Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

08 Grp02 LLT Engine

Caricato da

eurospeed2Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

08 Grp02 LLT Engine

Caricato da

eurospeed2Copyright:

Formati disponibili

08 GRP02 LLT Engine

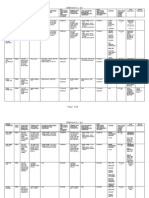

Component/ System heater circuits - electrical bank 1 sensor 1 (primary) Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Value Specifi ed Units Secondary Parameters Enable Condition Enable Value Units Time Required Frequency of Checks Criteria for Code MIL Illumination

bank 2 sensor 1 (primary)

P0030 P0031 P0032 P0050 P0051 P0052

circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage

Voltage

IC Internal

engine speed battery voltage battery voltage engine starting output

> 80 > 10.5 < 18.1 complete activated for complete checking

rpm V V -

0.01 sec

0.01 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Mass Air Flow (MAF) Sensor Ratoinality

P0101 range check low

measured mass air flow * threshold < Maximum modeled mass air flow

or fuel trim limits exceded range - multiplicative and correction factor (modeled air mass at throttle / air mass measured by air mass flow meter) range check high or fuel trim limits exceded range - multiplicative and correction factor (modeled air mass at throttle / air mass measured by air mass flow meter)

> delta lambda correction

0.2

< correction factor air mass

0.8

measured mass air flow * threshold < minimum modeled mass air flow

1.1

< delta lambda correction

-0.2

> correction factor air mass

1.2

battery voltage factor for time Condition bordnet voltage HFM supplied time after start crankshaft revolution counter factor ambient pressure valid desired cam angle valid long term fuel trim factor air flow mass air flow change gradient throttle angle change gradient engine running engine coolant temperature factor engine running time Air flow meter readiness pressure ratio over throttle factor pressure ratio across throttle during fuel cut off for time error: air flow meter (internal) factor error: throttle position sensor error: intake air temp. sensor Condition HFM signal electric valid

> > TRUE > > TRUE TRUE TRUE > < < TRUE > > TRUE < < > not set not set not set TRUE

10.5 0.1 0.3 150 1.39 0.25 2 9.8 1 0.8 0.5 -

V sec sec rev g/sec C sec sec -

0.01 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

P0100 open circuit check

sensor signal in period time

0.0

uS

P0102 range check low P0103 range check high

sensor signal in period time sensor signal in period time

83.2 697.6

uS uS

battery voltage Engine is running Key on time after start

> TRUE TRUE >

10.5

5 sec

0.3

sec

1 sec

Intake Air Temperature Sensor Rationality P0111 response check max intake air temperature - min intake air temperature 1.5 C drive period - count each with coolant temperature at start Intake Air Temperature Sensor 2 Electrical Failure Mass Air Flow Mass Air Flow Vehicle speed idle period - count each with coolant temperature at start Intake Air Temperature Sensor 2 Electrical Failure Mass Air Flow Vehicle speed engine coolant temperature >= <= FALSE > < > >= <= FALSE < < > 2 50 count C or 50 sec cumulative 42.2 20.0 50 2 50.3 g / sec g / sec mph count C 2 sec 0.1 sec continuous 4 sec continuous two driving cycles each with: 4 sec continuous or 50 sec cumulative

11.1 12.5 80

g / sec mph C

Circuit Continuity Check P0112 circuit continuity - high P0113 circuit continuity - low P0114 intermittent (discontinuity) Intake Air Temperature Sensor 2 Voltage > Intake Air Temperature Sensor 2 Voltage < Intake Air Temperature Sensor 2 Raw Voltage Intake Air Temperature Sensor 2 Filtered Voltage 4.87 0.21 V V Engine Coolant Temperature Mass air flow Vehicle speed Intermittent (discontinuous) time > < < > 60 27.8 2.5 1 C g / sec mph sec 2 sec 0.01 sec 4 sec continuous or 50 sec cumulative two driving cycles each with: 4 sec continuous or 50 sec

0.4

Oxygen Sensor sensor circuit (primary O2) bank 1 sensor 1 bank 2 sensor 1

P0130 sensor line short circuit P0150 to heater output line

secondary O2 sensor voltage gradient > within time after heater turn off < for occurrences > out of heater turn offs

2 0.04 4 6

engine running V battery voltage s primary O2 heater ever actived count and pri. O2 heater duty cycle count for time dew-point end passed error: injector circuit fault engine running battery voltage

TRUE > TRUE > > TRUE not set TRUE >

TRUE 10.4 TRUE 0.9 5 TRUE not set TRUE 10.4

V sec #REF! V

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

or primary O2 sensor voltage >

0.6

60 sec

Page 1 of 21

08 GRP02 LLT Engine

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria and primary O2 sensor voltage < and secondary O2 sensor voltage < or primary O2 sensor voltage > and primary O2 sensor voltage < and secondary O2 sensor voltage < Threshold Value 1.15 0.1 Specifi ed Units V V Secondary Parameters primary O2 heater ever actived and pri. O2 heater duty cycle for time error: injector circuit fault time after dew-point end passed and pri. O2 heater duty cycle or Primary Exhaut gas temp. model Integrated air mass purge diagnosis closed loop control engine running battery voltage primary O2 heater ever actived and pri. O2 heater duty cycle for time dew-point end passed error: injector circuit fault Integrated air mass purge diagnosis commanded lambda engine running battery voltage primary O2 heater ever actived and pri. O2 heater duty cycle for time dew-point end passed error: injector circuit fault engine running battery voltage primary O2 heater ever actived and pri. O2 heater duty cycle for time dew-point end passed error: injector circuit fault commanded lambda closed loop control engine speed engine speed engine load engine load exhaust gas temperature model

purge off or has been on for time

Enable Condition TRUE > > not set > TRUE > > > not set set TRUE > TRUE > > TRUE not set > not set < TRUE > TRUE > > TRUE not set TRUE > TRUE > > TRUE not set > active > > < > > > set set not set not set not set not set not set not set not set not set not set

Enable Value TRUE 0.9 5 not set 30 TRUE 0.68 600 2200 not set set TRUE 10.4 TRUE 0.9 5 TRUE not set 2200 not set 1.005 TRUE 10.4 TRUE 0.9 5 TRUE not set TRUE 10.4 TRUE 0.9 5 TRUE not set 0.995

Units

Time Required

Frequency of Checks

Criteria for Code

MIL Illumination

0.06 0.4 0.5

V V V

sec sec C g V sec g lambda V sec

60 sec

bank 1 sensor 1 bank 2 sensor 1

P0131 short circuit to ground P0151

primary O2 sensor voltage < and Secondary O2 sensor voltage >

0.06 0.5

V V

60 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

primary O2 sensor voltage < and cold start conditions present

0.06

0.1 sec

bank 1 sensor 1 bank 2 sensor 1

P0132 short circuit to battery voltage P0152

primary O2 sensor voltage >

1.15

V sec

0.1 sec continuous

4 sec continuous or 50 sec

two driving cycles each with: 4 sec

lambda

Primary O2 sensor slow response P0133 Bank 1 P0153 Bank 2

slow response

Continuously filtered normalized switching cycle duration 20 valid closed loop switching cycles (note: normalization of cycle duration

1.65

2400 1480 45 18 350 10

rpm rpm % % C sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

revised with new enable window and failure threshold)

scheduled by System Manager Primary O2 heater diagnosis finished high purge vapor concentration Evap. Leak diagnosis error: fuel adaptation error: purge valve error: misfire error: primary O2 heater error: secondary O2 heater error: secondary O2 slow sensor error: secondary O2 sensor

Oxygen Sensor sensor circuit (primary O2) bank 1 sensor 1 bank 2 sensor 1

P0134 sensor line disconnection P0154

primary O2 sensor voltage > and primary O2 sensor voltage < Or primary O2 sensor voltage < and mod. Exhaust gas temp. > or primary O2 sensor internal resistance > and when modeled exhaust gas temperature > or primary O2 sensor voltage > and secondary O2 sensor voltage > after a getting into fuel cut-off for

0.4 0.6 0.55 800 20000 600

0.2 0.2 3

engine running battery voltage primary O2 heater ever actived and pri. O2 heater duty cycle for time Ohm error: injector circuit fault C time after dew-point end passed and pri. O2 heater duty cycle V or Primary Exhaut gas V temp. model sec

V V V C

TRUE > TRUE > > not set > TRUE > >

TRUE 10.4 TRUE 0.9 5 not set 30 TRUE 0.68 600

V sec sec C

10 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

0.1 sec

two driving cycles each with: 4 sec continuous or 50 sec cumulative

0.1 sec

Oxygen Sensor Heating

Page 2 of 21

08 GRP02 LLT Engine

Component/ System heater performance (primary O2) bank 1 sensor 1 (primary) bank 2 sensor 1 (primary) Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Value Specifi ed Units Secondary Parameters Enable Condition Enable Value Units Time Required Frequency of Checks Criteria for Code MIL Illumination

P0135 primary O2 sensor P0155 internal resistance above threshold

measured primary O2 sensor internal resistance > nominal internal resistance multipy times degradation factor > for time

88 . . . 392 KFRINH / 2 5 . . . 63 FRINH1 / 2 6

battery voltage battery voltage Ohms engine running engine starting factor fuel cut off pri. O2 internal resistance sec intake air temperature engine off soak time modeled exhaust temp. suspicion of primary O2 sensor open circuit primary O2 voltage supply scheduled by System Manager for time primary O2 sensor dewpoint exceeded for no fault clear request during drive cycle deceleration fuel cut-off (DCFO) Since DCFO, secondary O2 sensor voltage has ever exceeded upper threshold battery voltage secondary O2 sensor readiness modeled exhaust gas temperature at secondary O2 sensor temperature secondary O2 sensor internal resistance secondary O2 sensor has measured lean and rich exhaust gas mass flow rate primary O2 sensor primary O2 sensor voltage Since DCFO, secondary O2 sensor voltage has ever exceeded upper threshold battery voltage secondary O2 sensor readiness modeled exhaust gas temperature at secondary O2 sensor temperature secondary O2 sensor internal resistance secondary O2 sensor has measured lean and rich exhaust gas mass flow rate primary O2 sensor primary O2 sensor voltage

> < TRUE complete FALSE valid > > < FALSE ON > > not set active > > TRUE > < TRUE > ready < > > TRUE > < TRUE > ready < > < < > > < > < < < active > > not set not set not set not set not set set

10.5 18.1 -30 120 525

V V C sec C

approx. 100 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

12 10

sec sec

Oxygen Sensor (Secondary O2 sensor) Delayed response voltage during DCFO P013A secondary O2 sensor bank 1 sensor 2 P013C bank 2 sensor 2 delayed response to DFCO

0.59 10.4 450 500 2.78 0.14 0.59 10.4 450 500 2.78 0.14 5.00 16.67 760 480 1040 2480 12.8 42 6 2.00 300 370 -30 -

V V C Ohms g/s V V V C Ohms g/s V g/sec g/sec C C rpm rpm % % C / sec % sec C -

4sec

time from start of DCFO till secondary O2 sensor voltage below the lower threshold or the oxygen mass integration from start of DCFO exceeded upper threshold before the voltage below the lower voltage threshold lower voltage threshold

sec

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

0.14

Slow response voltage during DCFO P013A secondary O2 sensor bank 1 sensor 2 P013C bank 2 sensor 2 slow response to DFCO

time from secondary O2 sensor voltage crosses upper threshold till it corsses lower voltage threshold upper voltage threshold lower voltage threshold

0.4

sec

0.4 0.2

V V

Catalyst Bank 1 Catalyst Bank 2

P0420 oxygen storage of catalyst P0430

EWMA filtered catalyst aging factor less than catalyst aging factor of a limit catalyst <

0.2

factor exhaust gas mass flow exhaust gas mass flow catalyst temp. model catalyst temp. model engine speed engine speed engine load engine load modeled catalyst temp. gradient relative exhaust gas mass flow gradient fuel system closed loop time after secondary O2 sensor exceeded dewpoint ambient temperature catalyst damaging misfire rate exceeded error: fuel system closed loop control at limit strong transient compenstation intervention catalyst clear out active (after fuel cutoff) fast mixture adaptation completed Trigger condition for step change Measured OSC < % of EWMA normalized filtered OSC

approx. 1000 sec during active driving 3 checks per driving cycle 3 checks per driving cycle 1 check per driving cycle

0.2 sec continuous

4 sec additional after block

immediate once code has been set

approx. 3 tests average run length (9 samples)

<

0.71

Engine Metal Overtemperature Protection ( Limp Home Function Active ) Rough Road Signal

P1258 engine coolant temperature too high

engine coolant temperature

>

132.8

engine run time error: engine coolant temp

> not set

30 -

sec -

1 sec

0.1 sec continuous

4 sec cont. or 50 sec cumulative 4 sec or 50 sec cum

code set then 5 sec

P1380 signal missing GMX295 only

signal missing

no error: misfire monitoring

TRUE

5 sec

0.1 sec continuous

no

Electronic Throttle Control P1551 limp-home throttle position out of range throttle position < OR throttle position > 39.8 % 10.1 % vehicle speed engine speed engine coolant temperature engine coolant temperature <= < >= <= 0 40 5.25 100.5 mph rpm C C 5 sec 0.01 sec at key on 4 sec continuous or 50 sec cumulative

code set then 5 sec with: 4 sec continuous or 50 sec

Page 3 of 21

08 GRP02 LLT Engine

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Value Specifi ed Units Secondary Parameters intake air temperature intake air temperature battery voltage accelerator pedal position Enable Condition >= <= > < Enable Value 5.25 143.8 10.0 14.9 C C V % Units Time Required Frequency of Checks Criteria for Code MIL Illumination cumulative

Fuel Level Sensor Circuit fuel level sensor 2

P2066 rationality

fuel level change < and cumulative driving distance >

4.6 100.0

% km

Primary fuel level Secondary fuel level Or Primary fuel level Secondary fuel level and battery voltage battery voltage engine starting electrical fuel level sensor(s) without failure

>= >= < > >= <= TRUE TRUE

41.1 6.2 41.1 6.2 10.5 18.1 -

% % % % V V -

0.1 sec continuous

4 sec continuous or 50 sec cumulative

no

Or cumulative driving distance >=

162.0

km

Primary fuel level Secondary fuel level battery voltage battery voltage engine starting electrical fuel level sensor(s) without failure battery voltage battery voltage engine starting battery voltage battery voltage engine starting

>= < >= <= TRUE TRUE >= <= TRUE >= <= TRUE

41.1 6.2 10.5 18.1 10.5 18.1 10.5 18.1 -

% % V V V V V V 60 sec 0.1 sec continuous 4 sec cont. or 50 sec cumulative 4 sec cont. or 50 sec cumulative no

P2067 range check low

voltage <

0.25

P2068 range check high

voltage >

3.2

60 sec

0.1 sec continuous

no

Secondary O2 Trim of primary O2 Sensor primary O2 sensor signal RICH / secondary O2 sensor signal LEAN Bank1 P2096 secondary O2 sensor fuel Bank 2 P2098 trim - rich shift - correction above threshold

secondary O2 sensor trim integral control >

0.8

sec

primary O2 sensor signal LEAN / secondary O2 sensor signal RICH Bank 1 P2097 secondary O2 sensor fuel Bank 2 P2099 trim - lean shift - correction below threshold

secondary O2 sensor trim integral control <

-0.8

sec

engine speed engine speed engine load engine load closed loop control active for time exhaust gas temp. model primary closed loop controller at upper limit at lower limit secondary O2 sensor readiness catalyst clear out after DCFO error: catalyst monitoring error: purge valve error: secondary O2 sensor response error: primary O2 heater error: secondary O2 heater error: fuel system monitoring error : Evap. Leak error : air flow meter

< > < > TRUE > > not set not set not set not set not set not set not set not set not set not set not set not set

3480 1280 65.3 . 65.3 16.5 . 20.3 1 250 0 -

rpm rpm % % sec C 0 -

200 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Accelerator Pedal Position Sensor 1

P2122 range check low P2123 range check high

voltage

0.74 4.82

V V

battery voltage

>

0.2 sec

0.01 sec continuous

4 sec cont. or 50 sec cumulative

code set then 5 sec

Accelerator Pedal Position Sensor 2

P2127 range check low P2128 range check high

voltage

0.63 4.82

V V

battery voltage

>

0.2 sec

Accelerator Pedal Position 1 versus Position 2

P2138 plausibility

voltage difference > idle range voltage difference pedal partially pressed > voltage difference > pedal fully pressed

0.25 0.31 0.31 1.69

V V V V

0.24 sec

Barometric Pressure Sensor Rationality P2227 range check high sensor signal > or sensor signal < 115 KPa error : barometric pressure sensor electrical for time error : barometric pressure sensor not set > not set 0.2 sec 2 sec continuous 4 sec two driving cycles each with: 4 sec continuous

range check low

50

KPa

2 sec

continuous

4 sec

Page 4 of 21

08 GRP02 LLT Engine

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Value Specifi ed Units electrical for time 10 30 KPa KPa error : barometric pressure sensor electrical time since engine start error : barometric pressure sensor electrical air mass flow meter readiness engine running time command air flow valid corrector factor calculation for mass-flow substitute load signal air flow meter signal valid enabling air flow meter diag. Evap. Leak detection active for time error: throttle position sensor error: air flow mass meter error : Baro pressure sensor electrical error : barometric pressure sensor electrical time since engine start error : barometric pressure sensor electrical air mass flow meter readiness engine running time command air flow valid corrector factor calculation for mass-flow substitute load signal air flow meter signal valid enabling air flow meter diag. Evap. Leak detection active for time error: throttle position sensor error: air flow mass meter error : Baro pressure sensor electrical enabled by scheduler for time Secondary Parameters Enable Condition Enable Value Units Time Required Frequency of Checks Criteria for Code MIL Illumination or 50 sec cumulative 2 sec continuous 4 sec

or sensor offset / jump test low sensor output change within 20 sec period > OR barometric pressure signal pressure jump from previous key off > AND sensor output + THRESHOLD < pressure model

> not set < not set TRUE > TRUE

0.2 5 1 -

sec sec sec -

KPa

TRUE TRUE TRUE not set > not set not set not set not set < not set TRUE > TRUE

1 5 1 -

sec sec sec 2 sec continuous 4 sec

sensor offset / jump test high

or sensor output change within 20 sec period > OR barometric pressure signal pressure jump from previous key off > AND sensor output - THRESHOLD > pressure model

10 30

KPa KPa

KPa

TRUE TRUE TRUE not set > not set not set not set >

1 1

sec sec 2 sec

P2228 range check low

voltage <

0.2

P2229 range check high Auxiliary Engine Coolant Pump Circuit Continuity P2600 circuit continuity - open P2602 circuit continuity - ground P2603 circuit continuity - voltage

voltage >

4.87

enabled by scheduler for time

>

sec

Voltage Voltage Voltage

IC Internal IC Internal IC Internal

engine speed battery voltage battery voltage

> > <

80 9.99 18.1

rpm V V

0.01 sec

0.01 sec

4 sec cont. or 50 sec cumulative

no / pending

Rationality P2601 monitoring of engine coolant temperature profile during soak ( engine off period ) temperature change gradient during soak period > -5.0 -1.5 C [ function of ambient temperature ] auxiliary coolant pump enabled ( coolant temp. at engine shutdown > 110 C ) coolant temp. sensor fault (electrical) coolant temp. sensor fault (performance) coolant temp. sensor fault (intermittent) IAT sensor fault (electrical) IAT sensor fault (plaus) auxiliary coolant pump fault (electrical) TRUE FALSE FALSE FALSE FALSE FALSE FALSE 80 sec 0.1 sec during after-run when pump is enabled only

Fuel Level Sensor Circuit fuel transfer pump

P2636 transfer pump failure

fuel level 1 < and fuel level 2 >

10.6 22.8

% %

sensor signal without failure fuel level state stable engine starting

TRUE TRUE complete

240 sec

0.1 sec continuous

4 sec cont. or 50 sec cumulative

no

Page 5 of 21

08 GRP02 LLT Engine

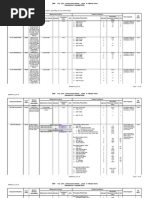

LOOK-UP TABLES (LLT)

P0135, P0155 KFRINV / 2 (internal manufacturer cross reference) Sensor Element (Ceramic) Impedance, Nominal Value - Secondary O2 Sensor Ohms Modeled Exhaust Gas Temperature at Secondary O2 Sensor ( C ) 260.006 320.006 380.006 440.006 500.006 O2 Heater Power (watts) 224 216 192 160 136 0.70 168 168 144 128 112 0.80 112 112 112 104 96 1.00

FRINV1 / 2 (internal manufacturer cross reference) Multiplication Factor for Internal Resistance KFRINH Nominal Value - Secondary O2 Sensor Modeled Exhaust Gas Temperature at Secondary O2 Sensor ( C ) 260.006 320.006 380.006 440.006 500.006 10.50 7.50 4.50 3.00 2.00 factor

P0141, P0161

KFRINH / 2 (internal manufacturer cross reference) Sensor Element (Ceramic) Impedance, Nominal Value - Secondary O2 Sensor Ohms Modeled Exhaust Gas Temperature at Secondary O2 Sensor ( C ) 299.991 359.991 419.991 479.991 539.991 O2 Heater Power (watts) 344 328 304 272 224 0.700 248 240 232 200 168 0.800 200 184 168 152 128 1.000

FRINH1 / 2 (internal manufacturer cross reference) Multiplication Factor for Internal Resistance KFRINH Nominal Value - Secondary O2 Sensor Modeled Exhaust Gas Temperature at Secondary O2 Sensor ( C ) 299.991 359.991 419.991 479.991 539.991 15.00 10.00 6.00 4.00 2.50 factor

P2601

DDTMOTMIN Maximum Second Derivative of tmot in Post Run tumg (degC) 2nd derivative (degC) -20.3 -5 0 -3 15 -2 50.3 -1.5

Page 6 of 21

08 GRP02 LLT Engine

LOOK-UP TABLES (LLT)

DDTMOTMIF Maximum Second Derivative of tmot in Post Run with Fans Active tumg (degC) 2nd derivative (degC) -20.3 -5 0 -3 15 -2 50.3 -1.5

Page 7 of 21

08 GRP02 LLT Engine

Component/ System Camshaft Control Electrical Bank 1 Intake Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Value Specifie Units Secondary Parameters Enable Condition Enable Value Units Time Required Frequency of Checks Criteria for Code MIL Illumination P0010 P2088 P2089 P0013 P2090 P2091 P0020 P2092 P2093 P0023 P2094 P2095 P0011 P0014 P0021 P0024 circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage rationality low / high Voltage IC Internal engine speed battery voltage battery voltage output > 80 rpm > 10 V < 18.1 V activated and deactivated for complete checking 0.01 sec 0.01 sec continuous 4 sec continuous or 50 sec cumulative two driving cycles each with: 4 sec continuous or 50 sec cumulative

Bank 1 Exhaust

Bank 2 Intake

Bank 2 Exhaust

System - Control Bank 1 Intake Bank 1 Exhaust Bank 2 Intake Bank 2 Exhaust

difference to start test (filtered actual angle versus filtered desired angle) > (desired must remain above value to test to complete the evaluation) same as above, but offset added to the difference, during cold start only: filtered actual angle < filtered desired angle from test start within time (detects 5 sec slow [time constant]) for multiple activation occurrences (decrements upon activations where no difference is seen between desired and actual) same as above, but during cold start only: difference (filtered actual angle max versus actual at test start) > ( to detect slow response versus stuck cam if above this limit ) at time (overlaps with time to detect above) (passes after multiple good activations in both cam phase rotation directions)

6.0 . . . 11.0 degrees engine speed KFDWNWDMXE / 2 engine run time KFDWNWDMXA / 2 camshaft control circuit test error: camshaft control circuit 0 degrees coolant temperature coolant temperature engine oil temperature engine oil temperature 2.5 sec cam-crank alignment adaptation

> > complete not set < > < > complete

480 1 143 -48 143 -48 -

rpm sec C C C C -

approx. 20 sec ( 2 times for 2.5 sec each )

0.01 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

10 count ( same as stated in "time required" column )

4 1.5

count degrees

2.5

sec

System - Cam - Crank Alignment Bank 1 Intake Bank 1 Exhaust Bank 2 Intake Bank 2 Exhaust Bank 1 / Idler Sprocket Bank 2 / Idler Sprocket

P0016 P0017 P0018 P0019 P0008 P0009

cam-crank adapted angle limit check (applies for each camshaft)

adapted angle > or adapted angle < or actual angle with parked cams > and < adapted angle for both cams > adapted angle for both cams <

9.9 9.9 15 21 6.0

degrees degrees degrees degrees

engine run time > engine coolant temp > engine coolant temp < model: engine oil temp <

> > < < not set not set

50 0 95.25 120 -

sec C C C -

approx. 600 sec fail after 2 adaptation cycles required

0.2 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

degrees error: camshaft sensor error: camshaft control circuit

Air / Fuel Ratio Sensor Heating and Oxygen Sensor Heating heater circuits - electrical bank 1 sensor 2 (secondary) P0036 circuit continuity - open P0037 circuit continuity - ground P0038 circuit continuity - voltage bank 2 sensor 2 (secondary) P0056 circuit continuity - open P0057 circuit continuity - ground P0058 circuit continuity - voltage High Pressure Fuel Control System Rationality P0088 P0087 P0089 P0089 pressure deviation from desired over pressure pressure deviation from desired under pressure C/L controller output value - above expected C/L controller output value - below expected

Voltage

IC Internal

engine speed battery voltage battery voltage secondary O2 sensor heating secondary O2 sensor dew point output

> 80 rpm > 10 V < 18.1 V ready reached activated and deactivated for complete checking

0.01 sec

0.01 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

difference ( desired versus actual fuel rail pressure difference ( desired versus actual fuel rail pressure Controller output value ( "p" part plus "i" part ) > Controller output value ( "p" part plus "i" part ) <

-2000 1500 2500 -2500

Kpa Kpa Kpa Kpa

error: electrical diagnosis of fuel volume co tester request for open fuel flow control va error: electrical diagnosis of fuel rail press airbag deployed battery voltage relative injected fuel mass relative injected fuel mass first engine start at assembly plant DFCO active engine speed syncronisation reference mark detected engine start temperature

not set FALSE not set FALSE < > < FALSE FALSE > TRUE >

18.1 5.016 500 25 -48

V % % rpm C

2 sec 2 sec 2 sec 2 sec

continuous continuous continuous continuous

4 sec 4 sec 4 sec 4 sec

Immdediate once code has been set

High Pressure Fuel Volume Control Valve Circuit rationality P0092 P0091 P0090 circuit rationality - feed-back voltage circuit rationality - feed-back voltage circuit rationality - feed-back voltage voltage test pulse - on command > 4.502 voltage test pulse - off command < 2.749 voltage test pulse - off command within window 749 < Voltage < 4.5 V V V battery voltage battery voltage battery voltage circuit switched off due to 5 volt supply fau Engine coolant model (cooled down) Soaking time after shut down previous accumulated air mass AND previous engine run time or ECT at shut down Controller Shut Down at end of last cycle Error - Engine Off Timer Powerfail during previous drive Block Heater if Startup IAT > < < not set < > > > > not detected not detected not detected > 6 18.1 off command voltage 50 19800 6000 600 81.75 72 V V V C sec g sec C C 0.1 sec 0.5 sec continuous 4 sec Immdediate once code has been set

Engine coolant temperature sensor

P0116

difference from Engine temperature model after soaking

filtered difference ( ECT at key on - ECTmodel at key on )

14.3

100 sec for block heating check

0.2 sec continuous

4 sec additional after block heater check when filtered difference exceeds threshold

immediate once code has been set

or filtered difference ( ECTmodel at key on - ECT at key on )

one filter update per cold start

14.3

approx. 6 test average run length (15C delta) two driving

Engine coolant

P0117

range check high

coolant temperature >

140.3

0.1 sec

4 sec

Page 8 of 21

08 GRP02 LLT Engine

Component/ System temperature sensor P0118 range check low coolant temperature < -42 C Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Value Specifie Units Secondary Parameters hot restart timer Enable Condition >= Enable Value 60 Units sec Time Required Frequency of Checks continuous Criteria for Code continuous or 50 sec cumulative MIL Illumination cycles each with: 4 sec cont. or 50 sec cum.

P0119

intermittent ( discontinuity )

delta coolant temp. during evaluation period < delta coolant temp. during evaluation period > weighted counter > ( up 5,000 w/jump; down 1 with steady ) sensor difference >

-4.5 4.5 60000

C C count

0.1 sec

0.01 sec continuous

Throttle Position Sensor 1 (primary)

P0121

range check poti voltage

battery voltage

>

continuous

0.1 sec continuous

4 sec continuous or 50 sec cumulative 4 sec continuous or 50 sec cumulative 4 sec continuous or 50 sec cumulative 4 sec continuous or 50 sec cumulative 4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec cont. or 50 Immdediate once code has been set

P0122 P0123

plausibility to other poti

sensor circuit low voltage < sensor circuit high voltage >

0.176 4.629

V V

battery voltage

>

continuous

0.1 sec continuous

Sensor 2 (redundant)

P0221

range check poti voltage,

sensor difference >

battery voltage

>

continuous

0.1 sec continuous

two driving cycles each with: 4 sec cont. or 50 Immdediate once code has been set

P0222 P0223

plausibility to other poti

sensor circuit low voltage < sensor circuit high voltage >

0.156 4.883

V V

battery voltage

>

continuous

0.1 sec continuous

Engine Coolant Thermostat Monitoring

P0128

Coolant Temperature Below Thermostat Regulating Temperature (plausibility check)

(calculated reference model coolant temp minus measured coolant temperature) > reference model calculation limit ( development vehicles indicated steady thermostat regulating temperatures of 89C, as measured by the engine coolant temp. sensor. The thermostat opening temp. is 82C. The thermostat is fully open by 95C. All critical OBD and emission functions are enabled above 60C. ) or

10.5

89.3

error: engine coolant temp error: vehicle speed sensor est. ambient temperature est. ambient temperature vehicle speed engine speed coolant temperature at start integrated air mass flow

not set not set > < >= > < >

-10.5 70 9.375 960 60.8 3000

C C mph rpm C g

5 sec

0.1 sec continuous

typical fault detection time for stuck open t-stat = ~ 700 sec

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Engine coolant temperature sensor

plausibility check

calculated coolant temperature model minus measured temperature >

9.8

the model temperature increases depending on air flow coolant temp at start ECT Electrical Failure Blockheater Detection

< not set not set

40.5 -

C -

120 to 300 sec approx. 500 sec

Oxygen Sensor sensor circuit (secondary O2) bank 1 sensor 2 bank 2 sensor 2

P0137 P0157

short circuit to ground

secondary O2 sensor voltage <

0.06

secondary O2 heating stable and secondary O2 dew point end for time engine running battery voltage mod. exhaust-gas temp. time after start engine temp at stop engine temp error: engine coolant temp secondary O2 heating stable and secondary O2 dew point end for time engine running battery voltage mod. exhaust-gas temp. secondary O2 heating stable and secondary O2 dew point end for time engine running battery voltage mod. exhaust-gas temp.

TRUE TRUE > TRUE > < < > < not set TRUE TRUE > TRUE > < TRUE TRUE > TRUE > <

90 10.4 800 1 60 40 90 10.4 800 90 10.4 800

sec V C sec C C sec V C sec V C

0.1 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

bank 1 sensor 2 bank 2 sensor 2

P0138 P0158

short circuit to battery voltage

secondary O2 sensor voltage >

1.15

5.1 sec

bank 1 sensor 2 bank 2 sensor 2

P0140 P0160

sensor line disconnection

secondary O2 sensor voltage > and secondary O2 sensor voltage < or secondary O2 sensor internal resistance > when modeled exhaust gas temperature >

0.401 0.519

V V

60 sec

40000 450

Ohm C

Oxygen Sensor Heating heater performance (secondary O2) bank 1 sensor 2 (secondary) bank 2 sensor 2 (secondary)

P0141 P0161

secondary O2 sensor internal resistance above threshold

measured secondary O2 sensor internal resistance > nominal internal resistance multipy times degradation factor for time

104 . . . 296 3.5 . . . 7.5 6

Ohms factor sec

battery voltage battery voltage engine running engine starting fuel cut off sec. O2 internal resistance intake air temperature engine off soak time modeled exhaust temp. at secondary O2 sensor suspicion of secondary O2 sensor open circuit

> < TRUE complete FALSE valid > > in range FALSE

10.5 18.1 -30 120 300 . . . 550

V V C sec C

approx. 100 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Page 9 of 21

08 GRP02 LLT Engine

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Value Specifie Units Secondary Parameters secondary O2 voltage supply from the deactivation for time Fuel Rail Pressure Sensor Rationality P0191 rationality check low Fuel pressure during power up init. < AND Fuel system fault exists: P0087 or P2188 or P2187 250 KPa engine speed for time engine run time > > > 25 0.5 30 rpm sec sec 0.1 sec During engine start only 4 sec continuous two driving cycles each with: 4 sec continuous or 50 sec cumulative Enable Condition ON > Enable Value 120 Units Time Required Frequency of Checks Criteria for Code MIL Illumination sec

rationality check high

or Fuel pressure during power up init. > AND Fuel system faults exist: P0088 or P2187 or P2177

1500

KPa

engine speed for time block heater active engine coolant at shutdown engine coolant at start difference : engine coolant at start intake air temperature differenec : intake air temperature engine coolant at start engine off time during soak

> > > < < < >

25 30 FALSE 84.5 54.8 35.3 9.75 16000

rpm sec C C C C sec

rationality check high

or Fuel pressure during power up init. > AND Fuel pressure rise during fuel pump prime >

1500 3500

KPa KPa

engine speed for time block heater active engine coolant at shutdown engine coolant at start difference : engine coolant at start intake air temperature differenec : intake air temperature engine coolant at start engine off time during soak

> > > < < < >

25 30 FALSE 84.5 54.8 35.3 9.75 16000

rpm sec C C C C sec

Fuel Rail Pressure Sensor Electrical P0193 P0192 circuit continuity - high circuit continuity - low Fuel pressure sensor output voltage > Fuel pressure sensor output voltage < 4.70 0.30 V V 0.5 sec 0.5 sec 0.01 sec 0.01 sec 4 sec 4 sec Immdediate once code has been set

High Pressure Fuel Injection Valve Circuit Continuity - High side (HS) and Low Side (LS) Cylinder #1 P0201 circuit continuity - open LS or HS P0261 circuit continuity - ground LS P0262 circuit continuity - battery LS P2146 circuit continuity - ground or battery HS Cylinder #2 P0202 P0264 P0265 P2149 P0203 P0267 P0268 P2152 P0204 P0270 P0271 P2155 P0205 P0273 P0274 P216A P0206 P0276 P0277 P216D P062B circuit continuity - open LS or HS circuit continuity - ground LS circuit continuity - battery LS circuit continuity - ground or battery HS circuit continuity - open LS or HS circuit continuity - ground LS circuit continuity - battery LS circuit continuity - ground or battery HS circuit continuity - open LS or HS circuit continuity - ground LS circuit continuity - battery LS circuit continuity - ground or battery HS circuit continuity - open LS or HS circuit continuity - ground LS circuit continuity - battery LS circuit continuity - ground or battery HS circuit continuity - open LS or HS circuit continuity - ground LS circuit continuity - battery LS circuit continuity - ground or battery HS Internal SPI Communication Fault or Internal ADC Voltage Booster Failure

Voltage

IC Internal

engine speed battery voltage battery voltage

> > <

80 8 18.1

rpm v v

0.01 sec

0.01 sec

4 sec

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Cylinider #3

Cylinder #4

Cylinder #5

Cylinder #6

SPI Communication

IC Internal IC Internal

engine speed battery voltage battery voltage

> > <

80 8 18.1

rpm v v

1.10 sec 0.50 sec

0.01 sec 0.01 sec

4 sec 4 sec

Diagnosis of Stuck Open Fuel Injector Rationality P029D fuel injector stuck open - cylinder #1 fuel pressure deviation from desired under pressure ( P0087 ) and cylinder # 1 misfire counts > fuel pressure deviation from desired under pressure ( P0087 ) and cylinder # 2 misfire counts > fuel pressure deviation from desired under pressure ( P0087 ) and cylinder # 3 misfire counts > set misfire monitor active ( see P0300 details ) engine speed engine speed counts relative engine load misfire counters accumulate within period < 200 ms > < < < 1520 4520 114.8 80 rpm rpm % rev continuous 4 sec Immdediate once code has been set

100 set

P02A1

fuel injector stuck open - cylinder #2

100 set

counts

P02A5

fuel injector stuck open - cylinder #3

100

counts

Page 10 of 21

08 GRP02 LLT Engine

Component/ System Fault Code P02A9 Monitor Strategy Description fuel injector stuck open - cylinder #4 Primary Malfunction Signal and Criteria fuel pressure deviation from desired under pressure ( P0087 ) and cylinder # 4 misfire counts > fuel pressure deviation from desired under pressure ( P0087 ) and cylinder # 5 misfire counts > fuel pressure deviation from desired under pressure ( P0087 ) and cylinder # 6 misfire counts > Threshold Value set Specifie Units Secondary Parameters Enable Condition Enable Value Units Time Required Frequency of Checks Criteria for Code MIL Illumination

100 set

counts

P02AD

fuel injector stuck open - cylinder #5

100 set

counts

P02B1

fuel injector stuck open - cylinder #6

100

counts

Misfire Emission Level Multiple Cylinder Cylinder #1 Cylinder #2 Cylinder #3 Cylinder #4 Cylinder #5 Cylinder #6

P0300 P0301 P0302 P0303 P0304 P0305 P0306

crankshaft speed fluctuation cylinder 1 to cylinder 6

emissions relevant misfire rate

1.82

engine speed engine speed indicated torque (idle, no drive) indicated torque (drive) (MISALUN) engine speed gradient volumetric efficiency gradient cylinder events after engine start air temperature rough road (GMX295 only) clutch switch press / release leak detection pull-down phase fuel cut off fuel level OR fuel level AND solid misfire MIL OR fuel level error error: throttle position error: crankshaft sensor error: ref.mark of crank sensor

> < > > < < > > not detected transition off not active > < on set not set not set not set

420 7000 5.86 7.05 . . . 29.3 2500 . . . 4600 225 . . . 1350 6 -30 FALSE 11.4 11.4 -

rpm rpm % % rpm/sec %/rev ignitions C % % -

1000 revs

cylinder firing frequency continuous

4 sec continuous After detection, the diagnostic can only pass if similar conditions are encountered

Fault during 1st interval: 2 faults in 2 different drive cycles. Fault during remaining intervals: 8 faults in 2 different drive cycles with at least 4 faults in each.

Catalyst Damaging Level Multiple Cylinder Cylinder #1 Cylinder #2 Cylinder #3 Cylinder #4 Cylinder #5 Cylinder #6

OR Catalyst damaging misfire rate P0300 P0301 P0302 P0303 P0304 P0305 P0306

18.1 . . . 5 see Misfire supplemental data (h) (2.5.1)

Includes all the above with the following exceptions: First interval extention engine coolant temperature fuel level OR fuel level AND blinking MIL AND NOT first blink event

< >= < blinking -

47 11.4 11.4 -

C % % -

1000 revs First interval 200 revs all remaining intervals

First occurance: immediate flashing while error present, then no MIL with no error. Second occurance: immediate flashing while error present, then solid MIL with no error.

Knock Control Circuit

P0324

test pulse

test pulse integral < for consecutive events

4 4

V count

0.1 sec engine coolant temp. knock control zero test , parity fault assumptions measuring window > active not set > > active not set > not set 60 1 60 60 C ms C C

0.1 sec continuous

4 sec continuous or 50 sec cumulative

or null test (zero test) absolute value (integrator gradient) > for consecutive events or parity check or SPI communication fficient RAM errors in knock IC, per 250 working cyc check word errors in knock IC, per 250 working cyc 5 25 count count 200 4

two driving cycles each with: 4 sec continuous or 50 sec

V / sec engine coolant temp. knock control count test pulse , parity fault assumptions engine coolant temp. test pulse fault assumption

Bank 1 Circuit check Performance

P0326 P0327

short circuit to B+ or GND range check low

faults detected on knock sensor pins, per 250 work reference voltage <

25 0.055 . . . 0.221 UDKSNU

count V

engine coolant temperature engine speed engine speed gradient (NGKRWN) engine load gradient error: knock control circuit (IC)

> > < < not set

60 2200 500 2300 50 . . . 100 -

C rpm rpm / sec kPa / sec -

approx. 20 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

for consecutive events P0328 range check high reference voltage > for consecutive events

30 3.1 . . . 39.1 UDKSNO 30

count V count

short circuit to B+ or GND

faults detected on knock sensor pins, per 250 working cycles (zkrks) >

Bank 2 Circuit check Performance

P0331 P0332

short circuit to B+ or GND range check low

faults detected on knock sensor pins, per 250 work reference voltage <

25 0.088 . . . 0.331

count V

engine coolant temperature engine speed gradient (NGKRWN) engine load gradient error: knock control circuit (IC)

> < < not set

60 500 2300 50 . . . 100 -

C rpm / sec kPa / sec -

approx. 20 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous

Page 11 of 21

08 GRP02 LLT Engine

Component/ System Fault Code P0333 range check high reference voltage > for consecutive events Crankshaft Position Sensor P0335 circuit continuity rationality check P0336 rationality check rationality check P0338 rationality check no engine signal but phase signals available reference gap missing > ( sensor signal but no reference ) unexpected re-synchronization > ( loss of reference mark ) intermittent loss of engine speed signal > difference in counted teeth between reference gap position events > 3.1 . . . 39.1 UDKSNO 100 0 6 2600 28 250 V count rpm gaps count count crankshaft teeth approx. 2 sec 1 per rev continuous camshaft revolutions detected > 12 counts approx. 5 sec 0.01 sec continuous 4 sec continuous or 50 sec cumulative immediate once code has been set Monitor Strategy Description Primary Malfunction Signal and Criteria for consecutive events Threshold Value 100 Specifie Units count Secondary Parameters Enable Condition Enable Value Units Time Required Frequency of Checks Criteria for Code MIL Illumination or 50 sec cumulative

Camshaft Position Sensor Bank 1 Intake

P0341 P0342 P0343 P0346 P0347 P0348 P0366 P0367 P0368 P0391 P0392 P0393

plausibility check circuit low circuit continuity or high plausibility check circuit low circuit continuity or high plausibility check circuit low circuit continuity or high plausibility check circuit low circuit continuity or high

signal erratic or out of position signal permanently low signal permanently high signal erratic or out of position signal permanently low signal permanently high signal erratic or out of position signal permanently low signal permanently high signal erratic or out of position signal permanently low signal permanently high

4 5 5

count count count

engine in synchronized mode

TRUE

10 revolutions

1 per rev continuous

4 sec continuous or 50 sec cumulative

Bank 2 Intake

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Bank 1 Exhaust

Bank 2 Exhaust

Ignition Coil circuit continuity Cylinder #1

Cylinder #2

Cylinder #3

Cylinder #4

Cylinder #5

Cylinder #6

P0351 P2300 P2301 P0352 P2303 P2304 P0353 P2306 P2307 P0354 P2309 P2310 P0355 P2312 P2313 P0356 P2315 P2316 P167D

circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage Internal SPI communication fault

Voltage

IC Internal

engine speed engine speed battery voltage battery voltage

< > <

6000 9.99 18.1

rpm V V

approx. 1 sec

engine cycle frequency continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Ignition Coil Driver Circuit Serial Communication

IC Internal

battery voltage battery voltage engine speed

< > <

18.1 9 6000

v v rpm

0.01 sec

Evaporative System and Leak Monitor Small Leak - 0.020 "

P0442

natural pressure/vacuum in tank

filtered fault index > based on: ( peak pressure - peak vacuum ) < [ Table KFEONVPT ]

0.6

540 . . . 1430

Pa

Eng. Running Vac. pull down or vac. pulldown suspect leak est amb air temp est amb air temp Engine stop coolant temp engine run time trip distance travelled @ vehicle speed above evap fuel volatility factor fuel level fuel level fuel level change from keyoff error: vehicle speed error: engine coolant temp error: purge valve error: fuel tank pressure error: system voltage error: air mass meter error: intake air temp error: canister vent valve altitude adaption tank vacuum out of range start (coolant - intake air) start engine coolant temp Start intake air temp Start intake air temp time since previous test amb pressure battery voltage vehicle odometer

not set 0.020" leak > < > > > > < > < < not set not set not set not set not set not set not set not set valid FALSE < < > < > > > >

( see P0455 for details ) ( see P0455 for details ) 1.5 C 32.25 C 74.25 C 600 sec 5.1 miles 1.6 mph 8 factor 11.0 % 88.1 % 10.2 % 9.75 C 42 C 1.5 C 32.3 C 0 sec 68 kPa 10.8 V 12.5 miles

approx. 600 sec each test approx. 6 test average run length

0.1 sec once per engine off cycle

filtered value exceeds threshold then 4 sec continuous

immediate once code has been set

approx. 6 test average run length ( The MIL actually is requested during shut down soak. It becomes visible on the following drive. )

Evaporative Emission System

Page 12 of 21

08 GRP02 LLT Engine

Component/ System Purge Solenoid Control Circuit Fault Code P0443 P0458 P0459 Monitor Strategy Description circuit continuity - open circuit continuity - ground circuit continuity - voltage Voltage Primary Malfunction Signal and Criteria Threshold Value IC Internal Specifie Units Secondary Parameters engine speed battery voltage battery voltage output Enable Condition Enable Value Units Time Required 0.01 sec Frequency of Checks 0.01 sec continuous Criteria for Code 4 sec continuous or 50 sec cumulative MIL Illumination two driving cycles each with: 4 sec continuous or 50 sec cumulative > 80 rpm > 9.99 V < 18.1 V activated and deactivated for complete checking

Evaporative System and Leak Monitor Canister Vent Valve

P0446

underpressure in tank

tank pressure <

-800

Pa

fuel system status vehicle speed engine battery voltage battery voltage fuel tank pressure fuel tank pressure ratio: ( MAP Model / Baro ) est amb air temp est amb air temp fuel level fuel level engine start temp - amb. temp time after engine start or fuel mixture adaptation amb pressure maximum number of attempts error: mass air flow error: coolant temp error: intake air temp error: fuel tank pres error: system voltage error: purge valve error: vehicle speed error: canister vent valve error: purge valve flow error: accelerator pedal engine speed battery voltage battery voltage output

closed loop < idling > < > < < > < > < < > stable > < not set not set not set not set not set not set not set not set not set not set

1.9 10.5 18.1 -2500 1300 0.812 1.5 32.25 11.2 91.2 9.75 600 68 10 -

mph V V Pa Pa C C % % C sec kPa -

approx. 5 sec Only one test per will be completed. The test will attempt to run up to 10 times until it successfully completes a test

0.1 sec one completed test per driving cycle

4 sec continuous

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Evap Vent Solenoid Control Circuit

P0449 P0498 P0499

circuit continuity - open circuit continuity - ground circuit continuity - voltage

Voltage

IC Internal

> 80 rpm > 9.99 V < 18.1 V activated and deactivated for complete checking

0.01 sec Only one test per

0.01 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative two driving cycles each with: 4 sec or 50 sec cumulative two driving cycles each with: 4 sec or 50 sec cumulative

Fuel Tank Pressure Sensor

P0450

rationality - signal oscillation

| delta pressure signal | ( = current pressure - old pressure) >

813

Pa

ambient temperature model vehicle speed >= time after canister vent valve open

> <= >

-7.5 18.75 4

C mph sec

25.5 sec

0.1 sec continuous

4 sec continuous or 50 sec

P0451

rationality - signal range check

sensor signal >= sensor signal >=

1750 -3500

Pa Pa

time after engine start time after canister vent valve open

> >

1 4

sec sec

25.5 sec

0.1 sec continuous

4 sec continuous or 50 sec

or rationality - drift check

| delta pressure signal | ( = current pressure - reference pressure at start ) >

344

Pa

Vent solenoid valve open Caniter purge flow (closed) ambient pressure fuel level fuel level fuel level Or fuel level valid for running Evap. leak detection Vehicle speed Vehicle speed Or ambient temperature model ambient temperature model time engine running

TRUE <= > < > <

0.0 68000 88.4 11.2 150

g / sec Pa % % %

TRUE > < <= >= > TRUE

0 93.75

mph mph C C sec 10 sec 0.1 sec continuous 4 sec continuous or 50 sec two driving cycles each with: 4 sec or 50 sec cumulative two driving cycles each with: 4 sec continuous or 50 sec cumulative

3 TRUE

P0452 P0453

circuit continuity - ground circuit continuity - voltage

sensor signal voltage < sensor signal voltage >

0.1514 4.702

V V

Large leak

P0455

vacuum pulldown slope

absolute value of vacuum pulldown slope < 4.5 ... 7.6 [ KLTLDSFS05 ]

fuel system status vehicle speed Pa/sec engine battery voltage battery voltage fuel tank pressure fuel tank pressure ratio: ( MAP Model / Baro ) est amb air temp est amb air temp fuel level fuel level engine start temp - amb. temp time after engine start or fuel mixture adaptation amb pressure error: mass air flow error: coolant temp error: intake air temp error: fuel tank pres error: system voltage

closed loop < idling > < > < < > < > < < > stable > not set not set not set not set not set

1.9 10.5 18.1 -2500 1300 0.81 1.5 32.25 11.4 88.1 9.75 600 68 -

mph V V Pa Pa C C % % C sec kPa -

11 sec Only one test per driving cycle completed. The test will attempt to run up to 10 times until it successfully completes a test

0.1 sec one completed test per driving cycle

4 sec continuous

Page 13 of 21

08 GRP02 LLT Engine

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Value Specifie Units Secondary Parameters error: purge valve error: vehicle speed error: canister vent valve error: purge valve flow error: accelerator pedal Fuel Level Sensor Circuit fuel level sensor 1 P0461 rationality fuel level change < and cumulative driving distance > 4.6 120.0 % km Primary fuel level Secondary fuel level Or Primary fuel level Secondary fuel level and battery voltage battery voltage engine starting electrical fuel level sensor(s) without failure OR Primary fuel level Secondary fuel level battery voltage battery voltage engine starting electrical fuel level sensor(s) without failure battery voltage battery voltage engine started battery voltage battery voltage engine started engine speed battery voltage battery voltage Enable Condition not set not set not set not set not set < <= < > >= <= TRUE TRUE Enable Value 41.1 6.2 41.1 6.2 10.5 18.1 Units % liter liter liter V V 0.1 sec continuous 4 sec continuous or 50 sec cumulative no Time Required Frequency of Checks Criteria for Code MIL Illumination

Or cumulative driving distance >=

162.0

km

>= < >= <= TRUE TRUE >= <= TRUE >= <= TRUE > > <

41.1 6.2 10.5 18.1 10.5 18 10.5 18 80 9.99 18.1

% % V V V V V V rpm V V 60 sec 0.1 sec continuous 0.1 sec continuous 4 sec cont. or 50 sec cumulative 4 sec cont. or 50 sec cumulative 4 sec continuous or 50 sec cumulative no

P0462

range check low

voltage <

0.25

P0463

range check high

voltage >

3.2

60 sec

no

Cooling fan 1 relay Control Circuit

P0480 P0691 P0692 P0481 P0693 P0694

circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage

Voltage

IC Internal

0.01 sec

0.01 sec continuous

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Cooling fan 2 relay Control Circuit

Voltage

IC Internal

Evaporative System and Leak Monitor Leaking purge valve

P0496

underpressure in tank

tank pressure loss gradient <

-60

Pa

fuel system status vehicle speed engine battery voltage battery voltage fuel tank pressure fuel tank pressure ratio: ( MAP Model / Baro ) fuel level fuel level engine start temp - amb. temp time after engine start or fuel mixture adaptation amb pressure maximum number of attempts est amb air temp est amb air temp error: mass air flow error: coolant temp error: intake air temp error: fuel tank pres error: system voltage error: purge valve error: vehicle speed error: canister vent valve error: purge valve flow error: accelerator pedal fuel system status vehicle speed engine battery voltage battery voltage fuel tank pressure fuel tank pressure ratio: ( MAP Model / Baro ) est amb air temp est amb air temp fuel level fuel level engine start temp - amb. temp time after engine start or fuel mixture adaptation amb pressure error: mass air flow error: coolant temp error: intake air temp error: fuel tank pres error: system voltage error: purge valve

closed loop < idling > < > < < > < < > stable > < > < not set not set not set not set not set not set not set not set not set not set closed loop < idling > < > < < > < > < < > stable > not set not set not set not set not set not set

1.9 10.5 18.1 -2500 1300 0.81 11.4 88.1 9.75 600 68 10 1.5 32.25 1.9 10.5 18.1 -2500 1300 0.81 1.5 32.25 11.4 88.1 9.75 600 68 -

mph V V Pa Pa % % C sec kPa C C mph V V Pa Pa C C % % C sec kPa -

about 4 sec Only one test per driving cycle completed. The test will attempt to run up to 10 times until it successfully completes a test

0.1 sec one completed test per driving cycle

4 sec continuous

two driving cycles with: 4 sec continuous or 50 sec cumulative

Stuck Closed Purge valve

P0497

vacuum pulldown slope

tank vacuum > -1.221 Pa

11 sec Only one test per driving cycle completed. The test will attempt to run up to 10 times until it successfully completes a test

0.1 sec one completed test per driving cycle

4 sec continuous

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Page 14 of 21

08 GRP02 LLT Engine

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Value Specifie Units Secondary Parameters error: vehicle speed error: canister vent valve error: purge valve flow error: accelerator pedal Idle Speed System (disabled during cold start) Enable Condition not set not set not set not set Enable Value Units Time Required Frequency of Checks Criteria for Code MIL Illumination

P0506 P0507

functional check

desired rpm - actual rpm > desired rpm - actual rpm < or fuel cut off due to overspeed > during this idle

100 -200 3

rpm rpm count

load (for underspeed only) coolant temp. intake air temp vehicle altitude factor ( sea level = 1.0 ) time after engine start evap purge (high HC conc.) cold start idle speed control intrusive evap test intrusive secondary air test (=not applicab error: throttle position error: vehicle speed error: coolant temperature error: intake air temperature error: evap system error: evap purge valve

< > > at idle > > FALSE FALSE not active not active not set not set not set not set not set not set

99.9 . . . 99.9 -11.3 -11.3 0.594 3.84

% C C factor sec

10 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Idle Speed System (enabled during cold start)

P050A

functional check

desired rpm - actual rpm > during catalyst heating on desired rpm - actual rpm < during catalyst heating on

100 -200

rpm rpm

Engine coolant start temp. vehicle altitude factor ( sea level = 1.0 ) Engine coolant start temp. catalyst heating evap purge (high HC conc.) idle speed control catalyst heating intrusive evap test error: throttle position error: vehicle speed error: coolant temperature error: intake air temperature error: evap system error: evap purge valve

> at idle > < TRUE FALSE TRUE not set not set not set not set not set not set not set

-10 . +40 0.594 80 -

C factor C -

7 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

System Voltage P0562 P0563 range check low range check high

powertrain supply relay feedback input voltage voltage

9.99 18.1

V V

time after engine start time after engine start vehicle speed

> > >

180 180 3.1

sec sec mph

2 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

no

ECM monitoring P0601 rationality wrong ROM checksum during initialization reaches ROMRSTA_UM times. 5 times checksum calculation at power down in the last driving cycle completely finished rationality P0602 P0603 rationality programming incomplete ETC monitoring controller reset wrong cyclic ROM checksum of critical regions service ECU bit set in calibration SW internal. Error from shut-down path test reaches DURNPRST_A times service ECU bit se 3 times partial checksum on critical variables power down calculation in the last driving cycle completly finished 30 sec 1 sec 5 sec TRUE 30 sec 0.01 sec at key off 0.01 sec at key on 0.01 sec at key on 0.01 sec continuous 4 sec continuous 4 sec continuous 4 sec continuous 4 sec continuous or 50 sec cumulative 4 sec continuous 4 sec continuous or 50 sec cumulative code set then 5 sec code set then 5 sec code set then 5 sec code set then 5 sec

P0604

functional check cyclic RAM-check

RAM writeability check read and write test writeability check of RAM SW internal

power down calculation in the last driving cycle power down calculation in the last driving cycle

completly finished completly finished

5 sec

0.01 sec at key off 0.01 sec continuous

code set then 5 sec code set then 5 sec

P0606

Electronic Throttle Control (ETC) checks SW internal ETC monitoring torque comparison ETC monitoring engine speed signal ETC monitoring volumetric efficiency signal ETC mon. vol. Eff., spark advance, A/D conv. grp. A, reaction crosscheck ETC monitoring throttle crosscheck ETC monitoring A/D conv group B, A/D converter supply voltage crosscheck ETC monitoring redundant pedal signal Electronic Throttle Control (ETC) checks SW internal SPI failure of throttle output stage

5 sec

SW Internal

Fuel Pump Relay Control Circuit

P0627 P0629

circuit continuity - open circuit continuity - voltage

voltage < voltage > voltage >

2.74 2.21 2.21

V V V

pump command off engine speed battery voltage battery voltage

> > <

80 9.99 18.1

rpm V V

0.1 sec

0.1 sec

50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

P0628

circuit continuity - ground

voltage <

2.21

pump command on engine speed battery voltage battery voltage

> > <

80 9.99 18.1

rpm V V

0.5 sec

Electronic Throttle Control P0638 motor control range check short term | circuit duty cycle | > ( absolute value ) 80 % battery voltage > 7 V 0.6 sec (recoverable) 0.01 sec continuous 4 sec continuous or 50 sec code set then 5 sec

Page 15 of 21

08 GRP02 LLT Engine

Component/ System Fault Code Monitor Strategy Description motor control range check long term 5V reference voltage monitoring Primary Malfunction Signal and Criteria Threshold Value Specifie Units Secondary Parameters Enable Condition Enable Value Units Time Required 5.0 sec (latched) Frequency of Checks Criteria for Code cumulative MIL Illumination

P0641 P0642 P0643 P0651 P0652 P0653 P0697 P0698 P0699

circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage circuit continuity - open circuit continuity - ground circuit continuity - voltage

Voltage

IC Internal

ignition key on ECM power relay

TRUE TRUE

3 sec

0.01 sec

4 sec continuous

code set then 5 sec

Voltage

IC Internal

Voltage

IC Internal

MIL Control Circuit

P0650

Voltage

IC Internal

engine speed battery voltage battery voltage output -

> 80 rpm > 10 V < 18.1 V activated and deactivated for complete checking -

0.01 sec

0.01 sec continuous

4 sec continuous or 50 sec cumulative 4 sec cont. or 50 sec cumulative

no (but is shown in Mode $03) code set then 5 sec

Transmission Control Module MIL Illumination Request

P0700 OBD emission fault detected by the TCM (Specific TCM DTC shown in freeze frame)

signal input

0.01 sec

0.01 sec continuous

Vehicle speed sensor Manual Transmission

P0501 P0502

rationality (high range check) rationality (low range check)

vehicle speed vehicle speed

171.9 3.1

mph mph

engine speed engine speed fuel shut off coolant temperature

> > TRUE > >

1800 3520 40 20

rpm rpm C count

2 sec 3 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative code set then 5 sec

Clutch Pedal Position Sensor Manual Transmission

P0806

rationality input cltuth pos. state changes

detected clutch pedal press count <

count - gear changes detected senso ( ratio of engine speed to presses vehicle speed -- range change ) detected Delay between shift detections vehicle speed between gear change detects V V

approx. 500 sec

0.1 sec continuous

> >

10 25.0

sec mph

4 sec continuous or 50 sec cumulative

P0807 P0808 Ignition Coil Driver Circuit Serial Communication P167D

Circuit Continuity - Ground Circuit Continuity - Voltage

Voltage < Voltage >

0.249 4.75

Internal SPI communication fault

IC Internal

battery voltage battery voltage engine speed

< > <

18.1 9 6000

v v rpm

0.01 sec

0.01 sec

4 sec

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Electronic Throttle Control P2100 P2101 circuit switch-off difference between set and actual position of throttle blade Electronic Throttle Control (ETC) checks ETC monitoring watchdog shutdown path functionality of return spring throttle blade return response 0.56 sec output circuits not deactivated as commanded difference between set and actual position of throttle blade > [ Table DWDKSBAMX ] electronic throttle adaptation battery voltage power down processing in the last driving cycle vehicle speed engine speed engine coolant temperature engine coolant temperature intake air temperature intake air temperature battery voltage accelerator pedal position not active > completly finished <= < >= <= >= <= > < 7 0 40 5.25 100.5 5.25 143.8 10.0 14.9 V mph rpm C C C C V % 0.1 sec 0.5 sec 0.01 sec at key on 0.01 sec continuous 0.01 sec at key on 0.01 sec at key on 4 sec continuous 4 sec cont. or 50 sec cumulative 4 sec continuous 4 sec continuous code set then 5 sec code set then 5 sec code set then 5 sec code set then 5 sec

4 . . . 50 % dep. on rate of change

P2105 P2119

5 sec 0.56 sec once per ignition on

Electronic Throttle Control P2176 throttle exchange detection learn fail or initial throttle learn failed or learning prohibited due to secondary parameters not met or minimum throttle position out of range range check poti1 value at lower stop throttle potentiometer 1 voltage < or throttle potentiometer 1 voltage > range check poti2 value at lower stop throttle potentiometer 2 voltage < or throttle potentiometer 2 voltage > 4.12 4.55 V V vehicle speed engine speed engine coolant temperature engine coolant temperature intake air temperature intake air temperature battery voltage accelerator pedal position <= < >= <= >= <= > < 0 40 5.25 100.5 5.25 143.8 10.0 14.9 mph rpm C C C C V % 1 sec once per ignition on 0.01 sec at key on 4 sec continuous code set then 5 sec

0.341 0.988

V V

Fuel System Lean/Rich Multiplicative Bank 1 P2177 P2178 P2179 P2180 fuel trim limits exceded range - multiplicative ( load > threshold and air flow > threshold ) delta lambda correction > or delta lambda correction < delta lambda correction > or delta lambda correction < 1.23 0.78 1.23 0.78 factor factor factor factor

Bank 2

air mass flow air mass flow engine load engine load engine speed engine speed closed loop control throttle angle engine coolant temperature

>= <= >= <= >= <= TRUE <= >

6.9 41.7 18.0 80.0 1200.0 4000.0 99.6 60

g/sec g/sec % % rpm rpm 99.6 C

approx. 300 sec from engine start ( after adaptation has

0.1 sec continuous

4 sec continuous or 50 sec cumulative After

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Page 16 of 21

08 GRP02 LLT Engine

Component/ System Fault Code Monitor Strategy Description Primary Malfunction Signal and Criteria Threshold Value Specifie Units Secondary Parameters intake air temperature primary A/F sensor 1 readiness primary A/F sensor 2 readiness command lambda catalyst heating critical misfire rate detected deceleration fuel cut-off transient compensation wide open throttle integrated fuel mass and empty-valid fuel level error: cam control diagnosis error: inection value fault error: catalyst damaging misfire Fuel System Lean/Rich additive Bank 1 P2187 P2188 P2189 P2190 range - additive low speed and low load delta fuel load correction > or delta fuel load correction < delta fuel load correction > or delta fuel load correction < 6.1 -6.0 6.1 -6.0 % % % % air mass flow air mass flow engine load engine load engine speed engine speed closed loop control engine coolant temperature intake air temperature primary A/F sensor 1 readiness primary A/F sensor 2 readiness command lambda catalyst heating critical misfire rate detected deceleration fuel cut-off transient compensation wide open throttle integrated fuel mass and empty-valid fuel level error: cam control diagnosis error: inection value fault error: catalyst damaging misfire >= <= >= <= >= <= TRUE > <= TRUE TRUE > not set not set not set not set not set > not set not set not set not set 1.7 7.8 11.0 45.0 520.0 1120.0 60 60 0.83 700.0 g/sec g/sec % % rpm rpm C C g Enable Condition <= TRUE TRUE > not set not set not set not set not set > not set not set not set not set Enable Value 60 0.83 700.0 Units C g Time Required Frequency of Checks Criteria for Code MIL Illumination

Bank 2

Oxygen Sensor sensor circuit (secondary O2) bank 1 sensor 2 bank 2 sensor 2

P2232 P2235

sensor line short circuit to heater output line

secondary O2 sensor voltage gradient > within time after heater turn off < for occurrences > out of heater turn offs

2 0.04 4 6

V sec count count

secondary O2 heating stable and secondary O2 dew point end for time engine running battery voltage mod. exhaust-gas temp. time after dew point exceeded

TRUE TRUE > TRUE > < > TRUE > ready > active FALSE > < > > FALSE FALSE FALSE FALSE running TRUE TRUE > ready > active FALSE > < > > FALSE FALSE FALSE FALSE running TRUE TRUE TRUE

90 10.4 800 10 10.4 10 5.56 33.33 3 9.72

sec V C sec V sec g/sec g/sec sec g/sec

10 sec

0.01 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

Oxygen Sensor sensor response (secondary O2) bank 1 sensor 2 bank 2 sensor 2

P2270 P2272

oscillation check low

secondary O2 sensor voltage < for time > then ramping in enrichment by at gradient for time (after enrichment limit reached)

0.582 . . . 0.661 100 0.2 0.017 10

engine running battery voltage secondary O2 sensor for time secondary O2 closed loop control lambda DFCO / sec engine air flow (intrusive test) sec and engine air flow for time engine air flow (passive monitor) sec. O2 trim - fast lean correction sec. O2 trim - fast rich correction sec. O2 trim - slow correction sec. O2 aging DFCO test failed engine scheduled by System Manager V sec engine running battery voltage secondary O2 sensor lambda for time / sec secondary O2 closed loop control sec DFCO engine air flow (intrusive test) and engine air flow for time engine air flow (passive monitor) sec. O2 trim - fast lean correction sec. O2 trim - fast rich correction sec. O2 trim - slow correction sec. O2 aging DFCO test failed engine scheduled by System Manager engine start successful during previous dr real time clock active V sec

approx. 600 sec additional time if fuel level is low and not failed 600 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative

bank 1 sensor 2 bank 2 sensor 2

P2271 P2273

oscillation check high

secondary O2 sensor voltage > for time > then ramping in enleanment by at gradient for time (after enleanment limit reached)

0.582 . . . 0.661 100 0.07 0.017 10

10.4 10

V sec

5.56 33.33 3 9.72

g/sec g/sec sec g/sec

Real time clock Engine Off Timer Status ( performed during engine off operation )

P2610

engine off timer signal check

engine off timer not valid

3.0

0.1 sec

0.1 sec continuous

4 sec continuous or 50 sec cumulative

two driving cycles each with: 4 sec continuous or 50 sec cumulative two driving

Real time clock Engine Off Timer Rationality

P2610

engine off timer incremental

reference clock time delta -

counts engine start successful

TRUE

0.1 sec

0.1 sec

4 sec

Page 17 of 21

08 GRP02 LLT Engine

Component/ System ( performed during engine running operation ) ( reference clock = independantly captured time value ) OBD ISO-15765 Communication Bus U0073 ISO-15765 Bus Error Invalid Message Received or Dual Port Ram Hardware Error; or No Communication / Bus Off CAN Bus consisting of: ignition on for battery voltage battery voltage normal bus communication message missing, delayed, or invalid content Automatic Transmission CAN Bus consisting of: ignition on for battery voltage battery voltage normal bus communication initialized and ready > > < running equipped initialized and ready > > < running 1 sec 0.01 sec 0.02 sec 0.01 sec continuous 4 sec continuous or 50 sec cumulative code set then 5 sec Fault Code check Monitor Strategy Description Primary Malfunction Signal and Criteria engine off timer delta > Threshold Value Specifie Units failure counts Secondary Parameters Enable Condition >= Enable Value 3 Units 3 Time Required Frequency of Checks continuous Criteria for Code continuous or 50 sec cumulative MIL Illumination cycles each with: 4 sec continuous or 50 sec cumulative

reference clock time delta engine off timer delta <

counts engine start successful failure counts

TRUE >=

counts

3 9.9 18.1 3 9.9 18.1 -

sec V V sec V V -

U0101

Communication with TCM

TCM Message Timeout

2.5 sec

0.01 sec continuous

4 sec continuous or 50 sec cumulative

code set then 5 sec

Page 18 of 21

08 GRP02 LLT Engine

LOOK-UP TABLES (COMMON)

P0011, P0021 (internal manufacturer cross reference) KFDWNWDMXE / 2 Maximum Allowed Deviation - Intake Camshaft Position degrees crank Modeled Engine Oil Temperature ( C ) 0 60 80 Engine Speed (rpm) 6.00 6.00 7.00 800 6.00 6.00 6.00 1200 6.00 6.00 6.00 1600 6.00 6.00 6.00 2000 6.00 6.00 6.00 2500 6.00 6.00 6.00 4000

100 9.00 6.00 6.00 6.00 6.00 6.00

130 11.00 7.00 7.00 6.00 6.00 6.00

P0116

(internal manufacturer cross reference) KLTCWCSTAB Engine coolant temperature model based on ambient temperature + engine off timer output Time (seconds) Coefficient: 1000 0.996 7200 0.488 10800 0.270 14400 0.191 21600 0.106 32400 0.063 43200 0.031 50400 0.008

P0141, P0161