Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

V5365 Z Ma 007 - 79445813

Caricato da

peeps1980Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

V5365 Z Ma 007 - 79445813

Caricato da

peeps1980Copyright:

Formati disponibili

Operating Instructions

HPU for Ringline System and AHC System Cardiff 3

Fo rT ra in in g Pu rp e os

RIG/PLANT REFERENCE REFERENCE DESCRIPTION

Cardiff Drillship 3

ADDITIONAL CODE REMARKS SDRL CODE TOTAL PGS

V5365

5.3 26

HPU for Ringline and AHC System

National Oilwell Varco Norway AS Postboks 401, Lundsiden N-4604 Kristiansand Norway Phone +47 38 19 20 00 Fax +47 38 19 26 04

Part of User Manual

MAIN TAG NUMBER CLIENT PO NUMBER DISCIPLINE

This document contains proprietary and confidential information which belongs to National Oilwell Varco; it is loaned for limited purposes only and remains the property of National Oilwell Varco. Reproduction, in whole or in part; or use of this design or distribution of this information to others is not permitted without the express written consent of National Oilwell Varco. This document is to be returned to National Oilwell Varco upon request and in any event upon completion of the use for which it was loaned. Copyright National Oilwell Varco - 2010 DOCUMENT NUMBER

y nl

CLIENT DOCUMENT NUMBER

REV

V5365-Z-MA-007

Fo

rT

in ra

g in

r Pu

po

s se

y nl

Document number Revision Page

V5365-Z-MA-007 0 3 of 26

TABLE OF CONTENTS 1 OPERATING INSTRUCTIONS ......................................................................................... 4 1.1 1.2 1.3 1.4 1.5 Introduction ............................................................................................................. 4 Abbreviations .......................................................................................................... 5 Safety Summary ..................................................................................................... 6 Emergency Stop ..................................................................................................... 7 Description of Controls ............................................................................................ 8 1.5.1 Cyberbase Controls in Drillers Cabin .......................................................... 8 1.5.1.1 Main Well Crown Mounted Compensator ................................................. 9 1.5.1.2 HPU Display ........................................................................................... 10 1.5.1.3 CMC & AHC Display ............................................................................... 13 1.5.1.4 AHC HPU Display ................................................................................... 15 1.5.2 PLC Control Cabinet .................................................................................. 16

Fo

rT

ra

1.6

Normal Operation.................................................................................................. 17 1.6.1 Pre-start Preparations................................................................................ 17 1.6.2 Start ........................................................................................................... 20 1.6.2.1 Start Ringline Pumps .............................................................................. 20 1.6.2.2 Start AHC Pumps ................................................................................... 21 1.6.3 During Operation ....................................................................................... 22 1.6.4 Stop ........................................................................................................... 23 1.6.4.1 Stop Ringline Pumps .............................................................................. 23 1.6.4.2 Stop AHC Pumps.................................................................................... 23 1.6.4.3 Shut Down Entire HPU ........................................................................... 24 1.6.5 Operation of Oil Heater .............................................................................. 24

in

in

Pu

rp

e os

y nl

1.7

Disturbance of Operation ...................................................................................... 25 1.7.1 Cooling Disturbance .................................................................................. 25 1.7.2 Pump Disturbance ..................................................................................... 25

1.8

Training Program for Operators ............................................................................ 26

Document number Revision Page

V5365-Z-MA-007 0 4 of 26

1 1.1

OPERATING INSTRUCTIONS Introduction This document describes correct use of the National Oilwell Varco TM Hydraulic Power Unit (HPU) for the rig/user stated at the document front page. The skid mounted HPU is a hydraulic power pack that feeds both the hydraulic ringline and the Active Heave Compensator (AHC) system. The HPU is water cooled and includes ringline pumps, circulation pumps, AHC pumps, replenishment pumps, and the required support systems. All pumps are driven by electric motors. The operating instructions are based on the assumption that the equipment has been installed and tested, and that the equipment thus is ready for ordinary routine operation. It is also assumed that the operator has studied the technical description and drawings, and is familiar with the overall system. Supplier is keeping and maintaining a field experience database for its offshore equipment. It is of great importance that user is reporting problems to supplier. This information is essential for supplier to identify critical items prone to failure or replacement, and it will highlight components that require a design review to improve safety and reliability. Areas of major concern shall without hesitancy be brought to the attention of supplier. If urgent deficiencies appear after the equipment is taken into use, supplier will issue Product Information Bulletins to user as deemed necessary.

Fo

rT

ra

in

in

Pu

rp e os s O y nl

Document number Revision Page

V5365-Z-MA-007 0 5 of 26

1.2

Abbreviations The following abbreviations may be used in the documents and drawings making up the user manual for subject equipment: AHC BOP CAPV CMC CPU DCDA DCR EDS FAT FW HP HPU LER LIR LMRP LP MCC NOV NS OD PLC PPM RPM SD SP T TP UPS WC WRTS Active heave compensator Blow-out preventer (installed on wellhead at the seabed) Composite air pressure vessel (versus conventional steel APV) Crown mounted compensator (= drillstring compensator) Central processing unit (part of PLC) Drilling control and data acquisition (= Cyberbase displays & keypads) Drilling control room (= drillers cabin) Emergency disconnect sequence Factory acceptance test Fresh water High pressure Hydraulic power unit Local equipment room (= LIR) Local instrument room (= LER) Lower marine riser package (installed at lower end of riser string) Low pressure Motor control centre National Oilwell Norway AS (= the system supplier) Norwegian Standard Outer diameter Programmable logic controller Parts per million Revolutions per minute Shutdown Setpoint Metric ton Terminal point Uninterruptible power supply Wellcentre Wireline riser tension system

Fo

rT

ra

in

in

Pu

rp

e os

y nl

Document number Revision Page

V5365-Z-MA-007 0 6 of 26

1.3

Safety Summary The following types of safety message may appear in this document: WARNING: Must be observed to prevent serious injury. CAUTION: Must be observed to prevent damage of equipment and/or loss of operating effectiveness. NOTE: Must be observed for correct and efficient operation. It is the responsibility and duty of all personnel involved in the operation and maintenance of this equipment to fully understand the SAFETY measures, by which hazards are reduced or eliminated. Personnel must familiarize themselves with all aspects of safety and operation of the equipment before starting any operation or maintenance. The following points summarize the safety aspects related to operation:

Fo

rT

Only qualified personnel are allowed to operate the HPU. The HPU must only be used for the prescribed purpose, within the design limitations, and in accordance with the operating instructions. The HPU compresses hydraulic oil to high pressures. Beware of the risk of pipe or hose burst. If anyone gets hydraulic oil into the eyes or open wounds, wash at once with lots of fresh water. Consult a doctor if necessary. Hydraulic components may have hot spots, and touching these may cause skin burn damage. In the case of a fire, be aware that hydraulic oil is flammable. The combustion point is ca. 200 Deg. C. Oil mist is highly flammable! When opening valves manually, always open slowly to avoid pressure shocks. Always use eye protectors while working with oil under pressure. Dropped objects are potential killers. Make sure that no loose objects (tools or equipment) are dropped from or forgotten at high places.

ra

in

in

Pu

rp

e os

y nl

Document number Revision Page

V5365-Z-MA-007 0 7 of 26

1.4

Emergency Stop Before starting any HPU operation the operator must familiarize with the locations and function of all the emergency stops. The HPU can be emergency stopped from the following locations: At the local HPU skid: There are two emergency stop pushbuttons (behind protective cover) located next to the main pumps at both sides of the HPU skid.

Push any of the emergency stop pushbuttons as quickly as possible in case of serious danger to people or equipment. The emergency stops will stop all the HPU pumps. Note that an emergency stop will have side effects on ongoing rig operations, and the use should be limited to what is absolutely necessary. After activation of the emergency stop the cause of the activation must be investigated, and the emergency stop pushbutton thereafter be reset. The stopped equipment can then be restarted. The emergency stop pushbuttons on the drill floor, and on the operator stations in drillers cabin, will not stop the HPU pumps. They will stop the operating drilling equipment, but the HPU pumps will continue operating until stopped individually. The drilling equipment will be stopped as if the individual emergency stops are activated. See the User Manuals for the specific drilling equipments.

Typical emergency stop pushbutton (with protective cover) on the HPU skid

Fo

rT

ra

in

in

Pu

rp e os s O y nl

Document number Revision Page

V5365-Z-MA-007 0 8 of 26

1.5

Description of Controls

1.5.1 Cyberbase Controls in Drillers Cabin Normal operation of the HPU is from drillers or assistant drillers Cyberbase operator station in the drillers cabins. There is one such cabin for the main well and another for the auxiliary well, each with two operator stations. It is assumed that the operator already is familiar with the general use of the Cyberbase operator station, and the present focus is therefore on how the station is used to operate the HPU. The operator station uses different sets of keypads and screen displays for machine control, and the ones for HPU control are described at the next pages. The operator station is shown below and has the following controls:

Fo

1. 2. 3. 4. 5. 6. 7.

Two operator screens Mode switch Machinery emergency stop button Two joysticks for machinery control Two keypads for machinery control Trackball (mouse) Numerical keyboard

rT

ra

in

Typical Cyberbase Operator Station

in

g Pu rp e os s O y nl

Document number Revision Page

V5365-Z-MA-007 0 9 of 26

1.5.1.1

Main Well Crown Mounted Compensator with AHC & CMC Auto Position System

MP Esc Ack

CMC/AHC

This keypad is available at the right side of drillers operator station in the main well drillers cabin. The controls of this keypad are described in the CMC & AHC, Main user manual. The keypad is mentioned here because of the AHC HPU On button: AHC HPU On button: The AHC HPU is an integrated part of the combined HPU for ringline and AHC, which includes the AHC main pumps and replenishment pump required for operation of the AHC. Push and confirm the button to start the two main pumps for main well AHC, and see the button being highlighted. One of the HPUs circulation pumps must be running before the main pumps can be started. When there is no consumption the main pumps will be idling. When the AHC no longer is needed, repeat the activation command to stop the two main pumps, and see the button highlighting disappear. The AHCs replenishment pump is not affected by this button. In the auxiliary drillers cabin there is a similar keypad and button for starting and stopping the main pumps pre-selected for serving the auxiliary well AHC.

Menu AHC HPU On

CH

IBOP Close AHC Pos. AHC Down CMC Valve Close Air Press AHC Stby AHC Manual CMC Valve Auto Air Valve Open AHC Up CMC Valve Open Air Press +

Fo

rT

ra

in

in

Pu

rp

e os

s

Confirm

O

Deactivate

y nl

CMC Pos./ DW ROP

Setp.Inc.

Slips Close

Setp.Dec.

Document number Revision Page

V5365-Z-MA-007 0 10 of 26

1.5.1.2

HPU Display

The present pump motor status is announced by the colour of the button as follows: Yellow bar: The pump motor is set to local control at the motor starter and cannot be controlled from Cyberbase. White: The main power switch is turned on and the pump motor is ready to be started. Green: The pump motor has been started and operates normally. Red: The pump motor failed during the start-up sequence, or the motor starter tripped. Red X: The pump motor is not available for use at the motor starter. Faded down/grey: The pump motor is not available for use because of an interlockable alarm.

Fo

rT ra in in

Cyberbase HPU Screen Display

g Pu rp e os s O y nl

Document number Revision Page

V5365-Z-MA-007 0 11 of 26

Ringline HPU Field Ringline Pump 1 to 5 buttons: Click the pump button, and then click the start or stop button on the pop-up display, to start or stop the belonging pump motor. The main/ringline pumps are used to feed the hydraulic ringline. The motors must be started and stopped in the order described in the Normal Operation section. The different pump motor statuses are described above. The control logic does not include automatic starting or stopping of any pumps. Stop All Pumps button: Click the button, and then click the OK button on the pop-up display, to stop all the ringline pumps at the same time.

Circulation Pumps Field Circulation Pump 1 and 2 buttons: Click the pump button, and then click the start or stop button on the pop-up display, to start or stop the belonging pump motor. The circulation pumps are used to circulate the hydraulic oil from the oil tank through the oil coolers. The circulation is for obtaining normal working temperature in the hydraulic ringline. If the hydraulic ringline is working on a high level, it can be necessary to run both circulation pumps to avoid too high oil temperature. The different pump motor statuses are described above.

Filter Faults Field

NOTE: If any of the filter fault lamps are lit, it normally means that the filter is clogged and the filter element must be changed. Follow the instructions in the Changing Oil Filter Elements section in the Maintenance Instructions document. Ringline Pump 1 to 5 Pressure Filter Fault lamp: The (red) lamp is lit to announce high pressure drop across the pressure filter for the ringline pump. This normally means that the filter is clogged and the filter element must be changed. Ringline Pump 1 to 5 Drain Filter Fault lamp: The (red) lamp is lit to announce high pressure drop across the drain filter for the ringline pump. This normally means that the filter is clogged and the filter element must be changed. Main Return Filter 1&2 and 3&4 Fault lamp: The (red) lamp is lit to announce high pressure drop across the duplex filter for the return line. This normally means that the filter in use is clogged and the filter element must be changed. Circulation Filter Fault lamp: The (red) lamp is lit to announce high pressure drop across the duplex filter for the circulation line. This normally means that the filter in use is clogged and the filter element must be changed. Main Drain Filter Fault lamp: The (red) lamp is lit to announce high pressure drop across the duplex filter for the drain line. This normally means that the filter in use is clogged and the filter element must be changed.

Fo

rT

ra

in

in

g Pu rp e os s O y nl

Document number Revision Page

V5365-Z-MA-007 0 12 of 26

System Status Field Ringline System Pressure indicator: This indicator shows the actual pressure in the ringline. Normal pressure is 207 barg. If the level is below 207 barg, it can be necessary to start more ringline pumps. Ringline Pressure Signal Fault lamp: The lamp is lit if something is wrong in the pressure transmitters loop. Investigate and remedy the cause of the alarm. Oil Level indicator: The indicator shows the actual oil level in the oil tank in percentage. The oil level is monitored by the alarm system. Oil Level High High lamp: The (red) lamp is lit to announce that the oil level is above the high level. Follow the instructions in the Fault Finding section in the Maintenance Instructions document. Oil Level Low lamp: The (red) lamp is lit to announce that the oil level is below the low level. Follow the instructions in the Fault Finding section in the Maintenance Instructions document. Oil Level Low Low lamp: The (red) lamp is lit to announce that the oil level is below the low-low level. All the HPU pumps will shut down when the oil level goes below the lowlow level. Oil Level Signal Fault lamp: The lamp is lit if something is wrong in the oil level transmitters loop. Investigate and remedy the cause of the alarm. Oil Temperature indicator: The indicator shows the oil temperature in the oil tank. Normal working temperature is between 40 to 60C. The oil temperature is monitored by the alarm system. Oil Temperature High High lamp: The (red) lamp is lit when the oil temperature is above 65C. All the HPU pumps except the circulation pump(s) will shut down when the oil temperature goes above 65C. Oil Temperature High lamp: The (red) lamp is lit to announce that the oil temperature is above 60C. Follow the instructions in the Fault Finding section in the Maintenance Instructions document. Oil Temperature Signal Fault lamp: The lamp is lit if something is wrong in the temperature transmitters loop. Investigate and remedy the cause of the alarm. HPU Local Emergency Stop lamp: The (red) lamp is lit to announce that one of the local emergency stop pushbuttons of the HPU has been activated. See the Emergency Stop section.

Fo

rT

ra

in

in

Pu

rp

e os

y nl

Document number Revision Page

V5365-Z-MA-007 0 13 of 26

1.5.1.3

CMC & AHC Display

Fo rT ra in

Cyberbase CMC Screen Display

in g Pu rp e os s O y nl

Document number Revision Page

V5365-Z-MA-007 0 14 of 26

Only the AHC HPU part of the CMC Display is described below: AHC Pumps 1 and 2 buttons: Click the pump button, and then click the start or stop button on the pop-up display, to start or stop the belonging pump motor manually. The AHC pumps are used to feed the AHC. The motors must be started and stopped in the order described in the Normal Operation section. The different pump motor statuses are described in the HPU Display section. The control logic does not include automatic starting or stopping of any pumps. AHC Replenishment Pump button: Click the pump button, and then click the start or stop button on the pop-up display, to start or stop the belonging pump motor manually. The replenishment pump is used to replenish the AHC. The motors must be started and stopped in the order described in the Normal Operation section. The different pump motor statuses are described in the HPU Display section. The control logic does not include automatic starting or stopping of any pumps. AHC HPU i-button: Click the button to make the AHC HPU info pop-up appear on the screen. The pop-up gives more detailed status information for the AHC HPU (the AHC part of the HPU for ringline and AHC) and is described separately below. AHC Press. Hi radio-button: Click the radio-button to select high pressure mode, and see a black dot appearing in the radio-button. Selecting this mode means selecting high discharge pressure (300 barg) from the main pumps for subject AHC. This selection is used during active heave compensation with heavy hookloads or at high heave. Deselect by selecting Normal mode. AHC Press. Lo radio-button: Click the radio-button to select low pressure mode, and see a black dot appearing in the radio-button. Selecting this mode means selecting low (normal) discharge pressure (210 barg) from the main pumps for subject AHC. This selection is used during active heave compensation with normal heave and hookloads. Deselect by selecting high pressure mode.

Fo

rT

ra

in

in

Pu

rp

e os

O y nl

Document number Revision Page

V5365-Z-MA-007 0 15 of 26

1.5.1.4

AHC HPU Display

Oil Level High High lamp: The (red) lamp is lit to announce that the oil level is above the high level. Follow the instructions in the Fault Finding section in the Maintenance Instructions document. Oil Level Low lamp: The (red) lamp is lit to announce that the oil level is below the low level. Follow the instructions in the Fault Finding section in the Maintenance Instructions document. Oil Level Low Low lamp: The (red) lamp is lit to announce that the oil level is below the low-low level. All the HPU pumps will shut down when the oil level goes below the lowlow level. Oil Temperature High High lamp: The (red) lamp is lit when the oil temperature is above 65C. All the HPU pumps except the circulation pump(s) will shut down when the oil temperature goes above 65C. Oil Temperature High lamp: The (red) lamp is lit to announce that the oil temperature is above 60C. Follow the instructions in the Fault Finding section in the Maintenance Instructions document.

Fo

rT

Cyberbase AHC HPU Information Screen Display

ra

in

in

g Pu rp e os s O y nl

Document number Revision Page

V5365-Z-MA-007 0 16 of 26

Oil Level indicator: The indicator shows the actual oil level in the oil tank in percentage. The oil level is monitored by the alarm system. Oil Temperature indicator: The indicator shows the oil temperature in the oil tank. Normal working temperature is between 40 to 60C. The oil temperature is monitored by the alarm system. AHC System Pressure indicator: This indicator shows the actual pressure in the AHC system. Normal pressure is 210 barg. Extreme pressure is 300 barg. Emergency Stop Local HPU lamp: The (red) lamp is lit to announce that one of the emergency stop buttons of the HPU has been activated. See the Emergency Stop section. 1.5.2 PLC Control Cabinet The PLC control cabinet for the HPU is installed in the LIR. The cabinet has no controls for normal operation.

Fo

rT

ra

in in g Pu rp e os s O y nl

Document number Revision Page

V5365-Z-MA-007 0 17 of 26

1.6

Normal Operation

1.6.1 Pre-start Preparations After the HPU has been shut down, prepare it as follows before returning to normal operation: Starting point: The HPU has been commissioned, and is ready for ordinary routine operation. The ambient temperature is within the design range stated in the Data Sheet document. Make sure that the HPU room is dry and well ventilated, and that the room temperature is within the limits stated in the Data Sheet document. Make sure that the hydraulic ringline is ready to be pressurized. Check the oil level indicator (1) to make sure that the oil tanks oil level is normal (between the normal max and normal min levels). If necessary, add oil and check the overall hydraulic system for leaks.

Fo

rT

ra in

1

in g Pu rp e os

Make sure that that no maintenance or repairs occurs at the HPU. Check visually that the eleven suction valves (2) for the ringline pumps, the AHC pumps, and the circulation pumps are fully opened. Check visually that the two suction valves (3) for the replenishment pumps are fully opened. If a pump is stopped for maintenance or repair, close the belonging suction valve.

y nl

Document number Revision Page

V5365-Z-MA-007 0 18 of 26

Check visually that the flushing valves (4) for all the ringline pumps and all the AHC pumps are fully opened. If a pump is stopped for maintenance or repair, close the belonging flushing valve.

Fo rT

Make sure that the filter selector valve (5) for all the duplex filters is set to one of the end positions (6). Intermediate positions are not allowed.

ra

in in g Pu rp e os s O y nl

5 6

Check visually that the cooling water inlets and outlets are fully open. The valves must be fully open at all times to prevent clogging of the coolers. Start the cooling water supply to the oil coolers. The temperature and flow requirements to the cooling water are specified in the product data sheet. Make sure the cooling water is circulating by feeling the water pipeline next to the cooler by hand. Make sure that the local emergency stops are reset. Check the motor starters in the MCC room: o Make sure that the motor starters are preset for remote control of the HPUs pump motors. o Make sure that the main power switch is turned on to all the HPUs pump motors. NOTE: If any of the pumps is stopped for maintenance or repair, the motor starters must remain isolated for those pump motors.

Document number Revision Page

V5365-Z-MA-007 0 19 of 26

At one of the Cyberbase operator stations, make sure that there are no active HPU alarms.

Fo rT ra in in

Start one of the circulation pumps from the HPU display by clicking the Circulation Pump button. Both the AHC and the ringline pumps require flushing, and cannot be started before the circulation pump is operating. Besides supplying the flushing, the circulation pumps circulate oil for cooling and filtration, and at least one circulation pump must always be operating during all HPU operation.

Pu

rp

e os

s O y nl

Document number Revision Page

V5365-Z-MA-007 0 20 of 26

1.6.2 Start The ringline pumps and the AHC pumps are equipped with a soft start system. The first seconds after a pump is started, the (idling) pressure will be 20 barg only. The PLC thereafter changes to ordinary discharge pressure. 1.6.2.1 Start Ringline Pumps Starting point: The HPU has been prepared as described in the Pre-start Preparations section. The cooling water supply and one of the circulation pumps are started and are operating without disturbances. Plan what pumps to use before starting the pumps. It is recommended to distribute the wear of the ringline pumps, so that the operation hours of all the pumps remain approximately the same. The ringline pumps are started from the Cyberbase HPU display. The different pump motor statuses are described in the HPU Display section. Start the first ringline pump from the HPU display by clicking the Ringline Pump button. Make sure that the ringline is pressurized to 207 barg. If the consumption exceeds the supply, the pressure will fall below 207 barg, and more ringline pumps must then be started. Start more ringline pumps, one at a time, until the demand is met and the ringline pressure is stabilized at 207 barg.

Fo

rT

ra

in

in

Pu rp e os s O y nl

Document number Revision Page

V5365-Z-MA-007 0 21 of 26

1.6.2.2

Start AHC Pumps Starting point: The HPU has been prepared as described in the Pre-start Preparations section. The cooling water supply and one of the circulation pumps are started and are operating without disturbances. Start the replenishment pump for the AHC of subject well from the CMC/AHC display by clicking the AHC Replenishment button. The pump will start operating as soon as the CMCs main air valve is opened. The pump must remain in active condition until the CMC is shut down. Initially, select low (normal) discharge pressure from the AHC pumps. Select the AHC Pressure Low radio-button at the CMC/AHC display.

Fo rT

Start the AHC pumps by selecting the AHC HPU On button from the Cyberbase keypad. The two AHC pumps start operating (idling), and the AHC enters passive mode.

ra

in

in

g Pu rp

Operate the AHC by following the instructions in the CMC & AHC User Manual.

e os s O y nl

Document number Revision Page

V5365-Z-MA-007 0 22 of 26

1.6.3 During Operation The ringline pumps can be started and stopped as necessary to meet the demand in the most efficient way. Over time it is recommended to distribute the wear of the pumps, so that the operation hours of all pumps of the same type remain approximately the same. The AHC is initially operating with low (normal) discharge pressure from the AHC main pumps. This pressure is suitable for normal hookloads and peak-to-peak heave below 1.5 meter. For higher heave and/or heavier loads, select high pressure mode (at the CMC/AHC display) instead. This gives high discharge pressure and more power to the active compensator cylinder. Return to low pressure mode when high pressure no longer is needed.

Fo

Make an inspection of the HPU from time to time to make sure of smooth operation: o Check that the AHC replenishment pump is operating. o Check all the motors and pumps for leaks, suspicious noise, heat, and vibrations. These inspections can gradually be less frequent as reliable operation is verified through field experience. o Check the oil temperature in the oil tank. Higher temperature than normal may be an indication of little oil in the tank, clogged oil cooler, high cooling water temperature, or no cooling water supply to the oil coolers.

rT

ra

in

in

Pu

rp e os s O y nl

Document number Revision Page

V5365-Z-MA-007 0 23 of 26

1.6.4 Stop 1.6.4.1 Stop Ringline Pumps Make sure that the hydraulic ringline is ready to be stopped. All equipment powered from the ringline should preferably be stopped before stopping the HPU. Stop all the ringline pumps by clicking the Stop All Pumps button. The ringline pumps can also be stopped individually by clicking the Ringline Pump buttons.

Fo rT ra in in g Pu rp

Make sure that the standstill heating of the main pump motor windings automatically has been turned on.

e os

1.6.4.2

Stop AHC Pumps

Make sure that the subject AHC is prepared for a stop of the AHC pumps. Follow the instructions in the CMC & AHC User Manual. Stop the AHC pumps by deselecting the HPU On button from the Cyberbase keypad. The AHC pumps can also be stopped individually by clicking the AHC Pump buttons on the CMC/AHC display.

O y nl

Keep the replenishment pump operating as long as the CMC is operating, and thereafter consider stopping it. (It is recommended to always keep the replenishment pump operating, except for long time storage and repair or maintenance of the replenishment pumps. It will be operating only when the CMCs main air valve is open.) Make sure that the standstill heating of the main pump motor windings automatically has been turned on.

Document number Revision Page

V5365-Z-MA-007 0 24 of 26

1.6.4.3

Shut Down Entire HPU

Before the annual main maintenance (changing all filter elements etc) and longer stops (storage), the entire HPU is shut down as follows: Before shut down of the HPU, grease all pump motor bearings. See the Maintenance Instructions document. It is recommended that the greasing is done while the motors are operating. If a motor needs to be started and stopped for greasing, this will be done from the CMC & AHC Display and the HPU display. Stop the ringline pumps and the AHC pumps as described in the sections above. The following HPU parts are still operating: the circulation pump, the cooling water supply, and the replenishment pumps. Stop the operation of the CMC. Follow the instructions in the CMC & AHC User Manual. Stop the replenishment pumps by clicking the AHC Replenishment button.

If necessary, stop the circulation pumps by clicking the Circulation Pump button. Unless the entire HPU will be stopped for a longer period (storage), it is recommended to keep the circulation pump operating.

Fo

rT

ra

in

in g

If necessary, stop the cooling water supply to the oil coolers. It is recommended to keep the cooling water supply turned on. The circulation of the cooling water will minimize clogging of the water coolers. If necessary, isolate the HPUs pump motors from the power supply at the motor starters. Do not turn off the standstill heating of the main pump motor windings.

Pu

rp

e os

1.6.5 Operation of Oil Heater

Make sure that the control power to the oil heater is turned on. The oil heater is controlled automatically. It turns on when the oil temperature is less than 40C and turns off when the oil temperature is more than 45C.

O y nl

Document number Revision Page

V5365-Z-MA-007 0 25 of 26

1.7

Disturbance of Operation If the equipment does not function as intended, make sure that the operating instructions has been followed correctly. If the problem remains, follow the instructions below and the Fault Finding section in the Maintenance Instructions document. See also the Technical Description section for a better understanding of the overall system.

1.7.1 Cooling Disturbance One cooling circuit is more than sufficient for the complete cooling requirements. The second circuit must not be started unless cooling problems occur. If this is the case, the second circuit can be started for a short time. A clogged oil cooler will most likely be detected by high oil temperature in the oil tank. Before isolation and cleaning of the cooler, check the HPU, as follows:

Fo

rT

Check that the oil level in the oil tank is normal. Check that the flow rate and the temperature of the cooling water are as specified in the Data Sheet document. Check that none of the pumps are running hot by feeling the pumps by hand. WARNING: Be careful when feeling the pumps. Hydraulic components may have hot spots, and touching these may cause skin burn damage. Check the setting and operation of the thermostatic bypass valve (H11-X). See the correct setpoints in the Data Sheet document.

If all of these possible reasons seem OK, it is likely that the cooler is clogged and needs cleaning. Turn off the cooler circuit and remedy the cause. See the Alfa Laval subvendor literature in the Standard Documentation document.

ra

in

in

Pu

rp

e os

1.7.2 Pump Disturbance Main Pumps

If a main/ringline pump stops functioning normally, the pump must be stopped until it can be serviced or repaired. The HPU can normally still be operated on the remaining main/ringline pumps, but at reduced capacity. Stop and isolate a pump, as follows: Stop the pump. See the Stop section. Isolate the pump motor from the power supply at the motor starter. Put an OUT OF USE sign at the pump and at the local control cabinet. Close the pumps belonging suction valve and flushing valve. If the pump needs to be removed for repair, contact the supplier for advice before removing the pump. After reparation and installation of the pump, open the suction valve and the flushing valve before the pump is returned to normal operation.

y nl

Document number Revision Page

V5365-Z-MA-007 0 26 of 26

Circulation Pumps If one of the circulation pumps must be taken out of service, the remaining circulation pump must be started manually. One circulation pump is sufficient to meet the cooling and the flushing requirements for the whole HPU. Only operate both circulation pumps if cooling problems occur with one circulation pump. 1.8 Training Program for Operators Training programs are available from supplier as required, but subject to separate agreement and described separately.

Fo rT ra in in g Pu rp e os s O y nl

Potrebbero piacerti anche

- SH Shaker-Brandt Mini CobraDocumento92 pagineSH Shaker-Brandt Mini CobraKapil Tiwari100% (1)

- Torque TDS4 Pocket Guide-2 PDFDocumento5 pagineTorque TDS4 Pocket Guide-2 PDFHaridev50% (2)

- Pyramid Product Line 1 PDFDocumento9 paginePyramid Product Line 1 PDFGerardo Luengas100% (1)

- TDS-02-11-PIB Rev D PDFDocumento5 pagineTDS-02-11-PIB Rev D PDFahmedsaid85Nessuna valutazione finora

- Nov Offshore Product Reference GuideDocumento80 pagineNov Offshore Product Reference Guidejoebraz100% (1)

- TDS1000AInstallationManual 03May28AbridgedDocumento20 pagineTDS1000AInstallationManual 03May28Abridgedbwd104Nessuna valutazione finora

- Cyber BaseDocumento39 pagineCyber BaseayhamNessuna valutazione finora

- Product Bulletin No.: TDS-03-16 Release Top Drive Drilling SystemDocumento8 pagineProduct Bulletin No.: TDS-03-16 Release Top Drive Drilling Systemahmedsaid85Nessuna valutazione finora

- West TucanaDocumento3 pagineWest TucanaSarfaraz PatelNessuna valutazione finora

- TDS 04 09 PibDocumento11 pagineTDS 04 09 PibNavin SinghNessuna valutazione finora

- Manual Bba Triplex BD-85 BopDocumento47 pagineManual Bba Triplex BD-85 BopwiloNessuna valutazione finora

- TM 120 Commissioning Manual - Rev.01 REVISADODocumento32 pagineTM 120 Commissioning Manual - Rev.01 REVISADOjaimeNessuna valutazione finora

- V5315 Z Ma 007 - 80346421Documento192 pagineV5315 Z Ma 007 - 80346421peeps1980100% (1)

- 1000012667-PIB Shot PinDocumento3 pagine1000012667-PIB Shot PinAdrian CantaragiuNessuna valutazione finora

- Iron Roughneck PW163 PDFDocumento51 pagineIron Roughneck PW163 PDFGustavo RiveraNessuna valutazione finora

- 3092834-Varco Bulletin On TDSDocumento9 pagine3092834-Varco Bulletin On TDSSushil GuptaNessuna valutazione finora

- FA2-FA2 5 Service Manual Parts ListDocumento61 pagineFA2-FA2 5 Service Manual Parts ListERNESTO NEGRETENessuna valutazione finora

- Difference Between TDS 9S & TDS 9SADocumento7 pagineDifference Between TDS 9S & TDS 9SAAbdelghani ZitouniNessuna valutazione finora

- 06b AppendixB2 (1000HPRig) 1582535891879Documento103 pagine06b AppendixB2 (1000HPRig) 1582535891879Harsh TiwariNessuna valutazione finora

- Drawing Package Crown Block: CB-375-7-50-1 3/8 Serial Number:0058Documento5 pagineDrawing Package Crown Block: CB-375-7-50-1 3/8 Serial Number:0058Noureddine AdjNessuna valutazione finora

- Roughneck RoughneckdetailsDocumento28 pagineRoughneck Roughneckdetailsrohit.g85100% (1)

- Cobra ManualDocumento180 pagineCobra ManualJairo Puentes75% (4)

- Providing Comprehensive Drilling Solutions WorldwideDocumento40 pagineProviding Comprehensive Drilling Solutions WorldwideLuis Rolando SirpaNessuna valutazione finora

- Blohm+Voss PS 500 Technical DocDocumento106 pagineBlohm+Voss PS 500 Technical Doc施咏胜100% (3)

- Maintenance Manual Varco ST 80 Roughneck 2 PDFDocumento42 pagineMaintenance Manual Varco ST 80 Roughneck 2 PDFNAMRAJ SHARMANessuna valutazione finora

- Onshore Product Reference Guide PDFDocumento44 pagineOnshore Product Reference Guide PDFPedro RiveraNessuna valutazione finora

- Slips Maintenance, Inspection, & Wear Data PDFDocumento3 pagineSlips Maintenance, Inspection, & Wear Data PDFcorsini999100% (1)

- Canrig TD 4 Inch Actuator ManualDocumento42 pagineCanrig TD 4 Inch Actuator ManualAshrafNessuna valutazione finora

- 3119049Documento10 pagine3119049Sug E QalanderNessuna valutazione finora

- Hawkjaw Jr. Manual 65K-950JR Serial Numbers 72 To 223Documento155 pagineHawkjaw Jr. Manual 65K-950JR Serial Numbers 72 To 223Andre Agmadila0% (1)

- 6923 PDFDocumento5 pagine6923 PDFMEHDINessuna valutazione finora

- Drift Indicator System ManualDocumento142 pagineDrift Indicator System ManualShag ShaggyNessuna valutazione finora

- National Oilwell Varco, in - SEC Filing 10KDocumento116 pagineNational Oilwell Varco, in - SEC Filing 10Kcaballero_tigreNessuna valutazione finora

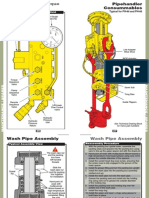

- Washpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)Documento12 pagineWashpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)osvaldoNessuna valutazione finora

- 1.2 - Rig General Arrangement DrawingsDocumento11 pagine1.2 - Rig General Arrangement Drawingsdanielra85Nessuna valutazione finora

- T3035 Complete User Manual Rev.1Documento557 pagineT3035 Complete User Manual Rev.1Suat Yaman100% (1)

- BOP LX 2 PDFDocumento75 pagineBOP LX 2 PDFOperaciones ComalcalcoNessuna valutazione finora

- Annular Bops D Bop DL Bop: To Contents PageDocumento6 pagineAnnular Bops D Bop DL Bop: To Contents PageJohn Alexander Bonilla AngelNessuna valutazione finora

- Automated Power CatwalkDocumento6 pagineAutomated Power CatwalkianherzogNessuna valutazione finora

- PS 1000 ManualDocumento117 paginePS 1000 Manualnoormanmubarak100% (3)

- Mccoy Drilling Completions Catalog 2011Documento59 pagineMccoy Drilling Completions Catalog 2011IgorCencičNessuna valutazione finora

- Installation, Operation and Maintenance Instructions For Baylor Eddy Current Brake Model 7040Documento54 pagineInstallation, Operation and Maintenance Instructions For Baylor Eddy Current Brake Model 7040luisedonossaNessuna valutazione finora

- Canrig torque wrench specificationsDocumento16 pagineCanrig torque wrench specificationsaris4silveyraNessuna valutazione finora

- 2.JC50DB-06 Drawworks Parts ListDocumento17 pagine2.JC50DB-06 Drawworks Parts ListAbo FatmaNessuna valutazione finora

- Draw WorkDocumento5 pagineDraw WorkriobmNessuna valutazione finora

- Induction Drilling Motor Instruction ManualDocumento33 pagineInduction Drilling Motor Instruction ManualAhmed MNessuna valutazione finora

- TDS 11SDocumento158 pagineTDS 11Sgabriel100% (1)

- Bomco F-500 800 1000 ManualDocumento98 pagineBomco F-500 800 1000 ManualFU LIN LINessuna valutazione finora

- Epl 1711Documento161 pagineEpl 1711Alessandra Floresfar0% (1)

- TM 0000 Rig Up Manual en Rev00Documento132 pagineTM 0000 Rig Up Manual en Rev00Noureddine AdjNessuna valutazione finora

- HDI Product Catalog-February 2017Documento74 pagineHDI Product Catalog-February 2017Cristof Naek Halomoan Tobing100% (1)

- CDS - Operations Guide - 883003Documento38 pagineCDS - Operations Guide - 883003mustafaNessuna valutazione finora

- Iron Roughnecks BrochureDocumento9 pagineIron Roughnecks BrochureMahmoud MorsiNessuna valutazione finora

- HC 26V Sm00478 PDFDocumento47 pagineHC 26V Sm00478 PDFetuk2Nessuna valutazione finora

- Preliminary Erection Manual DDocumento266 paginePreliminary Erection Manual Dganesan 0011Nessuna valutazione finora

- 160 75-rp1Documento114 pagine160 75-rp1siva_nagesh_2Nessuna valutazione finora

- Turret Swivel System Operation (Rev.00)Documento12 pagineTurret Swivel System Operation (Rev.00)hai dang maiNessuna valutazione finora

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Documento255 pagineD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- LRP Manual Rev. 2-0-2Documento32 pagineLRP Manual Rev. 2-0-2Sha'ban Hussaini100% (2)

- Asv Rt120 Operation and Maintenance Manual SN 00241 Current English AllDocumento100 pagineAsv Rt120 Operation and Maintenance Manual SN 00241 Current English AllJonathan Arnett100% (1)

- V5315 Z Ma 007 - 80346421Documento192 pagineV5315 Z Ma 007 - 80346421peeps1980100% (1)

- Read MeDocumento11 pagineRead Mepeeps1980Nessuna valutazione finora

- Gangway Control System ManualDocumento58 pagineGangway Control System Manualpeeps1980Nessuna valutazione finora

- V5365 Z Ma 007 - 79445813Documento26 pagineV5365 Z Ma 007 - 79445813peeps1980100% (1)

- Well Serve CingDocumento140 pagineWell Serve CingYounes MakNessuna valutazione finora

- DigiMasterIII Car Model ListDocumento72 pagineDigiMasterIII Car Model ListRAGB1989Nessuna valutazione finora

- Caterpillar 360 KWDocumento6 pagineCaterpillar 360 KWAde WawanNessuna valutazione finora

- Railway Electrification Projects Budget 2019-20Documento9 pagineRailway Electrification Projects Budget 2019-20Muhammad Meraj AlamNessuna valutazione finora

- 2nd Semester All Courses-100Documento194 pagine2nd Semester All Courses-100Ejiade PeterNessuna valutazione finora

- SPECIFIC GRAVITY - DENSITY OF HYDRAULIC CEMENT (IS - 4031-Part 11-1988)Documento6 pagineSPECIFIC GRAVITY - DENSITY OF HYDRAULIC CEMENT (IS - 4031-Part 11-1988)Pritha DasNessuna valutazione finora

- CHM Analysis and Comparisons of CRUS MULTHULLS2013Documento60 pagineCHM Analysis and Comparisons of CRUS MULTHULLS2013kkd108Nessuna valutazione finora

- Traxonecue Catalogue 2011 Revise 2 Low Res Eng (4!5!2011)Documento62 pagineTraxonecue Catalogue 2011 Revise 2 Low Res Eng (4!5!2011)Wilson ChimNessuna valutazione finora

- Scheme of Valuation and Key for Transportation Engineering ExamDocumento3 pagineScheme of Valuation and Key for Transportation Engineering ExamSivakumarNessuna valutazione finora

- Return SectionDocumento1 paginaReturn SectionDaniel Pouso DiosNessuna valutazione finora

- BASIC IMMUNOLOGY TERMSDocumento2 pagineBASIC IMMUNOLOGY TERMSAnnicoldjohn LariozaNessuna valutazione finora

- Systematic Literature Review and Mapping of The Prediction of Pile CapacitiesDocumento12 pagineSystematic Literature Review and Mapping of The Prediction of Pile CapacitiesCaio Augusto Lemke CostaNessuna valutazione finora

- Chinkon Kishin - Origens Shintoístas Do Okiyome e Do Espiritismo Na MahikariDocumento2 pagineChinkon Kishin - Origens Shintoístas Do Okiyome e Do Espiritismo Na MahikariGauthier Alex Freitas de Abreu0% (1)

- Evolis User ManualDocumento28 pagineEvolis User ManualIonmadalin1000Nessuna valutazione finora

- 25f8e d64fDocumento6 pagine25f8e d64fapi-233604231Nessuna valutazione finora

- Indo American Journal of Pharmaceutical Research (India)Documento4 pagineIndo American Journal of Pharmaceutical Research (India)Pharmacy2011journalsNessuna valutazione finora

- Answer Sheet FINAL LipidDocumento3 pagineAnswer Sheet FINAL LipidFaridah MagumparaNessuna valutazione finora

- 0580 w15 QP 42Documento16 pagine0580 w15 QP 42Shahrizan Noor100% (1)

- Grade 9 Unit 1 - Part 1: Square RootsDocumento20 pagineGrade 9 Unit 1 - Part 1: Square RootsWilson ZhangNessuna valutazione finora

- Smart Asthma ConsoleDocumento35 pagineSmart Asthma ConsoleMohamad Mosallam AyoubNessuna valutazione finora

- Iso 1924 2 2008Documento11 pagineIso 1924 2 2008Pawan Kumar SahaNessuna valutazione finora

- Ichroma™ COVID-19 Ab (With Ichroma™ II Reader) Test SystemDocumento6 pagineIchroma™ COVID-19 Ab (With Ichroma™ II Reader) Test SystemGopinath AgnihotramNessuna valutazione finora

- Starter Unit Basic Vocabulary: Smart Planet 3Documento21 pagineStarter Unit Basic Vocabulary: Smart Planet 3Rober SanzNessuna valutazione finora

- Balfour Relocation Feasibility StudyDocumento176 pagineBalfour Relocation Feasibility Studygreg32777Nessuna valutazione finora

- Conflict and Factional Disputes - Siegel & BealsDocumento12 pagineConflict and Factional Disputes - Siegel & BealsDanielNessuna valutazione finora

- Weekly Report 52Documento196 pagineWeekly Report 52Erceanu DanNessuna valutazione finora

- Manual de Uso Ecografo GE Logiq e PDFDocumento192 pagineManual de Uso Ecografo GE Logiq e PDFDaniel CortesNessuna valutazione finora

- Fundamentals of SwimmingDocumento7 pagineFundamentals of SwimmingSheila Mae Lira100% (1)

- Masterbrand Guidelines - September 2012: Confidential - For Internal Use OnlyDocumento35 pagineMasterbrand Guidelines - September 2012: Confidential - For Internal Use OnlyDemerson CamposNessuna valutazione finora

- Đánh giá chế độ ăn kiêng: Nhịn ăn gián đoạn để giảm cân- wed HarvardDocumento14 pagineĐánh giá chế độ ăn kiêng: Nhịn ăn gián đoạn để giảm cân- wed HarvardNam NguyenHoangNessuna valutazione finora