Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mto Lab

Caricato da

raghu_iictDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mto Lab

Caricato da

raghu_iictCopyright:

Formati disponibili

1.

VAPOR DIFFUSIVITY

AIM :

To determine the diffusivity of the given organic solvent.

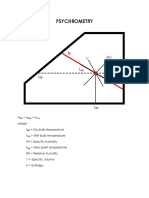

THEORY :

The diffusion operations always involve the contact of fluid, either gas or liquid with another

phase accompanied by transfer of material between the contacted phase. It is desirable to maintain

the contacted phase in relative motion with respect to one another. Molecular diffusion is the

transport of matter on a molecular scale through a fluid, which is stagnant, or if in laminar flow in a

direction perpendicular to the flowing streamlines. The diffusion of vapor A, from a volatile liquid

into another gas B (here air) can be conveniently studied by confining a small sample of the liquid

in a narrow vertical tube and observing its rate of evaporation into a stream of gas B passed across

the top of the tube.

The apparatus consists essentially a glass capillary tube placed in a transparent sided temperature

controlled water bath. A horizontal glass tube is fixed to the upper end of the capillary tube and air

is blown through this by a small air blower included with in the unit.

The arrangement allows the maintenance of a partial pressure difference within the capillary tube

between the evaporating liquid surface and the flowing air stream. A traveling microscope, with

sliding vernier scale is mounted on a rigid stand along side the thermostatic bath and is used to

measure the rate of fall of the solvent or air meniscus with in the capillary. The diffusivity cell used

here is a case of pseudo steady state diffusion in which one of the boundaries shift with time with

the effect that the length of the diffusion path changes though only by a small amount over a long

period of exposure.

Air(B) Air(B)

Z1 Z2

1

Org. solvent

Org.Solvent

Final liquid level

PROCEDURE :

Fill the water bath with water, switch on the stirrer. Heat the water to the desired

temperature by adjusting the thermostat. Fill the capillary tube with the given organic

solvent, say, carbon tetrachloride or acetone (to the level of about 75%) and replace the

capillary tube. Note down the initial liquid level in the capillary tube using vertical traveling

microscope. Allow the air to flow continuously over the capillary tube, to maintain zero

partial of the vapor at the top of the capillary tube. Let the experiment run in this fashion for

an hour and note down the liquid level in the capillary tube using vertical traveling

microscope at interval of every ten minutes. Repeat the experiment with atleast three

different bath temperatures of 50, 60, 70

0

C and plot the diffusion co-efficient against

temperature on a log-log sheet and confirm that the slope is 3/2.since DAB is proportional to

T

3/2

(

t

AB

P

T

D

2

3

).

Compare the experimental value with the theoretical value calculated from Wilke-Lee

equation:

DAB=

( )

,

_

,

_

AB

AB t

B A B A

KT

f r P

M M

T

M M

2

2

3

4

1 1 1 1

249 . 0 084 . 1 10

CALCULATIONS :

Refer fig. At t = 0, z = z1 (Initial height)

t = t , z = z 2 = z1 + z at t = t ;

since the flow of air is continuous , the concentration of the organic solvent at the top of the tube is

zero.

Density of solvent at room temp. () = _______

Vapor pressure of solvent at room temp.(PA1)= ____.

PB1 = Pt-PA1 = 760 - PA1 mmHg.

At Z=Z2 , the vapor pressure of solvent at air-solvent interface = 0 this means that PA,2 = 0.

2

PB,2 = Pt-PA,2 = 760mmHg.

PB,ln =

( )

,

_

1 ,

2 ,

1 , ,

ln

B

B

B Z B

P

P

P P

.

( )

2

.

1

. .

2

2

2

1

,

2 , 1 ,

ln

Z Z

M

P

t P P

P RT

P

Z

D

L A

B B

B

AB

3

2. LIQUID DIFFUSION

AIM :

To determine the diffusion coefficient of Sulphuric acid in Water.

THEORY :

The diffusional operations always involve the contact of fluid, either gas or liquid with another

phase accompanied by transfer of material between the contacted phase. It is desirable to maintain

the contacted phase in relative motion with respect to one another. Molecular diffusion is the

transport of matter on a molecular scale through a fluid, which is stagnant, or if in laminar flow in a

direction perpendicular to the flow.

PROCEDURE :

1. Take about 750ml of water in the beaker (note down the volume of water taken).

2. Fill the porous tube with about 150ml of dilute Sulphuric acid (known normality, say 0.05).

3. Allow the diffusion to continue for an hour. Note down the final volume of water in the beaker

and also the volume in the porous tube.

4. Find the normality of H2SO4 in the beaker and also normality of H2SO4 in the porous tube.

CALCULATIONS :

1. Standardize sodium hydroxide using 0.05 N oxalic acid.

2. Using the standardized sodium hydroxide (around 0.05 N), standardize H2SO4 .

3. After one hour titrate the solution in the beaker and the porous tube.

4. Initial volume of pure H2SO4 in the porous tube (Suppose 150 ml of 0.05 N H2SO4 is taken,

the volume of pure H2SO4 present in this 150 ml.)

Normality of H2SO4 = _____

Density of H2SO4 at room temperature = _________

Volume of H2SO4 in the porous tube = _________

4

Weight of H2SO4 = [N x mol. Wt . x vol taken] / [2 x 1000]

Volume of H2SO4 = weight / density

5. Volume of H2SO4 in the porous tube after diffusion = _________ ml.

Normality of H2SO4 after diffusion = ________ N

Weight of H2SO4 = [N x mol.wt. x vol.] / [2 x 1000] = ____ gm.

Moles of H2SO4 = wt. / mol.wt.

Volume of H2SO4 = weight / density (Q)

Volume of H2O in porous tube = P Q

Weight of H2O = volume x density

Moles of water = wt. of water / mol. Wt

Mole fraction of water in porous column,

XA1 = No.of moles of H2SO4/ No.of moles H2SO4+ moles of H2O

XB1 = 1 XA1

1 = weight/volume = [wt. Of H2SO4 + wt. Of H2O]/[vol.of H2SO4 + vol.of

H2O] or can be determined using specific gravity bottle.

M1 = average mol. Wt.= (XA1) (mol.wt. of H2SO4) + (XB1)( mol.wt. of H2O) Calculate (/M)1

IN BEAKER:

Volume of solution in beaker = ______ ml.

Normality of solution = _____ N

Moles of H2SO4 = [Nor. X Volume]/[2 x 1000] = ______ moles

Weight of H2SO4 = moles x mol.wt. = _____ gm

Volume of H2SO4 = weight / density of H2SO4 = ____ ml.

Initial volume of water in beaker = ____ ml.

Weight = volume x density

No. of moles = weight / mol.wt.

Mole fraction XA2 = [ moles of H2SO4]/ [ moles of H2SO4 + moles of H2O]

XB2 = 1 XA2 ; 2 = Weight / volume or find out using specific gravity bottle

M2 = average mol. Wt. = (XA2) (mol.wt. of H2SO4) + (XB2)( mol.wt. of H2O)

5

Calculate (/M)2 = ____

Determine (/M)avg. = [(/M)1+(/M)2]/2

Calculate, XBM = [XB1 XB2] / ln(XB1/XB2)

(a) Initial moles of H2SO4 in the porous tube = ______

(b) After diffusion number of moles of H2SO4 in porous tube = ______

Drop in moles of H2SO4 = (a) (b)

Increase in moles of H2SO4 in beaker = _____ moles

Moles of H2SO4 transferred =[Drop in moles of H2SO4 incr. in moles

of H2SO4 in beaker]/2

NA = no.of moles of H2SO4 transferred/ [DL x time]

D = diameter of the column; L = length of the column; Time = 3600s

NA = {(DAB/Z)( (/M)avg [(XA1 XA2)/ XBM] }; Calculate diffusivity

from the above equation.

Compare the result with Wilke Chang equation:

DAB

o

= [(117.3 x 10

-8

)(MB)

0.5

T] / [ VA

0.6

]

6

3. SIMPLE DISTILLATION

AIM: To verify the Rayleighs law by carrying out differential distillation for a given binary

mixture.

THEORY:

In a simple batch distillation or differential distillation a liquid mixture is slowly boiled in a

kettle. The vapors are removed immediately as soon as they are formed. The distillate is

then collected from the condenser. During the early part of vaporization the distillate is rich

in A, but as time proceeds, it becomes leaner in A.

Consider a batch of L1 moles of a liquid mixture consisting of components A and B in he

still and x1 be the mole fraction of A in the still. At any given time during distillation, there

are L moles of liquid left in the still and x and y are the mole fractions of A in liquid and

vapor respectively. A very small amount of liquid dL is vaporized. The composition is from

x to x-dx and the change in the amount of liquid is from L to L-dL.

Material balance for the component A gives,

xL = (x-dx)(L-dL) + y dL or xL = xL x dL Ldx + dx dL + y dL

Neglecting dx dL , the equation may be written as , dL / L = dx / (y-x)

Integrating, ln F/W =

xF

xw

x y

dx

*

; where , F= original moles in the still.

W= moles left in the still

The integration of Rayleigh equation can carried out graphically from the equilibrium curve,

by plotting 1 / (y* - x) vs x as follows:

Y3

*

Y2

*

Y

Y1

*

x1x2 x3

7

x

Plot 1/ (y

*

-x) vs x :

1/(y*-x)

xw xF

x

If LHS = RHS, Rayleigh law is verifed.

OBSERVATIONS:

Initial quantity of feed taken = ml

Vol x density = weight of distillate

Volume of distillate collected = ml

Density =

volume x density = weight

Volume of bottoms = feed distillate= ___ ml.

Volume x density = weight

8

x

ALTERNATIVE METHOD:

We know that Y * = x / [1+ ( - 1)x] assuming as an ideal mixture with constant relative

volatility.

Raleigh equation for this case is ln [FxF/ Wxw] = ln {[F(1-xF)/ W(1-xw)]}

9

4. BATCH DISTILLATION WITH RECTIFICATION

AIM:

To find determine the height equivalent to theoretical plate (HETP) and the capacity

coefficient for the given system using packed distillation tower.

THEORY:

The vapor produced during differential distillation is removed as fast as it is formed and as

a method of separation this technique is not very effective. In order to ensure a high

degree of separation and simultaneously obtaining a high degree of enrichment by simple

distillation, one good method is to distill both the residual liquid and the overhead products.

This can be accomplished by a repetition of simple distillation. There is yet another way, a

better one indeed, to obtain a high degree of separation. This is the method o using reflux

i.e., batch still is hooked up with a rectifying column to establish reflux policy. This method

is particularly useful to obtain products with a narrow range of composition.

PROCEDURE:

Charge the still with the given organic mixture and measure the composition by measuring

the density.Adjust the thermostat to 80

0

C, allow the mixture to boil for half an hour under

total reflux conditions.Measure the flow rate of the condensate, note down the time taken

to collect 10 ml of the condensate. Measure the composition of the condensate by

measuring the density.

Measure the composition of the bottoms.

Note down the temperature indicated by the thermometer.

10

CALCULATIONS:

Find out the number of trays required for the same separation using Mc Cabe thiele method.

Height of the column is one meter.

Height equivalent to theoretical plate can be calculated from height of the column and number of

theoretical plates as follows: HETP = Z / (n-1)

Z = NtoG . HtoG

NtoG = (y1 y2) / {[(y y1

*

)-(y- y2

*

)] / [ln (y y1

*

)/(y- y2

*

)}

{Plot the equilibrium curve and find the equilibrium values for feed and condensate}

Capacity coefficient, Kya = G / HtoG ; where G is the mass flow rate of condensate.

HtoG = Z / NtoG

Result: HETP = ___ ; HtoG= ; NtoG = ; Capacity Coefficient =

11

5. SOLID LIQUID EQUILIBRIUM

AIM:

To generate the solid liquid equilibrium data.

THEORY:

Solid liquid extraction is most widely used in metallurgical industries.Most useful minerals occurs

in mixtures with large proportions of undesirable constituents, and leaching of the valuable material

is a separation method which is applied. For example copper minerals are preferentially dissolved

from certain of their ores by leaching with sulphuric acid or ammoniacal solutions, and gold is

separated from its ores with the aid of sodium cyanide solutions. Leaching similarly plays an

important part in the metallurgical processing of alumina, cobalt, manganese, nickel, and zinc.

Many naturally occurring organic products are separated from their original structure by leaching.

For example sugar is leached from sugar beets with hot water, vegetable oils are recovered from

seeds such as soybeans and cotton seed by leaching with organic solvents, tannin is dissolved out

of various tree barks by leaching with water, and many pharmaceutical products are similarly

recovered from plant roots and leaves. Tea and coffee are prepared both domestically and

industrially by leaching operations.

PROCEDURE:

Take 5 beakers and number them as (i), (ii),(iii) (iv) &(v). Add 40gm of calcium carbonate and l00ml

of distilled water to each flask. Add around 2, 4, 6, 8 & l0gm of NaOH to (i), (ii),(iii) (iv) &(v)

respectively.

Stir the contents of the flask and allow the mixture to stand for 15- 20min.

Separate the liquid portion by filtration using filter paper. Measure the volume of the filtered liquid.

Measure the density of the filtrate using specific gravity bottle.

Take 10mlof the liquid and titrate against oxalic acid of known Normality (0.5N).

Calculate normality of sodium carbonate.

12

Note down the density of water at room temperature.

CALCULATIONS:

Normality of oxalic acid =

Normality of Na2CO3 =

Wt. of Na2CO3 in liquid phase = Normality*Vol. of filtrate* EqWt./1000

Wt. of Na2CO3 in solid phase = Original Wt. - Wt. of Na2CO3 in liquid phase

Wt. of water in solid phase,

X = Wt. of Na2CO3/ Wt. of Na2CO3+ Wt of H2O Liquid Phase

Nx = Wt. of calcium carbonate/ Wt. of Na2CO3 + Wt. of H2O

Y = Wt. of Na2CO3/ Wt. of Na2CO3+ Wt.of H2O Solid Phase

NY = Wt of calcium carbonate / Wt. of Na2CO3 + Wt of H2O

Measure of density of the decanted mixture,

Volume x mixture

= Wt. of the mixture.

Total Wt. - Wt of Na2CO3 in liquid phase = Wt. of water in solid phase.

X liq.= C/A+C =

X Sol. = C/A+C =

Nx = B/A+C = 0

Ny = B/A+C

Plot a graph by taking Nx, Ny on Y-axis and X, y on X-axis. Also draw Tie lines along with

Equilibrium curves.

13

6. LIQUID LIQUID EQUILIBRIUM

Aim:

To generate the liquid liquid equilibrium data for the given system.

Theory:

This is used as an alternative method for azeotropic distillation. When the boiling point difference is

very less then separation by distillation becomes difficult. Such mixtures are contacted with another

liquid which is soluble only with one of the components present in the mixture. The boiling point

difference between the solvent and the dissolved component should be large so that the separated

component can be separated by distillation. For example, if acetic acid and water mixture is present,

this is contacted either with chloroform or benzene , acetic acid dissolves with the organic solvent and

can be separated by distillation.

Freefatty acid dissolved in the vegetable oil can be separated by liquid liquid extraction using iso-

propyl alcohol as solvent.

PROCEDURE:

Take measured volume of water and acetic acid (A+C) and add measured volume of chloroform

(B)into a separating funnel. Mix the contents vigorously for 5 minutes.

Put the separating funnel into the stand provided and allow the mixture to separate into the

raffinate and extract phase.

Drain raffinate and extract phase in separate conical flask and measure their volume with the

measuring cylinder.

Titrate raffinate and extract phase with suitable NaOH solution and find out the volume required to

titrate the same using methyl orange as an indicator.

Tabulate these titer values in the table. In the, same manner take different amounts of (A+C) and B

and continue the experiment as above to get at least six-seven different equilibrium points.

OBSERVATION TABLE:

Density of Chloroform = kg/ m

3

Density of Water = kg/ m

3

14

Density of Acetic Acid = kg/ m

3

Normality of NaOH solution used for Raffinate = N

Normality of NaOH solution used for Extract = N

TABULAR COLUMN:

Sr. No.

Vol.of

water

(VA) ml

Vol. Of

CH3COOH

VC (ml)

Vol. Of

C6H6

VB (mL)

Vol. Of

Raffinate

phase

VR (m

3

)

Vol. Of

Extract

phase

VF (m

3

)

Titer value

for

Raffinate

phase

TR ml

Titer

value for

Extract

phase

TE ml

CALCULATIONS:

CR = [(TR*Normality of NaOH)/Volume of Raffinate sample]*Mol.Wt. of Acetic acid.

CE = [(TE*Normality of NaOH)/Volume of Extract sample]*Mol.Wt. of Acetic acid.

mR = VR*density of raffinate phase.

mE = VE*density of extract phase.

S. No.

Con. Of

A. A. in

Raffinate

CR (Kg/m

3

)

Con. Of

A. A. in

Extract CE

(Kg/m

3

)

Mass of

A. A.in

Raffinate mAR

= CR*VR (Kg)

Mass of

A. A.in

Extract

mAE = CE*VE

(Kg)

Mass

fraction of

A. A.in

Raffinate xR

= mAR/mR

Mass

fraction of

A. A.in

Extract yE

= mAE/mE

15

7. SOLUBILITY CHARACTERISTICS

AIM :

To determine the solubility data of ternary liquid system and plot the binodal curve on a

triangular graph. Compare the values with the standard data.

THEORY:

The ability of a substance to dissolve in a solvent is known as its solubility. The solubility of a solute

in a particular solvent is measured by its concentration in a saturated solution. When a substance

absorbs heat while dissolving, its solubility increases with rise in temperature.

The solubility of a solid in a liquid is virtually independent of pressure.

TERNARY EQUILIBRIUM AND BI NODAL CURVE:

The solubility of the three components in a ternary system is represented on a triangular graph.

This solubility curve is called the bi nodal curve. The shape of the bi nodal curve changes for

different types of systems.

Procedure for plotting on a triangular graph (Equilateral triangle is considered).

Deciding the vertices: If three components, water, chloroform and acetic acid are present, acetic

acid is miscible with water and chloroform, so the vertex C can be taken as 100% acetic acid.

Water and chloroform are partially miscible are taken A and B.

Example:

Consider a mixture containing 60% chloroform, 20% water and 20% acetic acid. On the line AB,

mark 60% starting from B (Note A at this point will be 40%), and move upward, as indicated. Mark

20% on CA; move down ward as indicated, the point of intersection Corresponds (horizontal line)

to 20% acetic acid on the line CB.

NOTE: Sample graph is enclosed.

PROCEDURE:

SET I:

1. Take 10 conical flasks (100 ml) with 10 ml of water in each and number the flasks.

2. To each flask respectively add 1,2,3,4,5,6,7,8,9,10ml of chloroform.

3. Fill the burette with acetic acid and titrate each flask, till the haziness

disappears (till the is clear) . Note the volume of acetic acid consumed in each case.

16

SET II:

1. Take 10 conical flasks with 10 ml of chloroform. In each and number the flasks.

2. To each flask respectively add 1,2,3,4,5,6,7,8,9,10ml of water.

3. Fill the burette with acetic acid and titrate each flask, till the haziness disappears (till the is

clear) . Note the volume of acetic acid consumed in each case.

OBSERVATION TABLE:

SET I:

S.no.

Volume of

H2O (ml)

Vol.of

CHCl3

(ml)

Amt.Of

acetic acid

consumed

1. 10 1

2. 10 2

3. 10 3

4 10 4

5 10 5

6 10 6

7 10 7

8 10 8

9 10 9

10 10 10

SET II:

S.no.

Volume of

CHCl3

(ml)

Vol.of

H2O (ml)

Amt.Of

acetic acid

consumed

1. 10 1

2. 10 2

3. 10 3

4 10 4

5 10 5

6 10 6

7 10 7

8 10 8

9 10 9

10 10 10

17

CALCULATIONS:

Caluclate the weight fraction of each component.

SAMPLE CALUCLATION:

Weight of CHCl3 = Vol. CHCl3

Weight of H 2O = Vol. H 2O

Weight of H 3COOH = Vol. CH 3COOH

100

2O) H 3COOH CH CHCl3 ( Weight

CHCl3 of Weight

CHCl3 of % Weight x

+ +

100

2O) H 3COOH CH CHCl3 ( Weight

2O H of Weight

2O H of % Weight x

+ +

100

2O) H 3COOH CH (CHCl3 Weight

3COOH CH of Weight

acid Acetic of % Weight x

+ +

SET1:

H2O (A) Chloroform (B) Acetic acid (C)

Vol. Wt. Wt.% Vol. Wt. Wt.% Vol.. Wt. Wt.%

SET2:

H2O (A) Acetic acid (C) Chloroform (B)

Vol. Wt. Wt.% Vol. Wt. Wt.% Vol.. Wt. Wt.%

Prepare a binodal curve using the above data and compare with the literature values.

18

DATA:

Solubility of Chloroform in 10 ml of water = 0.3ml

Solubility of water in 10 ml of Chloroform = 0.6ml

Standard values:

H2O at room temp = ------ gm/cc

CHCl3 at room temp = ----- gm/cc

CH3COOH at room temp = -------gm/cc

NOTE: Determine density using specific gravity bottle.

Extract Phase(Wt%): Raffinate Phase(Wt.%)

HCl3 H2O CH3COOH CHCl3 H2O CH3COOH

0.84 99.16 0 99.01 0.99 0

1.21 73.64 25.1 91.85 1.38 6.77

7.3 48.58 49.12 85 2.28 12.72

15.11 34.71 50.18 70.13 4.12 25.72

18.33 31.11 50.56 67.15 5.2 27.65

25.2 25.34 49.41 39.55 7.93 32.08

28.88 23.25 47.87 55.81 9.58 34.67

19

8. WETTED WALL COLUMN

AIM:

To determine the mass transfer coefficient (gas phase) at different

Reynolds numbers in wetted wall column for Air Water system.

THEORY:

A great deal of effort have been devoted in the literature to developing analogies among three

transport processes for turbulent transfer so as to allow prediction of one from any of the others.

The most successful and most widely used analogy is based on experimental data for gases and

liquids in both the laminar and turbulent flow region as

[ ] ( ) 3

2

.

3

2

Pr

2

Sc

avg

c

d

P

h

N

V

K

J N

G C

h

J

f

In order to derive the mass transfer coefficient in laminar flow, theoretical expressions may be

used, since the equations for momentum transfer and diffusion can be solved.

When a fluid is flowing in laminar flow and mass transfer by momentum diffusion is occurring, the

equations are very similar to those for heat transfer by conduction in laminar flow, though the

phenomenon of heat and mass transfer are not always completely analogous, since in mass

transfer several components may be diffusing.

Also the flux of mass perpendicular to the direction of the flow must be small so as not to distort the

laminar velocity profile. So, in many actual cases it is difficult to describe mathematically even

laminar flow. Hence, experimental mass transfer coefficient are often obtained and correlated for

different flowing conditions.

In wetted wall column, a volatile pure liquid is permitted to blow down the inside surface of a

circular pipe while a gas is flown upward or downward through the central case. Measurement of

the rate of evaporation of the liquid into the gas stream over the known surface permits calculations

of mass transfer coefficients for the gas phase in wetted wall column is highly dependent on

surface conditions. Since the liquid may be pure liquids, the concentration gradient for the diffusion

exists entirely within the gas stream and coefficient Kg may be obtained directly from the data. Use

of different gases and liquids provides variation of Nsc.

In this way, Sherwood and Gilliland covered values of NRe from 2000 to 35000 and gas pressure

range from 0.1 to 3 atm. and proposed for turbulent flow

20

( ) ( )

33 . 0 83 . 0

Re

023 . 0

Sc Sh

N N N ---------------- (1)

This equation holds for Nsc of 0.6 to 3000, though Nsc for gases is in the range of 0.5 -3.0 and for

liquid is above 100 in general.

(1) may be rewritten as

33 . 0 83 . 0

023 . 0

,

_

,

_

AB AB

BM G

D

Du

D

D

P

p K

----------------- (2)

The gas pressure drop from this type of equipment is very low, however, since it is almost entirely

confined to skin friction effects with few or no expansion or contraction losses. This equation

describes all the data for both liquids and gas flow rate.

This empirical relation is quite remarkable in the manner in which it generally confirms the

relationship between heat, mass and momentum transfer developed theoretically. It should be

noted that the evaporation of the volatile liquids in a wetted wall column results in cooling of the

liquids and a consequent simultaneous heat transfer between liquid and gas. The heat transfer

rates are somewhat higher, owing to turbulence caused by ripples and waves on the liquid surface,

than the given by the equation,

( ) ( )

3 . 0

Pr

8 . 0

Re

023 . 0 N N

K

hD

Wetted wall column are used for theoretical studies for mass transfer because the interfacial

surface between the phases is kept under control and is measurable. These have also been used

successfully as absorbers for hydrochloric acid gas, ammonia, acetone, benzene and other volatile

liquids.

PROCEDURE:

The apparatus consists of a wetted wall column with an inlet and out let for air. At both inlet and

outlet, two thermometers for measuring the dry and wet bulb temperatures. Air is supplied with the

help of a compressor. Rotameters are provided for measuring the flow rate of air and water.

Initially water flow rate is adjusted to be laminar (no ripples are formed). Then by changing the flow

rate of air through the column, dry bulb and wet bulb temperatures are noted down. This

procedure is repeated for five different airflow rates.

21

OBSERVATIONS:

S.No Flow rate Inlet air temp. Outlet air temp.

Air Water WBT DBT WBT DBT

1.

2.

3.

4.

5.

WBT:Wet bulb temperature.

DBT: Dry bulb temperature.

DATA:

Length of the column, L = 1000mm

Internal diameter of the tube = 33mm

Wetted surface in the column,A(m

2

) = *d*L

Average air temperature = [inlet DBT +outlet DBT] / 2

Molar Air flow rate (kmol/s) = (Air flow rate in LPM * 10

-3

)

*[273/(273+Tav)][1/22.4][1/60]

Total pressure in the column = 101.3kN/m

2

(P)lm = (P2 - P1)/ ln(P2/ P1)

P1 = PAi PA1

PAi = vapor pressure of water at the inlet air temp.

PA1 = partial pressure of air at the inlet absolute

Humidity(= Y1Pt/ [1+Y1])

P2 = PAi PA2

PAi = vapor pressure of water at the outlet air temp.

PA2 = partial pressure of air at the outlet absolute

Humidity. (= Y2Pt/ [1+Y2])

(P)Bm = [(Pt PA1)- (Pt PA2)]/ {ln[(Pt PA1)/(Pt PA2)]

P = PAi PA1

NA = KG (P)ln

NA = Ms (Y2-Y1)/ *d*L

22

Ms = Molar flow rate of dry air = (actual flow Rate)/(1+Y1)

Kc

1

= KG (P)Bm RT/Pt

NRe = d QA/(A) air

D = diameter of the column,m

A = cross sectional area of the column

QA = air mass velocity, kg/s

air = Kinematic viscosity, m

2

/s

PA,i = vapor pressure of water vapor corresponding to the in let and out

let temperature. This can be determined by using Antoine

Equation,

ln P1

sat

= 16.2887-[3816.44/(T-46.13)]; where PAi

sat

is in Kpa

and T in

o

K

(OR) taken from literature at the desired temperature.

Absolute Humidity: Determined from the humidity charts at the inlet and outlet wet bulb and dry

bulb temperatures.

NA = Molar flux; KG = Gas phase mass transfer coefficient.

Temp. Air viscosity Air density air water density sat.vap.pr.

(

0

K) (Kg/ms) (Kg/m

3

) (m

2

/s) (Kg/m

3

) (Pa)

311 19x10

-6

1.135 16.76x10

-6

992.9 6628

299 18.4x10

-6

1.181 15.62x10

-6

996.7 3413

287 17.8x10

-6

1.230 14.52x10

-6

999.1 1653

23

9. VAPOR LIQUID EQUILIBRIUM DATA

AIM:

To generate the vapor liquid equilibrium data of a given system and compare with the

standard values.

THEORY:

Distillation is a technique used for separating components of liquid mixtures based on the boiling

point difference. In a closed system the vapor liberated from a liquid mixture will be in equilibrium

and the composition depends on the temperature and the pressure. At equilibrium the composition

of the liquid will be different from the composition of the vapor. When a liquid mixture of two

components is distilled and the liquid is kept in contact with the liquid for a long time equilibrium is

reached. The liquid will be richer in the more volatile component than in the liquid and the

concentration depends on the concentration of the liquid phase. The relation between the

concentration of any component in liquid phase(x) and concentration of any component in vapor

phase(y) at equilibrium gives the vapor liquid equilibrium curve, which is determined at the boiling

point, corresponding to particular pressure.

For a binary solution, according to the phase rule if pressure is fixed, only one variable can be set.

If we set the liquid composition (x), the temp. the vapor composition(y) is automatically set.

A diagram representing the boiling point of a mixture of the liquid, completely miscible with each

other, against the composition of vapor and liquid in equilibrium is called boiling point diagram. The

boiling points are plotted as the ordinates and the mole fraction of the more volatile component in

vapor and liquid as abscissa. The upper line is saturated vapor line (dew point line) and the lower

is the saturated line (bubble point line) represents the vapor and liquid compositions respectively

any point above the upper curve represents the entire vapor phase and any point below lower

curve represents entire liquid phase. Points between the two curves represent the partially vapor

and partially liquid state of the mixture.

PROCEDURE:

24

1) Charge the still with the given feed mixture (ethanol-water). Find the composition of the feed by

determining the density using specific gravity bottle, record the composition from the calibration

graph.

2) Heat the mixture to the boiling temperature and allow the condensate to reflux for 2 or 3 times

and record the composition of the condensate for the 4

th

condensate.

3) After finding the composition (4

th

condensate), allow the condensate to reflux back to the still.

4) Repeat to determine the composition of the condensate till it is same for three successive

condensates. Constant condensate composition is recorded.

5) Record the boiling temperature with the help of the thermometer provided.

OBSERVATIONS:

Feed composition Condensate composition

XA YA

XB YB

P = Atmospheric pressure.

T = Temperature .

Assumptions: Vapor phase is ideal gas mixture.

Liquid phase is non-ideal solution.

From T, find

sat

B

sat

A

P P , either from Antoin equation or Perrys Handbook.

Find Van-Laar Constants.

A =

( )

( )

exp

exp

exp

ln

ln 1

ln

A A

B B

A

X

X

+

----------------- (1)

B =

( )

( )

exp

exp

exp

ln

ln 1

ln

B B

A A

B

X

X

+

------------------- (2)

Calculate exp by modified Raoults law, with the help of experimental data (XA, YA, XB, YB)

exp A A

sat

A A

X P P y

------------------- (3)

25

exp B B

sat

B B

X P P y

-------------------- (4)

Now A and B are known.

USING VAN-LAAR EQUATIONS:

( )

2

2

ln

,

_

B

B

A

X

B

A

AX

---------------- (5)

( )

2

ln

,

_

B A

A

B

X

A

B

X

BX

--------------- (6)

by assuming, XA = 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0

XB = 0.9, 0.8, 0.7, 0.6, 0.5, 0.4, 0.3, 0.2, 0.1, 0.0

Calculate the corresponding A and B for different values of XA and XB

Using the values of A , B, XA and XB find the values of YA and YB

YA =

P

P X

sat

A A A

YB =

P

P X

sat

B B B

Result: Plot X vs Y, the required equilibrium curve.

X

26

Y

10. STEAM DISTILLATION

AIM:

To study the characteristics of steam distillation like steam requirement, steam

consumption and efficiency.

THEORY:

Steam distillation is a unit operation of considerable practical importance. It is steam distillation

process with open steam i.e. where in the steam is in direct contact with the distilling system wither

in a batch or a continuous operation. It is a special case of carrier distillation, in which any low

boiling liquid could be used as a carrier whose purpose will be to exert its partial thus reducing the

boiling temperature of high boiling liquids. Ammonia, propane, gasoline etc. can also be used as a

carrier. However two preconditions must be met for carrying out steam i.e. carrier distillation:

(1) Substance must not react with steam and,

(2) Substances are immiscible in water.

Steam distillation has special value where it is desired to separate substances at a temperature

lower than their normal boiling because of heat sensitivity or other reasons. So high boiling liquids

at atmospheric pressure can be purified by steam distillation to avoid its decomposition.

Often the high boiling liquid are essentially insoluble in water. This method is often used to

separate a high boiling component from small amounts of non-volatile impurities. In steam

distillation, we have three phases i.e. two liquids (test liquid and condensed steam) and one vapor

phase (steam) and there are two components. So by phase rule, degree of freedom is one.

Therefore at a given pressure of distillation, the temperature as well as composition of the system

is formed.

27

In steam distillation, the distillation temperature is brought below the boiling of even water

as steam exerts its partial pressure and hence decomposition of high boiling liquid is avoided.

Liquids are purified by steam distillation not only because of lower temperature at which liquid

distills, but also because of injected steam keeps the liquid mass thoroughly agitated. Since both

the liquid phase are immiscible they do not effect each other properties. So each will exert its own

vapor pressure and cannot be influenced by others. Even where the mutual solubility is

appreciable, the vapor pressure of the pure components may be employed, since the fractional

reductions in the vapor pressures are approximately equal and the ratio is only slightly affected,

when, however the mutual solubility of the two substance is great, these considerations do not

apply, and experimental determination of VLE data is required. When the sum of the vapor

pressures of two liquid

(PA and PB) equals the total pressure, the mixture boils, i.e.

PA + PB = P ----------------- (1)

PA / PB = NA / NB = [WA/MA] / [WB/MB]

WA/ WB = Amount of aniline vaporized/ Amount of steam used

= [PB/PA] [MB/MA]

Ws = 1/B {WF CPA(TSDT - Ti) + AWA +wWB }

Where , WF = Weight of feed

WS = Theoretical steam condensed

WA = Weight of aniline in distillate

WB = Weight of water in distillate

CPA = Specific heat of anniline

B = latent heat of steam

A = latent heat of anniline

w = latent heat of water

28

OBSERVATIONS:

feed = 250 ml aniline

volume of aniline in distillate =

volume of water in distillate =

steady distillation temperature =

volume of bottoms =

volume of aniline in residue =

room temperature =

atmospheric pressure(barometric) = 742 mm hg

Data:

Aniline

Temp

0

C 34.8 57.9 69.4 82.0 96.7 106.0 119.9 140.1 161.9 181.4

PA, mmHg 1 5 10 20 40 60 100 200 400 760

Water

Temp

0

C 1.31 38.25 51.65 66.4 75.87 82.94 88.64 93.51 97.72

PA, mmHg 10 50 100 200 300 400 500 600 700

Plot PA Vs T and PB Vs T and generate a plot PT Vs T where PT = PA+PB

from the graph at barometric pressure 740 mm hg, corresponding temperature (tsdt) from graph =

(the corresponding temperature where the 740 mm hg line intersects the pt vs t curve)

29

vapor pressure of aniline = vpa =

(from graph)

vapor pressure of water = vpb =

(from graph)

Molecular weight of aniline (MA) = 93 gm/mole

Molecular weight of water (MB) = 18 gm/mole

A

B

PA

PB

l Theoretica

B

A

M

M

V

V

W

W

1

]

1

Volume of aniline in distillate = ----- (1)

Volume of water in distillate = ----- (2)

Density of aniline at room temperature (A) =

Density of water at room temperature (B) =

1

]

1

al Experiment

B

A

W

W

[volume of water in distillate x A] / [vol. Of aniline in distillate x B

Theoretical Steam condensed

Ws = 1/B [WF CPA (TSDT - Ti) + A WA + w WB ]

A = 113.728 KJ / Kg ; B = 2352 KJ / Kg ; CPA = 2.224 KJ /Kg

0

C at 32

0

C

Steam consumption = theoretical steam condensed i.e., (Ws) / [vol. Of aniline in distillate x (A)]

30

RESULT:

Atm.pr.

1. Experimental WB / WA PT Vs T

2. Theoretical WB / WA PB Vs T

3. Steam consumption VPB

4. Vaporization efficiency = {[2]/[1] } x 100

PA Vs T

P

(mm Hg)

VPA

TSDT

Temp. (

0

C)

31

11. TRAY DRIER

Aim:

To determine the drying characteristics of given solid material, to find the drying coefficient.

THEORY:

When wet sample is placed in contact with air, water evaporates from its surface and diffuses as

vapor through the air film that covers the surface. The concentration of moisture at the surface is

decreased, a concentration difference is set up and moisture then diffuses from the interior to the

surface of the slab or it moves to the surface as rapidly as it can vaporize from the surface, the rate

of drying is independent of the moisture content of the slab and is constant providing that the air

velocity, temperature and humidity do not change.

During this constant rate period the rate of drying is controlled by the rate of vapor diffusion through

the air film and is, therefore, dependent upon the humidity difference across the film and the

thickness of the film.

However, when the moisture content becomes less than a certain value known as the critical

moisture content, moisture can no longer move to the surface as rapidly as it could be vaporized

from the surface. The drying rate begins to fall and continues to fall with decreasing moisture

content until the equilibrium moisture content is reached and no further drying is possible under the

particular drying conditions.

PROCEDURE:

Weigh 100 gm of saw dust (50 gm in each tray) and wet the solid with 50 ml of water in each tray

and distribute the solid uniformly in the trays. Note down the initial weight of empty tray . The hot

air is adjusted to blow at 80

0

C (by setting the temperature). Note down the inlet and outlet wet

bulb and dry bulb temperatures. Ensure the wick is always kept wet with help of the provision

provided with the system. Note down the energy requirement .

All the above readings are taken for every ten minutes till the constant weight is obtained or steady

state is reached. Finally note down the air velocity.

OBSERVATIONS:

S.NO

Time

(min)

Weight

(grams)

Inlet air temp.(

0

C) Out let air temp.(

0

C) Energy

input(kWH) Dry Wet Dry Wet

32

CALCULATIONS:

Air flow rate over the trays = air velocity x cross section of the drier

Loss in weight with time = weight of the sample at the previous reading weight of the sample at

the given time.

Plot weight of sample Vs time. Draw tangents at different points and find slopes to get dw/d

Free water content (gm/gm dry stock) =

[weight of sample weight of dry material] / weight of

dry material

Drying coefficient during the constant rate period, dw/d = Kg A (Hw - Hg)

(HW - Hg) = 0.26(tg-tw) / w

where, tg = average dry bulb temperature.

tw = average wet bulb temperature

w = latent heat of vaporization of water at tw = 2500 KJ / Kg

Tabular form of calculations:

S.No

Time(

) min.

Wt. of

sampl

e (W)

gm

(min.)

w

(gm)

w/

(gm/min)

- dX/d

gm

moisture/gm

dry solid min

Drying rate

(gm/hr.m

2

)

Free

water

(gm)

Free water

content

(gm

moisture/g

m dry

solid)

(X)

Drying rate or drying flux is calculated as , N = - [Ss / A] [dX/d]

Where Ss = kg of dry solid

A = drying surface area.

33

GRAPHS:

1. Plot X vs , draw the tangents at different values of X and find the slope, -dX/d

2. Plot drying flux Vs X., determine Nc, Xc.

3. Plot drying rates or flux Vs time()

RESULT:

1. The drying coefficient, gm water evaporated/ hr m

2

unit humidity difference.

2. The critical flux and the critical moisture content from plot no. (2).

Note: Measure the surface area of the trays.

Technical Specifications:

The drier is a two tray drier made from Stainless /steel 304(inner body) and powder coated mild

steel (outer body) The inner body of the unit is insulated with 25 mm glass wool and cladded with

powder coated mild steel sheet to minimize the heat losses to the surroundings. Dimensions of the

tray dryer are

(1) Drying chamber:Cross section 400mm*400mm*1000mm long

(2) Heater Box: Cross section 400mm*400mm and 400 mm long with 6 kW heaters

(3) Axial flow fan chamber:Cross section 400mm*400mm and 400mm long with axial flow

fan(0.25 HP, 3 phase motor).

(4) Capacity of the digital balance is 5 Kg.

34

Potrebbero piacerti anche

- Final Mass Transfer - I All Practical WriteupsDocumento36 pagineFinal Mass Transfer - I All Practical WriteupsvkpaithankarNessuna valutazione finora

- Chemistry Discipline Khulna UniversityDocumento4 pagineChemistry Discipline Khulna Universityমেরাজ সিএস চৌধুরীNessuna valutazione finora

- Distillation Problem 4: Fig. 1: Flow Sheet For Distillation ColumnDocumento2 pagineDistillation Problem 4: Fig. 1: Flow Sheet For Distillation Columnshan02140% (1)

- Lab ManualDocumento29 pagineLab Manualchanjunshen_rmc100% (2)

- Experiment 5 Liquid Diffusion CoefficientDocumento55 pagineExperiment 5 Liquid Diffusion Coefficienttaj232Nessuna valutazione finora

- Student Handouts Background: (Please Refer To Your Textbook, Nelson and Cox 5Documento18 pagineStudent Handouts Background: (Please Refer To Your Textbook, Nelson and Cox 5YENTHIL ALEXANDRA VALENCIA REINANessuna valutazione finora

- Simple DistillationDocumento48 pagineSimple DistillationSundar SkNessuna valutazione finora

- Experiment No.-1: With Continuous Supply of Fresh Gas and Removal of The Products of DiffusionDocumento25 pagineExperiment No.-1: With Continuous Supply of Fresh Gas and Removal of The Products of DiffusionSohini RoyNessuna valutazione finora

- Titration Lab ReportDocumento10 pagineTitration Lab Reportbotato. exeNessuna valutazione finora

- Types DistillationDocumento81 pagineTypes Distillationhet sevakNessuna valutazione finora

- Stage 2 Physical Chem - Experiment (1,2,3,4,5) 111Documento39 pagineStage 2 Physical Chem - Experiment (1,2,3,4,5) 111nazaneenshexani0% (1)

- Exp - S2 - Packed Bed DistillationDocumento6 pagineExp - S2 - Packed Bed DistillationHarsh ThakurNessuna valutazione finora

- Single Effect EvaporatorDocumento5 pagineSingle Effect EvaporatorgowricivilNessuna valutazione finora

- Mass Transfer With/Without Chemical Rection (Solid-Liquid System)Documento7 pagineMass Transfer With/Without Chemical Rection (Solid-Liquid System)Sameep JainNessuna valutazione finora

- Mass Transfer With/Without Chemical Rection (Solid-Liquid System)Documento7 pagineMass Transfer With/Without Chemical Rection (Solid-Liquid System)Sameep JainNessuna valutazione finora

- Mass Transfer 1 CLB 20804Documento54 pagineMass Transfer 1 CLB 20804KumaranNessuna valutazione finora

- B.Sc. BT SEM IIIDocumento14 pagineB.Sc. BT SEM IIIZaid YahyaNessuna valutazione finora

- Protocols KineticsDocumento5 pagineProtocols KineticsbrajeshNessuna valutazione finora

- 4 Solution PDFDocumento14 pagine4 Solution PDFthinkiitNessuna valutazione finora

- Vle & Diff DistDocumento14 pagineVle & Diff DistChintan ModiNessuna valutazione finora

- Liquid Liquid Extraction ExperimentDocumento17 pagineLiquid Liquid Extraction Experimentmhd badhrul bin baharNessuna valutazione finora

- Distillation Columns and Their Process CalculationsDocumento6 pagineDistillation Columns and Their Process CalculationsOmer IbrahimNessuna valutazione finora

- Psychrometry: V RH T T SHDocumento13 paginePsychrometry: V RH T T SHKAL ELNessuna valutazione finora

- 206 Enthalpy Change of NeutralisationDocumento3 pagine206 Enthalpy Change of NeutralisationM DiNessuna valutazione finora

- Hno3 Baoh2 Neutralisation QDocumento4 pagineHno3 Baoh2 Neutralisation QloxadegoNessuna valutazione finora

- Experiment 1 chem english (氮 鋁 熱)Documento14 pagineExperiment 1 chem english (氮 鋁 熱)b0409119cguNessuna valutazione finora

- Chapter 3 ConSol PPT by E.cusslerDocumento39 pagineChapter 3 ConSol PPT by E.cusslerheena_scottNessuna valutazione finora

- Mass Trandsfer NoteDocumento41 pagineMass Trandsfer NoteSegun AlongeNessuna valutazione finora

- Solvolysis LabDocumento5 pagineSolvolysis LabAriesNessuna valutazione finora

- Adsorption Lab 1Documento11 pagineAdsorption Lab 1Anjam HamaNessuna valutazione finora

- Liquid - Liquid Extraction in A Packed Bed: Experiment No: 2Documento23 pagineLiquid - Liquid Extraction in A Packed Bed: Experiment No: 2Sameep JainNessuna valutazione finora

- The Partial Molar Volume 27 SeptDocumento6 pagineThe Partial Molar Volume 27 SeptmpumelaqqNessuna valutazione finora

- SolutionDocumento29 pagineSolutionAditya BansalNessuna valutazione finora

- Mass Transfer Lab ManuAL - 2Documento18 pagineMass Transfer Lab ManuAL - 2VigneshParthasarathy0% (1)

- Physical Chemistry Prac ManualDocumento50 paginePhysical Chemistry Prac ManualMurthy NandulaNessuna valutazione finora

- Changes in Vapour Pressure. (Vapour Pressure Lowering) : V - P Depends Only On The SolventDocumento5 pagineChanges in Vapour Pressure. (Vapour Pressure Lowering) : V - P Depends Only On The SolventMarthy DayagNessuna valutazione finora

- Mass Transfer - II 3350502: Parth Modi, LecturerDocumento39 pagineMass Transfer - II 3350502: Parth Modi, LecturerSMIT CHRISTIANNessuna valutazione finora

- Lecture 9 - Groundwater Pollution LectureDocumento39 pagineLecture 9 - Groundwater Pollution Lectureph4318Nessuna valutazione finora

- Contact Equilibrium ProcessesDocumento13 pagineContact Equilibrium ProcessesDavid Aremania100% (1)

- Batch DistillationDocumento9 pagineBatch DistillationShashank RaoNessuna valutazione finora

- Chem-1 ExpDocumento14 pagineChem-1 ExprajaaNessuna valutazione finora

- Property Tables + Equation of StateDocumento66 pagineProperty Tables + Equation of StateTetiana VitenkoNessuna valutazione finora

- 7 1. Vapor Liquid EquilibriumDocumento9 pagine7 1. Vapor Liquid Equilibriumwaseemkhan49Nessuna valutazione finora

- Liquid Solutions Type 1Documento19 pagineLiquid Solutions Type 1Kaushal VaibhavNessuna valutazione finora

- Sample Experiment RecordDocumento3 pagineSample Experiment RecordNemalnath reddy KasarapuNessuna valutazione finora

- Hand-Out: Chemistry Chapter 2: SolutionDocumento14 pagineHand-Out: Chemistry Chapter 2: SolutionLuisgarciaBerlangaNessuna valutazione finora

- LleDocumento30 pagineLlefirstlove_492_736373Nessuna valutazione finora

- Exp 8 Diffusion of Sodium Chloride in WaterDocumento5 pagineExp 8 Diffusion of Sodium Chloride in WaterYuli SalasNessuna valutazione finora

- CL-201 Chapter 6 Multiphase Systems (Compatibility Mode) PDFDocumento42 pagineCL-201 Chapter 6 Multiphase Systems (Compatibility Mode) PDFSuman MandalNessuna valutazione finora

- Lab Report 1Documento22 pagineLab Report 1Alia Izyan100% (1)

- Updating Unit-3 MaterialDocumento32 pagineUpdating Unit-3 MaterialRuhee ShaikNessuna valutazione finora

- Heat of NeutralizationDocumento4 pagineHeat of NeutralizationEsha ManzoorNessuna valutazione finora

- 4.3 Enthalpy ChangesDocumento14 pagine4.3 Enthalpy ChangesKaihlaNessuna valutazione finora

- Single Effect Evaporator PDFDocumento5 pagineSingle Effect Evaporator PDFshehryarNessuna valutazione finora

- Distillation PresentationDocumento61 pagineDistillation PresentationAli AmjadNessuna valutazione finora

- Humidification/ DehumidificationDocumento29 pagineHumidification/ DehumidificationCharles Arthel ReyNessuna valutazione finora

- Unit I - Properties of FluidsDocumento12 pagineUnit I - Properties of FluidsTed Anthony100% (1)

- Exp. 5 Diffusion of Sodium Chloride in Water - LatestDocumento5 pagineExp. 5 Diffusion of Sodium Chloride in Water - LatestKai Faha Lukum0% (1)

- Critical Evaluation of Some Equilibrium Constants Involving Organophosphorus ExtractantsDa EverandCritical Evaluation of Some Equilibrium Constants Involving Organophosphorus ExtractantsNessuna valutazione finora

- Bhagavad Gita Paramarthanda Transcript PDFDocumento3.327 pagineBhagavad Gita Paramarthanda Transcript PDFAnonymous R8qkzg80% (5)

- Utilization of Various Waste Materials in Concrete A Literature ReviewDocumento5 pagineUtilization of Various Waste Materials in Concrete A Literature ReviewYasemin PurtaşNessuna valutazione finora

- Automatic Stacking Machine MechanicalDocumento31 pagineAutomatic Stacking Machine Mechanicalraghu_iictNessuna valutazione finora

- Note On Inter-Country Differences in WasteDocumento17 pagineNote On Inter-Country Differences in Wasteraghu_iictNessuna valutazione finora

- 3.1 Heat ExchangersDocumento76 pagine3.1 Heat Exchangersraghu_iictNessuna valutazione finora

- Agro Waste Uitlization PDFDocumento15 pagineAgro Waste Uitlization PDFraghu_iictNessuna valutazione finora

- Shrimath Bhagavad Gita Kantha Bhashyam by Bodananda Telugu - Jangamwadi Math CollctionDocumento1.038 pagineShrimath Bhagavad Gita Kantha Bhashyam by Bodananda Telugu - Jangamwadi Math Collctionraghu_iictNessuna valutazione finora

- Different Methods of Extraction of Essential OilsDocumento35 pagineDifferent Methods of Extraction of Essential Oilsraghu_iictNessuna valutazione finora

- Aceite Esencial de CitricosDocumento8 pagineAceite Esencial de CitricosAnnie Diana Yumpiri AguilarNessuna valutazione finora

- Multiple Choice LachingDocumento3 pagineMultiple Choice Lachingraghu_iict100% (1)

- 1 s2.0 S0260877408003002 Main PDFDocumento5 pagine1 s2.0 S0260877408003002 Main PDFDoraGarciaNessuna valutazione finora

- Cromatografia Aceites EsencialesDocumento6 pagineCromatografia Aceites EsencialesGabriela CruzNessuna valutazione finora

- Food Chemistry: Aurélie Cendres, Mélanie Hoerlé, Farid Chemat, Catherine M.G.C. RenardDocumento8 pagineFood Chemistry: Aurélie Cendres, Mélanie Hoerlé, Farid Chemat, Catherine M.G.C. Renardraghu_iictNessuna valutazione finora

- Math8430 Lectures FisicaDocumento164 pagineMath8430 Lectures Fisicamariuccio254Nessuna valutazione finora

- CH05123Notes 1Documento2 pagineCH05123Notes 1raghu_iictNessuna valutazione finora

- D.Q. Kern - Process Heat Transfer (1950)Documento441 pagineD.Q. Kern - Process Heat Transfer (1950)raghu_iictNessuna valutazione finora

- Regimes of Multiple Emulsions of W /O/W and O /W/O Type in The Continuous Couette-Taylor Flow ContactorDocumento8 pagineRegimes of Multiple Emulsions of W /O/W and O /W/O Type in The Continuous Couette-Taylor Flow Contactorraghu_iictNessuna valutazione finora

- Economical Feasibility Evaluation of An Ethanol Injection Liposome Production PlantDocumento6 pagineEconomical Feasibility Evaluation of An Ethanol Injection Liposome Production Plantraghu_iictNessuna valutazione finora

- Lab ChemicalsDocumento2 pagineLab Chemicalsraghu_iictNessuna valutazione finora

- 145 FTPDocumento10 pagine145 FTPraghu_iictNessuna valutazione finora

- MBA R13 Coursestructure and SyllabusDocumento80 pagineMBA R13 Coursestructure and Syllabusraghu_iictNessuna valutazione finora

- Sri+Narasimha+Darshanam+217 BethamcherlaDocumento5 pagineSri+Narasimha+Darshanam+217 Bethamcherlaraghu_iictNessuna valutazione finora

- MLN 03Documento10 pagineMLN 03raghavlambiNessuna valutazione finora

- Saranagathi Enewsletter October 2013Documento8 pagineSaranagathi Enewsletter October 2013raghu_iictNessuna valutazione finora

- 09 Room SeatingDocumento8 pagine09 Room Seatingraghu_iictNessuna valutazione finora

- DVR College of Enggineering &technologyDocumento1 paginaDVR College of Enggineering &technologyraghu_iictNessuna valutazione finora

- 1Documento1 pagina1raghu_iictNessuna valutazione finora

- Lab ChemicalsDocumento2 pagineLab Chemicalsraghu_iictNessuna valutazione finora

- Codes and StandardsDocumento2 pagineCodes and Standardsraghu_iictNessuna valutazione finora

- Separation Methods Based On Distributions in Discrete Stages (9/26/12)Documento18 pagineSeparation Methods Based On Distributions in Discrete Stages (9/26/12)raghu_iictNessuna valutazione finora

- Atv DVWK A 281 e LibreDocumento25 pagineAtv DVWK A 281 e LibrerafapoNessuna valutazione finora

- General Biology 2 Midterms GRASPSDocumento2 pagineGeneral Biology 2 Midterms GRASPSAlbert RoseteNessuna valutazione finora

- Assignment Gravity and MotionDocumento23 pagineAssignment Gravity and MotionRahim HaininNessuna valutazione finora

- Anth 1020 Natural Selection Lab ReportDocumento4 pagineAnth 1020 Natural Selection Lab Reportapi-272845435Nessuna valutazione finora

- Exam 1Documento61 pagineExam 1Sara M. DheyabNessuna valutazione finora

- Lec Verilog TrafficLight SynthesisDocumento32 pagineLec Verilog TrafficLight SynthesisKartikey ManchandaNessuna valutazione finora

- Course Outline in Grade 1 MathematicsDocumento3 pagineCourse Outline in Grade 1 MathematicsRoselyn GutasNessuna valutazione finora

- Trio CT2036 Jaw Crusher Manual PDFDocumento44 pagineTrio CT2036 Jaw Crusher Manual PDFkenoy83% (6)

- Lloyds Register Type Approval ST PDFDocumento4 pagineLloyds Register Type Approval ST PDFJuan SantosNessuna valutazione finora

- Script PDFDocumento14 pagineScript PDFSachin SaraswatiNessuna valutazione finora

- Students United in Living-Out Its Identity For Truth, Integrity, Knowledge, and Academic Supremacy" or Simply Adu - PulitikaDocumento18 pagineStudents United in Living-Out Its Identity For Truth, Integrity, Knowledge, and Academic Supremacy" or Simply Adu - PulitikaJoshua Reggio BustamanteNessuna valutazione finora

- A Project Report ON Smart Knowledge Provider: Under The Supervision Of: Submitted byDocumento10 pagineA Project Report ON Smart Knowledge Provider: Under The Supervision Of: Submitted byPrince YadavNessuna valutazione finora

- Facebook Romanian Translation Style GuideDocumento20 pagineFacebook Romanian Translation Style GuideLeonNessuna valutazione finora

- Mevlana Jelaluddin RumiDocumento3 pagineMevlana Jelaluddin RumiMohammed Abdul Hafeez, B.Com., Hyderabad, IndiaNessuna valutazione finora

- ERM Introduction UnpadDocumento30 pagineERM Introduction UnpadMuhammadRivaresNessuna valutazione finora

- Sample Codal ComplianceDocumento1 paginaSample Codal Complianceshangz1511Nessuna valutazione finora

- Team Meeting - 6th MayDocumento11 pagineTeam Meeting - 6th MaySachin SharmaNessuna valutazione finora

- Free Local Food PPT Templates: Insert The Subtitle of Your PresentationDocumento47 pagineFree Local Food PPT Templates: Insert The Subtitle of Your PresentationEni SumarsihNessuna valutazione finora

- TrainingGuide Geomatica 1 2017Documento132 pagineTrainingGuide Geomatica 1 2017sam.scribdNessuna valutazione finora

- New Curriculum of Class 11 and 12 Optional Subject First 2076Documento157 pagineNew Curriculum of Class 11 and 12 Optional Subject First 2076Narendra KhadkaNessuna valutazione finora

- How To Prepare A Basic Training ModuleDocumento7 pagineHow To Prepare A Basic Training ModuleSumber UnduhNessuna valutazione finora

- Job Description Mechanical Design EngineersDocumento1 paginaJob Description Mechanical Design Engineersyinkaakins2001Nessuna valutazione finora

- Crossconnect Multiplexer CMXC User ManualDocumento156 pagineCrossconnect Multiplexer CMXC User ManualrzhevskiyNessuna valutazione finora

- Program Package For First Arrival Seismic TomographyDocumento17 pagineProgram Package For First Arrival Seismic TomographypraveenNessuna valutazione finora

- Data Mining in The Insurance Industry - Solving Business Problems Using SAS Enterprise Miner SoftwareDocumento20 pagineData Mining in The Insurance Industry - Solving Business Problems Using SAS Enterprise Miner SoftwareShehan1Nessuna valutazione finora

- Theme of Otherness and Writing Back A Co PDFDocumento64 pagineTheme of Otherness and Writing Back A Co PDFDeepshikha RoutrayNessuna valutazione finora

- Report To The Community - BlairDocumento2 pagineReport To The Community - BlairCFBISDNessuna valutazione finora

- WHITECROFT Energy Directive BrochureDocumento32 pagineWHITECROFT Energy Directive BrochureAriel TambisNessuna valutazione finora

- Summative Test English 8Documento2 pagineSummative Test English 8Cristina SarmientoNessuna valutazione finora

- UTP PG Admission (Terms & Conditions) - Attachment 1 PDFDocumento7 pagineUTP PG Admission (Terms & Conditions) - Attachment 1 PDFKhaleel HusainNessuna valutazione finora