Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pilot Operated Pressure Regulator 6" 25P: Typical Applications

Caricato da

Matias MancillaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pilot Operated Pressure Regulator 6" 25P: Typical Applications

Caricato da

Matias MancillaCopyright:

Formati disponibili

Pilot Operated Pressure

Regulators

Pilot Operated Pressure Regulator 6" 25P

The 25P is a self-actuated pilotoperated pressure regulator. Downstream pressure is fed back through an external sensing line to the pressure pilot, which adjusts the opening of the main valve so as to maintain the set pressure. The main valve meets ANSI class IV shut off. Model Sizes Connections ANSI 125, 250 Construction

Cast Iron

25P

6" ANSI 150,300 Cast Steel

Typical Applications

The 25P is a reliable, accurate regulator to reduce steam from a high supply pressure to the most efficient operating pressure of the equipment, and to protect the equipment from dangerously high pressures.

Capacities

For selection and sizing data, see TI-3-030-US

Options

Reduce Orifice Designated by S

Sample Specification

Limiting Operating Conditions Cast Iron 232

450 400 204

tur at

The pressure regulator shall be of the pilot-actuated diaphragm operated type. The main valve shall be single-seated with hardened stainless steel trim; the regulator body shall be cast iron. The pilot shall be externally mounted to the regulator body.

Temperature F

ANSI 250

200 100 15 0

a Ste

sa

Temperature C

300

c ion

e urv

149 93 38 1 300 (20)

" NPT sensing line connections

A1

ANSI 125

50

100 150 200 250 (14) (7) Pressure psig (barg)

The product should not be used in shaded area.

Cast Steel

600 500 450 400 Temperature F 300 200 100 15 0

S m tea at tur ion cu rve

315 260 204

ANSI 300

149 93

sa

Temperature C

ANSI 150

38 1 350

50

100 150 200 250 (14) (7) Pressure psig (barg)

300 (20)

The product should not be used in shaded area.

Downstream Pressure Ranges

For the following downstream pressures, three color-coded pilot valve springs are available: Yellow: 3 to 30 psi Blue: 20 to 100 psi Red: 80 to 250 psi

Cv Values

Size Cv value 6" 260 6" S 185

6"

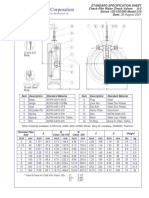

Dimensions

ANSI 125/150 ANSI 250/300

(nominal) in inches and millimeters

B C 11.75 302 D 16.7 424 E 28.6 725 Weight 560 lb 254 kg

Size A1 18.1 460

A1 19.0 483

19.75 502

Local regulation may restrict the use of this product below the conditions quoted. Limiting conditions refer to standard connections only. In the interests of development and improvement of the product, we reserve the right to change the specification. TI-3-016-US 08.09

1: 54

43 44 48 45 46 48 54 50 47 49 51 60 15

3 2 10 1 8

4 5

11

16

13 14 17 12 15

Construction Materials

No. Part 1 Valve Body 2 Cover 3 Cover Bolts 4 Main Valve Head 5 Main Valve Seat 7 Valve Return Spring 8 Valve Stem 10 Cover Gasket 11 Stem Bushing 12 Lower Diaphragm Case 13 Diaphragm Plate 14 Main Diaphragm (2 ply) 15 Tube &Orifice 16 Tubing Assembly 17 Diaphragm Gasket (2) 43 Adjustment Screw 44 Jam Nut 45 Pilot Valve Spring 46 Upper Diaphragm Case Material Cast Iron Cast Steel Cast Iron Cast Steel Steel Stainless Steel Stainless Steel Stainless Steel Stainless Steel Graphite Brass Cast Iron Cast Steel Stainless Steel Stainless Steel Brass Copper Graphite Stainless Steel Brass Steel Cast Iron Cast Steel ASTMA 126 CL B ASTMA 216 WC B ASTMA 126 CL B ASTMA 216 WC B AISI 1038 ASTM A 743 CA 40 ASTM A 743 CA 40 AISI 302 AISI 304 BS 2815 A ASTMB16 ASTMA 126 CL B ASTMA 216 WC B ASTM A 743 CA 40 AISI 301 ASTMB16 ASTMB280 (122) BS 2815 A AISI 304 ASTMB16 AISI1060 ASTMA 126 CL B ASTMA 216 WC B No. Part 47 Lower Diaphragm Case 48 Spring Plate 49 Diaphragm 50 Diaphragm Plate 51 Head & Seat Assembly 54 Diaphragm Case Screws 60 Pilot Gasket Material Cast Iron Cast Steel Steel Stainless Steel Brass Stainless Steel Stainless Steel Steel 5/16" - 18 x 1" Graphite ASTMA 126 CL B ASTMA 216 WC B ASTMA569 ASTMA240 ASTMB36 AISI440 AISI440F ASTMA449

Installation

Maintenance

Complete maintenance instructions are given in IM-3-000-US and ADVP 3029, a copy of which is supplied with each regulator. Available spare parts are shown on TI-3-029-US and TI-3-0271-US.

Spirax Sarco, Inc., 1150 Northpoint Blvd, Blythewood, SC 29016

TI-3-016-US 08.09 Telephone: (803) 714-2000 FAX (803) 714-2222

1: 55

Spirax Sarco, Inc. 2009

The regulator should be installed in a horizontal line with suitable bypass and isolating valves. A steam trap should be installed upstream to prevent condensate from reaching the regulator. The trap and regulator should both be protected with a strainer separator set. The pressure sensing line should be located in a straight section of the downstream piping at least 10 pipe diameters from the nearest fitting. Complete installation instructions are given in IM-3-000-US.

Pilot Operated Pressure

Regulators

Pilot Operated Pressure Regulator 6" 25P

Potrebbero piacerti anche

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- 25P 6inchDocumento2 pagine25P 6inchNguyen Xuan QuangNessuna valutazione finora

- Valve Spirax Sarco 25P Ti-3-015-UsDocumento2 pagineValve Spirax Sarco 25P Ti-3-015-Ussugesus100% (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Valves Reference PDFDocumento35 pagineValves Reference PDFJulio RodriguezNessuna valutazione finora

- CLAVAL Pressure Reducing ValveDocumento4 pagineCLAVAL Pressure Reducing ValvermgatocNessuna valutazione finora

- Spirax Sarco 25 PDocumento2 pagineSpirax Sarco 25 Pmairimsp2003Nessuna valutazione finora

- PRV SizingDocumento4 paginePRV SizingTiffany CombsNessuna valutazione finora

- Forged Steel Valves PDFDocumento12 pagineForged Steel Valves PDFDiwakar NigamNessuna valutazione finora

- Valvula de Purga para Caldera SerieVP-2013Documento6 pagineValvula de Purga para Caldera SerieVP-2013Renzo TartariniNessuna valutazione finora

- MasterSeries 850 Specification SheetDocumento2 pagineMasterSeries 850 Specification SheetFEBCONessuna valutazione finora

- Full Lift Spring Loaded Open PDFDocumento4 pagineFull Lift Spring Loaded Open PDFVenkatespatange RaoNessuna valutazione finora

- CVC Steel Valvulas LunkenheimerDocumento28 pagineCVC Steel Valvulas LunkenheimerAlex WilmerNessuna valutazione finora

- Aloyco Stainess Steel ValvesDocumento26 pagineAloyco Stainess Steel Valvescristi_molins100% (1)

- Valves & ControlsDocumento16 pagineValves & ControlseborresonNessuna valutazione finora

- Ritepro CorporationDocumento2 pagineRitepro CorporationCarlos GutierrezNessuna valutazione finora

- Literature Force Floating Ball Valve CatalogDocumento16 pagineLiterature Force Floating Ball Valve CatalogJohn Néstor Ramirez CalderónNessuna valutazione finora

- Flanged Ball Trunnion ValvesDocumento24 pagineFlanged Ball Trunnion ValvesMahdi DalyNessuna valutazione finora

- AV13 Air Vent For Steam Systems: DescriptionDocumento2 pagineAV13 Air Vent For Steam Systems: DescriptionUtku KepcenNessuna valutazione finora

- 90-01 Reductora de Presion Cla-ValDocumento4 pagine90-01 Reductora de Presion Cla-ValPablo SolisNessuna valutazione finora

- Vctds-02233 Model 171c (Asme) - enDocumento12 pagineVctds-02233 Model 171c (Asme) - enDGWNessuna valutazione finora

- Ratio Pressure Reducing ValvesDocumento4 pagineRatio Pressure Reducing Valveskanem1Nessuna valutazione finora

- Powell Gate ValvesDocumento3 paginePowell Gate Valveszguy360Nessuna valutazione finora

- Tyco Catalogue NetDocumento34 pagineTyco Catalogue NetAhmad Nasser0% (1)

- Comeval Cast Steel Gate Valve ANSI 150 PDFDocumento5 pagineComeval Cast Steel Gate Valve ANSI 150 PDFblizanacNessuna valutazione finora

- CBT 210Documento1 paginaCBT 210Carlos GutierrezNessuna valutazione finora

- rc18011 f09Documento7 paginerc18011 f09Trayo AyangbayiNessuna valutazione finora

- MasterSeries 876V Specification SheetDocumento4 pagineMasterSeries 876V Specification SheetFEBCONessuna valutazione finora

- RedvalvE 90 01Documento4 pagineRedvalvE 90 01Rizal FalevyNessuna valutazione finora

- Rovalve PDFDocumento4 pagineRovalve PDFWilliam ValenciaNessuna valutazione finora

- Valve Cast Steel Gate Globe PDFDocumento58 pagineValve Cast Steel Gate Globe PDFjua666nNessuna valutazione finora

- GLT Forged Steel Check ValveDocumento2 pagineGLT Forged Steel Check ValveantiokiaNessuna valutazione finora

- XMZ 210Documento3 pagineXMZ 210Carlos GutierrezNessuna valutazione finora

- KVC 01Documento35 pagineKVC 01hamidreza_m85Nessuna valutazione finora

- Bimetallic Steam TrapsDocumento2 pagineBimetallic Steam Trapsasad_naqviNessuna valutazione finora

- Ball ValveDocumento12 pagineBall ValveIdabaNessuna valutazione finora

- A3S and A3SS Bellows Sealed Stop Valve: DescriptionDocumento2 pagineA3S and A3SS Bellows Sealed Stop Valve: DescriptionNguyen Xuan QuangNessuna valutazione finora

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocumento20 pagineBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelNessuna valutazione finora

- Chem Oil - Check Valve PDFDocumento204 pagineChem Oil - Check Valve PDFClemente Rafael Marval EscalonaNessuna valutazione finora

- AloycoDocumento32 pagineAloycoSidney RiveraNessuna valutazione finora

- Navco b2 BrochureDocumento16 pagineNavco b2 Brochurejorge28csNessuna valutazione finora

- Astm A529 1972Documento5 pagineAstm A529 1972dharlanuctcom0% (1)

- Válvulas Bola SegmentadaDocumento12 pagineVálvulas Bola SegmentadarehynaldoNessuna valutazione finora

- ASCO Valve 8345 Spec R2Documento2 pagineASCO Valve 8345 Spec R2Calvin HaleyNessuna valutazione finora

- Valvula Reductora de Presion Bermad Area 675 720-ULDocumento4 pagineValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNessuna valutazione finora

- 11502Documento9 pagine11502balajivangaruNessuna valutazione finora

- ASV 10 20 BrochureDocumento8 pagineASV 10 20 BrochureThomas Duane DavidsonNessuna valutazione finora

- L&T Gate Globe Check Valves API 602Documento12 pagineL&T Gate Globe Check Valves API 602Nilesh MistryNessuna valutazione finora

- Top Entry Trunnion 600 - 2500Documento20 pagineTop Entry Trunnion 600 - 2500Danny PuchaNessuna valutazione finora

- PCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Documento6 paginePCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Moises Alvarez LeandroNessuna valutazione finora

- Check Valves With Tilting DiscDocumento2 pagineCheck Valves With Tilting DiscSamir RawalNessuna valutazione finora

- 61502YDocumento9 pagine61502YbalajivangaruNessuna valutazione finora

- E X52eDocumento4 pagineE X52eTommy DavisNessuna valutazione finora

- 11422Documento10 pagine11422balajivangaruNessuna valutazione finora

- DBB CatalogueDocumento20 pagineDBB Cataloguerawrr90Nessuna valutazione finora

- L&T Pipeline Ball ValvesDocumento24 pagineL&T Pipeline Ball Valvesjamil vora100% (1)

- APV Plug Valve CatalogueDocumento40 pagineAPV Plug Valve CatalogueVeerapandianNessuna valutazione finora

- Series 411 Specification SheetDocumento2 pagineSeries 411 Specification SheetWattsNessuna valutazione finora

- KGV Bi MDocumento3 pagineKGV Bi MArmando Palacios EscuderoNessuna valutazione finora

- Envirenmental EngineeringDocumento87 pagineEnvirenmental Engineering4919404Nessuna valutazione finora

- Amca Publication 11-03: Certified Ratings Program Operating ManualDocumento30 pagineAmca Publication 11-03: Certified Ratings Program Operating ManualMatias MancillaNessuna valutazione finora

- p-100 Vol2 1935 Part5Documento132 paginep-100 Vol2 1935 Part5Matias MancillaNessuna valutazione finora

- Catalago Resumen de ValvulasDocumento21 pagineCatalago Resumen de ValvulasMatias MancillaNessuna valutazione finora

- Refractories For Heat Treating: Industrial CeramicsDocumento6 pagineRefractories For Heat Treating: Industrial CeramicsMatias MancillaNessuna valutazione finora

- Amca Publication 11-03: Certified Ratings Program Operating ManualDocumento30 pagineAmca Publication 11-03: Certified Ratings Program Operating ManualMatias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 47 Rotary Furnace For AMPDocumento1 paginaHamada Boiler Catalogue Page 47 Rotary Furnace For AMPMatias MancillaNessuna valutazione finora

- CA3000A Dodge BearingDocumento708 pagineCA3000A Dodge BearingSuphi YükselNessuna valutazione finora

- Chapter 21Documento25 pagineChapter 21Matias MancillaNessuna valutazione finora

- Carter Variator CatDocumento40 pagineCarter Variator CatMatias MancillaNessuna valutazione finora

- CA3000A Dodge BearingDocumento708 pagineCA3000A Dodge BearingSuphi YükselNessuna valutazione finora

- Hamada Boiler Catalogue Page 64 Rice Husk Firing Boiler 3Documento1 paginaHamada Boiler Catalogue Page 64 Rice Husk Firing Boiler 3Matias MancillaNessuna valutazione finora

- CA3000A Dodge BearingDocumento708 pagineCA3000A Dodge BearingSuphi YükselNessuna valutazione finora

- Technical Documents of The BoilerDocumento20 pagineTechnical Documents of The BoilerMatias Mancilla0% (1)

- Hamada Boiler Catalogue Page 60 Coalmac 4Documento1 paginaHamada Boiler Catalogue Page 60 Coalmac 4Matias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 56 Heavy Duty Chain GrateDocumento1 paginaHamada Boiler Catalogue Page 56 Heavy Duty Chain GrateMatias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 22 Coal Storage and PLC ControlDocumento1 paginaHamada Boiler Catalogue Page 22 Coal Storage and PLC ControlMatias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 60 Coalmac 4Documento1 paginaHamada Boiler Catalogue Page 60 Coalmac 4Matias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 59 Coalmac 3Documento1 paginaHamada Boiler Catalogue Page 59 Coalmac 3Matias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 58 Coalmac 2Documento1 paginaHamada Boiler Catalogue Page 58 Coalmac 2Matias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 61 EFB Palm Waste FiringDocumento1 paginaHamada Boiler Catalogue Page 61 EFB Palm Waste FiringMatias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 62 Rice Husk Firing Boiler 1Documento1 paginaHamada Boiler Catalogue Page 62 Rice Husk Firing Boiler 1Matias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 63 Rice Husk Firing Boiler 2Documento1 paginaHamada Boiler Catalogue Page 63 Rice Husk Firing Boiler 2Matias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 57 Coalmac 1Documento1 paginaHamada Boiler Catalogue Page 57 Coalmac 1Matias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 59 Coalmac 3Documento1 paginaHamada Boiler Catalogue Page 59 Coalmac 3Matias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 67 TVTB 3Documento1 paginaHamada Boiler Catalogue Page 67 TVTB 3Matias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 65 Rice Husk Firing Boiler 4Documento1 paginaHamada Boiler Catalogue Page 65 Rice Husk Firing Boiler 4Matias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 7 Fluidizing Fire and Biomass FuelDocumento1 paginaHamada Boiler Catalogue Page 7 Fluidizing Fire and Biomass FuelMatias MancillaNessuna valutazione finora

- Solid Fuel Combustion On Water-Cooled Vibrating Grate: Plant Equipment and ComponentsDocumento2 pagineSolid Fuel Combustion On Water-Cooled Vibrating Grate: Plant Equipment and ComponentsMatias MancillaNessuna valutazione finora

- Hamada Boiler Catalogue Page 8 Model DF Series General ViewDocumento1 paginaHamada Boiler Catalogue Page 8 Model DF Series General ViewMatias MancillaNessuna valutazione finora

- Large Format Printing: Print Outdoor Print IndoorDocumento11 pagineLarge Format Printing: Print Outdoor Print IndoorRega PratamaNessuna valutazione finora

- Zinc Chromate PaintDocumento2 pagineZinc Chromate PaintBash MatNessuna valutazione finora

- EMM7241-Advanced Machine Design Examination June 2016Documento8 pagineEMM7241-Advanced Machine Design Examination June 2016Charles OndiekiNessuna valutazione finora

- GATE Metallurgical Engineering 2008 PDFDocumento12 pagineGATE Metallurgical Engineering 2008 PDFdrashokyvuceNessuna valutazione finora

- Huckbolt CatalogoDocumento8 pagineHuckbolt CatalogoAlejandro VillarroelNessuna valutazione finora

- Automotive Transmission - Lecture Notes CompleteDocumento156 pagineAutomotive Transmission - Lecture Notes CompleteAkshay PundeNessuna valutazione finora

- Product Form: Api 6A LT ASTM A694 F60Documento5 pagineProduct Form: Api 6A LT ASTM A694 F60Ejaz KNessuna valutazione finora

- Simulating The Cooling of A PlugDocumento2 pagineSimulating The Cooling of A Plugashfaq_a1Nessuna valutazione finora

- Commercial Cooling Load CalculationDocumento6 pagineCommercial Cooling Load CalculationMuhammad Kamran MalikNessuna valutazione finora

- Maintenance and Repair of Centrifugal PumpsDocumento4 pagineMaintenance and Repair of Centrifugal Pumpsaserf251Nessuna valutazione finora

- BFM 3A978 4 431 54237 7 2F1Documento10 pagineBFM 3A978 4 431 54237 7 2F1irajfarji2481Nessuna valutazione finora

- HeinDocumento4 pagineHeinRam BabuNessuna valutazione finora

- Design of Offshore Structures - Web PDFDocumento2 pagineDesign of Offshore Structures - Web PDFkarthickmectrNessuna valutazione finora

- C No-02 VFD PanelDocumento9 pagineC No-02 VFD PanelGeetu ElectricalNessuna valutazione finora

- Atoms, Elements & Compounds 1 MS PDFDocumento8 pagineAtoms, Elements & Compounds 1 MS PDFClinton ChikengezhaNessuna valutazione finora

- Chiller Heat RecoveryDocumento6 pagineChiller Heat RecoveryWid El-Amer100% (1)

- Data Sheet: Rates For Labour and Works (2012-2013)Documento24 pagineData Sheet: Rates For Labour and Works (2012-2013)anbugobiNessuna valutazione finora

- Wind Turbine Installation-ManualDocumento23 pagineWind Turbine Installation-Manualויליאם סן מרמיגיוסNessuna valutazione finora

- Samsung DVM Chiller InstallationManualDocumento56 pagineSamsung DVM Chiller InstallationManualjlmoleroNessuna valutazione finora

- Natural Water Filter - An Indigenous Rural ApplicationDocumento3 pagineNatural Water Filter - An Indigenous Rural ApplicationShwetha KamathNessuna valutazione finora

- Compressive Strength of ConcreteDocumento7 pagineCompressive Strength of ConcreteNick Genese100% (1)

- Method Statement Log-CivilDocumento1 paginaMethod Statement Log-CivilDia AjjouriNessuna valutazione finora

- Api and British Standard Trim DesignationsDocumento1 paginaApi and British Standard Trim DesignationsPOTDARNessuna valutazione finora

- DPWH PRICE MATRIX 1st QuarterDocumento264 pagineDPWH PRICE MATRIX 1st QuarterLauro LagoNessuna valutazione finora

- Conveyor IdlersDocumento255 pagineConveyor IdlersEd AceNessuna valutazione finora

- How Disassemble and Reassemble A ComputerDocumento35 pagineHow Disassemble and Reassemble A ComputertheoremineNessuna valutazione finora

- 155362Documento82 pagine155362a_minisoft2005Nessuna valutazione finora

- รายการคำนวณถังน้ำมันกลมIKEA PDFDocumento3 pagineรายการคำนวณถังน้ำมันกลมIKEA PDFGooddayBybs0% (1)

- M&E Assignment 3Documento12 pagineM&E Assignment 3han0701Nessuna valutazione finora

- PDFDocumento51 paginePDFMULYADI100% (1)