Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fluid Machines: Modular Division of The Syllabus

Caricato da

Abhijit DeyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fluid Machines: Modular Division of The Syllabus

Caricato da

Abhijit DeyCopyright:

Formati disponibili

FLUID MACHINES

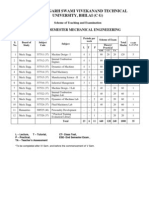

Subject Code ME / 6 / T1 / FMC Course offered in Part III 2nd Semester Course Duration 17 weeks 3 lecture + 1 tutorial contact periods per week Full Marks 75

MODULAR DIVISION OF THE SYLLABUS

GROUP A B MODULE 1 2 3 4 TOPIC IMPACT OF JETS PUMP HYDRAULIC TURBINE MISCELLANEOUS CONACT PDS. 8 20 24 6

Revision : 6 Periods

EXAMINATION SCHEME

GROUP MODULE TO BE SET 20 15 OBJECTIVE QUESTIONS TO BE ANSWERED ANY 25 MARKS PER QUESTION 1 TOTAL MARKS 25 TO BE SET 5 4 SUBJECTIVE QUESTION TO BE ANSWERED FIVE ATLEAST TWO FROM EACH GROUP MARKS PER QUESTION 10 TOTAL MARKS 50

A B

1,2 3,4

DETAIL COURSE CONTENT

1. IMPACT OF JET. 8PDS. 1.1 Direct impact of a jet on a stationary flat plate 1.2 Direct impact of a jet on an inclined fixed plate 1.3 Impact of a jet on a moving plate 1.4 Impact of a jet on a series of flat vanes mounted on the periphery of a large wheel 1.5 Condition fir maximum hydraulic efficiency 1.6 Force of jet impinging on a fixed curved vane 1.7 Force of jet impinging on a moving curved vane, velocity Diagram 1.8 All related problems 2. PUMPS 20 PDS. 2.1 Reciprocating pump Types 2.2 Classification of pumps 2.3 Working principle ( single acting & double acting), discharge, slip, pump work, power required, indicator diagram ( Simple related problems) 2.4 Use of air vessels 2.5 Advantages & disadvantages of reciprocating pump over reciprocating pump 2.6 Centrifugal pump types 2.7 Working of the pump, methods of converting the K.E of water leaving the impeller into pr. Energy, the volute chamber, the vortex or the whirl pool chamber, guide blades, priming 2.8 Inlet & outlet vector diagrams, work done by the impeller, the manometric head, the manometric effy., impeller power, the mechanical effy., the overall effy., (RELATED PROBLEMS) 2.9 Minimum speed to run the pump. loss of head due to reduced or increased flow ,multistage centrifugal pumps ,specific speed of centrifugal pumps 2.10 Selection of pump ( Both reciprocating & centrifugal) 3.HYDRAULIC TURBINE 24 PDS. 3.1 Classification Impulse ,reaction & kaplan 3.2 Pelton wheel components , working principle, velocity diagrams, work done, power ,effy. ( PROBLEMS)

3.3 Francis turbine components, working principle, velocity diagrams, work done, power, effy., (PROBLEMS) 3.4 Kaplan turbine- components 3.5 Governing of an impulse turbine ( pelton wheel) 3.6 Difference between impulse & reaction turbine 3.7 Layout diagram of a hydraulic power house 3.8 Selection of turbine specific speed 3.9 Draft tube 4. MISCELLANEOUS 6 PDS. 4.1 Hydraulic accumulator 4.2 Fluid coupling 4.3 Surge tank 4.4 Water hammer ,Surge tank & Cavitation 4.5 Intensifier

________

MACHINE DESIGN, ESTIMATING & COSTING

Subject Code ME / 6 / T2 / MDEC Course offered in Part III 2nd Semester Course Duration 17 weeks 3 lecture + 1 tutorial contact periods per week Full Marks 75

M 1 Introduction : Concepts of machine design, Machine & machine elements basic requirements. Factors to be considered during machine design. Types of load, types of stresses, factors of safety under different load conditions, stress concentration. Commercial design material available and their properties such as C.I., W. I. , M.S. , alloy steel, Copper alloy, Tin, G.M., Aluminium, Zinc, Non metal such as plastic, composite metal, designation of steel, Indian standard (I.S. 1570, 1970), selection of material, use of design data book, General procedure in design. [6 pds.] M 2 Design of riveted joint. : Rivet material, types of heads, types of riveted joints, types of failure of riveted joint, Relation between a) Plate thickness, b) Rivet hole diameter and c) Rivet diameter. Effy of the joints (Caulking and fullering , simple problem). [6 pds.] M 3 Design of welded joints. M 3.1 Application of welded joint. Advantages and disadvantages of welded joint over riveted joint, materials used in welded joint,type of welded joint Name and symbol as per I.S. M 3.2 Design of V Butt welded joint transverse and parallel fillet welded joints only, Circular fillet welded joint (subjected to pure torsion and bending only) (Simple problem) [6 pds.] M 4 Design all parts of a) Knuckle joints b) Cotter joints. M 5 Design of a) C.I. pulley for flat belt. b) Rigid shaft coupling. For transmission of given power. Design of all parts including shaft (pure torsion only) and keys) [8 pds.]

M 6 Cam Introduction, classification Cam, Classification of followers, definition, Motion of followers (Uniform velocity, uniform accelaration, retardation and simple harmonic motion) [4 pds.] Cam profile construction ( Knife edge and roller follower) ESTIMATING AND COSTING M 7 Definition of estimating and costing, elements of costing, overhead ( classification, allocation), depreciation, scrap, wastage & spoilage grouping of costing simple problems. [4 pds.] M 8 Determination of weight of various parts such as i) craules ii) stauffing box gland iii) simple bush bearing iv) Flonged pipe. [4 pds.] M 9 Estimation of simple forged parts such as i) Rivets ii) Bolts & Nuts, iii) Chain, iv) Simple spanner, v) Simple crank & connecting Rod. [4 pds.] M 10 Estimation of selling price of cost part such as i) C.I. pulley, ii) Coupling, iii) Piston, iv) V belt pulley, v) wooden pattern of flange. [6 pds.] M 11 Estimation of fabricated job by welding only such as I) rectangular square container, ii) Cylindrical tank, iii) Simple chimney, iv) Funnel, v) Racks, vi) manhole cover. [8 pds.]

ALLOCATION OF TIME & EVALUATION SCHEME

GROUP MODULE PERIODS ALLOTED 6 6 6 8 8 4 4 4 4 6 8 NO. OF QUES. TO BE SET 12 11 25 12 1 25 4 2 10 20 OBJECTIVE QUESTION NO. OF MARK QUES TO OF BE ANS. EACH TOTAL NO. OF QUES. TO BE SET 2 4 SUBJECTIVE QUESTION NO. OF MARK QUES TO OF BE ANS. EACH 1 2 10 10 TOTAL

A B

M1 M2 M-3 M4 M5 M6 M7 M8 M9 M 10 M 11

10 20

________

THEORY OF MACHINES

Subject Code ME / 6 / T3 / TOM Course offered in Part III 2nd Semester Course Duration 17 weeks 3 lecture + 1 tutorial contact periods per week Full Marks 75

MODULAR DIVISION OF THE SYLLABUS

GROUP A MODULE 1 2 3 TOPIC POWER TRANSMISSION BY BELTS & PULLYS POWER TRANSMISSION BY GEARS BALANCING OF ROTATING MASSES CONACT PERIODS 9 9 8

4 5

FLYWHEEL & GOVERNERS LINK MOTION

8 8

EXAMINATION SCHEME

GROUP MODULE TO BE SET 15 20 OBJECTIVE QUESTIONS TO BE ANSWERED 25 MARKS PER QUESTION 1 TOTAL MARKS 25 TO BE SET 4 6 SUBJECTIVE QUESTION TO BE ANSWERED FIVE AT LEAST TWO FROM EACH GROUP MARKS PER QUESTION 10 TOTAL MARKS 50

A B

1,2 3,4,5

DETAIL COURSE CONTENT

GROUP A 1) POWER TRANSMISSION BY BELT AND PULLYS 9 PDS. Open & cross belt drive, velocity ratio, length of belt, tension on tight side & slack side, initial tension, relation between tight side & slack side tension, centrifugal tension, power transmission, problems on flat belt drive, idea of v-belt drive, rope drive, compound drive( no problem) 2) POWER TRANSMISSION BY GEAR 9 PDS. Types of gear- important terms and definition related to spur gear ( pitch, pitch circle, addendum, dedendum, module etc.),velocity ratio, simple gear train, compound gear train, power transmitted by gears, problems on spur gear train, epicyclic gear train, problems GROUP - B 3) BALANCING OF ROTATING PARTS 8 PDS. Balancing of single rotating mass by another single mass rotating in the same plane, balancing of several rotating masses by a single mass rotating in the same plane ( graphical method),balancing of several masses rotating in different planes, problems 4) FLYWHEELS & GOVERNERS 8 PDS. Crank effort diagram, function of flywheel, co-efficient of fluctuation of speed, determination of weight of flywheel for a given crank effort diagram, governers, functions, types, simple watt, porter & hartnel governer, simple problems in relation to simple watt & porter governer 5) LINK MOTION 8 PDS. Definition of kinematic link, kinematic pair, kinematic chain mechanism & machines, relative motion, instantaneous centre,4 bar linkage, crank & connecting rod mechanism to determine velocity by relative velocity diagram & instantaneous center method EVALUATION 6 PDS.

________

AUTOMOBILE ENGINEERING II (ELECTIVE-II)

Subject Code ME / 6 / T4 / ELC2 Course offered in Part III 2nd Semester Course Duration 17 weeks 3 lecture contact periods per week Full Marks 75

MODULAR DIVISION OF THE SYLLABUS

GROUP A MODULE 1 2 3 TOPICS CHASSIS & BODY TRANSMISSION SYSTEM GEAR BOX PERIODS 2 8 4

4 5 6 7 8 9

PROPELLER SHAFT & FINAL DRIVE SUSPENSION SYSTEM STEERING SYSTEM BRAKING SYSTEM WHEEL & TYRE GARAGE & SERVICE STATION

8 6 4 8 4 4

EXAMINATION SCHEME

GROUP MODULE TO BE SET 19 13 12 4 OBJECTIVE QUESTIONS TO BE ANSWERED 25 MARKS PER QUESTION 1 TOTAL MARKS 25 TO BE SET 2 4 B C 4,5,6 7,8,9 SUBJECTIVE QUESTION TO BE ANSWERED MARKS PER QUESTION 10 TOTAL MARKS 50

1,2,3

FIVE AT LEAST ONE FROM EACH GROUP

DETAIL COURSE CONTENT

1) CHASSIS & BODY 2 PDS. 1.1) Chassis frame, functions 1.2) Automobile body, types, stream line body 2) TRANSMISSION SYSTEM 8 PDS. 2.1) Elements of power transmission system from crankshaft to rear axle ( line diagram) 2.2) Clutch, functions, types, single dry plate clutch, working principle, functions of component, clutch plate ( construction),pr. Plate, clutch facing 2.3) Centrifugal clutch ( simple type),working principle 2.4) Fluid coupling-working principle 3) GEAR BOX 4PDS. 3.1) Necessity, function, types, sliding mesh, constant mesh, synchromesh -working principle 3.2) Torque converter working principle 4) PROPELLER SHAFT & FINAL DRIVE 8 PDS. 4.1) Function & components, types of final drive, hotch kiss drive, torque-tube driveworking principle 4.2) Differential- construction & operation 4.3) Axle drive, types, semi floating, three quarter floating & fully floating type 4.4) Two wheel drive & four wheel drive- operation, advantages & disadvantages, layout of transmission system 5) SUSPENSION SYSTEM 6 PDS. 5.1) Functions, name of the components 5.2) Spring- leaf, coil, helper spring, torsion bar, camber 5.3) Shock absorber- hydraulic type(simple type) 5.4) Independent suspension, function, types, working principle of Mac-pherson street system, its advantages over conventional system 1) STEERING SYSTEM 4 PDS. 6.1) Components & functions, steering linkage ( layout diagram with function of each) ,steering ratio 6.2) Steering geometry- caster, camber, king-pin -location, toe-in, toe-out, aclear man steering 7) BRAKING SYSTEM 8 PDS. 7.1) Purpose of using, function & types

7.2) Working principle of air & hydraulic brakes system (layout) 7.3) Disc brake system- working principle 7.4) Working of master cylinder, service brake & pushing brake- use & mode of operation 7.5) Self adjusting brake, autislid device 8) WHEEL & TYRE 4 PDS. 8.1) Types, hubs, rims 8.2) Tyre classification- construction of pneumatic tyre, tyre thread, ply rating, matching of tyre, retreading of tyres, wheel balancing, radial tyre, vulcanising of tube, causes of excessive wear 9) GARAGE AND SERVICE STATION 9.1) Location and layout 9.2) Equipments & tools 9.3) Types of service carried out 4 PDS.

_______

Potrebbero piacerti anche

- Key Programming Brochure 39 - Keyprog - Brochure PDFDocumento30 pagineKey Programming Brochure 39 - Keyprog - Brochure PDFElectronicar Marcelo88% (8)

- Analytical Design of Radial Turbine Design-NasaDocumento162 pagineAnalytical Design of Radial Turbine Design-Nasamrbookani100% (1)

- Machine Design Elements and AssembliesDa EverandMachine Design Elements and AssembliesValutazione: 3.5 su 5 stelle3.5/5 (2)

- File 001977Documento3 pagineFile 001977julio binedaNessuna valutazione finora

- Directional DrillingDocumento129 pagineDirectional DrillingYuri Kost100% (7)

- Control SystemsDocumento160 pagineControl SystemsPintu DeyNessuna valutazione finora

- Fatique On Piston RingDocumento6 pagineFatique On Piston Ringmohanrajjercy71100% (1)

- Planar Spiral SpringDocumento104 paginePlanar Spiral SpringPrabhat PustakeNessuna valutazione finora

- Energy-saving Principles and Technologies for Induction MotorsDa EverandEnergy-saving Principles and Technologies for Induction MotorsNessuna valutazione finora

- R.A. 4136 Land Transportation & Traffic CodeDocumento19 pagineR.A. 4136 Land Transportation & Traffic CodeJason CabreraNessuna valutazione finora

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsDa EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNessuna valutazione finora

- 608B, 608S, 608L, 753G, 753GL Tier II Track Feller Buncher Introduction BulletinDocumento5 pagine608B, 608S, 608L, 753G, 753GL Tier II Track Feller Buncher Introduction BulletinRoberto Carlos Mayorga VelasquezNessuna valutazione finora

- Power Electronics and Electric Drives for Traction ApplicationsDa EverandPower Electronics and Electric Drives for Traction ApplicationsNessuna valutazione finora

- Brand Equity ModelDocumento86 pagineBrand Equity ModelYash Vora100% (1)

- Manafacturingcompanies in KanchiDocumento46 pagineManafacturingcompanies in KanchichandhrupgdmNessuna valutazione finora

- Syllabus Automobile EngineeringDocumento54 pagineSyllabus Automobile EngineeringmechanzsNessuna valutazione finora

- Sem 5Documento18 pagineSem 5Chiranjibi SahooNessuna valutazione finora

- Assignments Saraswati College of Engineering - CompressDocumento15 pagineAssignments Saraswati College of Engineering - CompressANUSHA SINGH V HNessuna valutazione finora

- Automobile SyllabusDocumento157 pagineAutomobile SyllabussolomonrajarNessuna valutazione finora

- Chhattisgarh Swami Vivekanand TechnicalDocumento8 pagineChhattisgarh Swami Vivekanand TechnicalLakshminarayana ChNessuna valutazione finora

- 5.1. Computer Applications in Mechanical Drafting, Design and AnalysisDocumento15 pagine5.1. Computer Applications in Mechanical Drafting, Design and AnalysisDIA WORLDNessuna valutazione finora

- Me53 Design of Machine Elements L T P CDocumento2 pagineMe53 Design of Machine Elements L T P CajithjkingsNessuna valutazione finora

- Kinematics of Machinery Anna University Question Papers CompiledDocumento77 pagineKinematics of Machinery Anna University Question Papers CompiledNatesha SundharanNessuna valutazione finora

- Anna University Coimbatore REGULATIONS 2007-08 B.E - Mechanical EngineeringDocumento28 pagineAnna University Coimbatore REGULATIONS 2007-08 B.E - Mechanical EngineeringRaajeshkrishnaNessuna valutazione finora

- Automobile VTU Syllabus For 6th SemesterDocumento22 pagineAutomobile VTU Syllabus For 6th SemesterprabhuswamygsNessuna valutazione finora

- Syllabus-MDU-ME 5 Sem FDocumento13 pagineSyllabus-MDU-ME 5 Sem Fraul2speedNessuna valutazione finora

- 5th Sem SyllabusDocumento14 pagine5th Sem Syllabusveer_sNessuna valutazione finora

- 5th Sem Syllabus DseuDocumento8 pagine5th Sem Syllabus DseuSachin KumarNessuna valutazione finora

- Btech 2Documento17 pagineBtech 2Divyesh SindhiNessuna valutazione finora

- Machines and Mechanism PDFDocumento3 pagineMachines and Mechanism PDFPradeepvenugopalNessuna valutazione finora

- MEL311Documento281 pagineMEL311Shiri ShaNessuna valutazione finora

- Rotordynamic Design Optimization of A Steam Turbine Rotor Bearing SystemDocumento72 pagineRotordynamic Design Optimization of A Steam Turbine Rotor Bearing SystemTarkan KaragozNessuna valutazione finora

- Devi Ahilya Vishwavidyalaya, I Dore I Stitute of E Gi Eeri G & Tech OlogyDocumento20 pagineDevi Ahilya Vishwavidyalaya, I Dore I Stitute of E Gi Eeri G & Tech OlogySonal MahajanNessuna valutazione finora

- Civil - Sem - 3Documento28 pagineCivil - Sem - 3Garima RajdevaNessuna valutazione finora

- Emd NotesDocumento182 pagineEmd Notesvpzfaris0% (1)

- B. Tech. 8 Semester Mechanical Engineering: Theory Sessional TotalDocumento10 pagineB. Tech. 8 Semester Mechanical Engineering: Theory Sessional TotalAbhishek MeNessuna valutazione finora

- Finet Element Analysis of Rollers PDFDocumento218 pagineFinet Element Analysis of Rollers PDFGaneshNessuna valutazione finora

- Fourth 1 PDFDocumento23 pagineFourth 1 PDFMathews P RejiNessuna valutazione finora

- Flow Simulation - CFD - & Static Structural Analysis - Fea - of A Radial TurbineDocumento18 pagineFlow Simulation - CFD - & Static Structural Analysis - Fea - of A Radial TurbineIAEME PublicationNessuna valutazione finora

- DTSDocumento7 pagineDTSmithundme659Nessuna valutazione finora

- Mech AutoDocumento36 pagineMech Autoapi-236544093Nessuna valutazione finora

- Mvjce Me 6 SemDocumento101 pagineMvjce Me 6 SemAkash AkuNessuna valutazione finora

- Lesson PlanDocumento6 pagineLesson Planshweta_770587Nessuna valutazione finora

- Assignment Booklet: BTME ProgrammeDocumento20 pagineAssignment Booklet: BTME ProgrammeSarvanKumarNessuna valutazione finora

- 6TH SEM SyllabusDocumento35 pagine6TH SEM Syllabussrujangowdasj2002Nessuna valutazione finora

- Mechanical Engineering s7 & s8Documento330 pagineMechanical Engineering s7 & s8The OpenstudioNessuna valutazione finora

- Department of Mechanical Engineering: B. Tech. Detailed Syllabus (Semester-V)Documento4 pagineDepartment of Mechanical Engineering: B. Tech. Detailed Syllabus (Semester-V)Thennarasu RamachandranNessuna valutazione finora

- Edibon CatalogDocumento32 pagineEdibon CatalogelenamoisoniNessuna valutazione finora

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsDa EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNessuna valutazione finora

- BTech Auto SyllDocumento30 pagineBTech Auto SyllAjayChouhanNessuna valutazione finora

- 2nd Year Civil Engineering Course Detail of IOE, TU NepalDocumento20 pagine2nd Year Civil Engineering Course Detail of IOE, TU NepalSunil Kharbuja100% (1)

- Automobile EngineeringDocumento4 pagineAutomobile EngineeringAshley_Rulzzzzzzz0% (2)

- AE Course PlanDocumento6 pagineAE Course PlanrameshszrNessuna valutazione finora

- MMP - Export SyllabusDocumento20 pagineMMP - Export SyllabusVarun KumarNessuna valutazione finora

- Mechanical Engineering Department, NIT Srinagar: 5 SemesterDocumento8 pagineMechanical Engineering Department, NIT Srinagar: 5 SemesterBISMA ZARGARNessuna valutazione finora

- Third Year Mechanical Engineering SyllabusDocumento54 pagineThird Year Mechanical Engineering SyllabusTonya WhitneyNessuna valutazione finora

- Me-301 F Dynamics of MachinesDocumento12 pagineMe-301 F Dynamics of MachinesRaj KumarNessuna valutazione finora

- Instruction: 4 Lectures & 1 Tutorial / Week Sessional Marks: 40 End Exam: 3 Hours End Exam Marks: 60Documento3 pagineInstruction: 4 Lectures & 1 Tutorial / Week Sessional Marks: 40 End Exam: 3 Hours End Exam Marks: 60Palaka RahulNessuna valutazione finora

- Mechanics of MachinesDocumento8 pagineMechanics of MachinesVikram RaoNessuna valutazione finora

- Gear Lever Sticks in 5th/reverse Gear Shift Gate BMW Sib230104-063Documento2 pagineGear Lever Sticks in 5th/reverse Gear Shift Gate BMW Sib230104-063wardofNessuna valutazione finora

- Weekly Report RitvikDocumento113 pagineWeekly Report RitvikRajesh JoshiNessuna valutazione finora

- TransmissionGuideBrochure RRSL0001 0218 LRDocumento29 pagineTransmissionGuideBrochure RRSL0001 0218 LROrlando RojasNessuna valutazione finora

- Stock Mentain in Excel by DEEPAK EDUWORLDDocumento10 pagineStock Mentain in Excel by DEEPAK EDUWORLDAdnan Raja GkNessuna valutazione finora

- The Failure of Daewoo Cielo in IndiaDocumento17 pagineThe Failure of Daewoo Cielo in IndiaKumar GauravNessuna valutazione finora

- AutomobileDocumento7 pagineAutomobileankit807Nessuna valutazione finora

- Company ProfileDocumento14 pagineCompany ProfileTanmay DohareyNessuna valutazione finora

- Report On Mahindra BoleroDocumento39 pagineReport On Mahindra BoleroÊvîl TɘʀɱiŋʌtorNessuna valutazione finora

- Makardhwaj Kumar Singh: Curriculam VitaeDocumento4 pagineMakardhwaj Kumar Singh: Curriculam VitaeVed Prakash UjjainNessuna valutazione finora

- Hvac Resume Technician ExampleDocumento2 pagineHvac Resume Technician ExampleMartin FloresNessuna valutazione finora

- Fundamental and Technical Analysis of Automobile SectorDocumento82 pagineFundamental and Technical Analysis of Automobile SectorAnant SharmaNessuna valutazione finora

- Trans Sys ChapDocumento8 pagineTrans Sys ChapDr. Ir. R. Didin Kusdian, MT.Nessuna valutazione finora

- CAP AS-RADIATOR 1531403 - CaterpillarDocumento4 pagineCAP AS-RADIATOR 1531403 - CaterpillarMovimento RockNessuna valutazione finora

- Section 1: Introduction About FirmDocumento1 paginaSection 1: Introduction About FirmAhmadDaimNessuna valutazione finora

- Indian Auto Industry . The Way: Presentation By-Sunil Kakkar General Manager (Supplychain) Maruti Suzuki India LTDDocumento35 pagineIndian Auto Industry . The Way: Presentation By-Sunil Kakkar General Manager (Supplychain) Maruti Suzuki India LTDViral JainNessuna valutazione finora

- User ManualDocumento25 pagineUser Manualtudor_patrutoiuNessuna valutazione finora

- D 020 4 16 EN RevCDocumento2 pagineD 020 4 16 EN RevCarrchilNessuna valutazione finora

- Nano Case StudyDocumento39 pagineNano Case StudyarushichananaNessuna valutazione finora

- Bosch Software Innovations Iot Whitepaper StrategyDocumento22 pagineBosch Software Innovations Iot Whitepaper Strategyramnadh803181Nessuna valutazione finora

- Case Analysis GM SATURNDocumento9 pagineCase Analysis GM SATURNgopaul123100% (1)

- Sumit RanaDocumento4 pagineSumit RanasumitranaNessuna valutazione finora

- Ch18 SG BLTS 8eDocumento20 pagineCh18 SG BLTS 8eHolli Boyd-White100% (1)

- Report On Marketing Strategy of Rahimafrooz Bangladesh LimitedDocumento28 pagineReport On Marketing Strategy of Rahimafrooz Bangladesh LimitedMuntasirNessuna valutazione finora

- OEM Tyre Customer Satisfaction IndexDocumento3 pagineOEM Tyre Customer Satisfaction Indexdeepakjmartin8427Nessuna valutazione finora