Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sarvani Profile

Caricato da

dox4printCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sarvani Profile

Caricato da

dox4printCopyright:

Formati disponibili

SARVANI READYMIX CONCRETE INDUSTRY

PROFILE

CONTENTS Introduction Company data Products Quality Capacity & equipment Structure References PAGE 1 2 3 4 5 9 10 SARVANIS GOAL To become market leader in readymix concrete Industry and achieve Benchmark in quality and service. SARVANI QUALITY POLICY To provide best quality readymix concrete at most competitive price and in time delivery by continuous improvement of process techniques and Service the customer to his best satisfaction.

INTRODUCTION

Sarvani Ready Mix Concrete Industry was started in the

year 2003 under the able Leadership of Sri P.Gopala Reddy, Managing Director having enormous experience in cement industry. Sri P. Gopala Reddy, with his innovative idea, introduced Ready Mix Concrete first time in coastal Andhra Pradesh located at Kolanukonda Village, Tadepalli Mandal, Guntur Dist. near Vijayawada. The new concept has brought revolutionary change in construction segment of Krishna and Guntur Districts. At the same time Sarvani RMC contributed for speedy and timely completion of major projects and constructions in the region.. Later, in the year 2005, a new RMC unit was started at our capital city Hyderabad which has gained confidence of Builders , Architects and Engineers of both Public & Private Sectors for maintaining consistent quality and prompt service. Subsequently, three more Units were established, one at Visakhapatnam in March 2007, one at Guntur in February 2010 and one at Atchutapuram, Visakhapatnam in November 2010 with most sophisticated German Technology, each having a capacity of 60 cubic meters per hour. In addition to these, three more dedicated Plants have been set up two at Hyderabad and one at Visakhapatnam in 2010. Sarvani RMC is the exclusive unit in Andhra Pradesh for its successful supply of quality concrete to various clients, public/private/other major projects, having units at Vijayawada/Guntur/Hyderabad/Visakhapatnam/Atchutapuram . As a part of expansion programme. Company is planning to open new units at major towns of AP in the year 2011

COMPANY DATA Sarvani Readymix Cocnrete Industry Ho & VJA Plant: Sy.No.17/1, Cement factory Road, Kolanukonda Village, Tadepalli Mandal, Guntur Dist, A.P. PIN 522502 Fax: 08645-246166 E-Mail: sarvanirmc@yahoo.co.in Website: www.sarvanirmc.com The Company is managed by a team of experienced professionals under the leadership of P.Gopala Reddy Managing partner who has vast experience in Cement and Infrastructure industry. Our Bankers are Syndicate Bank, Labbipet branch. We are having CC Limit of Rs.350 Lakhs with this bank. We are engaged in the manufacture and supply of Readymix Concrete. Also we establish and operate RMC plants at Customer project sites. We are having 350 dedicated employees across our facilities in A.P. Contact Person 1. P.Gopala Reddy - 9989521279 2. D.V.Krishna Reddy 9676891717 3. N.Satyanarayana - 9989521285 4. Y.Brahma Reddy - 9701110303 5. P.Srinivas 9989521272 6. N.Emmanuel 9989521271 7. P.Mallikhajuna Rao 9989521240 Function Overall Incharge Marketing Manager Quality Control Manager - Accounts Asst.Manager Production Guntur & Vijayawada plants Asst.Manager Production Vizag Manager Hyderabad plant

Ours is a firm registered under Indian partnership Act.

PRODUCTS

We manufacture and supply concrete of various grades as per ISI design Or as per Customer design mix i.e M-7.5, M-10, M-15, M-20, M-25, M30, M-35, M-40, M-45 and M-50. We also Manufacuure Screed type Concrete. We also Manufacutre cool Concrete We will also undertake transport and pumping of all type of Concrete.

QUALITY CONTROL PLAN FOR RAW MATERIALS

RAW MATERIAL TESTING PLAN

1. Testing plan for Acceptance during Introduction / Source Approval Raw Material Fine Aggregate (Sand) IS Codes for reference IS 383 (Specification s) IS 2386 (Test methods) Internal Laboratory Tests Grading analysis Fineness modulus Specific gravity Bulk Density Silt content Deleterious materials Water absorption Surface Moisture Grading analysis Specific gravity Bulk Density Deleterious materials Flakiness Index Elongation Index Water absorption Surface moisture Impact Value Crushing Value External Laboratory Tests All the tests mentioned in the Internal Laboratory and Other chemical tests such as Aggregate-alkali reactivity

Coarse Aggregate s

IS 383 (Specs) IS 2386 (Test methods)

All the tests mentioned in the Internal Laboratory and other chemical tests such as Aggregate-alkali reactivity

Cement

IS 8112, IS12269, IS 455 (Specification sdepending on the type of cement) IS 4031 (Test methods)

Physical properties such as Setting times 3 days, 7 days and 28 days compressive strength with standard cement mortar cubes

Physical and Chemical properties Third Party Certification from the Suppliers

Admixture

IS 9103 (Specification s) IS 8142 (Concrete Setting Time)

Evaluation of admixture based on trial mixes for: Water reduction efficiency Slump Retention over a period of time Concrete setting time

Third Party Certification from the Supplier

Water

IS 456 (Specification s) IS 3025 (Test methods)

..

Permissible limits of solids Chlorides Sulphates Ph value Suspended matter Water neutralization

List of Laboratory Equipments General: Electronic Balance Electric Oven Cement Testing Cement mortar cube Vibrating Machine Vicat Apparatus with consistency needle and setting time needles 70.7 mm cube moulds Le-Chatelier Flask Digital Compression Testing Machine of 2000 KN capacity Blaines Apparatus Aggregate Testing Set of IS Sieves for carrying out grading analysis of sand Set of IS Sieves for carrying out grading analysis of coarse aggregates Impact Value Apparatus Crushing Value apparatus Los Angeles Abrasion Value Apparatus Pycnometers for conducting specific gravity test of aggregates Thickness gauge for conducting Flakiness Index of Coarse aggregates Length gauge for conducting Elongation Index of Coarse aggregates Bulk Density Measures Concrete 150 mm Cube Moulds Slump Cone Apparatus

Air Entrainment meter Penetrometer for evaluating Setting times of fresh concrete Laboratory concrete mixer Yield measurement measure Digital Compression Testing Machine of 2000KN capacity Vibrating Table

CAPACITY & EQUIPMENT The company is one of the few companies having their own full fledged equipment detailed below. Batching Plants CP30 Model 4 Nos. Batching Plants - M1 Model - 1 No Batching Plants H1.25 Model 3 No The Combined capacity of Batching plants is over 6 lakh cu.M. In addition we have 59 Transit Mixers 20 Cement Bulkers 16 Concrete pumps 8 Hyva Tippers 9 Loaders

ORGANAISATION CHART

MANAGING PARTNER HO FINANCE & ACCOUNTS ACCOUNTS PERSONNEL PURCHASE STORES UNITS PLANT MANAGER Q.C.DEPT PROD.DEPT. TRANSPORT ACCOUNTS

REFERENCES SARVANI has supplied readymix Concrete to various prestigious projects and establishments like Vijayawada & Guntur 1.Star Hotels like Gateway Hotel, Murali fortune, Leila hotel 2. IJM India Infrastructure Limited 3. Wall mart 4. Engineering Colleges Like Siddhartha, KLC, SRK 5. Schools Like Kenedy, Chaitanya 6. Commercial Complexes Like Varun Motors, Reliance stores 7. CCRoads and Water tanks of VMC 8. Railway Plotforms 7. Vijayawada Airport Hyderabad 1.Fortune fields apartments and Villas of Indu projects Ltd. 2. JNTU Engineering college,Yellaki engineering college. 3. Ramky Infrastructure projects 4. Chalte Hotel at Raheja IT Park. 5. Lahari Homes 6. Vijaynirman Company Ltd AERO SEZ -Shamshabad 7. Vijaynirman Company Ltd ESI Hospital - Erragadda Visakhapatnam 1.SBEC projects at Vizag SEZ 2. Ankur Projects Reddy lab factory 3. MVR Infrastructure projects Asilmetla Flyover 4. Chandana Bros multiplex 5. Engineering Colleges Like VTC,Vignan 6. Vijay Nirman Company Ltd - HP Petro Park 7. Sarojini Eng.works - Abhijeet Ferrotech Ltd VSEZ Plant

The years to come will see more project orders. Besides Product development, Focus will be on better service and competitive.

Potrebbero piacerti anche

- Renuka TantramDocumento110 pagineRenuka TantramPravin Patil100% (1)

- How To Crack CLAT - Know It From ExpertsDocumento11 pagineHow To Crack CLAT - Know It From Expertschandra lekha100% (1)

- Sai Techno Logist Catlouge PDFDocumento16 pagineSai Techno Logist Catlouge PDFGanesh KumarNessuna valutazione finora

- Rsume - Production EngineerDocumento4 pagineRsume - Production Engineerdayashankar dubeyNessuna valutazione finora

- Source Approval Kataline Part 1Documento11 pagineSource Approval Kataline Part 1Arun KumarNessuna valutazione finora

- Shivam ReportDocumento29 pagineShivam ReportMAHAKAL LOGISTICSNessuna valutazione finora

- Company Profile 2Documento7 pagineCompany Profile 2R Saravana KumarNessuna valutazione finora

- To Find Out The Scope of Submersible Pumps in Present Era of AgricultureDocumento84 pagineTo Find Out The Scope of Submersible Pumps in Present Era of Agricultureshahinnocent100% (1)

- ACC INDIA Company ProfileDocumento5 pagineACC INDIA Company Profilevarunk060504Nessuna valutazione finora

- ICCTI South India Brochure 12.12.13Documento2 pagineICCTI South India Brochure 12.12.13bjreddy930Nessuna valutazione finora

- Acc Report On RMC Industry in AhmedabadDocumento43 pagineAcc Report On RMC Industry in AhmedabadMaulik Padh100% (1)

- Subburu Resume New 2Documento5 pagineSubburu Resume New 2SUBRAMANIAN SUBBURUNessuna valutazione finora

- A Project Report To Be Submitted To The Saurashtra University in Partial Fulfillment of The Requirements For The Award of The Degree ofDocumento22 pagineA Project Report To Be Submitted To The Saurashtra University in Partial Fulfillment of The Requirements For The Award of The Degree ofAkshat Utsav DhànshaNessuna valutazione finora

- Winter Internship Report (23/09/2016 - 31/01/2017)Documento56 pagineWinter Internship Report (23/09/2016 - 31/01/2017)AyushNessuna valutazione finora

- Project CaseDocumento4 pagineProject CasesagarNessuna valutazione finora

- Corporate Profile ShivajiDocumento9 pagineCorporate Profile Shivajipinak powerNessuna valutazione finora

- Company ProfileDocumento3 pagineCompany Profilesalil kumar padhyNessuna valutazione finora

- Sachin Sharma ProfileDocumento45 pagineSachin Sharma ProfileSandip PurohitNessuna valutazione finora

- Comtech Metal Company Profile As On 30.04.2011Documento17 pagineComtech Metal Company Profile As On 30.04.2011palsNessuna valutazione finora

- Resume (Gopi) QCDocumento5 pagineResume (Gopi) QCP.Hari PrasadNessuna valutazione finora

- Hincol Company ProfileDocumento9 pagineHincol Company ProfileVenkateswaraRaoPothinaNessuna valutazione finora

- Hincol - Company ProfileDocumento9 pagineHincol - Company Profilevenkateswara rao PothinaNessuna valutazione finora

- Introduction Brochure v50Documento4 pagineIntroduction Brochure v50vivek guptaNessuna valutazione finora

- INDCARE - ProfileDocumento7 pagineINDCARE - ProfileB ManoranjanNessuna valutazione finora

- Cement Testing ServicesDocumento18 pagineCement Testing Servicessiddhi jadhavNessuna valutazione finora

- Showpreview BC India Participants Australia 2013Documento58 pagineShowpreview BC India Participants Australia 2013indusexposiumNessuna valutazione finora

- Heritage Infraspace Private LimitedDocumento10 pagineHeritage Infraspace Private LimitedGagan GoswamiNessuna valutazione finora

- Shri Vile Parle Kelavani Mandal's Narsee Monjee College of Commerce & Economics (Autonomous)Documento9 pagineShri Vile Parle Kelavani Mandal's Narsee Monjee College of Commerce & Economics (Autonomous)Rishit SanghviNessuna valutazione finora

- Krishna Mech EngineerDocumento6 pagineKrishna Mech EngineeranjeeNessuna valutazione finora

- Vetrivel Engineering Enterprises ProfileDocumento34 pagineVetrivel Engineering Enterprises ProfileDinesh Babu PugalenthiNessuna valutazione finora

- RBK Profile JRILDocumento31 pagineRBK Profile JRILrbk.tendersNessuna valutazione finora

- Aea ProfileDocumento23 pagineAea ProfileNeevinternational NeevNessuna valutazione finora

- Company Profile ConDocumento4 pagineCompany Profile ConSudipThapaNessuna valutazione finora

- Submission of Product Approval For Segment Bolts, Nuts, Washers & Grommet From Delhi Industries P20C30TU02PRW-LANT-QMSDOCMAL-00031Documento19 pagineSubmission of Product Approval For Segment Bolts, Nuts, Washers & Grommet From Delhi Industries P20C30TU02PRW-LANT-QMSDOCMAL-00031subhash kumarNessuna valutazione finora

- Isorropia Structures PVT - LTD.: Info@isorropia - in Web Site: WWW - Isorropia.in Google Map: "Isorropia Structures"Documento8 pagineIsorropia Structures PVT - LTD.: Info@isorropia - in Web Site: WWW - Isorropia.in Google Map: "Isorropia Structures"isorropia structures Pvt LtdNessuna valutazione finora

- MCOG Eng & Fab PVT LTDDocumento16 pagineMCOG Eng & Fab PVT LTDEliyas YesudossNessuna valutazione finora

- Company Analysis Of: Prof. Nikhil Ranjan Barat Dr. Kaustav GhoshDocumento17 pagineCompany Analysis Of: Prof. Nikhil Ranjan Barat Dr. Kaustav GhoshPiyali BhattacharjeeNessuna valutazione finora

- Jaypee ProjectDocumento13 pagineJaypee Projectjituyadav421Nessuna valutazione finora

- ACC Cement LakheriDocumento54 pagineACC Cement Lakherikeshav181100% (4)

- Attachment (5) Rohit ProjectDocumento73 pagineAttachment (5) Rohit ProjectMakwana RahuLNessuna valutazione finora

- IVCC Brief Profile Introductory LetterDocumento3 pagineIVCC Brief Profile Introductory LetterZohair Ahmed Ataullah100% (1)

- J.K.cemeNT LTD Manufacturing Process and Financial ActivitiesDocumento102 pagineJ.K.cemeNT LTD Manufacturing Process and Financial ActivitiesJitendra VirahyasNessuna valutazione finora

- Viraj Hirpara (920004240988) SIP ProjectDocumento47 pagineViraj Hirpara (920004240988) SIP ProjectViraj HirparaNessuna valutazione finora

- Profile Snapshot: H.Yashik Ahammed B.E., Certified Welding Inspeector-3.1 Qa/Qc Engineer - Pipeline & StructuralDocumento5 pagineProfile Snapshot: H.Yashik Ahammed B.E., Certified Welding Inspeector-3.1 Qa/Qc Engineer - Pipeline & StructuralVijaya BaraniNessuna valutazione finora

- Vrishabh EnterprisesDocumento61 pagineVrishabh EnterprisesAnonymous 4lpRzfFNessuna valutazione finora

- A Study On Financial Analysis of Diamond Engineering 2Documento51 pagineA Study On Financial Analysis of Diamond Engineering 2Priya VijayaNessuna valutazione finora

- Business Marketing Group Assignment Company: ACC Limited: Submitted byDocumento11 pagineBusiness Marketing Group Assignment Company: ACC Limited: Submitted byHasan ArmoghanNessuna valutazione finora

- On Industrial Training Report (18!03!21)Documento15 pagineOn Industrial Training Report (18!03!21)Vicky KumarNessuna valutazione finora

- Brakes India Private LimitedDocumento10 pagineBrakes India Private Limitedrathan50% (2)

- SUKRA ConcreteDocumento12 pagineSUKRA ConcreteSales TeamNessuna valutazione finora

- M. Harish Mohammed: Junior Design EngineerDocumento2 pagineM. Harish Mohammed: Junior Design Engineerharish mohammedNessuna valutazione finora

- Applied - Research On MRFDocumento23 pagineApplied - Research On MRFJankiNessuna valutazione finora

- Gondela Mahesh CELL NO: 9502086722: Technical QualificationDocumento5 pagineGondela Mahesh CELL NO: 9502086722: Technical QualificationMahesh GondelaNessuna valutazione finora

- Resume: Career ObjectiveDocumento5 pagineResume: Career Objectivemanish upadhyayNessuna valutazione finora

- Internship Report On RMCDocumento20 pagineInternship Report On RMCsampatharao.grnNessuna valutazione finora

- Paramasivam SVC Mech 2Documento30 pagineParamasivam SVC Mech 2mech deptNessuna valutazione finora

- Sip Project Report. RAJDocumento51 pagineSip Project Report. RAJmanuNessuna valutazione finora

- Study of Quality Inspections in Manufacturing of Transmission TowersDocumento18 pagineStudy of Quality Inspections in Manufacturing of Transmission TowersKarna Satish KumarNessuna valutazione finora

- SGIL Profile (SG)Documento21 pagineSGIL Profile (SG)Soumitra GuptaNessuna valutazione finora

- Royal IncDocumento14 pagineRoyal Inclab_tech12Nessuna valutazione finora

- O2 Gen Company ProfileDocumento17 pagineO2 Gen Company ProfileaditiguptaNessuna valutazione finora

- Guide to Performance-Based Road Maintenance ContractsDa EverandGuide to Performance-Based Road Maintenance ContractsNessuna valutazione finora

- BambooDocumento52 pagineBamboohksmallray100% (2)

- Price Price: Gannon Dunkerley & Co. LTDDocumento1 paginaPrice Price: Gannon Dunkerley & Co. LTDdox4printNessuna valutazione finora

- Beam Deflection FormulaeDocumento2 pagineBeam Deflection Formulae7575757575100% (6)

- Solar Accessories: U / Z Clams Aluminum Exclusion Clamps / Sections Steel Structures Cold RoleDocumento5 pagineSolar Accessories: U / Z Clams Aluminum Exclusion Clamps / Sections Steel Structures Cold Roledox4printNessuna valutazione finora

- AP Model Schools: Rashtriya Madhyamika Shiksha Abhiyan Registration FormDocumento1 paginaAP Model Schools: Rashtriya Madhyamika Shiksha Abhiyan Registration Formdox4printNessuna valutazione finora

- MR K Ramakrishnan Managing Infrastruc Proj RiskDocumento22 pagineMR K Ramakrishnan Managing Infrastruc Proj Riskdox4printNessuna valutazione finora

- Mail Elevation A, B, C& D A0Documento1 paginaMail Elevation A, B, C& D A0dox4printNessuna valutazione finora

- 06 Weekly Progress Report For Jun ' 13Documento1 pagina06 Weekly Progress Report For Jun ' 13dox4printNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento14 pagineDisclosure To Promote The Right To Informationdox4printNessuna valutazione finora

- M/S. Gannon Dunkerly & Co LTD., 6-3-1111/16, Nishanth Bagh, Begumpet, Hyderabad - 16Documento1 paginaM/S. Gannon Dunkerly & Co LTD., 6-3-1111/16, Nishanth Bagh, Begumpet, Hyderabad - 16dox4printNessuna valutazione finora

- GDCL Manglore 1Documento3 pagineGDCL Manglore 1dox4printNessuna valutazione finora

- Ref: MAI / GDCL / Q: 2012 - 2013 / 600: Email: Mai@maroor - inDocumento2 pagineRef: MAI / GDCL / Q: 2012 - 2013 / 600: Email: Mai@maroor - indox4printNessuna valutazione finora

- Bangalore: Gulshan Trading CompanyDocumento1 paginaBangalore: Gulshan Trading Companydox4printNessuna valutazione finora

- VedicReport8 7 202010 32 00PMDocumento56 pagineVedicReport8 7 202010 32 00PMVenkatNessuna valutazione finora

- 3085 3089 PDFDocumento5 pagine3085 3089 PDFKumarNessuna valutazione finora

- SPSR Nellore Category 1 RanksDocumento10 pagineSPSR Nellore Category 1 RanksPrasanth KumarNessuna valutazione finora

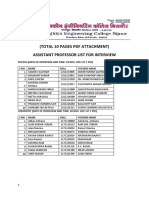

- Candidates List For Interview...Documento10 pagineCandidates List For Interview...ajayNessuna valutazione finora

- Gandhar Food Products PVT - Ltd.Documento8 pagineGandhar Food Products PVT - Ltd.faizalNessuna valutazione finora

- First Puc Term ExamDocumento6 pagineFirst Puc Term Examvardhanviswanadhula5Nessuna valutazione finora

- DIPSEV - 01 Dec 2022 - To - 31 Dec 2022Documento17 pagineDIPSEV - 01 Dec 2022 - To - 31 Dec 2022sudhu79Nessuna valutazione finora

- Appendix 3 Study On The Impact On Stress and Anxiety Through Yoga Nidra Indian Journal of Traditional Knowledge Vol. 7 No 3Documento4 pagineAppendix 3 Study On The Impact On Stress and Anxiety Through Yoga Nidra Indian Journal of Traditional Knowledge Vol. 7 No 3blanquiloNessuna valutazione finora

- (3 Files Merged)Documento40 pagine(3 Files Merged)Niaz AhmedNessuna valutazione finora

- Worldbuilding 101: Strange New WorldsDocumento27 pagineWorldbuilding 101: Strange New WorldsJason Erik LundbergNessuna valutazione finora

- History of Indian Influence On Southeast AsiaDocumento28 pagineHistory of Indian Influence On Southeast AsiaRekha G S HrishikeshNessuna valutazione finora

- 12 Interesting Facts of Nepal CountryDocumento3 pagine12 Interesting Facts of Nepal CountryUmeshNessuna valutazione finora

- Module For Theravada Buddhism Week 8Documento4 pagineModule For Theravada Buddhism Week 8Anatta AttanaNessuna valutazione finora

- Paritosh Das, Sahajiya Cult of Bengal and Panca-Sakha Cult of OrissaDocumento220 pagineParitosh Das, Sahajiya Cult of Bengal and Panca-Sakha Cult of Orissanandana11Nessuna valutazione finora

- List of BooksDocumento10 pagineList of BooksJanardhan GannigaNessuna valutazione finora

- Invocation and Shanti MantraDocumento2 pagineInvocation and Shanti MantraShreejay MehtaNessuna valutazione finora

- India - Commemorative Coin AlbumDocumento3 pagineIndia - Commemorative Coin AlbumrameshgshenoyNessuna valutazione finora

- Sarojini Naidu PDFDocumento4 pagineSarojini Naidu PDFashwini_bramhaneNessuna valutazione finora

- Kvpy Answer Keys 05 Nov 2017 SB-SXDocumento3 pagineKvpy Answer Keys 05 Nov 2017 SB-SXAbhishek KunduNessuna valutazione finora

- List of Kapil Sharma EpisodesDocumento8 pagineList of Kapil Sharma EpisodesAshok BhojaneNessuna valutazione finora

- 11 Socio Cultural (Chap. 7)Documento22 pagine11 Socio Cultural (Chap. 7)Meridian Ela100% (1)

- Rental Tempo TravellerDocumento18 pagineRental Tempo Travelleranil kumarNessuna valutazione finora

- Practical Guide To YogaDocumento106 paginePractical Guide To YogaAnonymous eDyMaC6CNessuna valutazione finora

- History 2 PDFDocumento29 pagineHistory 2 PDFAishani ChakrabortyNessuna valutazione finora

- CalendarDocumento10 pagineCalendarNandkishor MeenaNessuna valutazione finora

- Neuro Rahab CenterDocumento4 pagineNeuro Rahab CenterRamesh BabuNessuna valutazione finora

- Pages From Karma & Rebirth in Hindu Astro - Kotamraj Narayana Rao & K. Sud - 2395Documento10 paginePages From Karma & Rebirth in Hindu Astro - Kotamraj Narayana Rao & K. Sud - 2395amit nakraNessuna valutazione finora

- A Sequel To Essentials of ZoroastrianismDocumento165 pagineA Sequel To Essentials of Zoroastrianism06jonasNessuna valutazione finora