Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Candle Powered Engine

Caricato da

Jim0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

3K visualizzazioni2 pagineBuild a model engine that runs on the power of a candle. This is not a Stirling engine, but it is just as interesting a concept.

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoBuild a model engine that runs on the power of a candle. This is not a Stirling engine, but it is just as interesting a concept.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

3K visualizzazioni2 pagineCandle Powered Engine

Caricato da

JimBuild a model engine that runs on the power of a candle. This is not a Stirling engine, but it is just as interesting a concept.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

THAT'S right!

The flame of a common

candle is the sole source of power—no

boiler, no displacement chamber, no ex-

plosion within the cylinder itself. Fig. 1

shows how it works. You will see right

away that it is essentially a model of the

heavy-duty, horizontal-type gasoline en-

gine, except for the hinged valve mounted

on the cylinder head. This trap-door affair

fits tightly over an opening in the cylinder

when closed, and is actuated by a cam on

the crankshaft. The lighted candle is set

with its flame adjacent to the opening. As

the piston moves in one direction, the valve

opens and the flame is sucked into the cyl-

inder. At the end of the stroke the valve

closes. The moment the flame is cut off a

vacuum is produced in the cylinder, and

the piston is drawn inward on a power

stroke. When the piston reverses its di-

rection, the cycle is repeated.

Fig. 2 details the base which is simply a

matter of bending, filing and soldering

sheet metal. The cylinder, Fig. 3, is a more

fussy job. A 1-in. pipe nipple and cap form

the body. The inside surface of the pipe

must be machined smooth and bored to a

diameter uniform throughout the length.

Later the piston is turned to fit the bore di-

ameter. The contact surfaces of the valve

mechanism should be surface ground and

then finished up on a surface plate. Soot

which accumulates on the meeting sur-

faces tends to seal the valve. As you will

see from Fig. 3 the pipe-cap cylinder head

requires just a simple shoulder cut in the

lathe and then some careful hand filing.

Fig. 4 shows the crankshaft, flywheels

connecting rod is filed from a piece of

5/16 by 5/16-in. aluminum or duralumin.

The same applies to the push rod. The cam

follower strip is spring steel from an old

clock or phonograph. The tension of the

spring must be determined by experiment.

and miscellaneous parts that finish up the It should be sufficient to close the valve

assembly. The crankpin is pressed into the quickly when the engine is running at full

crank throws, making the crankshaft and speed. The cylinder is lubricated by coat-

connecting rod a unit assembly. The fly- ing the piston with white vaseline each

wheels can be cast of gray iron, brass, or time it is taken out to clean the cylinder.

type metal. The cam must be mounted on If the engine is operated considerably, the

the shaft with its center line at 90 degrees cylinder must be cleaned frequently. When

to the center line of the crank. The piston soot accumulation reaches a certain stage

is made from a piece of aluminum rod ap- it will interfere with efficient operation.

proximately 1 in. in diameter. The ring Note in Fig. 2 that there are no caps over

slot is wound with asbestos cord coated the main bearings. This is done purposely

with graphite. Spacing sleeves center the so that the whole crank assembly can be

connecting-rod end on the piston pin. The removed easily for cleaning.

Potrebbero piacerti anche

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideDa EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNessuna valutazione finora

- Air Cooled Hot Air EngineDocumento6 pagineAir Cooled Hot Air EngineJim50% (2)

- Hot AirEngine PDFDocumento9 pagineHot AirEngine PDFHenry PannellNessuna valutazione finora

- Suitcase PowercycleV2Documento13 pagineSuitcase PowercycleV2Jim67% (3)

- PowerCycle With SideCarDocumento7 paginePowerCycle With SideCarJim100% (2)

- Fee Jee PMFM47Documento7 pagineFee Jee PMFM47Jim100% (3)

- Mini-Skat 6-Wheel Plans AssemblyDocumento40 pagineMini-Skat 6-Wheel Plans AssemblyВладимир Батманов100% (3)

- Six Wheeled ATV by Mechanix IllustratedDocumento7 pagineSix Wheeled ATV by Mechanix IllustratedJim100% (6)

- Homebuilt Wood CarDocumento26 pagineHomebuilt Wood Carsjdarkman1930100% (3)

- Free Electric Power WindmillDocumento3 pagineFree Electric Power WindmillJim100% (4)

- 1901 TruckDocumento10 pagine1901 TruckGary B. Watts100% (3)

- Lathe Cross-Sli Olders.: " DuplexDocumento3 pagineLathe Cross-Sli Olders.: " Duplexjohnboy183100% (1)

- Wartime ScooterDocumento7 pagineWartime ScooterJim100% (5)

- Pudgy A 12 Foot Canvas Runabout Boat PlansDocumento5 paginePudgy A 12 Foot Canvas Runabout Boat PlansJim100% (5)

- Tote All ScooterDocumento7 pagineTote All ScooterJimNessuna valutazione finora

- Bicycle MinibikeDocumento6 pagineBicycle MinibikeJim100% (1)

- Wren Minibike PlansDocumento7 pagineWren Minibike PlansJim100% (5)

- 42SWP22 Lawn SweeperDocumento12 pagine42SWP22 Lawn SweeperPurpleRyderNessuna valutazione finora

- Micro TransportationDocumento6 pagineMicro TransportationJim100% (3)

- Relive the romance of early automobiles with a half-size 1901 Packard replicaDocumento8 pagineRelive the romance of early automobiles with a half-size 1901 Packard replicaDillon Hartsyker100% (1)

- Vintage Power Tool Plans 1950sDocumento180 pagineVintage Power Tool Plans 1950sPierre799es100% (5)

- Water Motor: Figure 105 Is A Perspective View of ADocumento4 pagineWater Motor: Figure 105 Is A Perspective View of AHenry Pannell100% (1)

- SMFeb 56 Roamabout Part 1Documento17 pagineSMFeb 56 Roamabout Part 1Jim86% (7)

- Mite Cycle by Mechanix IllustratedDocumento7 pagineMite Cycle by Mechanix IllustratedJim100% (3)

- Building One Lung KartsDocumento7 pagineBuilding One Lung KartsJim100% (5)

- Diamond Tool Holder for Mini LatheDocumento12 pagineDiamond Tool Holder for Mini Latheian_newNessuna valutazione finora

- Wooden Scooter and PopcycleDocumento6 pagineWooden Scooter and PopcycleJim75% (4)

- YardHorse ScooterDocumento9 pagineYardHorse ScooterJim100% (5)

- 3 in Shaper PDFDocumento5 pagine3 in Shaper PDFRob NairNessuna valutazione finora

- Suburban Runabout Three Wheel ScooterDocumento14 pagineSuburban Runabout Three Wheel ScooterJim100% (8)

- Clayton Steam Truck-Ocr PDFDocumento76 pagineClayton Steam Truck-Ocr PDFbackyardcnc100% (1)

- Lewis MillDocumento9 pagineLewis MillCelso Ari Schlichting100% (2)

- Mini Dozer Info 1979Documento6 pagineMini Dozer Info 1979Jim100% (3)

- The Boy Mechanic Book 3Documento488 pagineThe Boy Mechanic Book 3liketoreadNessuna valutazione finora

- 3 Wheel Dune BuggyDocumento5 pagine3 Wheel Dune BuggyyukitadaNessuna valutazione finora

- KW Dirt MasterDocumento5 pagineKW Dirt MastertaxmacNessuna valutazione finora

- Midgettractor PSMar 54Documento7 pagineMidgettractor PSMar 54JimNessuna valutazione finora

- Yard-Dozer MidgetDocumento5 pagineYard-Dozer MidgetOlin Stej80% (5)

- Super Scooter by Mechanix IllustratedDocumento12 pagineSuper Scooter by Mechanix IllustratedJim100% (3)

- Something New in Model Boat Building - How to Make Out-of-the Ordinary Model Boats with Simple Tools and MaterialsDa EverandSomething New in Model Boat Building - How to Make Out-of-the Ordinary Model Boats with Simple Tools and MaterialsNessuna valutazione finora

- Simple Boat-Building - Rowing Flattie, V-Bottom Sailing Dinghy, Moulded Pram, Hull for OutboardDa EverandSimple Boat-Building - Rowing Flattie, V-Bottom Sailing Dinghy, Moulded Pram, Hull for OutboardNessuna valutazione finora

- A Model Boat Builder's Guide to Rigging - A Collection of Historical Articles on the Construction of Model Ship RiggingDa EverandA Model Boat Builder's Guide to Rigging - A Collection of Historical Articles on the Construction of Model Ship RiggingNessuna valutazione finora

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheDa EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheValutazione: 4.5 su 5 stelle4.5/5 (2)

- Ready the Cannons!: Build Wiffle Ball Launchers, Beverage Bottle Bazookas, Hydro Swivel Guns, and Other Artisanal ArtilleryDa EverandReady the Cannons!: Build Wiffle Ball Launchers, Beverage Bottle Bazookas, Hydro Swivel Guns, and Other Artisanal ArtilleryValutazione: 3 su 5 stelle3/5 (2)

- Fueless Space EngineDocumento6 pagineFueless Space Enginecvele77100% (1)

- Projects For The Unimat Part 2Documento95 pagineProjects For The Unimat Part 26KILLER100% (2)

- Bayero University Kano Automotive Engineering AssignmentDocumento6 pagineBayero University Kano Automotive Engineering Assignmentmuhyideen6abdulganiyNessuna valutazione finora

- Model Elbow EngineDocumento5 pagineModel Elbow EngineJim100% (3)

- TM 5-1100 Roller Road, Gasoline Driven, 3-Wheel, 10-Ton, Galion, Model ChiefDocumento245 pagineTM 5-1100 Roller Road, Gasoline Driven, 3-Wheel, 10-Ton, Galion, Model ChiefddlevyNessuna valutazione finora

- Engine Construction: Cylinder Block, Piston, Crankshaft & MoreDocumento55 pagineEngine Construction: Cylinder Block, Piston, Crankshaft & MoreArindom NagNessuna valutazione finora

- Bull Frog Go KartDocumento15 pagineBull Frog Go KartJim100% (3)

- Homemade ATVDocumento67 pagineHomemade ATVJim100% (7)

- Electric Scooter PlansDocumento6 pagineElectric Scooter PlansJim88% (8)

- Magnetic Current PamphletDocumento9 pagineMagnetic Current PamphletJim100% (2)

- Breeze Baby Sailboat PlansDocumento5 pagineBreeze Baby Sailboat PlansJim100% (5)

- Mineral Vegetable and Animal LifeDocumento4 pagineMineral Vegetable and Animal LifeJim86% (7)

- Free Electric Power WindmillDocumento3 pagineFree Electric Power WindmillJim100% (4)

- Polliwog Sailboat PlansDocumento6 paginePolliwog Sailboat PlansJim100% (4)

- Star Lite SailboatDocumento13 pagineStar Lite SailboatJim100% (8)

- Dorothy 24 Foot Sailing CruiserDocumento11 pagineDorothy 24 Foot Sailing CruiserJim92% (12)

- Model Hot Air EngineDocumento4 pagineModel Hot Air EngineJim100% (4)

- Listening LoopsDocumento2 pagineListening LoopsJim75% (4)

- Magnetic BaseDocumento3 pagineMagnetic BaseJim100% (2)

- Foxhole RadioDocumento2 pagineFoxhole RadioJim89% (9)

- Radio SimplifiedDocumento94 pagineRadio SimplifiedJim100% (3)

- War Toys For BoysDocumento48 pagineWar Toys For BoysJim100% (2)

- Super Scooter by Mechanix IllustratedDocumento12 pagineSuper Scooter by Mechanix IllustratedJim100% (3)

- Flashlight RadioDocumento5 pagineFlashlight RadioJim67% (3)

- Vintage Transistor RadioDocumento4 pagineVintage Transistor RadioJim100% (1)

- A Crystal Set For The Boy BuilderDocumento3 pagineA Crystal Set For The Boy BuilderJim100% (4)

- The Boy's Book of Crystal SetsDocumento36 pagineThe Boy's Book of Crystal SetsJim100% (9)

- Vintage Transistor RadioDocumento4 pagineVintage Transistor RadioJim100% (1)

- Space Age Crystal SetDocumento3 pagineSpace Age Crystal SetJim100% (3)

- O Livro de Ouro Dos Experimentos Químicos (RARIDADE)Documento114 pagineO Livro de Ouro Dos Experimentos Químicos (RARIDADE)Davidson De Oliveira Lima100% (1)

- Wren Minibike PlansDocumento7 pagineWren Minibike PlansJim100% (5)

- Crystal Radio LampDocumento4 pagineCrystal Radio LampJim100% (2)

- Build A Scintillometer Uranium Detector For ProspectingDocumento11 pagineBuild A Scintillometer Uranium Detector For ProspectingJim80% (5)

- Receive Short W A V E Onyour HomeradioDocumento5 pagineReceive Short W A V E Onyour HomeradioJim100% (9)

- Shrinkage DefectsDocumento11 pagineShrinkage DefectsMohsin Abbas100% (1)

- ASTM A1011 NovaDocumento9 pagineASTM A1011 NovaAlonso BrocheroNessuna valutazione finora

- Metallic Coated MC Structural S Zincform G250 Steel G250S SteelDocumento2 pagineMetallic Coated MC Structural S Zincform G250 Steel G250S SteelIndu SoodNessuna valutazione finora

- Champion Dual Disc Wafer Check ValvesDocumento8 pagineChampion Dual Disc Wafer Check ValvesShanghai koko ValvesNessuna valutazione finora

- Dye Pentrant Test ProcedureDocumento6 pagineDye Pentrant Test ProcedurePer DCNessuna valutazione finora

- ASTM A131 Steel grade EH36 mechanical propertiesDocumento1 paginaASTM A131 Steel grade EH36 mechanical propertiesI-SignNessuna valutazione finora

- Ji MMMMMMMMMMDocumento6 pagineJi MMMMMMMMMMGeorgian GradeaNessuna valutazione finora

- Resistance Seam WeldingDocumento7 pagineResistance Seam WeldingaashulhedaNessuna valutazione finora

- 1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceDocumento12 pagine1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceYusuf Shano100% (1)

- 612 B Fig702 Flanged y Type Strainer UlDocumento2 pagine612 B Fig702 Flanged y Type Strainer UlPradipta DwiNessuna valutazione finora

- Classifications of Magnetic MaterialsDocumento3 pagineClassifications of Magnetic MaterialsNasha Agarwal100% (1)

- 10 DIY Kettle BellDocumento7 pagine10 DIY Kettle BellcagedraptorNessuna valutazione finora

- Ecoreco E-Waste Recovery-By Mr. T R Rao 2Documento10 pagineEcoreco E-Waste Recovery-By Mr. T R Rao 2bksoni100% (1)

- CSBB Fabrication & Installation of PipingDocumento26 pagineCSBB Fabrication & Installation of PipingLương TrườngNessuna valutazione finora

- Naamm Stair Manual FinalDocumento126 pagineNaamm Stair Manual FinalChrisYapNessuna valutazione finora

- Arc Welding Electrodes (Product Catalogue)Documento28 pagineArc Welding Electrodes (Product Catalogue)ddprt123Nessuna valutazione finora

- A Study of Low Young's Modulus Ti-Nb-Zr Alloys Using D ElectronsDocumento4 pagineA Study of Low Young's Modulus Ti-Nb-Zr Alloys Using D ElectronsCrescencio RodríguezNessuna valutazione finora

- Cold Formed SteelDocumento66 pagineCold Formed Steelarkirthi1175Nessuna valutazione finora

- Bomba FlightDocumento2 pagineBomba FlightGustavo HRNessuna valutazione finora

- Din 3357Documento7 pagineDin 3357sheik MohammedNessuna valutazione finora

- Grounding & Earthing PDFDocumento108 pagineGrounding & Earthing PDFRajeevAgrawal100% (1)

- Unconventional Machining ProcessDocumento39 pagineUnconventional Machining Processuday bavandla100% (1)

- SPC - CR - UR - 510 - 3, Urea GradeDocumento35 pagineSPC - CR - UR - 510 - 3, Urea Gradesaadpervaiz14Nessuna valutazione finora

- No Good Gremlins Rules PDFDocumento4 pagineNo Good Gremlins Rules PDFPedro HenriqueNessuna valutazione finora

- C BoilermakingDocumento9 pagineC BoilermakingAldeline SungahidNessuna valutazione finora

- Purple Cows Tonic Studios 2013 CatalogDocumento17 paginePurple Cows Tonic Studios 2013 CatalogPurple Cows, Inc.Nessuna valutazione finora

- DurbalDocumento2 pagineDurbalmoinkotaNessuna valutazione finora

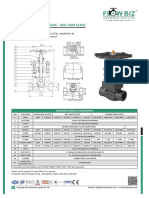

- FlowBiz Forged Steel Globe Valve 1500 ClassDocumento2 pagineFlowBiz Forged Steel Globe Valve 1500 ClassFlowBiz Exports Pvt. Ltd.Nessuna valutazione finora

- Cot - Smaw 8Documento41 pagineCot - Smaw 8Joy Molina - PanagueNessuna valutazione finora