Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Welding Coordination

Caricato da

Ion PlesaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Welding Coordination

Caricato da

Ion PlesaCopyright:

Formati disponibili

Firma Name

WELDING COORDINATION QA/QC

Doc. nr. : Date : Page:

xxxxx 06/11/2009 1 of 3

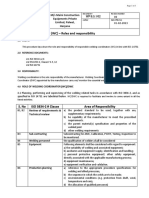

Welding is a particular process, that requires coordination of all activities. This document defines the tasks and responsibilities from everyone who is involved in the welding process. Guideline for this document are the following standards : -EN ISO 14731 Ann. B Welding Coord.; tasks and responsibilities -ISO 3834-1 Ann. A Quality Requirements for fusion welding of metals -DIN18800-7 El. (1303) Werkseigene Produktionskontrolle

Responsible Internal Production Control : LORELINE PIRA

NR

1 1a CONTRACT REVIEW

ACTIVITY

General -incl. kick off meeting to hand over the project Sales ProL (present : Sales, ProL, Eng, Prod, Purch, KwalM, Erect) If applicable : -specific requirements conc. welding -specific other QA/QC requirements

BY WHOM

-ComDProLBDir -ProL -KwalM -LasC -KwalM

DOCUMENTATION

-VER-01-F1 to be filled in and signed + letter to client -project sheet / projectblad PRL-01-F1 -standard QIP csm in : ProL makes copy requir. for LasC and/or KwalM out : Welding Matrix (and/or W. Plan) to KwalM & LasV & Client out : project specific QIP to ProL/ENG/AANK/PROD/MON

1b 2 2a

TECHNICAL (DESIGN) REVIEW INCL. CHOICE MATERIAL GRADES -choice material grade to EN 10025-..., EN 10210/10219 incl. suppl. requirements (Z-qual., UT-doubling, ...) -weld design (BW-FW-PPW) & location -ordering materials acc. to 2a incl. cert. to EN 10204 (2.2, 3.1, 3.2) -choice weld process & design weld details incl. bevels, ... -choice accept. level (B, C, D) for welds to EN ISO 5817 -choice W. consumables, incl. mat. cert. to EN 10204 IngO + HEng out : design doc, on drawings, listings in: ENG-04 + EN-NEN-DIN Keuze staalkwal. out: PRL-01-F1 (ProL) to all techn. departments out: material ordering list (ProjEng) to HAank ; reception of mat.cert. in : LAS-LASVOORBEW = weld preps for several W. proc. out : general-, production- & erection drawings -on drawings (ProjEng) + in Welding Matrix (LasC) -in Welding Matrix; specialties : e-mail to Aank

2b

ProjEng + HEng

2c 2d

ProjEng + LasC -LasC -LasC + Aank

Firma Name

WELDING COORDINATION QA/QC

Doc. nr. : Date : Page:

xxxxx 06/11/2009 2 of 3

NR

3 3a 3b 4 4a 4b SUBCONTRACTING

ACTIVITY

-choice subcontractor for production part (incl. welding) -follow up execution -choice subcontr. for ext. (N)DT on welds, W. procedures, ... -invite operator to do NDT at Hamont / on site WELDING- & INSPECTION PERSONNEL Welders & Welding operators -organisation and records -training and witnessing of test pieces -Welding Coordination -Welding supervision on the floor (N)DT of welds : -VT on ongoing fabrication(before-during-after welding) -PT, macro -RT, UT, MT, macro

BY WHOM

DirProj + ProL ProL + LasC or LasV LasC ProdDir-LasV/ LasC

DOCUMENTATION

-subcontract INK-WB-41/-42-F -inspection report Year contract to MME MME-report

LasC LasV (+LasC) LasC LasV LasV LasV or MME MME (ext. organ.)

-Qual. records to EN 287-1, EN 1418, EN ISO 14555, AWS,... -Welders List LAS-LASSERSLIJST + storing test pieces for 3 Years -EWE-certificate -WELD-VT+PT by LasV + 1 eye-test/Yr + training by LasC -Cert. CSM : eye-test, internal education, experience -Cert. No 0301/95394 = PT level 2 (EN 473) or MME-cert. level -MME-cert.

4c 5 5a 5b 5c 6 6a 6b 6c

WELDING WELDING DOCUMENTS IDENTIFICATION DURING WELDING Storage / Choice correct welding consumables shop / site Choice correct welding sequence if applicable Draw up WPSs to cover the weld activities Qualify new PQRs to cover the WPSs Identification of BWs during process EQUIPMENT & CALIBRATION Possession of suitable production equipment for prefab, welding, lifting, testing, transport,storing facilities, ... incl. safety equipment & protective clothes Equipment maintenance Calibration of measuring, inspection & testing equipment ProdDir PrevAdv OndV KaliV KWH-04 p 26 Calibration reports PRO-WB-20 Facilities Achel PRO-WB-21 Facilities Hamont ... List Safety Materials LasV / LasV / LasC LasC LasC + LasV LasC + Welder +MME Welders stamp Weld Matrix (specific) or LAS-LASTOEVOEGSTOFFEN Weld Plan WPSs that cover the weld activities PQRs that cover the WPSs Welders nr (C...) on NDT-report for prolongation of Qual. records

Firma Name

WELDING COORDINATION QA/QC

Doc. nr. : Date : Page:

xxxxx 06/11/2009 3 of 3

NR

7 7a

ACTIVITY

QUALITY CONTROL, OTHER THEN WELDING Production Achel : -reception of incoming steel and shop primer -prefab. Elements with acceptable tolerances -control of shop blasting & thickness weld primer Production Hamont : -reception of incoming steel and parts from subcontractors -dimensional control during production -dimensional control of complicated structures Painting Hamont : -reception of paint -control of environmental circumstances before start -control wet layer thickness & quality during painting -control average dry film thickness after each layer Erection on site : -erection in accordance to ENV 1090-1 NCR IF REQUIRED QUALITY CANT BE ACHIEVED -deviations on incoming steel -deviations on incoming welding consumables -deviations on production parts from Hamont -deviations on parts from subcontractors -deviations on erected parts QUALITY RECORDS END DOCUMENTATION

BY WHOM

DOCUMENTATION

MagSt/painter Every worker Painter/blaster

Signing off order note Stamping off production list Daily test plate (stored for 2 weeks)

7b

QCHam Signing off order note Every worker + foreman Stamping off drawing + checklist PRO-02-F1 Foreman Dimensional report + checklist PRO-02-F1 Paint foreman Paint foreman Every painter + foreman foreman foreman Signing off order note PRO-03-F1 / Layer thickness print outs + checklist PRO-02-F1 PRL-01-F5 and PRL-01-F6

7c

7d 8 8a 8b 8c 8d 8e 9

MagSt/HProdA LasV/Aank Client/ProL/foreman Client/ProL Client/HMon KwalM

Extra remark on order note Extra remark on order note NCR KWH-08-F1 NCR KWH-08-F1 NCR KWH-08-F1 Kept in archive for >= 10 Years

Potrebbero piacerti anche

- Welding Coordination Activities and Responsibilities To ISO 14731 Task Allocation ListDocumento7 pagineWelding Coordination Activities and Responsibilities To ISO 14731 Task Allocation ListeliiiiiiNessuna valutazione finora

- KOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2Documento28 pagineKOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2Ivan DulicNessuna valutazione finora

- Template For "Review of Requirements"Documento1 paginaTemplate For "Review of Requirements"Satish KeskarNessuna valutazione finora

- QWS Best Practices GuideDocumento34 pagineQWS Best Practices GuidechowhkNessuna valutazione finora

- Duties of The RWCDocumento3 pagineDuties of The RWCbluegalago100% (1)

- Weld Joint Repaire Procedure - 08.04.14Documento6 pagineWeld Joint Repaire Procedure - 08.04.14Raj AryanNessuna valutazione finora

- Need of ISO 3834 To Welding Fabrication IndustryDocumento4 pagineNeed of ISO 3834 To Welding Fabrication IndustrySatish Keskar100% (1)

- Welding Personnel ResponsibilityDocumento2 pagineWelding Personnel ResponsibilityIlkin hasanovNessuna valutazione finora

- Tecnical Review ChecklistDocumento6 pagineTecnical Review ChecklistShaun Holder100% (1)

- Welding Process Control - PR - 0XXDocumento21 pagineWelding Process Control - PR - 0XXRAMAKRISHNA100% (2)

- PDF Iso 3834 Checklist 1 CompressDocumento12 paginePDF Iso 3834 Checklist 1 CompressViệt VũNessuna valutazione finora

- Assessment Procedure Welding Report FormDocumento23 pagineAssessment Procedure Welding Report Formssierro100% (1)

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Documento14 pagineList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNessuna valutazione finora

- WP-8.5.1-02 Role of RWCDocumento3 pagineWP-8.5.1-02 Role of RWCNitin SharmaNessuna valutazione finora

- Welding Coordination-Tasks & ResponsibilitiesDocumento14 pagineWelding Coordination-Tasks & Responsibilitieskumaraswamy.kNessuna valutazione finora

- Certification To Iso 3834 For Fabrication IndustryDocumento9 pagineCertification To Iso 3834 For Fabrication IndustryvilukNessuna valutazione finora

- Factory Production Control System - Welding Quality Manual 23-01-17 - Issue 1Documento29 pagineFactory Production Control System - Welding Quality Manual 23-01-17 - Issue 1Scott Trainor100% (2)

- Welding Procedure Specification (WPS) : Joint Design Welding SequencesDocumento1 paginaWelding Procedure Specification (WPS) : Joint Design Welding SequencesFerhat KahveciNessuna valutazione finora

- Sample of Welding Quality ManualDocumento5 pagineSample of Welding Quality ManualwentropremNessuna valutazione finora

- ESAB Electrodes User ManualDocumento44 pagineESAB Electrodes User ManualF. Alijani100% (1)

- Weld Test Checklist: Welder (S) DetailsDocumento2 pagineWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- WELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Documento65 pagineWELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Ethem Güngör100% (1)

- Iso 14344 2010Documento9 pagineIso 14344 2010MOHAMEDNessuna valutazione finora

- ISO 3834 Awareness Program OutlineDocumento1 paginaISO 3834 Awareness Program OutlineSatish KeskarNessuna valutazione finora

- Guidance To Prepare Wps PQR For WeldingDocumento1 paginaGuidance To Prepare Wps PQR For WeldingHamid MansouriNessuna valutazione finora

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocumento31 pagineALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNessuna valutazione finora

- WeldingFabricatorCertificationScheme ISO3834Documento11 pagineWeldingFabricatorCertificationScheme ISO3834Weld Bro Sandeep100% (1)

- WPS Format For ISO 9606-1 WelderDocumento2 pagineWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- List of WPS (Jerp) PDFDocumento2 pagineList of WPS (Jerp) PDFAlam MD SazidNessuna valutazione finora

- ISO 3834-2 Compliance Check ListDocumento1 paginaISO 3834-2 Compliance Check ListMichael Tayactac100% (1)

- Welding Coordinator Tasks and ResponsibilitiesDocumento3 pagineWelding Coordinator Tasks and ResponsibilitiesShaun Holder100% (4)

- Control Procedures For The Calibration and Measurement of The Welding Power Supplies For PDFDocumento11 pagineControl Procedures For The Calibration and Measurement of The Welding Power Supplies For PDFNenad NedeljkovicNessuna valutazione finora

- Welding Procedure QualificationDocumento23 pagineWelding Procedure QualificationHosam AhmedNessuna valutazione finora

- Welding Program Quality Assurance GuideDocumento19 pagineWelding Program Quality Assurance GuideDonald ray100% (1)

- Inspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationDocumento3 pagineInspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationKhaled GamalNessuna valutazione finora

- Welding Control ProcedureDocumento4 pagineWelding Control Procedurevenkatesh100% (2)

- WPQ WeldCanada PDFDocumento1 paginaWPQ WeldCanada PDFAhmad DanielNessuna valutazione finora

- ISO 3834 - ChecklistDocumento26 pagineISO 3834 - ChecklistAbhishek Anand83% (6)

- Welding Quality Control Plan (WQCP) Requirements: OrganizationDocumento2 pagineWelding Quality Control Plan (WQCP) Requirements: Organizationmangalraj900Nessuna valutazione finora

- Technical Review For ISO 3834Documento1 paginaTechnical Review For ISO 3834Satish Keskar100% (3)

- Welding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Documento2 pagineWelding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Go MocNessuna valutazione finora

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocumento3 pagineWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENessuna valutazione finora

- Duties Before WeldingDocumento1 paginaDuties Before WeldingMuhammed ThanzeelNessuna valutazione finora

- ISO 3834 Check ListDocumento2 pagineISO 3834 Check Listsheikmoin100% (1)

- KON 8.2 QA PRO 0020 C1 Welding Control ProcedureDocumento15 pagineKON 8.2 QA PRO 0020 C1 Welding Control ProcedureAlizamin Salmanov100% (1)

- Welder Qualification Test - WQT by ITPI-IWESDocumento1 paginaWelder Qualification Test - WQT by ITPI-IWESsanul mulyNessuna valutazione finora

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocumento2 pagineWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNessuna valutazione finora

- Iso 3834Documento2 pagineIso 3834Jaay Vel0% (1)

- WPS As Per ISO 15609 Ref.Documento3 pagineWPS As Per ISO 15609 Ref.AnilNessuna valutazione finora

- Preparation and Control of WeldingDocumento3 paginePreparation and Control of Weldingbalakumar rajaramNessuna valutazione finora

- Spezifikation HazemagDocumento3 pagineSpezifikation HazemagaansewuNessuna valutazione finora

- Fab 04 WPS, WPQR, Welder Qualification, Welding Positions, Defect - Repair WeldingDocumento39 pagineFab 04 WPS, WPQR, Welder Qualification, Welding Positions, Defect - Repair WeldingRaghu vamshiNessuna valutazione finora

- Up Dated CV of D K Jena - DNV GLDocumento15 pagineUp Dated CV of D K Jena - DNV GLParag WadekarNessuna valutazione finora

- Sandeep Kumar CV - Welding Engineer-Welding InspectorDocumento4 pagineSandeep Kumar CV - Welding Engineer-Welding InspectorWeld Bro Sandeep100% (1)

- Quality PlanDocumento11 pagineQuality PlanArief Bahtiar BahryNessuna valutazione finora

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkDocumento38 pagineMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTNessuna valutazione finora

- Din 18800Documento8 pagineDin 18800Batuhan TatarNessuna valutazione finora

- 21Documento6 pagine21Dannis AnantoNessuna valutazione finora

- T-MCE-STD-001 Rev 0 - Welding and Inspection of Process and Utility Pipework Vessels and EquipmentDocumento59 pagineT-MCE-STD-001 Rev 0 - Welding and Inspection of Process and Utility Pipework Vessels and EquipmentMichael CovillNessuna valutazione finora

- How to prepare Welding Procedures for Oil & Gas PipelinesDa EverandHow to prepare Welding Procedures for Oil & Gas PipelinesValutazione: 5 su 5 stelle5/5 (1)

- Marketing Contact ModelDocumento2 pagineMarketing Contact ModelIon PlesaNessuna valutazione finora

- Customer Satisfaction 2014Documento1 paginaCustomer Satisfaction 2014Ion PlesaNessuna valutazione finora

- Consum UtilitatiDocumento6 pagineConsum UtilitatiIon PlesaNessuna valutazione finora

- Standard 3834 Si Audit AtasatDocumento107 pagineStandard 3834 Si Audit AtasatIon PlesaNessuna valutazione finora

- En15085-2 1st StepDocumento50 pagineEn15085-2 1st Steprameshqc100% (1)

- Prodis Presentation - EnglishDocumento7 pagineProdis Presentation - EnglishIon PlesaNessuna valutazione finora

- 11505-HF MT (130-220 Ton) Operators Manual X40882e (Sep-03)Documento220 pagine11505-HF MT (130-220 Ton) Operators Manual X40882e (Sep-03)Ion Plesa50% (2)

- AMADA, CNC PRESS BRAKE, Building Year 2001 Ref. 4141Documento2 pagineAMADA, CNC PRESS BRAKE, Building Year 2001 Ref. 4141Ion PlesaNessuna valutazione finora

- #Lista Sudorilor Autorizati TUV Rev 30Documento3 pagine#Lista Sudorilor Autorizati TUV Rev 30Ion PlesaNessuna valutazione finora

- Welding Coordination Tasks and Responsibilities DIN en ISO 14731 EnglischDocumento1 paginaWelding Coordination Tasks and Responsibilities DIN en ISO 14731 EnglischIon Plesa100% (1)

- Wood Plastic CompositesDocumento38 pagineWood Plastic CompositesIon Plesa100% (1)

- The Minimum Means of Reprisal - China's S - Jeffrey G. LewisDocumento283 pagineThe Minimum Means of Reprisal - China's S - Jeffrey G. LewisrondfauxNessuna valutazione finora

- Hindi ShivpuranDocumento40 pagineHindi ShivpuranAbrar MojeebNessuna valutazione finora

- Powerwin EngDocumento24 paginePowerwin Engbillwillis66Nessuna valutazione finora

- PH of Soils: Standard Test Method ForDocumento3 paginePH of Soils: Standard Test Method ForYizel CastañedaNessuna valutazione finora

- DISCHARGE PLAN CuyosDocumento6 pagineDISCHARGE PLAN CuyosShaweeyah Mariano BabaoNessuna valutazione finora

- LicencesDocumento5 pagineLicencesstopnaggingmeNessuna valutazione finora

- Lateritic NickelDocumento27 pagineLateritic NickelRAVI1972100% (2)

- Obara BogbeDocumento36 pagineObara BogbeOjubona Aremu Omotiayebi Ifamoriyo0% (1)

- Research On Export Trade in BangladeshDocumento7 pagineResearch On Export Trade in BangladeshFarjana AnwarNessuna valutazione finora

- 100 20210811 ICOPH 2021 Abstract BookDocumento186 pagine100 20210811 ICOPH 2021 Abstract Bookwafiq alibabaNessuna valutazione finora

- Optimal Dispatch of Generation: Prepared To Dr. Emaad SedeekDocumento7 pagineOptimal Dispatch of Generation: Prepared To Dr. Emaad SedeekAhmedRaafatNessuna valutazione finora

- Understanding The Marshall AttackDocumento6 pagineUnderstanding The Marshall Attacks.for.saad8176Nessuna valutazione finora

- III.A.1. University of Hawaii at Manoa Cancer Center Report and Business PlanDocumento35 pagineIII.A.1. University of Hawaii at Manoa Cancer Center Report and Business Planurindo mars29Nessuna valutazione finora

- TrellisDocumento1 paginaTrellisCayenne LightenNessuna valutazione finora

- Why File A Ucc1Documento10 pagineWhy File A Ucc1kbarn389100% (4)

- Health and Safety For The Meat Industry: Guidance NotesDocumento198 pagineHealth and Safety For The Meat Industry: Guidance NotesPredrag AndjelkovicNessuna valutazione finora

- Usm 1Documento47 pagineUsm 1Abhishek KumarNessuna valutazione finora

- Advent Wreath Lesson PlanDocumento2 pagineAdvent Wreath Lesson Planapi-359764398100% (1)

- Better Photography - April 2018 PDFDocumento100 pagineBetter Photography - April 2018 PDFPeter100% (1)

- Topic Group Present (Week 8) Chapter 1:sociology and Learning ManagementDocumento2 pagineTopic Group Present (Week 8) Chapter 1:sociology and Learning ManagementLEE LEE LAUNessuna valutazione finora

- Microeconomics Term 1 SlidesDocumento494 pagineMicroeconomics Term 1 SlidesSidra BhattiNessuna valutazione finora

- Revit 2023 Architecture FudamentalDocumento52 pagineRevit 2023 Architecture FudamentalTrung Kiên TrầnNessuna valutazione finora

- QuinnmcfeetersresumeDocumento1 paginaQuinnmcfeetersresumeapi-510833585Nessuna valutazione finora

- 21st CENTURY TECHNOLOGIES - PROMISES AND PERILS OF A DYNAMIC FUTUREDocumento170 pagine21st CENTURY TECHNOLOGIES - PROMISES AND PERILS OF A DYNAMIC FUTUREpragya89Nessuna valutazione finora

- Model TB-16Documento20 pagineModel TB-16xuanphuong2710Nessuna valutazione finora

- Nutrition Great Foods For Getting Vitamins A To K in Your DietDocumento1 paginaNutrition Great Foods For Getting Vitamins A To K in Your DietDhruv DuaNessuna valutazione finora

- Electric Vehicles PresentationDocumento10 pagineElectric Vehicles PresentationVIBHU CHANDRANSH BHANOT100% (1)

- IPM GuidelinesDocumento6 pagineIPM GuidelinesHittesh SolankiNessuna valutazione finora

- Rare Malignant Glomus Tumor of The Esophagus With PulmonaryDocumento6 pagineRare Malignant Glomus Tumor of The Esophagus With PulmonaryRobrigo RexNessuna valutazione finora