For Manual Seat)Documento2 pagineRemoval: Seat - Front Seat Assembly (For Manual Seat)diemnganNessuna valutazione finora

- Child Restraint Seat Anchor Bracket: ComponentsDocumento2 pagineChild Restraint Seat Anchor Bracket: ComponentsdiemnganNessuna valutazione finora

- Remove and Replace Front Power Seat Lumbar SwitchDocumento2 pagineRemove and Replace Front Power Seat Lumbar SwitchdiemnganNessuna valutazione finora

- Child Restraint Seat Anchor Bracket: ComponentsDocumento2 pagineChild Restraint Seat Anchor Bracket: ComponentsdiemnganNessuna valutazione finora

- Removal: Seat - Front Seat Cushion HeaterDocumento2 pagineRemoval: Seat - Front Seat Cushion HeaterdiemnganNessuna valutazione finora

- 028005Documento3 pagine028005diemnganNessuna valutazione finora

- Front Power Seat Lumbar Switch: ComponentsDocumento2 pagineFront Power Seat Lumbar Switch: ComponentsdiemnganNessuna valutazione finora

- Seat Belt Warning System OperationDocumento2 pagineSeat Belt Warning System OperationdiemnganNessuna valutazione finora

- Seat Heater System: PrecautionDocumento2 pagineSeat Heater System: PrecautiondiemnganNessuna valutazione finora

- Power Seat Switch: ComponentsDocumento2 paginePower Seat Switch: ComponentsdiemnganNessuna valutazione finora

- Front Seat Frame With Adjuster: InspectionDocumento2 pagineFront Seat Frame With Adjuster: InspectiondiemnganNessuna valutazione finora

- Check Seat Belt Warning System Using Data Link ConnectorDocumento2 pagineCheck Seat Belt Warning System Using Data Link ConnectordiemnganNessuna valutazione finora

- Joints in Poured Walls - tcm45-342541Documento3 pagineJoints in Poured Walls - tcm45-342541Youssef RomanosNessuna valutazione finora

- Joint Design RequirementsDocumento21 pagineJoint Design RequirementskhudubaNessuna valutazione finora

- Aeroquip - Formed Metal Tubing Design RulesDocumento21 pagineAeroquip - Formed Metal Tubing Design RulesbenNessuna valutazione finora

- Ring Hangers: (Formerly Afcon Fig. 300) Adjustable Swivel Ring, Tapped Per NFPA StandardsDocumento1 paginaRing Hangers: (Formerly Afcon Fig. 300) Adjustable Swivel Ring, Tapped Per NFPA StandardsANTONIO GUTIERREZ MIRANDANessuna valutazione finora

- Astm A 795Documento6 pagineAstm A 795djfreditoNessuna valutazione finora

- Sample and Injection Quill CatalogDocumento48 pagineSample and Injection Quill Catalogdiego pinedaNessuna valutazione finora

- GB 50108-2008-EnDocumento70 pagineGB 50108-2008-En柳德米拉Nessuna valutazione finora

- Rail Clip Mounting GuideDocumento2 pagineRail Clip Mounting Guidejhon jairo arangoNessuna valutazione finora

- Cement Concrete Pavement ConstructionDocumento6 pagineCement Concrete Pavement ConstructionAmit Singh80% (5)

- Rodrigo GuardhouseDocumento7 pagineRodrigo GuardhouseRodrigo MiñozaNessuna valutazione finora

- Synaxis Prequalification (2018)Documento82 pagineSynaxis Prequalification (2018)Synaxis ReadymixNessuna valutazione finora

- Type of Thread PDFDocumento13 pagineType of Thread PDFrefae0% (1)

- X17CrNi16-2 HTTP - WWW - Steelnumber.com - en - Steel - Composition - Eu - PHP - Name - IdDocumento2 pagineX17CrNi16-2 HTTP - WWW - Steelnumber.com - en - Steel - Composition - Eu - PHP - Name - IddabarcinaNessuna valutazione finora

- Workshop Welding ShopDocumento80 pagineWorkshop Welding ShopBhaskar KandpalNessuna valutazione finora

- Corrosion Resistance of MiTek Metal ConnectorsDocumento4 pagineCorrosion Resistance of MiTek Metal ConnectorsEduardo Depiné TarnowskiNessuna valutazione finora

- Trends in Powder MetallurgyDocumento39 pagineTrends in Powder MetallurgyManjunath GowdaNessuna valutazione finora

- 3 Week AheadDocumento2 pagine3 Week AheadAlessandro Del BorgiaNessuna valutazione finora

- Modified Guidelines For Geopolymer Concrete Mix Design Using Indian StandardDocumento13 pagineModified Guidelines For Geopolymer Concrete Mix Design Using Indian StandardDl Divakar LNessuna valutazione finora

- Lecture 6 - BricksDocumento28 pagineLecture 6 - BricksVanessa AlexanderNessuna valutazione finora

- 904L (Valbruna)Documento2 pagine904L (Valbruna)Claudia MmsNessuna valutazione finora

- Revere Concept 175w-250w Mercury Series Bulletin 1966Documento2 pagineRevere Concept 175w-250w Mercury Series Bulletin 1966Alan MastersNessuna valutazione finora

- Metric Thread Coarse Pitch ChartDocumento2 pagineMetric Thread Coarse Pitch ChartIvanNessuna valutazione finora

- Rate Analysis of Banganga NagarpalikaDocumento127 pagineRate Analysis of Banganga NagarpalikaKobid KunwarNessuna valutazione finora

- Lighting Circuits DiagramDocumento25 pagineLighting Circuits DiagramCrizel N. Potante100% (1)

- STR Myanmar Co., LTD Mgs Kitchen Project 7/6/2020Documento5 pagineSTR Myanmar Co., LTD Mgs Kitchen Project 7/6/2020Myanmar Ding Ming XinNessuna valutazione finora

- 7861 2 PDFDocumento26 pagine7861 2 PDFUdit Kumar SarkarNessuna valutazione finora

- 2124R 04Documento13 pagine2124R 04Cynti DZNessuna valutazione finora

- PI-Pagoda Tents and AccessoriesDocumento2 paginePI-Pagoda Tents and AccessoriesManishh Venkateshwara RaoNessuna valutazione finora

- Inspection Procedure SMALL BORE PIPINGDocumento3 pagineInspection Procedure SMALL BORE PIPINGInspection jr100% (1)

- Advantages of Bubble Deck Slab Over RCC Slab: Presentation On Project Review - IIDocumento25 pagineAdvantages of Bubble Deck Slab Over RCC Slab: Presentation On Project Review - IIsumitNessuna valutazione finora