Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Yarn Weight: Yarn Knitters Weavers Crocheters Fiber Artists

Caricato da

mirmoinulDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Yarn Weight: Yarn Knitters Weavers Crocheters Fiber Artists

Caricato da

mirmoinulCopyright:

Formati disponibili

Yarn weight

Yarn weight refers to the thickness of yarn used by knitters, weavers, crocheters and other fiber artists. Changing yarn weight or needle size can have a significant impact on the finished project, so standardized systems have been spread about, as well as conversion systems for regional standards (especially needle sizes[1]).Yarn weight is important in achieving the correct gauge or tension for a particular project and can help with yarn substitution. The Craft Yarn Council of America has developed a system that seeks to standardize the labeled weights of yarn.[2] Most yarns state their weight on the ball band. Some brands use a standardized numbering system that uses 7 ranges of relative thickness of yarn. One way of determining the weight of an unknown yarn is to use the wrapping method. Wrap the yarn around a large needle or a ruler. Make sure the yarn lies flat. Push the yarn together so there are no gaps between wraps. Smooth it out so it is neither too loose nor too tight. Measure the number of wraps per inch (2.5 cm). For better accuracy, measure the wraps at the centre of your yarn sample. Standard Yarn Weight System 0 or Lace 1 or Superfine 2 or Fine 3 or Light 4 or Medium 5 or Bulky 6 or Super Bulky Yarn Type (US) Thread, Cobweb and Lace Fingering Sport DK Worsted Bulky Super Bulky Ply (UK, NZ, AU)[3] 1 - 3 ply 4 ply 5 ply 8 ply 10 ply 12 ply m/100g 600-800 400-480 300-400 240-300 120-240 100-130 Less than 100 Wraps Per Inch (WPI)[3] 18+ wpi 14 wpi 12 wpi 11 wpi 9 wpi 7 wpi 5-6 wpi

Different terminology is used in different countries: USA Laceweight Fingering Sock Sport Worsted 1 ply 2 ply 3 ply 4 ply Aran UK Australia Suggested needle (mm) 2 ply 3 ply 3 ply 5 ply 8 ply 10 ply 1.52.25 mm 2.25 3 mm 2.25 3.25 mm 3.25 3.75 mm 3.75 4.5 mm 4.5 5.5 mm

DK/Light Worsted DK

Bulky Super Bulky

Chunky

12 ply

5.5 8 mm 8 mm and up

Super Chunky 14 ply

Fabric

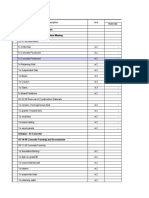

The following equation may be used to determine the weight of warp and weft required for a particular fabric:

Weight of warp = (0.65 x qty. of fabric (metres) x no. of warp ends) / count

If there are two colors in the warp, use the following equations:

Weight of color A (kg) = (0.65 x qty. of fabric (metres) x no. of warp ends of color A) / count of color A Weight of color B (kg) = (0.65 x Qty. of fabric (metres) x no. of warp ends of color B) / count of color B

If the counts of two warps are the same:

Weight of color A (kg) = (total weight of warp reqd. x no. of ends of color A) / total no. of warp ends Weight of color B (kg) = (total weight of warp reqd. x no. of ends of color B) / total no. of warp ends

or

Weight of color (B) = total weight of warp reqd. - weight of color A Weight of weft = (0.6 x qty. of fabric (metres) x PPI x reed space) / count

If there are two colors in the weft:

Weight of color A (kg) = (0.6 x qty. of fabric (metres) x PPI of color A x reed space) / count of color A Weight of color B (kg) = (0.6 x qty. of fabric (metres) x PPI of color B x reed space) / count of color B

or

Weight of color (B) = total weight of weft reqd. - weight of color A Another formula

1. Reed x width / 7000 = Ans 2. Ans x quantity (mtr) / count = The weight required(Kg)

Potrebbero piacerti anche

- Edvard Munch: Behind The ScreamDocumento391 pagineEdvard Munch: Behind The Screamdavidlightman100% (8)

- Pedretti C. (Ed) The Literary Works of Leonardo Da Vinci A Commentary Volume 1Documento464 paginePedretti C. (Ed) The Literary Works of Leonardo Da Vinci A Commentary Volume 1JosephLadyNessuna valutazione finora

- Fundamentals of Yarn Technology: Learning ObjectivesDocumento14 pagineFundamentals of Yarn Technology: Learning ObjectivesSalimNessuna valutazione finora

- Circular Knitted FabricsDocumento16 pagineCircular Knitted Fabricsrdsekar7633% (3)

- Textile Testing and Product EvaluationDocumento64 pagineTextile Testing and Product EvaluationAnmol Jain100% (3)

- Loops, Double Loops, and Spontaneous Loops: Cross-Examination: Science and Techniques 2 EditionDocumento8 pagineLoops, Double Loops, and Spontaneous Loops: Cross-Examination: Science and Techniques 2 Editionmirmoinul100% (1)

- Second Grade Master Spelling ListsDocumento5 pagineSecond Grade Master Spelling Listsapi-229179789Nessuna valutazione finora

- Techniques, Tips and Recipes: Soda FiringDocumento21 pagineTechniques, Tips and Recipes: Soda FiringCristiane SouzaNessuna valutazione finora

- 3d Drawing and Optical IllusionsDocumento70 pagine3d Drawing and Optical IllusionsValter Carvalho100% (4)

- Fundamentals of Yarn Technology: Learning ObjectivesDocumento16 pagineFundamentals of Yarn Technology: Learning Objectivesdwidha100% (1)

- Yarns. Definition of Yarn. Classification - Types of Yarn. Yarns May Be - in Addition, Filament Yarns May Be - From Fibers To YarnsDocumento10 pagineYarns. Definition of Yarn. Classification - Types of Yarn. Yarns May Be - in Addition, Filament Yarns May Be - From Fibers To YarnssintamelkNessuna valutazione finora

- How To Calculate Fabric Yardage For QuiltsDocumento8 pagineHow To Calculate Fabric Yardage For QuiltsSundhar AvinaashNessuna valutazione finora

- Sizing Systems: Monofilament ThreadDocumento1 paginaSizing Systems: Monofilament ThreaddieselakiasNessuna valutazione finora

- Outlandish Bodice v2020.1Documento15 pagineOutlandish Bodice v2020.1Madeline Critchley-Mcswain100% (1)

- Yarn ClassificationDocumento10 pagineYarn ClassificationVirendra Kumar Saroj100% (1)

- Learn Textile0Documento208 pagineLearn Textile0Hassan ShahzadNessuna valutazione finora

- Importance of Analysis of Fabric SampleDocumento5 pagineImportance of Analysis of Fabric SampleRavi Jain75% (4)

- LinenDocumento15 pagineLinenswarna swarna100% (1)

- FiberDocumento9 pagineFiberAryan PatelNessuna valutazione finora

- Blow Room-2Documento13 pagineBlow Room-2Tarif HasanNessuna valutazione finora

- Chapter - Three: Yarn Count, Yarn Twist and Tensile TestingDocumento57 pagineChapter - Three: Yarn Count, Yarn Twist and Tensile TestingGadisa AbrahimNessuna valutazione finora

- Textile in DepthDocumento59 pagineTextile in DepthBoopathi Sadasivam50% (2)

- Note Polyster FiberDocumento16 pagineNote Polyster FiberMohammed Atiqul Hoque ChowdhuryNessuna valutazione finora

- Sectional Warping and Its CalculationsDocumento6 pagineSectional Warping and Its CalculationsMANOJNessuna valutazione finora

- Tibetan Knottted CarpetDocumento13 pagineTibetan Knottted CarpetSumit SagarNessuna valutazione finora

- Yarn Numbering - Count Lecture1Documento11 pagineYarn Numbering - Count Lecture1Muhammad SagheerNessuna valutazione finora

- Yarn Numbering and Sewing ThreadsDocumento44 pagineYarn Numbering and Sewing Threadsnitishkohli100% (9)

- Yarn Manufacturing IDocumento219 pagineYarn Manufacturing IfekadeNessuna valutazione finora

- YarnweightinfoDocumento5 pagineYarnweightinfoextradesignappNessuna valutazione finora

- Crimp Interchange: The Change in The Ratio of The Crimp of The Warp and Weft System Is Termed As Crimp InterchangeDocumento12 pagineCrimp Interchange: The Change in The Ratio of The Crimp of The Warp and Weft System Is Termed As Crimp InterchangeAshutoshNessuna valutazione finora

- 2.3 YARN - MFG 2MBADocumento60 pagine2.3 YARN - MFG 2MBAKAWSER RAFINessuna valutazione finora

- Threads: Sewing Sewing by Hand Different Types of Sewing ThreadDocumento35 pagineThreads: Sewing Sewing by Hand Different Types of Sewing ThreadAnamika SinghNessuna valutazione finora

- 纺纱学双语Documento653 pagine纺纱学双语Gizachew Zeleke100% (1)

- Yarn FormationDocumento125 pagineYarn FormationDhana SeelanNessuna valutazione finora

- Yarn Formation - Spinning - AymanDocumento125 pagineYarn Formation - Spinning - AymanTamer Farouk KhalifaNessuna valutazione finora

- What Is Sectional Warping?: Creel Drum BeamDocumento6 pagineWhat Is Sectional Warping?: Creel Drum Beamamar9247Nessuna valutazione finora

- Textile Testing and Product EvaluationDocumento64 pagineTextile Testing and Product EvaluationBhaswati PandaNessuna valutazione finora

- Textiles Product InformationDocumento6 pagineTextiles Product InformationTeodoro CornejoNessuna valutazione finora

- New Microsoft Office Word DocumentDocumento26 pagineNew Microsoft Office Word DocumentVeera KumarNessuna valutazione finora

- To Calculate The Count of Given Samples of Lap, Sliver, Roving and Yarn.Documento2 pagineTo Calculate The Count of Given Samples of Lap, Sliver, Roving and Yarn.Ammar Naeem BhattiNessuna valutazione finora

- Tex FormulaDocumento11 pagineTex FormulaThangaraj Goldking0% (1)

- Yarn Numbering SystemDocumento36 pagineYarn Numbering SystemARYAN RATHORE100% (4)

- Yarn QualityDocumento4 pagineYarn Qualityalireza vahabi100% (1)

- Unraveling The Mystery of Thread SizeDocumento5 pagineUnraveling The Mystery of Thread SizeChaminda JayaweeraNessuna valutazione finora

- Knits LudhianaDocumento25 pagineKnits LudhianaRoha RohaNessuna valutazione finora

- YarnDocumento37 pagineYarnMohammad HossainNessuna valutazione finora

- Raw Material CalculationsDocumento12 pagineRaw Material CalculationsArivaazhi PeriyaswamyNessuna valutazione finora

- Yarn Count & Yarn ModificationDocumento52 pagineYarn Count & Yarn Modificationmhrscribd014Nessuna valutazione finora

- Woven Fabric FeaturesDocumento16 pagineWoven Fabric FeaturesRauf SyahNessuna valutazione finora

- Linear - Density - of - Man - Made - Fibers - and - Their (1) - 1Documento17 pagineLinear - Density - of - Man - Made - Fibers - and - Their (1) - 1VivekNessuna valutazione finora

- Module 114 Basic Textile - 001-KnittingDocumento60 pagineModule 114 Basic Textile - 001-KnittingTran Quoc VietNessuna valutazione finora

- Classification & Yarn NumberingDocumento21 pagineClassification & Yarn NumberingMewar FashionsNessuna valutazione finora

- Fiber FinenessDocumento7 pagineFiber FinenessFahima RashidNessuna valutazione finora

- Class Lecture-6 TTQC-IDocumento9 pagineClass Lecture-6 TTQC-IMoshiur Rahman KayesNessuna valutazione finora

- YarnDocumento9 pagineYarnmuthuguru259474Nessuna valutazione finora

- 2 - Fiber TestingDocumento22 pagine2 - Fiber Testingarchanachandran13Nessuna valutazione finora

- Dimensional Properties of Fleece FabricDocumento5 pagineDimensional Properties of Fleece Fabricmac2022Nessuna valutazione finora

- Research & Development in TextileDocumento40 pagineResearch & Development in Textileapi-19978170100% (2)

- Job, Viva, Interview Questions For Textile EngineersDocumento86 pagineJob, Viva, Interview Questions For Textile EngineersMazedul Hasan Shishir100% (8)

- TestingDocumento36 pagineTestingMd.Milon HossainNessuna valutazione finora

- Basic Knitting: All the Skills and Tools You Need to Get StartedDa EverandBasic Knitting: All the Skills and Tools You Need to Get StartedNessuna valutazione finora

- Adorable Baby Knits: 25 Patterns for Boys and GirlsDa EverandAdorable Baby Knits: 25 Patterns for Boys and GirlsValutazione: 4.5 su 5 stelle4.5/5 (3)

- Baby Hats to Crochet: 10 Fun Designs for Newborn to 12 MonthsDa EverandBaby Hats to Crochet: 10 Fun Designs for Newborn to 12 MonthsValutazione: 5 su 5 stelle5/5 (1)

- Brief History of Shia Ismaili Imams (892) - DSDocumento178 pagineBrief History of Shia Ismaili Imams (892) - DSmirmoinulNessuna valutazione finora

- Hurqalya - HavarqalyaDocumento64 pagineHurqalya - HavarqalyaBVILLARNessuna valutazione finora

- WB QVM I Pvkzixi Kz©Vejxt: (CVZV Bs-1)Documento62 pagineWB QVM I Pvkzixi Kz©Vejxt: (CVZV Bs-1)mirmoinulNessuna valutazione finora

- The Banking System in Bangladesh: Definition of BankDocumento10 pagineThe Banking System in Bangladesh: Definition of BankmirmoinulNessuna valutazione finora

- The Central Bank: Bangladesh BankDocumento3 pagineThe Central Bank: Bangladesh BankmirmoinulNessuna valutazione finora

- Banking Structure of BangladeshDocumento9 pagineBanking Structure of BangladeshAhnafTahmid100% (4)

- Chodkiewicz TwoEssaysOnIbnArabi EndlessVoyage-VisionOfGod PDFDocumento21 pagineChodkiewicz TwoEssaysOnIbnArabi EndlessVoyage-VisionOfGod PDFabd al-shakurNessuna valutazione finora

- The Great Chain of Consciousness Renovatio 1.1 2017 PDFDocumento12 pagineThe Great Chain of Consciousness Renovatio 1.1 2017 PDFmirmoinul100% (1)

- Insu EssentialsDocumento7 pagineInsu Essentialsparth_upadhyay_1Nessuna valutazione finora

- Land Conflicts PDFDocumento122 pagineLand Conflicts PDFsubxaanalahNessuna valutazione finora

- TMP 21426-Banking On19may20161639083367Documento122 pagineTMP 21426-Banking On19may20161639083367Homi NathNessuna valutazione finora

- E - BankingDocumento10 pagineE - BankingRoy OvNessuna valutazione finora

- Ligal Notice - Nurul Abdul Alim - OCT - 01Documento3 pagineLigal Notice - Nurul Abdul Alim - OCT - 01mirmoinulNessuna valutazione finora

- Banking & Insurance12Documento1 paginaBanking & Insurance12mirmoinulNessuna valutazione finora

- Ibn Arabi - Futuhat 317 The Mi'Raj and Ibn 'Arabi's Own Spiritual Ascension and The IsraDocumento58 pagineIbn Arabi - Futuhat 317 The Mi'Raj and Ibn 'Arabi's Own Spiritual Ascension and The IsraQazim Ali Sumar100% (1)

- Weeping in Classical Sufism by ChittickDocumento8 pagineWeeping in Classical Sufism by ChittickmirmoinulNessuna valutazione finora

- Criminal RulesDocumento169 pagineCriminal RulesmirmoinulNessuna valutazione finora

- Fusus Al Hikam Ibn Arabi PDFDocumento134 pagineFusus Al Hikam Ibn Arabi PDFarslanahmedkhawaja100% (11)

- CabinetDocumento8 pagineCabinetmirmoinul100% (1)

- Poznar & DoddDocumento56 paginePoznar & Doddmirmoinul100% (3)

- Contract Law Final Exam Question 2018Documento1 paginaContract Law Final Exam Question 2018mirmoinulNessuna valutazione finora

- Ibn Arabi's Concept of Ahl Al-Bayt by AddasDocumento11 pagineIbn Arabi's Concept of Ahl Al-Bayt by AddasmirmoinulNessuna valutazione finora

- Diplomatic ImmunityDocumento15 pagineDiplomatic ImmunitymirmoinulNessuna valutazione finora

- DiplomatDocumento4 pagineDiplomatmirmoinulNessuna valutazione finora

- Should You Register Your Partnership?: Register of Joint Stock Companies and FirmDocumento3 pagineShould You Register Your Partnership?: Register of Joint Stock Companies and FirmmirmoinulNessuna valutazione finora

- The Banking System in Bangladesh: History of BankDocumento7 pagineThe Banking System in Bangladesh: History of Bankmirmoinul100% (1)

- Nuevo Microsoft Office Word DocumentDocumento7 pagineNuevo Microsoft Office Word DocumentmirmoinulNessuna valutazione finora

- Right of AsylumDocumento8 pagineRight of AsylummirmoinulNessuna valutazione finora

- Cause of Action: Civil Procedure in The United StatesDocumento4 pagineCause of Action: Civil Procedure in The United StatesmirmoinulNessuna valutazione finora

- Aras Jung Curriculum IndividualDocumento72 pagineAras Jung Curriculum IndividualdianavaleriaalvarezNessuna valutazione finora

- Kinrara QasehDocumento7 pagineKinrara QasehyunalescarikkuNessuna valutazione finora

- Sketchup TutorialDocumento288 pagineSketchup TutorialNagaraja Prasanna Rass100% (3)

- Zaha Hadid From WikipediaDocumento2 pagineZaha Hadid From WikipediaLilyNessuna valutazione finora

- The Art of Lettering and Sign Painters' ManualDocumento88 pagineThe Art of Lettering and Sign Painters' ManualGuilherme Serpieri100% (5)

- Heartney PostmodernismDocumento6 pagineHeartney PostmodernismThomas MooreNessuna valutazione finora

- Module Cpar Unit IIDocumento70 pagineModule Cpar Unit IIJeffrey De Belen100% (1)

- Dyeing and PrintingDocumento31 pagineDyeing and PrintingmksanalrajrajNessuna valutazione finora

- Unit Rates and Cost Per ItemDocumento213 pagineUnit Rates and Cost Per ItemDesiree Vera GrauelNessuna valutazione finora

- Words To Inspire WritersDocumento208 pagineWords To Inspire WritersTristano Ajmone100% (1)

- Bill of MaterialsDocumento3 pagineBill of MaterialsJun Michael Artates VelascoNessuna valutazione finora

- Individual PresentationDocumento6 pagineIndividual PresentationPatricia ByunNessuna valutazione finora

- Arts dlp.3-5. (Grade 6) .Coleen LaoDocumento8 pagineArts dlp.3-5. (Grade 6) .Coleen LaoJesson AlbaranNessuna valutazione finora

- 3 Ways To Removing ChromeDocumento3 pagine3 Ways To Removing ChromeJalu Prasetyo SugiantoroNessuna valutazione finora

- Galvanized Steel Inspection GuideDocumento20 pagineGalvanized Steel Inspection GuidePham Ngoc Khan100% (2)

- AntonymsDocumento15 pagineAntonymsEngr Saleem Chandio100% (1)

- Revell Colour ChartDocumento2 pagineRevell Colour ChartmoipedrasNessuna valutazione finora

- Mil STD 2193C PDFDocumento23 pagineMil STD 2193C PDFNicolasSuchNessuna valutazione finora

- UntitledDocumento6 pagineUntitledapi-233604231100% (3)

- Fifty Nifty United StatesDocumento5 pagineFifty Nifty United Statesapi-273322274Nessuna valutazione finora

- Michaël BorremansDocumento3 pagineMichaël BorremansE EstebanNessuna valutazione finora

- SIERRA CALADORA ORBITAL DeWALT DW318 PDFDocumento5 pagineSIERRA CALADORA ORBITAL DeWALT DW318 PDFPakito XtradaNessuna valutazione finora

- IGCSE-ART-SoW-2 2Documento24 pagineIGCSE-ART-SoW-2 2Benji NgNessuna valutazione finora

- Painting St. Michael v. by Raphael.2Documento3 paginePainting St. Michael v. by Raphael.2John NdasabaNessuna valutazione finora

- Rococo and NeoclassicismDocumento13 pagineRococo and NeoclassicismLucas LehmannNessuna valutazione finora