Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bollhoff Rivkle - Blind Rivet Nut With Slotted Shank

Caricato da

Ace Industrial SuppliesCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bollhoff Rivkle - Blind Rivet Nut With Slotted Shank

Caricato da

Ace Industrial SuppliesCopyright:

Formati disponibili

2375/03.

02

Blind rivet nuts with slotted shank

RIVKLE PN

Blind rivet nuts and tools for ultimate tear resistance designed for use in plastic and thin sheet metal.

sa l

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

RIVKLE PN for ultimate pull-out force values.

The RIVKLE PN blind rivet nut has been specially designed for integrating into thin-walled sheet steel, hollow sections or synthetic parts requiring high pull-out forces. The slotted shank splays out into four petals on the blind side of the base material, thus offering a large bearing surface and ensuring maximum pull-out force. Additional design benefits of RIVKLE PN are: s In addition, the RIVKLE PN displays the largest clamping area of the range of blind rivet nuts for variable thicknesses of material s Large clamping area to reinforce the workpiece s Minimal radial stresses in the setting process to avoid the risk of breakage on soft or fragile materials s Available in steel, aluminium and stainless steel s Available in thread sizes M 4 to M 10 (non-metric/imperial measurements on request)

Pultruded plastic

Rotoformed plastic

Thin-walled sheet

RIVKLE PN Pre-Bulbed (on request)

The Pre-Bulbed RIVKLE PN blind rivet nut features all the functions and advantages of the standard design. In addition, thanks to its gentle pre-splaying, torque can be applied to the fastener as it is being assembled with a pneumatic riveting tool. Assembly is also possible using a simple, inexpensive manual key mounting tool, which can be supplied to the customer together with Pre-Bulbed RIVKLE PN (in which case a standard screw will have to be substituted for the riveted joint when assembling the screwdown component).

Impressive pull-out resistance

The following table compares pull-out forces for the standard RIVKLE blind rivet nut and the RIVKLE PN blind rivet nut in the materials illustrated above.

Blind rivet nut type 0.76 mm steel 2.92 mm vinyl extrusion 6.29 mm pultruded plastic 6.76 kN 3.04 mm rotoformed plastic 0.1 kN 1.65 mm SMC plastic 0.6 kN 4.69 mm blow-moulded plastic 1.25 kN

RIVKLE RIVKLE PN

sa l

2.13 kN

5.40 kN

Note: Pull-out testing was conducted with a circular holding-down plate, dia. 65 mm. Bllhoff recommends testing under real application conditions in order to determine the exact pull-out force.

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

SMC plastic

0.9 kN 2.75 kN 8.40 kN 0.7 kN 1.62 kN

Vinyl extrusion

Blow-moulded plastic

3.22 kN

Customer-specific assembly tools

C 302: Pneumatic assembly tool

With the C 302 setting tool, all types of blind rivet nuts from the RIVKLE PN range can be mounted. For constant material thicknesses, the setting stroke can be adjusted to that of the blind rivet nut in question (tension setting: stroke regulated). For applications with multiple or variable material thicknesses, the setting stroke can be maximized and the compressed air supply to the tool restricted so that the tool always sets the blind rivet nut correctly (tension setting: power regulated). Thanks to this dual capability, the C 302 is an extremely versatile setting tool.

The setting process: Four simple steps

Winding onto the tool mandrel

sa l

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

s Cycle time: up to 2 / min. s Max. setting stroke: 6 mm Insertion into the location hole Clenching Unwinding

s s s s

Cycle time: 15 to 20 / min. Weight: 2.8 kg Max. setting stroke: 12.7 mm Max. setting power: 26.7 kN

Of course, all blind rivet nuts from the standard range can be riveted with the C 302 as well.

Type S: One-dimensional manual installation tool

One-dimensional riveting tool with helical gearing. Winds the RIVKLE PN blind rivet nut on and off manually by means of a crank handle and key (included in scope of delivery).

This tool is supplied with a nose pece and threaded mandrel for a single dimension (e.g. M 6).

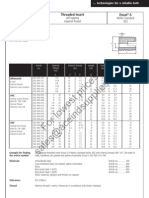

RIVKLE PN Technical data

The RIVKLE PN blind rivet nut was designed to achieve maximum pull-out resistance in thin-walled sheet metal and plastic. The slotted shank splays out into four petals, thereby presenting a large closing head bearing area on the blind side of the base material. In addition, the RIVKLE PN displays the largest clamping area of the range of blind rivet nuts.

H

E

All dimensions given in millimetres d

Measurements

Clamping area

M 4 x 0.7 M 5 x 0.8 M 6 x 1.0 M 8 x 1.25 M 10 x 1.50

0.50-3.80 0.50-4.45 0.50-7.10 0.50-7.10 0.50-7.10

Note 1: Also available in stainless steel and aluminium materials upon request. Note 2: Countersunk head, non-standard measurements, finishes or design modifications upon request.

Business Unit Fastening and Assembly Technology P.O. Box 14 02 29 33622 Bielefeld Archimedesstrae 1 4 33649 Bielefeld Germany Phone (+49) 5 21 / 44 82 - 03 (-2 32) Fax (+49) 5 21 / 44 8 2 - 3 71 Internet www.boellhoff.com E-mail ihoernlein@boellhoff.de

sa l

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

H D E B L L2

Location hole Min. Max. Max. shank dia. Headthickness Head dia. Total length Assembled length

Thread tolerance: 6 H Material: steel Surface: 8 Zinc Di-Chromate

L2

Part No.

6.13 7.48 8.80

6.25 7.62 8.93

6.12 7.47 8.79

0.96 0.96 1.50

11.1 12.7 15.9

17.6 22.0 26.9

8.6 9.9

6683 041 1038 6683 051 1044

12.8

6683 061 1071

11.11

11.50

11.10

1.57

19.0

30.5

14.5

6683 081 1071

13.07

13.26

13.06

2.24

22.2

33.2

15.8

6683 101 1071

Potrebbero piacerti anche

- PowerCoil Screw Thread InsertsDocumento103 paginePowerCoil Screw Thread InsertsAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Insert Specs ImperialDocumento1 paginaHeliCoil Insert Specs ImperialAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Product RangeDocumento40 pagineHeliCoil Product RangeAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Stud-Lock InsertsDocumento2 pagineHeliCoil Stud-Lock InsertsAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Self Tapping InsertsDocumento4 pagineHeliCoil Self Tapping InsertsAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Stud-Lock ApplicationsDocumento2 pagineHeliCoil Stud-Lock ApplicationsAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Tangless ApplicationsDocumento2 pagineHeliCoil Tangless ApplicationsAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Insert Specs MetricDocumento1 paginaHeliCoil Insert Specs MetricAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Serrated Spark Plug InsertsDocumento4 pagineHeliCoil Serrated Spark Plug InsertsAce Industrial Supplies100% (1)

- HeliCoil Tangless Gall Resistant InsertsDocumento2 pagineHeliCoil Tangless Gall Resistant InsertsAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Pipe Thread Inserts NPT ANPT NPSCDocumento8 pagineHeliCoil Pipe Thread Inserts NPT ANPT NPSCAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Screw Thread InsertsDocumento36 pagineHeliCoil Screw Thread InsertsAce Industrial Supplies0% (1)

- HeliCoil Aftermarket Kits Oxygen SensorDocumento1 paginaHeliCoil Aftermarket Kits Oxygen SensorAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Gall Resistant InsertsDocumento2 pagineHeliCoil Gall Resistant InsertsAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Primer Free II ApplicationsDocumento2 pagineHeliCoil Primer Free II ApplicationsAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Primer Free II InsertsDocumento2 pagineHeliCoil Primer Free II InsertsAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Aftermarket KIts Sav-A-Thread HTDocumento1 paginaHeliCoil Aftermarket KIts Sav-A-Thread HTAce Industrial SuppliesNessuna valutazione finora

- HeliCoil NPT Inserts 8UNDocumento4 pagineHeliCoil NPT Inserts 8UNAce Industrial SuppliesNessuna valutazione finora

- Bollhoff Rivkle RivnutsDocumento52 pagineBollhoff Rivkle RivnutsAce Industrial SuppliesNessuna valutazione finora

- HeliCoil NPT Inserts 8UN 2Documento2 pagineHeliCoil NPT Inserts 8UN 2Ace Industrial SuppliesNessuna valutazione finora

- Ripp Lock WashersDocumento8 pagineRipp Lock WashersAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Aftermarket Catalogue 2Documento24 pagineHeliCoil Aftermarket Catalogue 2Ace Industrial SuppliesNessuna valutazione finora

- Ensat Self Tapping Inserts 307 308 SeriesDocumento1 paginaEnsat Self Tapping Inserts 307 308 SeriesAce Industrial SuppliesNessuna valutazione finora

- Ensat Self Tapping Inserts 302 Series ImperialDocumento1 paginaEnsat Self Tapping Inserts 302 Series ImperialAce Industrial SuppliesNessuna valutazione finora

- Ensat Self Tapping Inserts 303 SeriesDocumento1 paginaEnsat Self Tapping Inserts 303 SeriesAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Aftermarket CatalogueDocumento24 pagineHeliCoil Aftermarket CatalogueAce Industrial SuppliesNessuna valutazione finora

- RivclinchDocumento28 pagineRivclinchAce Industrial SuppliesNessuna valutazione finora

- Ensat Self Tapping Inserts 302 Series MetricDocumento1 paginaEnsat Self Tapping Inserts 302 Series MetricAce Industrial SuppliesNessuna valutazione finora

- HeliCoil Aftermarket Kits Head Bolt Thread RepairDocumento1 paginaHeliCoil Aftermarket Kits Head Bolt Thread RepairAce Industrial SuppliesNessuna valutazione finora

- WTI Screw Thread InsertsDocumento16 pagineWTI Screw Thread InsertsAce Industrial SuppliesNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Balinghasay V CastilloDocumento1 paginaBalinghasay V CastilloMirella100% (3)

- Amine Processing Unit DEADocumento9 pagineAmine Processing Unit DEAFlorin Daniel AnghelNessuna valutazione finora

- Chapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsDocumento27 pagineChapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsEdwin ChuenNessuna valutazione finora

- DU Series MCCB CatalogueDocumento8 pagineDU Series MCCB Cataloguerobinknit2009Nessuna valutazione finora

- Propp Function's Types:: 1-Absentation: One of The Members of A Family Absents Himself From HomeDocumento10 paginePropp Function's Types:: 1-Absentation: One of The Members of A Family Absents Himself From HomeRohith KumarNessuna valutazione finora

- 30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Documento64 pagine30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Trần MaiNessuna valutazione finora

- Topic 6 Nested For LoopsDocumento21 pagineTopic 6 Nested For Loopsthbull02Nessuna valutazione finora

- Zkp8006 Posperu Inc SacDocumento2 pagineZkp8006 Posperu Inc SacANDREA BRUNO SOLANONessuna valutazione finora

- Bloomsbury Fashion Central - Designing Children's WearDocumento16 pagineBloomsbury Fashion Central - Designing Children's WearANURAG JOSEPHNessuna valutazione finora

- Old Highland Park Baptist Church E01Documento74 pagineOld Highland Park Baptist Church E01Lawrence Garner100% (2)

- Activity Sheet Housekeeping Week - 8 - Grades 9-10Documento5 pagineActivity Sheet Housekeeping Week - 8 - Grades 9-10Anne AlejandrinoNessuna valutazione finora

- Technical and Business WritingDocumento3 pagineTechnical and Business WritingMuhammad FaisalNessuna valutazione finora

- GSM Radio ConceptsDocumento3 pagineGSM Radio ConceptsMD SahidNessuna valutazione finora

- O Repensar Da Fonoaudiologia Na Epistemologia CienDocumento5 pagineO Repensar Da Fonoaudiologia Na Epistemologia CienClaudilla L.Nessuna valutazione finora

- Menara PMB Assessment Criteria Score SummaryDocumento2 pagineMenara PMB Assessment Criteria Score SummarySyerifaizal Hj. MustaphaNessuna valutazione finora

- B2B Marketing: Chapter-8Documento23 pagineB2B Marketing: Chapter-8Saurabh JainNessuna valutazione finora

- Financial Statement AnalysisDocumento18 pagineFinancial Statement AnalysisAbdul MajeedNessuna valutazione finora

- Little: PrinceDocumento18 pagineLittle: PrinceNara Serrano94% (18)

- CCNP SWITCH 300-115 - Outline of The Official Study GuideDocumento31 pagineCCNP SWITCH 300-115 - Outline of The Official Study GuidehammiesinkNessuna valutazione finora

- Silk Road Ensemble in Chapel HillDocumento1 paginaSilk Road Ensemble in Chapel HillEmil KangNessuna valutazione finora

- Operation of A CRT MonitorDocumento8 pagineOperation of A CRT MonitorHarry W. HadelichNessuna valutazione finora

- Gummy Bear Story RubricDocumento1 paginaGummy Bear Story Rubricapi-365008921Nessuna valutazione finora

- 1ST Term J1 Fine Art-1Documento22 pagine1ST Term J1 Fine Art-1Peter Omovigho Dugbo100% (1)

- Singer 900 Series Service ManualDocumento188 pagineSinger 900 Series Service ManualGinny RossNessuna valutazione finora

- Invitation of Nomination For The Rajiv Gandhi Wildlife Conservation Award For The Year 2011&2012Documento2 pagineInvitation of Nomination For The Rajiv Gandhi Wildlife Conservation Award For The Year 2011&2012Naresh KadyanNessuna valutazione finora

- Intertext: HypertextDocumento8 pagineIntertext: HypertextRaihana MacabandingNessuna valutazione finora

- Johari WindowDocumento7 pagineJohari WindowSarthak Priyank VermaNessuna valutazione finora

- I. Objectives:: Semi-Detailed Lesson Plan in Reading and Writing (Grade 11)Documento5 pagineI. Objectives:: Semi-Detailed Lesson Plan in Reading and Writing (Grade 11)Shelton Lyndon CemanesNessuna valutazione finora

- Elementary Electronics 1968-09-10Documento108 pagineElementary Electronics 1968-09-10Jim ToewsNessuna valutazione finora

- Fire Guard Study MaterialDocumento14 pagineFire Guard Study MaterialSerina Sanusi100% (1)