Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Daily JSA

Caricato da

umn_mlkDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Daily JSA

Caricato da

umn_mlkCopyright:

Formati disponibili

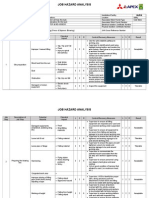

ALASCO

EASTERN DISTRIBUTION DEPARTMENT SAFETY MANAGEMENT SYSTEM JOB SAFETY ANALYSIS (JSA) RECORD SHEET JOB SAFETY ANALYSIS RECORD SHEET PLANT/EQUIPMENT: Sump Pit # 1 near control room DESCRIPTION OF JOB/TASK: Electrical works PREPARED By: Akif Ansari REFERENCES: GI 2.100 Workpermit System Badge # 8856247 REVIEWED BY: APPROVED BY: DEPARTMENT : ERDD DIVISION : ED/OEU/TRBP DATE: JSA NO:

SAFETY EQUIPMENT REQUIRED: Receviver, work crew is required to wear PPE, including: 1 Safety Helmet 2 Safety Glass 3 FRC Coverall 4 Hand gloves 5 Safety Shoes STEP # 1 SEQUENCE OF BASIC JOB STEPS Receiving work permit prior to start of work POTENTIAL HAZARDS * Unauthorized work * Invalid permit REQUIRED HAZARD CONTROLS * Obtain hot work permit before start of work * Responsible person will conduct inspection and ensure safety standards and procedures are followed * Boom truck should have a valid inspection sticker from SA or an SA approved third party. * Details of work shall be communicated to the affected personnel in the area. * SA certified operator shall inspect slings, fittings, and shackles prior to use. De-energize/isolate all service lines in accordance with Isolation, Lock out and use of hold tags. Action By Issuer & Receiver

Preperatory Operations

* Mishap * Personal injury

Issuer & Receiver

Excavation up to required depth 1.20 mtr

Energized underground/ electricity, water, gas, telephone

Issuer & Receiver

Excavation up to required depth 1.20 mtr

lines, sewer and other service lines Electrocution, fire, explosion, and toxic gas release. Soil heap located less than 2ft from edge. Failed to perform gas test. Side wall collapse.

Comply with G.I. 6.012 Use hand digging if found underground utilities Keep soil materials at least 0.6m (2 ft) from the edge of all sides Conduct gas test for excavation/trench. Daily inspections must be done by site forman/ competent person Competent Contractor supervisor assigned Water runoff diversions Provide benching method to protect the walls from cave in/collapse Electricity Safety section. Forman make sure workers are doing safe operat Check and follow the instruction given in manual. Asses the load and assign the workers Conduct tool talk meeting for proper manual lifting. When using spanners, use appropriate torque Electrical contact grease should be used in joints. Check for loose connections Issuer & Receiver

Installation of new electric devices, lighting and cabling to new junction boxes and panels and pumps.

*Wrong working technique *Improper manual lifting *Falling objects *Torque Control *Not Check in Connections *improper Insulation *Not Check Wire Harnesses *Check for Moisture *Check for Corrosion

Potrebbero piacerti anche

- Eurocargo Tector 6-26t Electronic System PDFDocumento192 pagineEurocargo Tector 6-26t Electronic System PDFRogério Moreno80% (15)

- SOX With ISO 27001 & 27002 Mapping AuditsDocumento18 pagineSOX With ISO 27001 & 27002 Mapping Auditshumdil0% (1)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Documento3 pagineKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNessuna valutazione finora

- 10 - Cherry Picker Inspection ChecklistDocumento1 pagina10 - Cherry Picker Inspection Checklistsanjeev kumar100% (1)

- Tbam: Dikkowita Fisheries HarbourDocumento8 pagineTbam: Dikkowita Fisheries HarbourkskahatadeniyaNessuna valutazione finora

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocumento2 pagineProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- JSA - Installation of U G PipingDocumento11 pagineJSA - Installation of U G PipingOws Anish100% (1)

- Ehs PR 03.f01 Patos FormDocumento2 pagineEhs PR 03.f01 Patos FormClyde Villanueva100% (4)

- Painting Job Hazard AnalysisDocumento2 paginePainting Job Hazard Analysisisaacjoe77Nessuna valutazione finora

- Specifying Multiple Account AssignmentDocumento8 pagineSpecifying Multiple Account AssignmentGopalakrishnan KuppuswamyNessuna valutazione finora

- Auditing Test Bank Chapter 15Documento34 pagineAuditing Test Bank Chapter 15Heejin Kwon100% (10)

- Is.3025.14.1984 - ISO 7888 PDFDocumento13 pagineIs.3025.14.1984 - ISO 7888 PDFRoyal BimhahNessuna valutazione finora

- JSA For Erection Modification QSTECDocumento7 pagineJSA For Erection Modification QSTECMohamed NouzerNessuna valutazione finora

- Gi-0006 011Documento2 pagineGi-0006 011malika_00Nessuna valutazione finora

- TBT-Driving in FogDocumento2 pagineTBT-Driving in FogImran KhanNessuna valutazione finora

- 07 - JSA Compaction and BackfillingDocumento4 pagine07 - JSA Compaction and Backfillingsatti100% (2)

- JSA Excavation PDFDocumento6 pagineJSA Excavation PDFmohamedamine.zemouriNessuna valutazione finora

- Job Safety Analysis WorksheetDocumento7 pagineJob Safety Analysis WorksheetMohamedSaidNessuna valutazione finora

- Building De-Dusting JSADocumento3 pagineBuilding De-Dusting JSAJayesh J PillaiNessuna valutazione finora

- Rigging JSA RiggerDocumento12 pagineRigging JSA RiggeraQiLGunawanNessuna valutazione finora

- Crane Hoist Sling Safety ProgramDocumento14 pagineCrane Hoist Sling Safety Programomar sadiqNessuna valutazione finora

- 9 Use of Hand Roller Compactor SafetyDocumento2 pagine9 Use of Hand Roller Compactor SafetyarchieNessuna valutazione finora

- Scaffold CampaignDocumento9 pagineScaffold CampaignAdel SukerNessuna valutazione finora

- Tool Box Talk - MK - Emergency Response ProceduresDocumento2 pagineTool Box Talk - MK - Emergency Response ProceduresPaul McGahanNessuna valutazione finora

- Brazing RiskDocumento2 pagineBrazing Riskanon_12627423Nessuna valutazione finora

- HLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistDocumento1 paginaHLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistLemuel Petronio100% (3)

- Refractory Risk AssessmentDocumento2 pagineRefractory Risk AssessmentSehrish JabeenNessuna valutazione finora

- JSA Formet New Structural Steel FabricationDocumento7 pagineJSA Formet New Structural Steel Fabricationsakthi venkatNessuna valutazione finora

- Diesel RefuelingDocumento3 pagineDiesel RefuelingAMINNessuna valutazione finora

- JHA M&F ToiletDocumento3 pagineJHA M&F ToiletBala Subra ManiamNessuna valutazione finora

- MSDS - Asada Threading Oiil Red - ENDocumento7 pagineMSDS - Asada Threading Oiil Red - ENnghiaNessuna valutazione finora

- Form N - OHS Practitioner Resume Template-V3.0 EnglishDocumento5 pagineForm N - OHS Practitioner Resume Template-V3.0 EnglishfaizalpsNessuna valutazione finora

- Job Safety & Environment Analysis: Revision NoDocumento3 pagineJob Safety & Environment Analysis: Revision NonishanthNessuna valutazione finora

- Job Safety Analysis: Potential Risk FactorsDocumento1 paginaJob Safety Analysis: Potential Risk FactorsFrancis VinojNessuna valutazione finora

- Subject: Work at Height: Unit: Maihar Cement WorksDocumento3 pagineSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- JOB SAFETY PLAN Replacement of CylinderDocumento2 pagineJOB SAFETY PLAN Replacement of CylinderMaxi ProNessuna valutazione finora

- JS A Excavation Work For Electrical CableDocumento3 pagineJS A Excavation Work For Electrical CableMohammed MinhajNessuna valutazione finora

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Documento4 pagineThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNessuna valutazione finora

- Job Safety Analysis - Clinker StorageDocumento4 pagineJob Safety Analysis - Clinker StorageMohammed MinhajNessuna valutazione finora

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocumento1 paginaJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNessuna valutazione finora

- Safe Work Procedures For Confined SpaceDocumento3 pagineSafe Work Procedures For Confined SpaceHtin Lin Aung100% (2)

- Lifting Hoisting Hazard HuntDocumento1 paginaLifting Hoisting Hazard Hunt曹庆园100% (1)

- JSA For Piping-Hydro TestDocumento10 pagineJSA For Piping-Hydro TestMuthu AlaguRajNessuna valutazione finora

- Hot Work Activities (Cutting)Documento9 pagineHot Work Activities (Cutting)Al Mughsar CompanyNessuna valutazione finora

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocumento2 pagineRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Alexander County: What To Do in Case of An On-The-Job InjuryDocumento12 pagineAlexander County: What To Do in Case of An On-The-Job InjuryAli JalilNessuna valutazione finora

- TBT Attendance Format - NRP WorkersDocumento2 pagineTBT Attendance Format - NRP WorkersIsrael Raja AbhilashNessuna valutazione finora

- Ra02 - Container OffloadingDocumento3 pagineRa02 - Container OffloadingSamNessuna valutazione finora

- 1-Coveralls, 2-Gloves, 3-Safety Boots, 4-Safety Hard Hat 5-Safety Glasses, 6-Full Body Safety Harness & 7-Derrickman's BeltDocumento3 pagine1-Coveralls, 2-Gloves, 3-Safety Boots, 4-Safety Hard Hat 5-Safety Glasses, 6-Full Body Safety Harness & 7-Derrickman's BeltkhurramNessuna valutazione finora

- Copy of JSA For Cathodic Protection For Oily Water LineDocumento6 pagineCopy of JSA For Cathodic Protection For Oily Water LineMohammed Minhaj80% (5)

- Jsa Loading and Unloading of Pile PipesDocumento4 pagineJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- Wire Rope Cutting ChartDocumento8 pagineWire Rope Cutting ChartAkash SharmaNessuna valutazione finora

- JHA Blowing PressDocumento5 pagineJHA Blowing PressLuqman OsmanNessuna valutazione finora

- 14.lifting Operations & Lifting EquipmentDocumento28 pagine14.lifting Operations & Lifting EquipmentbabadapbadapNessuna valutazione finora

- Monthly Store Inspection ReportDocumento1 paginaMonthly Store Inspection ReportgkNessuna valutazione finora

- Jsa For The Installation of I EamDocumento5 pagineJsa For The Installation of I EamMohammed MinhajNessuna valutazione finora

- PVCMS-BMV-HSE-JSA-001 InsulationDocumento6 paginePVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNessuna valutazione finora

- JHA Lifting-Moving Heavy ObjectsDocumento6 pagineJHA Lifting-Moving Heavy ObjectsMiguel AugustoNessuna valutazione finora

- Grating Control ProcedureDocumento25 pagineGrating Control ProcedureMuneeb Rehman100% (1)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocumento2 pagineJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNessuna valutazione finora

- Safety Signs On Construction SiteDocumento1 paginaSafety Signs On Construction SiteBëBå Wossen AssefaNessuna valutazione finora

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocumento2 pagineJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiNessuna valutazione finora

- Safe Work Procedure A Complete Guide - 2020 EditionDa EverandSafe Work Procedure A Complete Guide - 2020 EditionNessuna valutazione finora

- Ac 0071Documento4 pagineAc 0071umn_mlkNessuna valutazione finora

- Concrete PrimerDocumento2 pagineConcrete Primerumn_mlkNessuna valutazione finora

- Amercoat 383HDocumento4 pagineAmercoat 383Humn_mlkNessuna valutazione finora

- PolyflameDocumento2 paginePolyflameumn_mlkNessuna valutazione finora

- TDS Renderoc TG Saudi ArabiaDocumento4 pagineTDS Renderoc TG Saudi Arabiaumn_mlkNessuna valutazione finora

- Compliance Sheet-Foundation Waterproofing MFGCDocumento2 pagineCompliance Sheet-Foundation Waterproofing MFGCumn_mlkNessuna valutazione finora

- Via 200Documento2 pagineVia 200umn_mlkNessuna valutazione finora

- SR# Duties & ResponsibilitiesDocumento7 pagineSR# Duties & Responsibilitiesumn_mlkNessuna valutazione finora

- Utilities Department Facilities Major Project Group: Connect CPS and CRAC Units To EPO & BMS in ECC, DhahranDocumento1 paginaUtilities Department Facilities Major Project Group: Connect CPS and CRAC Units To EPO & BMS in ECC, Dhahranumn_mlkNessuna valutazione finora

- EXPERIENCE CERTIFICATE-AkifDocumento1 paginaEXPERIENCE CERTIFICATE-Akifumn_mlkNessuna valutazione finora

- Weekly Internal Report 05augDocumento3 pagineWeekly Internal Report 05augumn_mlkNessuna valutazione finora

- Revised Leave Application Form 2017EDocumento1 paginaRevised Leave Application Form 2017Eumn_mlkNessuna valutazione finora

- U&TSD in House Safety Training Program-January 2017Documento3 pagineU&TSD in House Safety Training Program-January 2017umn_mlkNessuna valutazione finora

- Operations ResponsibilitiesDocumento1 paginaOperations Responsibilitiesumn_mlkNessuna valutazione finora

- Inquiry Report at Construction SiteDocumento2 pagineInquiry Report at Construction Siteumn_mlkNessuna valutazione finora

- Comparison VISA vs. Maxlite Wall MountedDocumento2 pagineComparison VISA vs. Maxlite Wall Mountedumn_mlkNessuna valutazione finora

- Voyager DVD ManualDocumento80 pagineVoyager DVD ManualGianniNessuna valutazione finora

- Syvecs Software Basic ManualDocumento33 pagineSyvecs Software Basic ManualRyan GriffithsNessuna valutazione finora

- Marketing Mix Kuat HarimauDocumento11 pagineMarketing Mix Kuat HarimauFakhriHamzah100% (1)

- US LCI Database Projct User's GuideDocumento21 pagineUS LCI Database Projct User's GuideAbbyNessuna valutazione finora

- Xanthan Gum E415Documento4 pagineXanthan Gum E415sharemwNessuna valutazione finora

- Transparent BridgingDocumento6 pagineTransparent BridgingDimas PrajokoNessuna valutazione finora

- NVM Express SCSI Translation Reference 1 1 GoldDocumento55 pagineNVM Express SCSI Translation Reference 1 1 Goldkr0465Nessuna valutazione finora

- MTU Setting For Internet Speed BostDocumento4 pagineMTU Setting For Internet Speed BostDennis HerreraNessuna valutazione finora

- Ashish Dembla PDFDocumento2 pagineAshish Dembla PDFAnurag PrabhakarNessuna valutazione finora

- OTTP-S ISO20243 STD v1.1 enDocumento44 pagineOTTP-S ISO20243 STD v1.1 enTiffany Tzeng100% (1)

- Baskar-Barsched 8666Documento33 pagineBaskar-Barsched 8666Ganesh Kumar GuptaNessuna valutazione finora

- D187 PDFDocumento4 pagineD187 PDFJuan Diego ArizabalNessuna valutazione finora

- Programming Dynamic ALV in WebDynpro For ABAPDocumento6 pagineProgramming Dynamic ALV in WebDynpro For ABAPAdriano OliveiraNessuna valutazione finora

- TAUS Evaluating Post-Editor Performance Guidelines 2014Documento5 pagineTAUS Evaluating Post-Editor Performance Guidelines 2014TAUSNessuna valutazione finora

- Curriculum Vitae: Career ObjectiveDocumento4 pagineCurriculum Vitae: Career ObjectivePrashant KumarNessuna valutazione finora

- Electrical Email Method of Exchanging MessagesDocumento2 pagineElectrical Email Method of Exchanging MessagesVick54GraversenNessuna valutazione finora

- BECHEM High Performance Chain Oils 2015 GBDocumento7 pagineBECHEM High Performance Chain Oils 2015 GBduy tanNessuna valutazione finora

- Installation Guide For 20/20: Profile Ridge, Rollridge, Roll Hip, Profile Mono Ridge and 20/20 Verge InstallationDocumento6 pagineInstallation Guide For 20/20: Profile Ridge, Rollridge, Roll Hip, Profile Mono Ridge and 20/20 Verge Installationslindelft-cool7056Nessuna valutazione finora

- SPECS Tideflex Check Valves 0806Documento9 pagineSPECS Tideflex Check Valves 0806cwiejkowska0% (1)

- How To Balance Traffic Between 900Documento3 pagineHow To Balance Traffic Between 900saeedtarkianNessuna valutazione finora

- ISO 9863 1 2005 en PreviewDocumento7 pagineISO 9863 1 2005 en PreviewKhushwant BansalNessuna valutazione finora

- How To Configure Samba As A Primary Domain ControllerDocumento150 pagineHow To Configure Samba As A Primary Domain ControllerJoemon JoseNessuna valutazione finora

- AudioCodes 400HD IP Phones PDFDocumento2 pagineAudioCodes 400HD IP Phones PDFalsvrjNessuna valutazione finora

- RS - Auto Renewal of Bundle & Minute - Packs v6Documento13 pagineRS - Auto Renewal of Bundle & Minute - Packs v6Bristy Rany DusNessuna valutazione finora

- Mpeg-Introuduction: MPEG Video Compression Seminar Report 01Documento33 pagineMpeg-Introuduction: MPEG Video Compression Seminar Report 01Santhiraj David JohnNessuna valutazione finora