Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

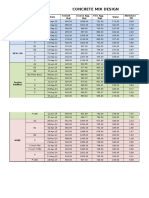

Conrete Mix Design ACI and JSCE Example. (20+33 Mpa)

Caricato da

nirmaljoshiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Conrete Mix Design ACI and JSCE Example. (20+33 Mpa)

Caricato da

nirmaljoshiCopyright:

Formati disponibili

Structual material lab

Title: JSCE method of concrete mix design Air entrained 20MPa concrete Reference: STANDARD SPECIFICATIONS FOR CONCRETESTRUCTURES 2007"Materials and Construction"

Assignment 1 Name Nirmal Raj Joshi Class ID 13ME135

Input data Given Data as follow: Required strength Slump Air entrained Air content Air entrainment Relation between w/c and f'cr

fcr s ac

20 Mpa 150 mm Yes 7 % With air entraining, water reducing agent fcr = - 10+20(C/W) for JSCE Method

Materials Cement Cement type Specific gravity of cement Fine aggregate Fineness modulus of fine aggregate Specific gravity of fine aggregate Coarse aggregate Maximum size of coarse aggregate Bulk density of coarse aggregate Specific gravity of coarse aggregate

Water 7.82%

sc fm sf

ASTM type 1 3.15 2.4 2.6 20 mm 1600 kg/m3 2.7

sco

Output Ingredients Cement Fine aggregate Coarse aggregate Water Total w/c ratio

kg/m3 260.87 776.06 1011.93 173.91 2222.77 0.67

proportion 1.00 2.97 3.88 0.67

JSCE method of concrete mix design

Cement 11.74%

Cement Fine aggregate Coarse aggregate 45.53% Fine aggregate 34.91% Coarse aggregate Water

Step 1 Calculate w/c ratio fcr' Coefficient of variation, V Overdesign factor (calculated) over design factor (used) c/w w/c

=1/(1-1.65*V/100)

20.00 Mpa 0 1.000 1.00 1.50 0.67

[section 4.4.3]

2 Find amount of water and s/a(fine aggregate ratio) Table C4.5.2 Approximate values of the unit bulk volume of coarse aggregate, sand percentage Air entrained concrete Maximum size Unit bulk volume of coarse of coarse Entrained air aggregate aggregate

With air entraining agent Sand percentage (s/a) Water content (W) kg 47 44 42 39 180 175 170 165

mm 15 20 25 40

m3/m3 0.58 0.62 0.67 0.72

% 7.0 6.0 5.0 4.5

With air entraining, water reducing agent Sand percentage Water (s/a) content (W) % kg 48 170 45 165 43 160 40 155

The values shown above are average values determined with reference to the standard mix proportions adopted by ready-mixed concrete industrial associations in Japan and are for concrete made by using sand of an ordinary particle size distribution (fineness modulus: about 2.80) and crushed stone. Max size of coarse aggregate In Table C4.5.2 Standard fineness modulus Standard slump Standard air content Standard w/c Actual values are fineness modulus slump air content w/c ratio Air entrainment condition From table above, Sand percentage from table (s/a) actual adopted s/a Water content (W') 20 mm 2.8 80 mm 6 % 0.55

2.40 150.00 mm 7.00 0.67 With air entraining, water reducing agent 45.0 % 45.0 % 165.0 kg

2.2 Correction for water content and s/a Table C4.5.3 Approximate amounts of correction for the sand percentage and the watercontent due to variations in the quality of materials used or concrete Correction of s/a (%) Correction of W Category description value description value For every 0.1 in fineness modulus of -2.00 No correction sand greater (smaller) than reference Increase (decrease) by 0.5. value For every 1 cm in slump greater Increase (decrease) by No correction ----(smaller) than reference value 1.2%. For every 1% in air content higher Decrease (increase) by Decrease (increase) by 0.5 to 1. -1.00 (lower) than reference value 3%. For every 0.05 in water/cement ratio higher (lower) than reference value For every 1% in s/a higher (lower) than reference value When river gravel is used. Increase (decrease) by 1. No correction Decrease by 3 to 5 (unit??) Correction for s/a 2.33 No correction Increase (decrease) by ----1.5 kg. 0.00 Decrease by 9 to 15 kg -0.67 correction for w (%) Correction for w (kg)

----8.40 -3.00 ----0.00 0.00 5.40 0.00

If the unit bulk volume of coarse aggregate is used, the unit bulk volume of coarse aggregate is decreased (increased) by 1% for every 0.1 in the fineness modulus of sand greater (smaller) than the reference value. Corrected water content Corrected s/a w=w'-w s/a=s/a'-s/a 173.91 kg 44.33 %

1 of 2

Structual material lab

Title: JSCE method of concrete mix design Air entrained 20MPa concrete Reference: STANDARD SPECIFICATIONS FOR CONCRETESTRUCTURES 2007"Materials and Construction"

Assignment 1 Name Nirmal Raj Joshi Class ID 13ME135

3 Calculate ingredients w/c ratio Weight of cement Total volume of aggregate Weight of fine aggregate Weight of coarse aggregate Ingredients Cement Fine aggregate Coarse aggregate Water

Wc=w/(w/c) Va=1-(w/1000+Wc/sc/1000+ac/100) Wf=Va*sf*(s/a)/100*1000 Wco=Va*sf*(1-s/a)/100*1001 Weight/m3 260.87 776.06 1011.93 173.91 Unit Kg/m3 Kg/m3 Kg/m3 Kg/m3

0.67 260.87 0.67 776.06 1,011.93

kg/m3 m3/m3 kg/m3 kg/m3 Proportion 1.00 2.97 3.88 0.67

2 of 2

Structual material lab

Title: JSCE method of concrete mix design Air entrained 33MPa concrete Reference: STANDARD SPECIFICATIONS FOR CONCRETESTRUCTURES 2007"Materials and Construction"

Assignment 1 Name Nirmal Raj Joshi Class ID 13ME135

Input data Given Data as follow: Required strength Slump Air entrained Air content Air entrainment Relation between w/c and f'cr

fcr s ac

33 Mpa 80 mm Yes 5 % With air entraining, water reducing agent fcr = - 10+20(C/W) for JSCE Method

Materials Cement Cement type Specific gravity of cement Fine aggregate Fineness modulus of fine aggregate Specific gravity of fine aggregate Coarse aggregate Maximum size of coarse aggregate Bulk density of coarse aggregate Specific gravity of coarse aggregate

Water 6.56%

sc fm sf

ASTM type 1 3.15 2.4 2.6 40 mm 1600 kg/m3 2.7

sco

Output Ingredients Cement Fine aggregate Coarse aggregate Water Total w/c ratio

kg/m3 328.25 645.20 1201.41 152.68 2327.53 0.47

proportion 1.00 1.97 3.66 0.47

JSCE method of concrete mix design

Cement 14.10% Fine aggregate 27.72%

Cement Fine aggregate Coarse aggregate Water

Coarse aggregate 51.62%

Step 1 Calcualte w/c ratio fcr' Coefficient of variation, V Overdesign factor (calculated) over design factor (used) c/w w/c

=1/(1-1.65*V/100)

33.00 Mpa 0 1.000 1.00 2.15 0.47

[section 4.4.3]

2 Find amount of water and s/a(fine aggregate ratio) Table C4.5.2 Approximate values of the unit bulk volume of coarse aggregate, sand percentage Air entrained concrete Maximum size Unit bulk volume of coarse of coarse Entrained air aggregate aggregate

With air entraining agent Sand percentage (s/a) Water content (W) kg 47 44 42 39 180 175 170 165

mm 15 20 25 40

m3/m3 0.58 0.62 0.67 0.72

% 7.0 6.0 5.0 4.5

With air entraining, water reducing agent Sand percentage Water (s/a) content (W) % kg 48 170 45 165 43 160 40 155

The values shown above are average values determined with reference to the standard mix proportions adopted by ready-mixed concrete industrial associations in Japan and are for concrete made by using sand of an ordinary particle size distribution (fineness modulus: about 2.80) and crushed stone. Max size of coarse aggregate In Table C4.5.2 Standard fineness modulus Standard slump Standard air content Standard w/c Actual values are fineness modulus slump air content w/c ratio Air entrainment condition From table above, Sand percentage from table (s/a) actual adopted s/a Water content (W') 40 mm 2.8 80 mm 4.5 % 0.55

2.40 80.00 mm 5.00 0.47 With air entraining, water reducing agent 40.0 % 40.0 % 155.0 kg

2.2 Correction for water content and s/a Table C4.5.3 Approximate amounts of correction for the sand percentage and the watercontent due to variations in the quality of materials used or concrete Correction of s/a (%) Correction of W Category description value description value For every 0.1 in fineness modulus of -2.00 No correction sand greater (smaller) than reference Increase (decrease) by 0.5. value For every 1 cm in slump greater Increase (decrease) by No correction ----(smaller) than reference value 1.2%. For every 1% in air content higher Decrease (increase) by Decrease (increase) by 0.5 to 1. -0.50 (lower) than reference value 3%. For every 0.05 in water/cement ratio higher (lower) than reference value For every 1% in s/a higher (lower) than reference value When river gravel is used. Increase (decrease) by 1. No correction Decrease by 3 to 5 (unit??) Correction for s/a -1.70 No correction Increase (decrease) by ----1.5 kg. 0.00 Decrease by 9 to 15 kg -4.20 correction for w (%) Correction for w (kg)

----0.00 -1.50 ----0.00 0.00 -1.50 0.00

If the unit bulk volume of coarse aggregate is used, the unit bulk volume of coarse aggregate is decreased (increased) by 1% for every 0.1 in the fineness modulus of sand greater (smaller) than the reference value. Corrected water content Corrected s/a w=w'-w s/a=s/a'-s/a 152.68 kg 35.80 %

1 of 2

Structual material lab

Title: JSCE method of concrete mix design Air entrained 33MPa concrete Reference: STANDARD SPECIFICATIONS FOR CONCRETESTRUCTURES 2007"Materials and Construction"

Assignment 1 Name Nirmal Raj Joshi Class ID 13ME135

3 Calculate ingredients w/c ratio Weight of cement Total volume of aggregate Weight of fine aggregate Weight of coarse aggregate Ingredients Cement Fine aggregate Coarse aggregate Water

Wc=w/(w/c) Va=1-(w/1000+Wc/sc/1000+ac/100) Wf=Va*sf*(s/a)/100*1000 Wco=Va*sf*(1-s/a)/100*1001 Weight/m3 328.25 645.20 1201.41 152.68 Unit Kg/m3 Kg/m3 Kg/m3 Kg/m3

0.47 328.25 0.69 645.20 1,201.41

kg/m3 m3/m3 kg/m3 kg/m3 Proportion 1.00 1.97 3.66 0.47

2 of 2

Title: ACI method of concrete design Air entrained Structural material lab 20MPa concrete Reference: Standard Practice for Selecting Proportions forNormal, Heavyweight, and Mass Concrete (ACI 211.1-91)- Chapter-5

Assignment 1 Name Nirmal Raj Joshi Class ID 13ME135

Concrete properties Designated Strength, fc' Curing period Type of concrete Placing condition of concrete Workability of the concrete (slump value) Maximum size of aggregate Is concrete air entrained Design air content Output Volume of concrete required Ingredients Cement Fine aggregate Coarse aggregate Water Pozzolanic Materials Weight of water reducer

33 28 RCC Moderate 75 to 100 37.5 Yes 5.00 vol Proportion of ingredients 1.00 1.47 3.01 0.41 0.00 0.00 Total

Mpa days

mm mm % (Reccomended:4.5%)

1.00 m3 Weight of ingredients 398.55 586.45 1200.00 165.00 0.00 0.00 2350.00 Kg Kg Kg Kg Kg Kg Kg/m2

Material properties Cement Type Specific gravity of cement Coarse aggregate Unit weight of dry roadded coarse aggregate Specific gravity of coarse Free moisture in coarse aggregate Fine aggregate (sand) Fineness modulus of fine aggregate Specific gravity of fine (sand) Free moisture in sand

Pozzolanic Materials 0.00%

Gc

ASTM Type-1 3.15 1600 Kg/m3 2.70 0 % 2.40 2.60 0 %

spa cam

spf fm

Water 7.02%

Weight of water reducer 0.00% Cement 16.96% Coarse aggregate 51.06%

ACI Method Proportions required

Cement Fine aggregate Coarse aggregate Water Pozzolanic Materials Weight of water reducer

W/C ratio= 0.414

Fine aggregate 24.96%

Calculations Steps As per chapter 5 of ACI 211.1 1 Choice of slump Recommended slumps for various types of construction (Table 6.3.1) Types of construction Reinforced foundation walls and footings Plain footings, caissons, and substructure walls Beams and reinforced walls Building columns Pavements and slabs Mass concrete 1.1 Maximum slump 1.2 Minimum slump 2 Choice of nominal maximum size of aggregate In no event should the nominal maximum size exceed one-fifth of the narrowest dimension between sides of forms, one-third the depth of slabs, nor three-fourths of the minimum clear spacing between individual reinforcing bars, bundles of bars, or pretensioning strands 37.5 mm Maximum Slump (mm) 75 75 100 100 75 75 75 mm 25 mm Minimum Slump (mm) 25 25 25 25 25 25

2.1

Maximum aggregate size 3 Estimation of mixing water and air content A If concrete is air entrained 3.1 Slump (mm) 25 to 50 75 to 100 150 to 175 More than 175 Level of Exposure Mild Moderate Severe For, Slump Maximum aggregate size Exposure level we get, 3.1.1 water weight for air-entrained concrete 3.1.2 Recommended averages air content Design air content B If concrete is not air entrained 3.2 Slump (mm) 25 to 50 75 to 100 150 to 175 More than 175 Slump (mm) All For, Slump Maximum aggregate size Exposure level we get, 3.2.1 water weight for air-entrained concrete 3.2.1 Approximate air content Final value to use Is concrete air entrained 3.3 Weight of water 3.4 Air content 4 Selection of water-cement or watercementitiousmaterials ratio

AIR-ENTRAINED CONCRETE (TABLE A1.5.3.3) Approximate mixing water (kg/m3) for indicated nominal maximum sizes of aggregate

9.5 181 202 216 9.5 4.5 6 7.5 12.5 4 5.5 7 12.5 175 193 205 19 3.5 5 6 19 168 184 197 25 3 4.5 6 25 160 175 184 37.5 2.5 4.5 5.5 37.5 150 165 174 50 2 4 5 50 142 157 166 75 122 133 154 75 1.5 3.5 4.5 150 107 119

Recommended averages of total air content (%) for level of exposure

150 1 3 4

75 to 100 mm 37.5 mm Moderate ww A 165 kg/m3 4.5 % 5 % (Reccomended:4.5%)

NON-AIR-ENTRAINED CONCRETE (TABLE A1.5.3.3) Approximate mixing water (kg/m3) for indicated nominal maximum sizes of aggregate

9.5 207 228 243 9.5 3 2.5 199 216 228 12.5 2 12.5 190 205 216 19 1.5 19 179 193 202 25 1 25 37.5 166 181 190 37.5 0.5 50 154 169 178 50 0.3 130 145 160 75 0.2 75 113 124 150 150

Approximate amount of entrapped air in non-air-entrained concrete (%)

75 to 100 mm 37.5 mm Moderate ww 181 kg/m3 1.00 %

Yes 165.00 kg/m3 5.00 %

4.1 Characteristic strength Table from ACI 318 When standard deviation is available 1. fcr'=fc'+1.34*s 2. fcr'=fc'+2.33*s-3.45 Mpa 3. fcr'=0.9*fc'+2.33*s for fc'<=35 Mpa max of equation 1 and 2 for fc'>35 Mpa max of equation 1 and 3 Is standard deviation available? Standard deviation Design strength Mean strength (28 days),fmean

Calculated value

When standard deviation is not available Value Specified compressive Required average compressive strength, strength, f'c , MPa 29.46 Less than 21 f' c + 7.0 29.70 21 to 35 f' c + 8.5 33.00 Over 35 1.10 f' c + 5.0 33.00 33.00 Yes 0 Mpa 33 Mpa 33.00 Mpa

f'cr, MPa 40.00 41.50 41.30

s fc' fcr'

33

1 of 2

Title: ACI method of concrete design Air entrained Structural material lab 20MPa concrete Reference: Standard Practice for Selecting Proportions forNormal, Heavyweight, and Mass Concrete (ACI 211.1-91)- Chapter-5

Assignment 1 Name Nirmal Raj Joshi Class ID 13ME135

5 Calculation of cement content.

Relationship between water-cement or water-cementations materials ratio and compressive strength of concrete (TABLE A1.5.3.4(a))

Compressive strength at 28 days (MPa) 15 20 25 30 35 40 5.1 Water cement ratio for required strength 5.2 Maximum permissible water-cement ratio Water-cement ratio by weight (Air-entrained concrete) 0.7 0.6 0.52 0.45 0.39 0.39 wc1 0.414

w/c

Water-Cement ratio

0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0

0.414 Graph point

x 33 33 x5

10 15 20 25 30 35

y 0 0.414 y 40

45

Compressive strength (MPa)

33 0

0.414 0.414

Maximum permissible water-cement or water-cementations materials ratios for concrete in severe exposure (TABLE A1.5.3.4(b))

Type of Structure Thin section (railings, curbs, sills, ledges, ornamental work) and sections with less than 25 mm cover over steel All other structures 5.3 Maximum w/c ratio and minimum cement Water cement to use Weight of cement wc2 wc=min(wc1,wc2) Cm=ww/wc NA 0.414 398.55 kg/m3 Structure wet continuously and exposed to frequent freezing and thawing Structure exposed to sea water or sulfates

0.45 0.50

0.40 0.45

5.4 Is pozzolanic material used? No Use of pozzolanic materials such as Fly Ash, Silica Fumes, Ground Granulated Blast-Furnace Slag (GGBFS) pozzolanic materials percentage by weight of cement 0.00 % specific gravity of pozzolanic material 2.40 Adjusted water-cementations materials ratio Weight of pozzolanic materials 0.000 kg/m3 Weight of cement 398.55 kg/m3

ok

6 Weight of coarse aggregate

Volume of oven-dry-rodded coarse aggregate per unit volume of concrete for different fineness moduli of fine aggregate (TABLE A1.5.3.6)

Nominal maximum size of aggregate (mm)

9.5 12.5 19

25 37.5 50 75 150 Fineness modulus of fine aggregates Nominal maximum size of aggregate Proportion of coarse aggregate in volume Weight of coarse aggregate per m3

2.4 0.5 0.59 0.66 0.71 0.75 0.78 0.82 0.87

2.6 0.48 0.57 0.64 0.69 0.73 0.76 0.8 0.85

2.8 0.46 0.55 0.62 0.67 0.71 0.74 0.78 0.83

3 0.44 0.53 0.6 0.65 0.69 0.72 0.76 0.81 2.40 37.5 mm 0.75 1200 Kg/m3

v ca=v*unit wt of dry rodded coarse aggregate

7 Weight of fine aggregate

First estimate of concrete weight (kg/m ) (TABLE A1.5.3.7.1)

Nominal maximum size of aggregate (mm) 9.5 12.5 19 25 37.5 50 75 150 Is air entrainment used Maximum size of aggregate Concrete weight Weighted average of specific gravity of coarse+fine aggregate when mixed theoretically exact calculation of fresh concrete (Unit mass of fresh concrete) Specific gravity of cement Air content Cement requirement Mixing water requirement Fine aggregate to be used 8 Moisture correction 8.1 Moisture correction for aggregates Moisture in fine aggregate Moisture in coarse aggregate Water required after reduction Actual quantity of fine aggregate Actual quantity of coarse aggregate Air-entrained concrete 2200 2230 2275 2290 2350 2345 2405 2435 Yes Um 37.5 mm 2350 kg/m3 Non-air entrained concrete 2280 2310 2345 2380 2410 2445 2490 2530

Ga=(spa+spf)/2 Um'=10*Ga*(100-A)+Cm*(1-Ga/Gc)-w*(Ga-1) Gc A Cm w f=con-c-w-ca

2.65 2308.51 Kg/m3 3.15 5.00 % 398.55 Kg/m3 165.00 586.45 Kg/m3

Iteration wfa=f*fm% wca=ca*cam% w=wfa-wca f=f+wfa ca=ca+wca

1 0.00 0 165.00 586.45 1200

2 0.00 0.00 165.00 586.45 1200.00 No 0.00 0.00 165.00 0.00

3 0.00 Kg 0.00 Kg

Unit

165.00 Kg=liters 586.45 Kg 1200.00 Kg

8.2 Is water reducer used Dosage of water reducer (if applied) as percentage of cement weight % of reduction in water (as given by the manufacturer) due to applied dosage of water reducer Adjusted water in mix Weight of water reducer 9 Final proportion by weight Ingredients Cement Fine aggregate Coarse aggregate Water Pozzolanic Materials Weight of water reducer Weight/m3 398.55 586.45 1200.00 165.00 0.00 0.00 Unit Kg/m3 Kg/m3 Kg/m3 Kg/m3 Kg/m3 Kg/m3 Proportion 1.00 1.47 3.01 0.41 0.00 0.00

% % Kg/m3 Kg/m3

ok ok

Weight of ingredients for given volume of concrete 398.55 586.45 1200.00 165.00 0.00 0.00

Unit Kg Kg Kg Kg Kg Kg

2 of 2

Structural material lab

Title: ACI method of concrete design Air entrained 20MPa concrete Reference: Standard Practice for Selecting Proportions forNormal, Heavyweight, and Mass Concrete (ACI 211.1-91)- Chapter-5

Assignment 1 Name Nirmal Raj Joshi Class ID 13ME135

Concrete properties Designated Strength, fc' Curing period Type of concrete Placing condition of concrete Workability of the concrete (slump value) Maximum size of aggregate Is concrete air entrained Design air content Output Volume of concrete required Ingredients Cement Fine aggregate Coarse aggregate Water Pozzolanic Materials Weight of water reducer

20 28 RCC Moderate 150 to 175 19 Yes 7.00 vol Proportion of ingredients 1.00 2.11 3.22 0.60 0.00 0.00 Total

Mpa days

mm mm % (Reccomended:5%)

1.00 m3 Weight of ingredients 328.33 693.67 1056.00 197.00 0.00 0.00 2275.00 Kg Kg Kg Kg Kg Kg Kg/m2

Material properties Cement Type Specific gravity of cement Coarse aggregate Unit weight of dry roadded coarse aggregate Specific gravity of coarse Free moisture in coarse aggregate Fine aggregate (sand) Fineness modulus of fine aggregate Specific gravity of fine (sand) Free moisture in sand

Pozzolanic Materials ACI Method 0.00% Proportions required Weight of water reducer Water 0.00% Cement 8.66% 14.43%

Gc

ASTM Type-1 3.15 1600 Kg/m3 2.70 0 % 2.40 2.60 0 %

spa cam

spf fm

Cement Fine aggregate

W/C ratio= 0.600

Coarse aggregate 46.42%

Fine aggregate 30.49%

Coarse aggregate Water Pozzolanic Materials Weight of water reducer

Calculations Steps As per chapter 5 of ACI 211.1 1 Choice of slump Recommended slumps for various types of construction (Table 6.3.1) Types of construction Reinforced foundation walls and footings Plain footings, caissons, and substructure walls Beams and reinforced walls Building columns Pavements and slabs Mass concrete 1.1 Maximum slump 1.2 Minimum slump 2 Choice of nominal maximum size of aggregate In no event should the nominal maximum size exceed one-fifth of the narrowest dimension between sides of forms, one-third the depth of slabs, nor three-fourths of the minimum clear spacing between individual reinforcing bars, bundles of bars, or pretensioning strands 19 mm Maximum Slump (mm) 75 75 100 100 75 75 100 mm 25 mm Minimum Slump (mm) 25 25 25 25 25 25

2.1

Maximum aggregate size 3 Estimation of mixing water and air content A If concrete is air entrained 3.1 Slump (mm) 25 to 50 75 to 100 150 to 175 More than 175 Level of Exposure Mild Moderate Severe For, Slump Maximum aggregate size Exposure level we get, 3.1.1 water weight for air-entrained concrete 3.1.2 Recommended averages air content Design air content B If concrete is not air entrained 3.2 Slump (mm) 25 to 50 75 to 100 150 to 175 More than 175 Slump (mm) All For, Slump Maximum aggregate size Exposure level we get, 3.2.1 water weight for air-entrained concrete 3.2.1 Approximate air content Final value to use Is concrete air entrained 3.3 Weight of water 3.4 Air content 4 Selection of water-cement or watercementitiousmaterials ratio

AIR-ENTRAINED CONCRETE (TABLE A1.5.3.3) Approximate mixing water (kg/m3) for indicated nominal maximum sizes of aggregate

9.5 181 202 216 9.5 4.5 6 7.5 12.5 4 5.5 7 12.5 175 193 205 19 3.5 5 6 19 168 184 197 25 3 4.5 6 25 160 175 184 37.5 2.5 4.5 5.5 37.5 150 165 174 50 2 4 5 50 142 157 166 75 122 133 154 75 1.5 3.5 4.5 150 107 119

Recommended averages of total air content (%) for level of exposure

150 1 3 4

150 to 175 mm 19 mm Moderate ww A 197 kg/m3 5 % 7 % (Reccomended:5%)

NON-AIR-ENTRAINED CONCRETE (TABLE A1.5.3.3) Approximate mixing water (kg/m3) for indicated nominal maximum sizes of aggregate

9.5 207 228 243 9.5 3 2.5 199 216 228 12.5 2 12.5 190 205 216 19 1.5 19 179 193 202 25 1 25 37.5 166 181 190 37.5 0.5 50 154 169 178 50 0.3 130 145 160 75 0.2 75 113 124 150 150

Approximate amount of entrapped air in non-air-entrained concrete (%)

150 to 175 mm 19 mm Moderate ww 216 kg/m3 2.00 %

Yes 197.00 kg/m3 7.00 %

4.1 Characteristic strength Table from ACI 318 When standard deviation is available 1. fcr'=fc'+1.34*s 2. fcr'=fc'+2.33*s-3.45 Mpa 3. fcr'=0.9*fc'+2.33*s for fc'<=35 Mpa max of equation 1 and 2 for fc'>35 Mpa max of equation 1 and 3 Is standard deviation available? Standard deviation Design strength Mean strength (28 days),fmean

Calculated value

When standard deviation is not available Value Specified compressive Required average compressive strength, strength, f'c , MPa 16.46 Less than 21 f' c + 7.0 18.00 21 to 35 f' c + 8.5 20.00 Over 35 1.10 f' c + 5.0 20.00 20.00 No 0 Mpa 20 Mpa 20.00 Mpa

f'cr, MPa 27.00 28.50 27.00

s fc' fcr'

27

1 of 2

Structural material lab

Title: ACI method of concrete design Air entrained 20MPa concrete Reference: Standard Practice for Selecting Proportions forNormal, Heavyweight, and Mass Concrete (ACI 211.1-91)- Chapter-5

Assignment 1 Name Nirmal Raj Joshi Class ID 13ME135

5 Calculation of cement content.

Relationship between water-cement or water-cementations materials ratio and compressive strength of concrete (TABLE A1.5.3.4(a))

Compressive strength at 28 days (MPa) 15 20 25 30 35 40 5.1 Water cement ratio for required strength 5.2 Maximum permissible water-cement ratio Water-cement ratio by weight (Air-entrained concrete) 0.7 0.6 0.52 0.45 0.39 0.39 wc1 0.600

w/c

Water-Cement ratio

0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0

0.600

Graph point x 20 20 x5

10 15 20 25 30 35

y 0 0.6 y 40

45

Compressive strength (MPa)

20 0

0.6 0.6

Maximum permissible water-cement or water-cementations materials ratios for concrete in severe exposure (TABLE A1.5.3.4(b))

Type of Structure Thin section (railings, curbs, sills, ledges, ornamental work) and sections with less than 25 mm cover over steel All other structures 5.3 Maximum w/c ratio and minimum cement Water cement to use Weight of cement wc2 wc=min(wc1,wc2) Cm=ww/wc NA 0.600 328.33 kg/m3 Structure wet continuously and exposed to frequent freezing and thawing Structure exposed to sea water or sulfates

0.45 0.50

0.40 0.45

5.4 Is pozzolanic material used? No Use of pozzolanic materials such as Fly Ash, Silica Fumes, Ground Granulated Blast-Furnace Slag (GGBFS) pozzolanic materials percentage by weight of cement 0.00 % specific gravity of pozzolanic material 2.40 Adjusted water-cementations materials ratio Weight of pozzolanic materials 0.000 kg/m3 Weight of cement 328.33 kg/m3

ok

6 Weight of coarse aggregate

Volume of oven-dry-rodded coarse aggregate per unit volume of concrete for different fineness moduli of fine aggregate (TABLE A1.5.3.6)

Nominal maximum size of aggregate (mm)

9.5 12.5 19

25 37.5 50 75 150 Fineness modulus of fine aggregates Nominal maximum size of aggregate Proportion of coarse aggregate in volume Weight of coarse aggregate per m3

2.4 0.5 0.59 0.66 0.71 0.75 0.78 0.82 0.87

2.6 0.48 0.57 0.64 0.69 0.73 0.76 0.8 0.85

2.8 0.46 0.55 0.62 0.67 0.71 0.74 0.78 0.83

3 0.44 0.53 0.6 0.65 0.69 0.72 0.76 0.81 2.40 19 mm 0.66 1056 Kg/m3

v ca=v*unit wt of dry rodded coarse aggregate

7 Weight of fine aggregate

First estimate of concrete weight (kg/m ) (TABLE A1.5.3.7.1)

Nominal maximum size of aggregate (mm) 9.5 12.5 19 25 37.5 50 75 150 Is air entrainment used Maximum size of aggregate Concrete weight Weighted average of specific gravity of coarse+fine aggregate when mixed theoretically exact calculation of fresh concrete (Unit mass of fresh concrete) Specific gravity of cement Air content Cement requirement Mixing water requirement Fine aggregate to be used 8 Moisture correction 8.1 Moisture correction for aggregates Moisture in fine aggregate Moisture in coarse aggregate Water required after reduction Actual quantity of fine aggregate Actual quantity of coarse aggregate Air-entrained concrete 2200 2230 2275 2290 2350 2345 2405 2435 Yes Um 19 mm 2275 kg/m3 Non-air entrained concrete 2280 2310 2345 2380 2410 2445 2490 2530

Ga=(spa+spf)/2 Um'=10*Ga*(100-A)+Cm*(1-Ga/Gc)-w*(Ga-1) Gc A Cm w f=con-c-w-ca

2.65 2191.57 Kg/m3 3.15 7.00 % 328.33 Kg/m3 197.00 693.67 Kg/m3

Iteration wfa=f*fm% wca=ca*cam% w=wfa-wca f=f+wfa ca=ca+wca

1 0.00 0 197.00 693.67 1056

2 0.00 0.00 197.00 693.67 1056.00 No 0.00 0.00 197.00 0.00

3 0.00 Kg 0.00 Kg

Unit

197.00 Kg=liters 693.67 Kg 1056.00 Kg

8.2 Is water reducer used Dosage of water reducer (if applied) as percentage of cement weight % of reduction in water (as given by the manufacturer) due to applied dosage of water reducer Adjusted water in mix Weight of water reducer 9 Final proportion by weight Ingredients Cement Fine aggregate Coarse aggregate Water Pozzolanic Materials Weight of water reducer Weight/m3 328.33 693.67 1056.00 197.00 0.00 0.00 Unit Kg/m3 Kg/m3 Kg/m3 Kg/m3 Kg/m3 Kg/m3 Proportion 1.00 2.11 3.22 0.60 0.00 0.00

% % Kg/m3 Kg/m3

ok ok

Weight of ingredients for given volume of concrete 328.33 693.67 1056.00 197.00 0.00 0.00

Unit Kg Kg Kg Kg Kg Kg

2 of 2

Potrebbero piacerti anche

- Diagnosis and Control of Alkali-Aggregate Reactions in ConcreteDocumento26 pagineDiagnosis and Control of Alkali-Aggregate Reactions in ConcreteIrfan OmarNessuna valutazione finora

- Aggregate and Concrete TestingDocumento32 pagineAggregate and Concrete TestingAdrian Liviu Bugea100% (1)

- 2a-Concrete Mix DesignDocumento21 pagine2a-Concrete Mix Designpankaj_paul6451Nessuna valutazione finora

- Concrete Mix DesignDocumento23 pagineConcrete Mix DesignSyahmi FadziNessuna valutazione finora

- Concrete Mixture OptimizationDocumento13 pagineConcrete Mixture OptimizationAbdo AtawyNessuna valutazione finora

- M-30 Concrete Mix Design As Per IS 10262-2009 & MORT&H A-1 Stipulations For Proportioning Grade Designation M30Documento4 pagineM-30 Concrete Mix Design As Per IS 10262-2009 & MORT&H A-1 Stipulations For Proportioning Grade Designation M30Kumkum MukherjeeNessuna valutazione finora

- MIX Proportioning: Design Consideration: Obtaining Good WorkabilityDocumento20 pagineMIX Proportioning: Design Consideration: Obtaining Good Workabilityshahid aliNessuna valutazione finora

- Concrete Mix Design Optimized ApproachDocumento8 pagineConcrete Mix Design Optimized ApproachHerman MwakoiNessuna valutazione finora

- Concrete Mix Design: Plant Class Date Water Cement (KG) Coarse Agg. (KG) Fine Agg. (KG) Admixture (LT)Documento6 pagineConcrete Mix Design: Plant Class Date Water Cement (KG) Coarse Agg. (KG) Fine Agg. (KG) Admixture (LT)Suara Jatim PostNessuna valutazione finora

- Optimal Mix Design For Pervious ConcreteDocumento9 pagineOptimal Mix Design For Pervious ConcretejanakarajNessuna valutazione finora

- CIP33-High Strenght ConcreteDocumento2 pagineCIP33-High Strenght Concrete7774R105Nessuna valutazione finora

- M 15 Mix Designs As Per IS-10262-2009Documento25 pagineM 15 Mix Designs As Per IS-10262-2009Prasad MsrkNessuna valutazione finora

- Chanakya Niti in HindiDocumento48 pagineChanakya Niti in HindiVineet Pandey100% (6)

- Presentation Admixture For ConcreteDocumento51 paginePresentation Admixture For Concretemohan mohanNessuna valutazione finora

- Self Compacting ConcreteDocumento16 pagineSelf Compacting ConcreteAnubhab GhoshNessuna valutazione finora

- Ropeways in Nepal PDFDocumento282 pagineRopeways in Nepal PDFnirmaljoshi100% (1)

- Design Mix Concrete/ RMC Proportioning - M 40: Annex ADocumento9 pagineDesign Mix Concrete/ RMC Proportioning - M 40: Annex AWilliam ReedNessuna valutazione finora

- Self Compacting Concrete - An Indian ScenarioDocumento9 pagineSelf Compacting Concrete - An Indian ScenariorajamaneeckemNessuna valutazione finora

- Self Compacting Concrete & Pre Placed ConcreteDocumento33 pagineSelf Compacting Concrete & Pre Placed Concretesanthu256100% (2)

- Crack Width As Per BS 8110Documento1 paginaCrack Width As Per BS 8110Pujan NeupaneNessuna valutazione finora

- IELTS Writing Answer SheetDocumento4 pagineIELTS Writing Answer SheetHighPoint IELTS Preparation Services, Inc.Nessuna valutazione finora

- Mix Design Using Is CodeDocumento67 pagineMix Design Using Is CodeNilesh SaksenaNessuna valutazione finora

- Final PDF of Standard SpecificationDocumento179 pagineFinal PDF of Standard SpecificationabualamalNessuna valutazione finora

- Use of Water ReducersDocumento7 pagineUse of Water ReducersVaibhav MehtaNessuna valutazione finora

- 3.3 Road Note No. 4-1Documento40 pagine3.3 Road Note No. 4-1Asad Choudhary100% (1)

- Concrete Lab Procedure 1Documento33 pagineConcrete Lab Procedure 1Lim Shwe WenNessuna valutazione finora

- Concrete Admixtures....Documento35 pagineConcrete Admixtures....santhu256100% (1)

- Accelerating Admixtures For ShotcreteDocumento7 pagineAccelerating Admixtures For Shotcreteneen61Nessuna valutazione finora

- Normal Concrete Mix DesignDocumento4 pagineNormal Concrete Mix Designmurnal0% (1)

- Self Compacted Concrete Seminar 1Documento57 pagineSelf Compacted Concrete Seminar 1aymanmohmed100% (1)

- 1 Hot Weather Concreting - PDFDocumento51 pagine1 Hot Weather Concreting - PDFYoumna ShatilaNessuna valutazione finora

- Mix Design Specification For Low Strength Concretes Containing Recycled and Secondary AggregatesDocumento15 pagineMix Design Specification For Low Strength Concretes Containing Recycled and Secondary AggregatesASearth100% (1)

- EFNARC European Specification For Sprayed Concrete Euro Concrete Spec EngDocumento35 pagineEFNARC European Specification For Sprayed Concrete Euro Concrete Spec Engengineerh100% (1)

- Engineering Materials: CementDocumento26 pagineEngineering Materials: CementSathvika KodimyalaNessuna valutazione finora

- Mix DesignDocumento29 pagineMix Designshahhassa9Nessuna valutazione finora

- ACI 207.1R-05 (Guide To Mass Concrete) PDFDocumento31 pagineACI 207.1R-05 (Guide To Mass Concrete) PDFyessicagodoy83% (6)

- RCC Thumb RuleDocumento7 pagineRCC Thumb RuleRahat ullah100% (6)

- Curing of ConcreteDocumento46 pagineCuring of Concretepmonica0850% (2)

- Mathcad-Isolated Foundation BBSDocumento20 pagineMathcad-Isolated Foundation BBSValentinNessuna valutazione finora

- Lab Manual HardenedDocumento190 pagineLab Manual HardenedmuhanadNessuna valutazione finora

- Concrete Mix DesignDocumento20 pagineConcrete Mix DesignRony BaloyiNessuna valutazione finora

- Mix Design As Per BSDocumento10 pagineMix Design As Per BSChetan SohalNessuna valutazione finora

- Self Consolidating ConcreteDocumento32 pagineSelf Consolidating ConcreteOmar NajmNessuna valutazione finora

- Pozzolana Role PDFDocumento36 paginePozzolana Role PDFOsman QaasimNessuna valutazione finora

- Silica Fume 5 PDFDocumento14 pagineSilica Fume 5 PDFNour KottiNessuna valutazione finora

- Concrete Mix Design For M65 Grade ConcreteDocumento12 pagineConcrete Mix Design For M65 Grade ConcreteDevendrasinh PadhiyarNessuna valutazione finora

- Setting and Hardening ConcreteDocumento24 pagineSetting and Hardening Concreteabdulwahab1175% (4)

- Self Compacting ConcreteDocumento27 pagineSelf Compacting ConcreteJatin MaggoNessuna valutazione finora

- APPLICATONS & LIMITATIONS of Self Compacting ConcreteDocumento38 pagineAPPLICATONS & LIMITATIONS of Self Compacting ConcretePrashant Sunagar100% (1)

- ACI Mix-Design Summary SheetDocumento3 pagineACI Mix-Design Summary SheetAbu ZaforNessuna valutazione finora

- 7-SCC C60 Mix Design MDC 2Documento1 pagina7-SCC C60 Mix Design MDC 2Kelly JuarezNessuna valutazione finora

- Fly Ash Cement Replacement Tds PDFDocumento2 pagineFly Ash Cement Replacement Tds PDFabualamalNessuna valutazione finora

- Testing Fresh Concrete: Participant Workbook Laboratory ManualDocumento42 pagineTesting Fresh Concrete: Participant Workbook Laboratory ManualMohammed J. Al-JubooriNessuna valutazione finora

- Setting Time of ConcreteDocumento2 pagineSetting Time of ConcretevempadareddyNessuna valutazione finora

- Concret CementDocumento29 pagineConcret CementKamal Hameed Al-taiy100% (1)

- Proportioning Concrete Mixtures With Graded AggregatesDocumento86 pagineProportioning Concrete Mixtures With Graded AggregatesM HAFEEZ RAJA100% (1)

- Mix Design 8 2Documento6 pagineMix Design 8 2Eulogio JameroNessuna valutazione finora

- Concrete Proportion and Concrete Mixture RatioDocumento58 pagineConcrete Proportion and Concrete Mixture RatioMicah VicenteNessuna valutazione finora

- 19 Self Compacting ConcreteDocumento33 pagine19 Self Compacting ConcreteSrijaJuluruNessuna valutazione finora

- Cement & Concrete 2023Documento42 pagineCement & Concrete 2023Joel MisaNessuna valutazione finora

- High Strength Concrete Mix DesignDocumento2 pagineHigh Strength Concrete Mix DesignKimo KenoNessuna valutazione finora

- 13 Melander-AASHTO M240 - ASTM C595 PDFDocumento0 pagine13 Melander-AASHTO M240 - ASTM C595 PDFErick AbarientosNessuna valutazione finora

- The Use and Abuse of The Slump Test For Measuring The Workability of Concrete PDFDocumento11 pagineThe Use and Abuse of The Slump Test For Measuring The Workability of Concrete PDFdep_vinNessuna valutazione finora

- Concrete Mix Design: by K.ShahDocumento48 pagineConcrete Mix Design: by K.ShahBùi Quang MinhNessuna valutazione finora

- 2.2 ACI Method of Mix DesignDocumento7 pagine2.2 ACI Method of Mix Designtiwari.dipesh001Nessuna valutazione finora

- Cc-Mix DesignDocumento37 pagineCc-Mix DesignManoj Kumar SinghNessuna valutazione finora

- Specific Gravity & Water Absorption Test (I S 2386 Iii/63)Documento11 pagineSpecific Gravity & Water Absorption Test (I S 2386 Iii/63)End EndNessuna valutazione finora

- Mix Design With SuperplasticizersDocumento8 pagineMix Design With SuperplasticizerskwameNessuna valutazione finora

- Appendix 1: Step 1Documento13 pagineAppendix 1: Step 1Akshit thakurNessuna valutazione finora

- MS Project 2007 Tutorial-Final VersionDocumento61 pagineMS Project 2007 Tutorial-Final Versionlimmil100% (1)

- MelamchiDocumento2 pagineMelamchinirmaljoshiNessuna valutazione finora

- Afno MancheDocumento16 pagineAfno ManchenirmaljoshiNessuna valutazione finora

- Sketches Model PDFDocumento1 paginaSketches Model PDFnirmaljoshiNessuna valutazione finora

- Gopal Pande: The First Mathematician of Nepal: March 2013Documento2 pagineGopal Pande: The First Mathematician of Nepal: March 2013nirmaljoshiNessuna valutazione finora

- 76Documento203 pagine76gutenbergNessuna valutazione finora

- Amara Et Al-English PDFDocumento11 pagineAmara Et Al-English PDFnirmaljoshiNessuna valutazione finora

- Curriculum Vitae (CV) : Aabiral Engineering and Construction Pvt. LTDDocumento1 paginaCurriculum Vitae (CV) : Aabiral Engineering and Construction Pvt. LTDnirmaljoshiNessuna valutazione finora

- Watch PriceDocumento2 pagineWatch PricenirmaljoshiNessuna valutazione finora

- AnalayisDocumento5 pagineAnalayisnirmaljoshiNessuna valutazione finora

- Experiment Setup ModelDocumento1 paginaExperiment Setup ModelnirmaljoshiNessuna valutazione finora

- Modification of Sealing of Radial Gate PDFDocumento1 paginaModification of Sealing of Radial Gate PDFnirmaljoshiNessuna valutazione finora

- Aac PoreDocumento8 pagineAac PorenirmaljoshiNessuna valutazione finora

- CrossingsDocumento47 pagineCrossingsnirmaljoshiNessuna valutazione finora

- Date Main Work Sub Works 1 Sub Works 2Documento1 paginaDate Main Work Sub Works 1 Sub Works 2nirmaljoshiNessuna valutazione finora

- Casio ManualDocumento7 pagineCasio ManualnirmaljoshiNessuna valutazione finora

- Questionnaire (Domestic Participants)Documento2 pagineQuestionnaire (Domestic Participants)nirmaljoshiNessuna valutazione finora

- Realization of The Dhamma - Sayadaw U DhammapiyaDocumento138 pagineRealization of The Dhamma - Sayadaw U DhammapiyaDhamma Thought100% (1)

- Basic Kanji Book Vol 1 & 2Documento460 pagineBasic Kanji Book Vol 1 & 2api-370005096% (67)

- File 53735Documento109 pagineFile 53735Evgeny BobryashovNessuna valutazione finora

- Slab Experiment 57 Days: ID Task Mode Task Name Duration PredecessorsDocumento1 paginaSlab Experiment 57 Days: ID Task Mode Task Name Duration PredecessorsnirmaljoshiNessuna valutazione finora

- Nepal AdventureDocumento21 pagineNepal AdventurenirmaljoshiNessuna valutazione finora

- Zielke E521 ProjectDocumento44 pagineZielke E521 ProjectsahooraNessuna valutazione finora

- SEEPW 2007 Engineering BookDocumento319 pagineSEEPW 2007 Engineering BooknirmaljoshiNessuna valutazione finora

- Report AssignmentDocumento12 pagineReport AssignmentnirmaljoshiNessuna valutazione finora

- Separadores para HormigonDocumento2 pagineSeparadores para HormigonpablopelaNessuna valutazione finora

- Effect of Nano Silica On The Compressive Strength of ConcreteDocumento4 pagineEffect of Nano Silica On The Compressive Strength of ConcreteEditor IJTSRDNessuna valutazione finora

- Bonafide Certificate: Signature SignatureDocumento8 pagineBonafide Certificate: Signature SignatureMOHAMED RIYAAZ N ANessuna valutazione finora

- ATT - 1.2.0 - Global GC Bid Template MV1 - CGK-063 - CIVIL EXT WORKS REVDocumento2 pagineATT - 1.2.0 - Global GC Bid Template MV1 - CGK-063 - CIVIL EXT WORKS REVDeri AnggaraNessuna valutazione finora

- Precast ConcreteDocumento9 paginePrecast ConcreteAmulyaReddy ThummetiNessuna valutazione finora

- Input Data in Green Cells: Phils. Standard Reinforcing BarsDocumento10 pagineInput Data in Green Cells: Phils. Standard Reinforcing BarsreynoldNessuna valutazione finora

- Fimi 19133 PTSD Mvis1 001 - CDocumento1 paginaFimi 19133 PTSD Mvis1 001 - CMacneoNessuna valutazione finora

- Sulphate Resisting Cement Product Data SheetDocumento3 pagineSulphate Resisting Cement Product Data SheetAnoop Kumar SharmaNessuna valutazione finora

- Industrial Training ReportDocumento11 pagineIndustrial Training ReportAashu MahlaNessuna valutazione finora

- Mini Project PPT FinalDocumento25 pagineMini Project PPT FinalabcdNessuna valutazione finora

- Engineering MaterialsDocumento61 pagineEngineering MaterialsAlvee AyonNessuna valutazione finora

- Formative Assessment 3: Title: Exercise in Estimating Materials in Concrete Works and Earth WorksDocumento7 pagineFormative Assessment 3: Title: Exercise in Estimating Materials in Concrete Works and Earth WorksbumrocksmusicNessuna valutazione finora

- Investigation of The Effect of Palm Bunch Ash On Concrete PropertiesDocumento6 pagineInvestigation of The Effect of Palm Bunch Ash On Concrete PropertiesJonatan Porras PeñaNessuna valutazione finora

- Indian Standard: Specification FOR Lime-Pozzolana Concrete Blocks For Paving (FirstDocumento11 pagineIndian Standard: Specification FOR Lime-Pozzolana Concrete Blocks For Paving (FirstrajjaNessuna valutazione finora

- Setting:-: Concrete Technology (I) Lecture 5Documento10 pagineSetting:-: Concrete Technology (I) Lecture 5Mahmoud HosnyNessuna valutazione finora

- Lusail Katara Hotel, Lusail District, Doha INSPECTION REQUEST LOG Date 7/8/2016Documento1 paginaLusail Katara Hotel, Lusail District, Doha INSPECTION REQUEST LOG Date 7/8/2016edla3710Nessuna valutazione finora

- Bond Strength of Coconut Shell Aggregate Concrete by Pull-Out TestDocumento14 pagineBond Strength of Coconut Shell Aggregate Concrete by Pull-Out TestlintianananNessuna valutazione finora

- Astm-C129 CompressDocumento4 pagineAstm-C129 CompressAlex MolinaNessuna valutazione finora

- نسخة من 550.5-18 Code Requirements for the Design of Precast Concrete Diaphragms for Earthquake Motions and CommentaryDocumento28 pagineنسخة من 550.5-18 Code Requirements for the Design of Precast Concrete Diaphragms for Earthquake Motions and CommentarywalidkcNessuna valutazione finora

- Bridge Design Standard For LGEDDocumento7 pagineBridge Design Standard For LGEDZubayer Ibna ZahidNessuna valutazione finora

- Cement Mix Ratio GuideDocumento5 pagineCement Mix Ratio Guidelebron100% (1)

- Upang Cea Bsce Year-3 p1Documento81 pagineUpang Cea Bsce Year-3 p1Jaira Pitogo MasuangatNessuna valutazione finora

- Meti Fina STRDocumento1 paginaMeti Fina STRAbdi YonasNessuna valutazione finora

- Rebar Contract VS ExecutedDocumento3 pagineRebar Contract VS ExecutedAbdulselam MaruNessuna valutazione finora

- Method Statement For Pipe Culvert Anil SahabDocumento2 pagineMethod Statement For Pipe Culvert Anil SahabAsad AshfaqNessuna valutazione finora