Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

INVOLUTE SPUR GEARS TERMINOLOGY AND MESHING

Caricato da

jiteshpaulDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

INVOLUTE SPUR GEARS TERMINOLOGY AND MESHING

Caricato da

jiteshpaulCopyright:

Formati disponibili

Lecture 2: INVOLUTE SPUR GEARS TERMINOLOGY Contents 1. Nomenclature of involute spur gears 2. Meshing of gears 3. Interference in gears 4.

Methods of eliminating interference 5. Length of line of action 6. Contact ratio

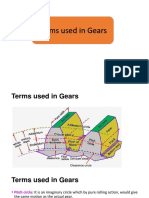

Pitch surface: The surface of the imaginary rolling cylinder (cone, etc.) that replaces the toothed gear. Pitch surface: The surface of the imaginary rolling cylinder (cone, etc.) that replaces the toothed gear. Pitch circle: A normal section of the pitch surface. Addendum circle: A circle bounding the ends of the teeth, in a normal section of the gear. Dedendum circle or Root circle: The circle bounding the spaces between the teeth, in a normal section of the gear. Addendum: The radial distance between the pitch circle and the addendum circle. Dedendum: The radial distance between the pitch circle and the root circle. Clearance: The difference between the Dedendum of one gear and the addendum of the mating gear. Face of a tooth: That part of the tooth surface lying outside the pitch surface. Flank of a tooth: The part of the tooth surface lying inside the pitch surface. Top land: The top surface of a gear tooth. Bottom land: The bottom surface of the tooth space.

Circular thickness (tooth thickness): The thickness of the tooth measured on the pitch circle. It is the length of an arc and not the length of a straight line.

Tooth space: The space between successive teeth. Width of space: The distance between adjacent teeth measured on the pitch circle. Backlash: The difference between the tooth thickness of one gear and the tooth space of the mating gear. Circular pitch p: The width of a tooth and a space, measured on the pitch circle. It is equal to the pitch circumference divided by the number of teeth. If, d p= (1) z p - circular pitch P - diametral pitch z - number of teeth d - pitch diameter Diametral pitch P: The number of teeth of a gear per unit pitch diameter. The diametral pitch is hence the number of teeth divided by the pitch diameter. P = z/d (2) The product of the diametral pitch and the circular pitch equals . pP = (3)

The effect of diametral pitch on the size of the gear tooth

Actual tooth size for various diametral pitches.

Standard diametral pitches 1 4 16 72 1.25 5 18 80 1.5 6 20 96 1.75 2 2.5 3 8 10 12 14 24 32 48 64 120

Module m: Pitch diameter divided by number of teeth. The pitch diameter is usually specified in millimeters. m = d/z (4) Standard modules in mm 0.3 1.25 3.5 7 14 26 45 0.4 1.5 4 8 15 28 50 0.5 1.75 4.5 9 16 30 0.6 2.0 5 10 18 33 0.7 2.25 5.5 11 20 36 0.8 2.5 6 12 22 39 1.0 3 6.5 13 24 42

Further increase is in terms of 5 mm

Fillet Radius: The small radius that connects the profile of a tooth to the root circle. Crowning: Grinding of tooth edges to prevent edge loading is known as crowning.

Pinion: The smallest of any pair of mating gears. Gear: The largest of the pair is called simply the gear. Velocity ratio i: The ratio of rotational speed of the driving gear n1 (or input gear) to the rotational speed of the driven gear n2 (or output gear). If z1 & z2 , d1 & d2, r1 & r2, and 1 & 2 are corresponding number of teeth, pitch diameters, radii and angular velocities of pinion and the gear, then

i=

n1 1 z 2 d2 r2 = = = = n2 2 z1 d1 r1

(5)

Base circle: An imaginary circle used in involute gearing to generate the involutes that form the tooth profiles.

Pitch point: The point of tangency of the pitch circles of a pair of mating gears. Common tangent: The line tangent to the pitch circle at the pitch point. Line of action: A line normal to a pair of mating tooth profiles at their point of contact. Path of contact: The path traced by the contact point of a pair of tooth profiles. Pressure angle : The angle between the common normal at the point of tooth contact and the common tangent to the pitch circles. Pressure angle is also the angle between the line of action and the common tangent

Gear meshing

INVOLUTE GEAR TOOTH PROFILE

Gear tooth Interference

If the portion of the gear exists below the base circle, then it results in interference and leads to undercutting of the tooth.

Methods of elimination of Gear tooth Interference

Interference of spur gears is eliminated by (a) removing the cross hatched tooth tips i.e., using stub teeth (b) increasing the number of teeth on the mating pinion. (c) increasing the pressure angle (d) tooth profile modification or profile shifting (e) increasing the centre distance as illustrated in the next figure. For a given gear, the interference can also the eliminated by increasing the centre distance.

Minimum No. of Teeth on pinion to avoid interference for a given gear

The involute profile doesnt exist beyond base circle. When the pinion rotates clockwise, first and last point of contacts are e and g where the line of action is tangent to the base circles. Any part of the pinion tooth face extending beyond a circle through g interferes with gear flank as shown at i. The interference limits the permissible length of addendum. As the diameter of the pinion is reduced, the permissible addendum of larger gear becomes smaller. Let the addendum height be k times the module i.e., km. From the figure maximum gear addendum circle radius is :

AE = r2 + km =

AG 2 + GE 2

(6)

But , AG = r2 cos and GE = (r1 + r2 )sin Substituting in equation (5) & simplifying

r2 + km =

r22 cos 2 + (r1 + r2 )2 sin 2

(7)

Substituting and rearranging in equation (7)

2 z1 + 2 z1 z2 =

4k(z2 + k) sin 2

(8)

For a rack and pinion, z2 = and the equation (8) reduces to

Z1 =

2k sin 2

(9)

For full depth gears(i.e., k = 1) engaging with rack, minimum teeth on the pinion to avoid interference is z1 = 31.9 = 32 for 14.50 pressure angle z1 = 17.097 = 17 for 200 pressure angle z1 = 13.657 = 14 for 22.50 pressure angle Rounded to integer value. The equation (8) indicates that the minimum number of teeth on pinion permissible and it depends on the gear ratio and pressure angle. From the practical consideration it is observed that rack gear generation and hobbing process for lower value than the one given earlier, a little undercutting takes place and the strength of the gear is not affected. Hence, corresponding minimum number of teeth are 27,14 and 12 for 14.50, 200, and 22.50 instead of 32,17 & 14 .

Line of Action

In order to have smooth continuous rotation, the arc of action should be greater than the circular pitch or line of action or path of contact should be equal to or greater than base pitch. GE = (r2 + r1) sin p cos (10) From which p (r2 + r1) tan (11) And 2

z1 + z 2

tan

(12)

The line of action should be at least 1.4 times the circular pitch for continuous action.

Contact ratio

The theoretical length of line of action of any pair of true involute gears La is :

La = (r1 + a1 )2 - r12 cos 2 + (r2 + a2 )2 - r2 2 cos 2 - (r1 + r2 ) sin

(13)

Contact ratio: is defined as the maximum number of teeth in contact at any time Higher the contact ratio smoother will be gear operation

Contact ratio =

La La = p cos m cos

(14)

Potrebbero piacerti anche

- Assignment 3Documento20 pagineAssignment 3Siddhesh RaulNessuna valutazione finora

- Terminology SpurDocumento3 pagineTerminology SpurNimish Pande100% (1)

- Machine Design & Drawing - II - GEARSDocumento12 pagineMachine Design & Drawing - II - GEARSSenthil KumarNessuna valutazione finora

- Formulas For Gear Calculation - External GearsDocumento10 pagineFormulas For Gear Calculation - External GearsJag WaramNessuna valutazione finora

- Gear Terms Explained: Pitch Circle, Diametral Pitch and MoreDocumento10 pagineGear Terms Explained: Pitch Circle, Diametral Pitch and MoreJawad Ullah100% (2)

- Optimize Your Gear Drive Design with Proper Material SelectionDocumento8 pagineOptimize Your Gear Drive Design with Proper Material SelectionLovely BalajiNessuna valutazione finora

- Gear Terms and DefinitionsDocumento5 pagineGear Terms and DefinitionsAaron_Liu_1555Nessuna valutazione finora

- CH 13Documento27 pagineCH 13Sanjay KumarNessuna valutazione finora

- Design of ChainDocumento9 pagineDesign of ChainArun Pravin APNessuna valutazione finora

- Gear NomenclatureDocumento41 pagineGear NomenclatureViswanathan SrkNessuna valutazione finora

- Chapter 9 Spur Gear DesignDocumento31 pagineChapter 9 Spur Gear DesignRamesh Martha100% (1)

- Gear CorrectionDocumento17 pagineGear CorrectionMurugesanNessuna valutazione finora

- Helical Gears: Definition and Useful InformationDocumento13 pagineHelical Gears: Definition and Useful InformationRobert Michael CorpusNessuna valutazione finora

- Rolling Contact BearingsDocumento11 pagineRolling Contact BearingsritNessuna valutazione finora

- Bevel GearsDocumento12 pagineBevel GearsJason Dequin VillarosaNessuna valutazione finora

- Helical Gears: Design, Terminology & Load AnalysisDocumento12 pagineHelical Gears: Design, Terminology & Load AnalysisBoris PalaoNessuna valutazione finora

- Rolling Contact BearingDocumento29 pagineRolling Contact BearingBimlendra RayNessuna valutazione finora

- Tooth ThicknessDocumento9 pagineTooth ThicknessPraveen VundrajavarapuNessuna valutazione finora

- 10.1 - Calculation of Strength For Spur and Helical Gears - TechnicalData - KGSTOCKGEARS PDFDocumento14 pagine10.1 - Calculation of Strength For Spur and Helical Gears - TechnicalData - KGSTOCKGEARS PDFChetan NeheteNessuna valutazione finora

- Shaft LayoutDocumento21 pagineShaft LayoutAmmar SafwtNessuna valutazione finora

- Helical GearsDocumento12 pagineHelical Gearsgamini ranaweera100% (1)

- Spur Gear Design 1Documento16 pagineSpur Gear Design 1Nagu SriramaNessuna valutazione finora

- BevelDocumento20 pagineBevelOmer NadeemNessuna valutazione finora

- Gears FundamentalDocumento25 pagineGears FundamentalMOHD ZULHELMIE ZAINAL ABIDINNessuna valutazione finora

- Solved Examples For Spur Gear DesignDocumento1 paginaSolved Examples For Spur Gear Designpawan12340% (1)

- Addendum Modified Gear For An All-Terrain Vehicle GearboxDocumento6 pagineAddendum Modified Gear For An All-Terrain Vehicle GearboxIJRASETPublicationsNessuna valutazione finora

- Spur Gear CalculationsDocumento2 pagineSpur Gear CalculationsPuneet Verma100% (2)

- GearsDocumento20 pagineGearsFarhad Noruzi100% (14)

- Spur Gear Theory and Design: Soumitra Bhattacharya, M.Tech (Mech), Professional Member of ASMEDocumento16 pagineSpur Gear Theory and Design: Soumitra Bhattacharya, M.Tech (Mech), Professional Member of ASMESyed Shoaib RazaNessuna valutazione finora

- Helical GearDocumento18 pagineHelical GearNitin B maskeNessuna valutazione finora

- Gears KinematicsDocumento19 pagineGears Kinematicsavinashn12Nessuna valutazione finora

- Name: Roll No: AssignmentDocumento6 pagineName: Roll No: Assignmentigualdi53Nessuna valutazione finora

- Splines: Key Components and Torque TransferDocumento4 pagineSplines: Key Components and Torque TransferthirumalaikumaranNessuna valutazione finora

- Effect of Increased Center Distance on Gear Teeth Contact Ratio and StressDocumento21 pagineEffect of Increased Center Distance on Gear Teeth Contact Ratio and StressDavide MaranoNessuna valutazione finora

- 2 Gear BasicsDocumento6 pagine2 Gear BasicsMohamed Adel RizkNessuna valutazione finora

- Gear TrainDocumento26 pagineGear Trainraaz1007Nessuna valutazione finora

- Tutorial Sheet No 1 On Spur GearDocumento3 pagineTutorial Sheet No 1 On Spur GearChirayuNessuna valutazione finora

- Spur Gears: Are Used in Transmitting Torque Between Parallel ShaftsDocumento31 pagineSpur Gears: Are Used in Transmitting Torque Between Parallel ShaftsDipakNessuna valutazione finora

- Mechanical Advantage of Inclined PlaneDocumento4 pagineMechanical Advantage of Inclined PlaneShuja MarwatNessuna valutazione finora

- Sheet No. 1 Design of GearsDocumento3 pagineSheet No. 1 Design of GearssallyNessuna valutazione finora

- Multi-plate clutch problems for power transmission calculationsDocumento6 pagineMulti-plate clutch problems for power transmission calculationsShweta BramhaneNessuna valutazione finora

- Chapter 1-Gear SystemDocumento27 pagineChapter 1-Gear SystemDanielRao100% (2)

- Planetary Gear CalculatorDocumento19 paginePlanetary Gear CalculatorDaris M Al-MubarokNessuna valutazione finora

- Introduction To Direct Gear DesignDocumento15 pagineIntroduction To Direct Gear DesignburaktuncerNessuna valutazione finora

- Gear DesignDocumento83 pagineGear DesignmuhammadaminjamalmutNessuna valutazione finora

- Gear TechnologyDocumento31 pagineGear TechnologyRishabh GawriNessuna valutazione finora

- Rack and PinionDocumento16 pagineRack and PinionjeronimoisraelNessuna valutazione finora

- Dynamic Force Analysis ProblemsDocumento8 pagineDynamic Force Analysis Problemsa c s KumarNessuna valutazione finora

- Gear ForcesDocumento7 pagineGear ForcesSahil Kumar100% (1)

- W 300 3 PDFDocumento44 pagineW 300 3 PDFMahesh Daxini ThakkerNessuna valutazione finora

- Shaft, Keys and CouplingDocumento29 pagineShaft, Keys and CouplingDarshanNessuna valutazione finora

- Design II MDE 221 Mott CH 8 and CH 9 Spur GearsDocumento42 pagineDesign II MDE 221 Mott CH 8 and CH 9 Spur GearsThieroy PelendaNessuna valutazione finora

- Gears - General: Shigley's Mechanical Engineering DesignDocumento229 pagineGears - General: Shigley's Mechanical Engineering DesignbasitNessuna valutazione finora

- Gear TerminologyDocumento42 pagineGear Terminologyyair Enrique Romero OspinoNessuna valutazione finora

- Types of Gears ExplainedDocumento50 pagineTypes of Gears ExplainedMuralikrishnan GM100% (1)

- Details of GearsDocumento88 pagineDetails of Gearsramchandra rao deshpandeNessuna valutazione finora

- Design of Spur GearDocumento67 pagineDesign of Spur GearShubham DhurjadNessuna valutazione finora

- Gears, Splines, and Serrations: Unit 24Documento8 pagineGears, Splines, and Serrations: Unit 24Satish Dhandole100% (1)

- Profile Contact Ratio, Active Profile Diameter, Lowest and Highest Point of Single Tooth ContactDocumento11 pagineProfile Contact Ratio, Active Profile Diameter, Lowest and Highest Point of Single Tooth Contactmohanrajjercy71Nessuna valutazione finora

- Kinematics of Gears and Gear TrainsDocumento27 pagineKinematics of Gears and Gear TrainsAbdur RahmanNessuna valutazione finora

- Bullseye Coverage ErrorDocumento1 paginaBullseye Coverage ErrorjiteshpaulNessuna valutazione finora

- Student Slides M1Documento5 pagineStudent Slides M1jiteshpaulNessuna valutazione finora

- Passport FormDocumento3 paginePassport FormjiteshpaulNessuna valutazione finora

- Business CommunicationDocumento46 pagineBusiness Communicationadeeb75% (4)

- 2 - 2 History ND Type of GearDocumento9 pagine2 - 2 History ND Type of GearjiteshpaulNessuna valutazione finora

- SSC JE 2013 1-100 MechDocumento10 pagineSSC JE 2013 1-100 Mechjiteshpaul100% (1)

- SSC JE 2013 100-200 MechDocumento9 pagineSSC JE 2013 100-200 Mechjiteshpaul100% (2)

- P12163 187 PDFDocumento25 pagineP12163 187 PDFdikdik2302Nessuna valutazione finora

- Differentiation FormulaDocumento2 pagineDifferentiation FormulahaqjmiNessuna valutazione finora

- General Studies IDocumento16 pagineGeneral Studies ISatish ChandNessuna valutazione finora

- General Ability 2012 SCRA Aryan Classes PDFDocumento31 pagineGeneral Ability 2012 SCRA Aryan Classes PDFVinay KumarNessuna valutazione finora

- Steel Single Flanged Rail Wheels: 975Kg 1.4KgDocumento27 pagineSteel Single Flanged Rail Wheels: 975Kg 1.4KgFranciscoNessuna valutazione finora

- Conectores de Sensores y Actuadores de Spark 2008 1.0Documento13 pagineConectores de Sensores y Actuadores de Spark 2008 1.0Victor SanchezNessuna valutazione finora

- Torque TighteningDocumento2 pagineTorque TighteningAnonymous fbeCwgBFY100% (1)

- Transmission: ClutchDocumento15 pagineTransmission: ClutchDidier ÁlvarezNessuna valutazione finora

- REPAIR KIT FOR BLOWING VALVEDocumento7 pagineREPAIR KIT FOR BLOWING VALVEYiğit ErpakNessuna valutazione finora

- Komatsu D41e 6Documento401 pagineKomatsu D41e 6Gleidson Anterio100% (1)

- MM - 9e.pdf AXEL TECH PRC7534 KALMAR PDFDocumento41 pagineMM - 9e.pdf AXEL TECH PRC7534 KALMAR PDFRachid SmailiNessuna valutazione finora

- Parts Manual: CascadeDocumento12 pagineParts Manual: CascademaNessuna valutazione finora

- Bearing Flow ChartDocumento7 pagineBearing Flow Chartfazly07Nessuna valutazione finora

- Musso GearboxmanualDocumento81 pagineMusso GearboxmanualembokoNessuna valutazione finora

- Strutfast Clamps, Fasteners & Anchors LRDocumento7 pagineStrutfast Clamps, Fasteners & Anchors LRzimtonyNessuna valutazione finora

- Toyota R150 R151Documento4 pagineToyota R150 R151Christian Rhadames Barkley Chavez100% (1)

- Shaker Screen Bearings InterchangeDocumento2 pagineShaker Screen Bearings InterchangeJorge Israel Figueroa100% (1)

- Peugeot 307 Component ListDocumento3 paginePeugeot 307 Component ListStar MotorsNessuna valutazione finora

- Oil Cooler Rubber Oring & Kit: Nissan Rd8 Nissan Rd8Documento3 pagineOil Cooler Rubber Oring & Kit: Nissan Rd8 Nissan Rd8สมโภช แก้วเขียวNessuna valutazione finora

- APACHE / APACHE RTR/ RTR REF. / RTR EFI / NEW RTR REF. PARTS CATALOGUE CYLINDER HEAD ASSEMBLYDocumento74 pagineAPACHE / APACHE RTR/ RTR REF. / RTR EFI / NEW RTR REF. PARTS CATALOGUE CYLINDER HEAD ASSEMBLYLukesh Kumar100% (2)

- E450 456Documento4 pagineE450 456Miguel CanoNessuna valutazione finora

- HD 13 - 14 H2.01 - PartsDocumento178 pagineHD 13 - 14 H2.01 - PartsLucas Rodrigues GuimarãesNessuna valutazione finora

- BMW X5 E70 Service Repair Workshop ManualDocumento3.160 pagineBMW X5 E70 Service Repair Workshop ManualBùi Công Sơn100% (4)

- Soal Latihan Simple MachineDocumento4 pagineSoal Latihan Simple Machinegracelynfelicia46Nessuna valutazione finora

- 2022 01 Pricelist Spareparts Ergoselect II enDocumento65 pagine2022 01 Pricelist Spareparts Ergoselect II enkritonNessuna valutazione finora

- TUCSON (JM) 2008 G 2.7 DOHC Clutch SystemDocumento20 pagineTUCSON (JM) 2008 G 2.7 DOHC Clutch Systemrobin machadoNessuna valutazione finora

- Hobart Model 610 Slicer Parts ManualDocumento8 pagineHobart Model 610 Slicer Parts ManualpagehopperNessuna valutazione finora

- 00-01 Honda CBR929RR Parts BookDocumento118 pagine00-01 Honda CBR929RR Parts BookelderhomeNessuna valutazione finora

- Cummins: Engine: 4BT3.9L Non-Emission Certified 4T-390 CDC Non-Emission CertifiedDocumento2 pagineCummins: Engine: 4BT3.9L Non-Emission Certified 4T-390 CDC Non-Emission CertifiedHugo PinedaNessuna valutazione finora

- SPRINGS: Mechanical Engineering Laboratory Head Explains Spring CalculationsDocumento15 pagineSPRINGS: Mechanical Engineering Laboratory Head Explains Spring CalculationsKara KruzNessuna valutazione finora

- View Auxiliary Illustrations Fuse/Relay BoxDocumento13 pagineView Auxiliary Illustrations Fuse/Relay BoxfrgmanNessuna valutazione finora

- Gear TechnologyDocumento31 pagineGear TechnologyRishabh GawriNessuna valutazione finora

- Inventory Database - All Parts Inc (8/20/20)Documento2.835 pagineInventory Database - All Parts Inc (8/20/20)All Parts Inc.Nessuna valutazione finora

- Manual Transaxle: AT AXDocumento64 pagineManual Transaxle: AT AXTony SaborioNessuna valutazione finora