Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Minimization of Reworks in The Apparel Industry

Caricato da

zoomerfins22Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Minimization of Reworks in The Apparel Industry

Caricato da

zoomerfins22Copyright:

Formati disponibili

January 2013. Vol. 1, No.

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

MINIMIZATION OF REWORKS IN QUALITY AND PRODUCTIVITY IMPROVEMENT IN THE APPAREL INDUSTRY

Md. Mazedul Islam Adnan Maroof Khan 2 Md.Mashiur Rahman Khan

1 1

Department of Textile Engineering, Daffodil International University, Bangladesh 1 Department of Apparel Manufacturing Engineering, Bangladesh University of textiles. mazed@daffodilvarsity.edu.bd ; maroof215@gmail.com ; mrktex@yahoo.com

Abstract

The fast changing economic conditions such as global competition, declining profit margin, customer demand for high quality product, product variety and reduced lead time etc. had a major impact on manufacturing industries. The demand for higher value at lower price is increasing and to survive, apparel manufacturers need to improve their operations through-Producing right first time quality and waste reduction. This paper discusses the quality and productivity improvement in a manufacturing enterprise through practical study. The paper deals with an application of methodology in an industry which provides a framework to identify quantify and eliminate sources of variation in an operational process, to optimize the operation variables, improve and sustain process performance with well-executed control plans. The application of this paper improves the process performance of the critical operational process, leading to better utilization of resources, decreases variations & maintains consistent quality of the process output. The outcome of this observation reflected that an industry may gain higher productivity and profitability with improved quality product by minimizing reworks activities. It also minimizes cost and improves internal throughput time. A general overview over this development is given in this paper.

Keywords Costs, Operation, Productivity, Profitability, product Quality, Reworks.

I. Introduction As the global economic condition changing in a rapid motion, generally in an industry more focus is given on profit margin, customer demand for high quality product and improved productivity. In garment manufacturing, it is usual few rejected garments after shipment. Reason, most of the manufacturers believe that garments are soft goods and non-repairable defect may occur due to low quality raw materials or faulty process or employee casual behavior. However, factory must have check points to control over this issue. There is no ready-made solution that can reduce rejection percentage overnight. Each order is unique. But this paper works suggest how to handle this issue and bring down rejection rate to minimum. We see a lot of rejected garment after shipment. Most of the organization termed these garments as rejected because those garments cant be repaired by any means. Reworks in the garments industry is a common works that hampers the smooth production rate and focus poor quality products having an impact on overall factory economy. Minimization of reworks is a must in quality and productivity improvement. Rework is a vital issue for poor quality product and low production rate. Reworks are the non -productive activities focusing on any activity that customer are not willing to pay for. Non-productive activities describe that the customer does not consider as adding value to his product. By reacting quicker in minimization of reworks to make a product as per customer demand with expected quality, the company can invest less money and more costs savings. Therefore, a study was carried out in the garment industry named Opex & Sinha Textile Group located at Mirpur, Dhaka,

147

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

Bangladesh at cutting, sewing and finishing section to identify reworks so as to eliminate them for saving 2. Problem Definition and Methodology In the Apparel Manufacturing Industry, main raw material is fabric; others are different types of trimming and accessories. Operational wastages in the Apparel manufacturing process are- top surface rework, printed label rework, sewing fault rework, pinhole rework, fabric rework Improper fly shape, and other reworks. The general methodology followed to minimize reworks is given below. Review of the existing quality system in the company 2. Identification of defects in the various departments by collecting data from old records 3. Analysis of data collected in order to identify majorly occurring defects 4. Categorization of defects 5. Development of a model Quality Inspection System 2.1. Review of factory existing Quality System 1.

time,

cost

and

improved

product

quality.

6. 7.

8. 9.

10.

11. 12.

13.

Implementation of check sheets to capture defects in different departments Training on concepts of quality, importance of maintaining correct data, usage of the collected data to analyze and solve quality issues through the tools of quality Introduction of Inline Inspection on Sewing floor through a pilot run in one line Training on the Sewing floor to QCs, supervisors and checkers on filling in the format and on making Cause & Effect Diagrams Analysis of defects occurring in the check sheets implemented in various departments and devising suggestions to improve upon them Spreading of Inline inspection to other lines Tracking of improvements and comparing them with previous situation in different departments Visual communication of performance.

Fig. 1 Review of Existing Quality System

148

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

2.1. Identification of Defects The reports of quality inspections in various departments were studied for the period of January April- 2012. 2.1.1 Cutting Department: Percentage of lots

3%

21% PASS FAIL HOLD 76%

Fig. 2 Lots percentages overview of cutting departments

2.1.2 Sewing Department 6.00 5.06 5.00 4.00 3.00 2.00 1.00 0.00 OPEN SEAMS UNEVEN MARGIN UNEVEN NECK/PLACKET/W.BAND EXPOSED RAW STITCH FULLNESS UNEVEN GATHER BROKEN STITCH SHADE VARIATION ZIPPER PLACEMENT JOINT OUT BALANCING OUT PUCKERING ROPING WRONG LABEL ATTACH/LABEL MISSING FABRIC DEFECTS LOOSE TENSION WRONG PANEL ATTACH HOOK /LACE/ BUTTON PLACEMENT

Defect categories wise D.H.U.

3.36

3.12 2.70 2.63 2.00 1.57 1.30 1.19 1.13 1.11 1.02 0.94 0.68 0.49 0.36 0.34 0.23 0.19 0.10 0.09

Fig. 3 Defect categories wise D.H.U in the sewing department

149

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

2.1.3 Categorizations of Defects Sewing Defects: These defects are usually caused by errors arising from wrong functioning of sewing machines. Seaming defects: These defects are usually caused by errors arising from the interaction of the operator and machine in the handling of garment. Placement Defects: These defects are usually caused by errors arising in marking and cutting as well as 2.1.4 Sewing Department Defects categories wise sewing operations in the sewing room or a combination of these Fabric defects: These defects are usually caused by errors arising from the fabric processing like knitting and dyeing. Embroidery defects: These defects are usually caused by errors arising from the embroidery processing of the garments.

Defect categories wise D.H.U. (Defects per Hundread Unit)

Total pieces inspected- 30030 25.00 20.73 20.00 14.00 D.H.U. 15.00 10.00 5.00 0.00 Defect Categories 3.37 1.02 0.10 Where, Seaming defects- 6224 Sewing defects- 4204 Placement defects-1012 Fabric defects-307 Embroidery defects-31 SEAMING DEFECTS SEWING DEFECTS PLACEMENT DEFECTS FABRIC DEFECTS EMBROIDERY DEFECTS Fig. 4 Defect categories wise D.H.U in the sewing department Defects encountered-11778 D.H.U.- 39.22

150

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

2.2 Stages of Model Development

Identification of various options at the check points to capture defects

Selection of various tools to be used the model

Developments of model

2.3 Development of Model

Inline Inspection through Defect Frequency Rating System

Defect capturing at the End Line through check sheets

Analysis of defects

Cause & Effect Analysis of highest occurring Defects

Effective Solutions Provided

2.4 Formats introduced in various departments. 1. Cutting audit format 2. Cutting pattern check format. 3. Sewing in-line inspection format 4. Sewing end-line inspection format 5. Sewing cause & effect analysis format. 6. Finishing initial inspection format

151

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

3.0 Experimental Sewing Data

Uneven Raw Margin Exposed Raw stitch

Uneven Top Stitch

Label Attachment

Measurement out

Uneven fly shape

Thread Tension

Total Defective Pieces 56 22 22 5 12 16 17 10 23 17 11 12 18 14 17 29 14 8 8 8 339

Total Checked Pieces

Broken stitch

1-Mar 3-Mar 4-Mar 5-Mar 6-Mar 7-Mar 8-Mar 10-Mar 1 11-Mar 12-Mar 13-Mar 14-Mar 15-Mar 17-Mar 18-Mar 19-Mar 20-Mar 21-Mar 24-Mar 25-Mar TOTAL 1

4 6

10 13 2

56 4 9 2 9 9 7 4 3 3 3 2 3 3 3 1 3 2 1 3 2 55

4 9 2 5 2 5

2 6 10 1 3 3 1 1 11 20 4

1 4 2 2

5 3 4 1 5 3 2 2

2 2

4 2 3 35

72

3 2 14

2 27

30

70

56 8 42 11 77 4 42 8 78 6 67 8 75 3 70 15 139 5 97 5 55 4 116 7 203 9 151 11 139 12 207 12 135 3 87 2 70 1 94 134 2000

100 52 29 12 15 24 23 14 17 18 20 10 9 9 12 14 10 9 11 9 17

Table.1 Defect categories wise and percentage defectives in the sewing department

152

Percentage Defective

Puckering

Slip stitch

Roping

Others

DATE

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

4.0 Cause & Effect diagram for major occurring defects and their implemented solutions 4.1 Measurement out of tolerance

Improper sweep shape after panel attachment

Notches not proper

Solutions Provided Cause Notches improper at pleats Solution Cutting Department was informed about the cause and the reason identified was misalignment of plies during cutting. This being a major defect causing activity was asked to be checked 100% in the audit before sending the bundles to sewing. A template was provided against which the pieces were checked and in case of any deviation, white pencil was used to mark pleat positions. Bottom trimming was done to make the sweep uniform.

Improper sweep panel attachment

shape

after

153

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

4.2 Puckering at waistband

Improper pre-setting of waistband

Causes Improper pre- setting of waistband after thumb pressing

Solution Pressing was done by steam iron with a spray of starch over it. This made the handling of the waistband easier while stitching and thus reduced puckering at the waistband.

154

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

4.3 Roping

4.4 Waistband extension uneven

Causes Improper folder setting on machine

Solution The folder guide was adjusted and improper materials handling avoided

155

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

Causes Margin not followed while attaching waistband and waistband edge not finished properly 4.5 Improper fly shape

Solution The operator was instructed to be careful while feeding and following the margins strictly

Causes Top stitch is being inhibited by zipper lock underneath

Solution A template was provided to the operator and the stitch was shifted a little below, altering the fly shape within tolerance level

156

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

4.6 Fusing shining marks

Causes Poor quality fusing used

Solution Fusing was changed and skilled operator required

5.0 Trend chart showing reduction in defect levels after implemented solutions D.H.U. levels in Measurement Out 60 40 20 0 1-Mar 2-Mar 3-Mar 4-Mar

Fig. 5 Defects level Reduction in Measurements Out

157

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

D.H.U. levels in Puckering 25 20 15 10 5 0

Fig. 6 Defects levels Reduction in Puckering

D.H.U. levels in Roping

14 12 10 8 6 4 2 0

7-Mar

6-Mar

8-Mar

9-Mar

15-Mar

10-Mar

11-Mar

12-Mar

13-Mar

14-Mar

16-Mar

17-Mar

18-Mar 6-Mar

Fig. 7 Defects levels Reduction in Roping

D.H.U. levels in Uneven fly shape 40 30 20 10 0 3-Mar 4-Mar 5-Mar

158

19-Mar

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

Fig. 8 Defects levels Reduction in Uneven Fly Shape

Defects levels in Label Attachment

16 14 12 10 8 6 4 2 0

Fig. 9 Defects levels Reduction in Label Attachment

Defects levels in Uneven Top Stitch 25 20 15 10 5 0 3-Mar 4-Mar 5-Mar 6-Mar 7-Mar 8-Mar 9-Mar 10-Mar 11-Mar 12-Mar Uneven top stitch Fig. 10 Defects levels Reduction in Uneven top Stitch

159

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

6.0 Defects analysis in finishing department 239 206 200 150 100 50 0 SOIL/ DUST/ RUST STICKER MARKS SWEAT MARKS VEGETABLE MARKS Fig. 11 Defects analysis in finishing department OIL SPOT INK/CHALK MARK TOBACCO MARK 132 106

250

6.1 Recommended Suggestions Implemented to Reduce Defects in finishing section 1.Oil spots: Application of a scrap paper under the presser feet of sewing machines after the days work so that the machines which are leaking oil can be tracked. 2. Proper oiling level to be maintained in order to prevent leakage of extra oil 3.Operator to take responsibility of cleaning the machine after lubrication 4. Immediate reporting of oil leakage Ink/ chalk marks: Usage of good quality markers, the marks of which are easily washable 2.Avoid using pencils for marking. 3. Usage of chalks on white and light colored fabrics. Soil and dust: 1.Usage of plastic bags for storing and transportation of pieces. 2. Cleaning of checking tables and machines before the start of days work 3. Avoid keeping garments on the floor, using trolleys for storage. 4. Creating a polyethene sheet partition between sewing and finishing departments so that fabric dust doesnt come over to the finishing unit and settle down on the washed fabric. Suggestions implemented to reduce no. of uncut & loose thread: 1.Thread cutting operation to be carried out after washing in order to counteract unraveling of threads after washing 2. Use of thread sucking machine to prevent any loose threads to reach the checkpoint

160

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

7.0 Department wise results and discussion (Sewing, Finishing and Cutting department) 7.1 Cutting Department 45 40 35 30 25 20 15 10 5 0 01/02/08 08/02/08 15/02/08 22/02/08 29/02/08 07/03/08 14/03/08 21/03/08 28/03/08 04/04/08 11/04/08

Fig. 12 Overall reductions in defect levels for cutting department

7.2 Sewing Department Overall Percent defective trend

120

100 80 60 40 20 0 1-Mar 2-Mar 3-Mar 4-Mar 5-Mar 6-Mar 7-Mar 8-Mar 9-Mar 10-Mar 11-Mar 12-Mar 13-Mar 14-Mar 15-Mar 16-Mar 17-Mar 18-Mar 19-Mar 20-Mar 21-Mar 22-Mar 23-Mar 24-Mar 25-Mar

Percentage defective Fig. 13 Overall reductions in defect levels for sewing department

161

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

7.4 Finishing Department

20 18 16 14 12 10 8 6 4 2 0 Shade Variation Fabric Fault Hard Stains Uncut/ Loose thread Insecure stitch Cut & Hole Embroidery/Beads/Printing Wrong/Missing Label Touching Mending Stitching Others

February

March

April 1- 15

Fig. 14 Overall reductions in defect levels for finishing department Cutting lot failure rate reduced to zero percent generally. Sewing percent defective reduced to approximately 40%. In finishing, stitching D.H.U. came down to approximately 8% from 16% as earlier, uncut thread D.H.U. came down to approximately 10% from 22% as earlier. Rework increased the cost of the different work categories between 2% to 30%. However, some best practices to control defect generation within the factory were suggested as- Make the workplace clean from fabric store to cutting to sewing to washing and finishing. Place quality control system in proper place. Implies that sufficient no. of checkers, trained checkers, checkers making report while checking, analysis of reports and take action based on the quality check reports. Conduct training program for the checkers on how to check piece correctly to capture defective pieces. Train them to make garment checking reports. Run quality awareness program for your employees. Quality standard must be understood by each employee and everybody have to work to meet quality goal. No low standard work should be accepted by the following department. In sewing line dont allow operators to keep bundles open and each bundle must be completed before forwarding to the next. It will help you track missing pieces. It is usual experience that operators throw pieces under tables when they make mistake or receive defective (incomplete) garments from previous operator. Nobody keeps track of these missing pieces until you found shortage of garments in finishing. Set standard operating procedures (SOP) for each task performed by your employees. SOP for quality control system for each department. Set audit team to audit your quality system in a regular interval. These

162

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

recommendations were suggested to the individual 8. Conclusion The suggestive tools developed in this article cover a comprehensive series of aspects in minimizing reworks in the sewing section of apparel industries by ensuring quality production. The importance of the textile industry in the economy of Bangladesh is very high. The explosive growth of the RMG industry in the country, however, has not been enough supported by the growth of backward linkage facilities. So manufacturing the quality product is mandatory to sustain in this global competitive market. Quality is ultimately a question of customer satisfaction. Good Quality increases the value of a product or service, establishes brand name, and builds up good reputation for the garment exporter, which in turn

department.

results into consumer satisfaction, high sales and foreign exchange for the country. The perceived quality of a garment is the result of a number of aspects, which together help achieve the desired level of satisfaction for the customer. However, we should bear in mind that 1% defective product for an organization is 100% defective for the customer who buys that defective product. The study clearly indicates that by eliminating non-productive activities like reworks in the apparel industries time as well as cost are saved by ensuring quality production which have an important impact on overall factory economy.

References [1] Dr P Khanna: Work study, time and motion study, Dhanpat Rai and Sons, New Delhi, (pp 21-31). [2] F.M. Gryna, J.A. DeFeo, Quality Planning & Analysis for Enterprise Quality, Tata McGrawHill, Edition, 2008 [3] (Opex Group) (n.d.). Retrieved december 2012, from viyellatex group: http//www.opexgroup.com [4] (viyellatex group)(n.d.). Retrieved december 2012, from viyellatex group: http//www.viyellatexgroup.com [5] http//www.asiantextilejournal.com [6] (Sepal Group)(n.d.). Retrieved december 2012. From sepal group http//www.sepalgroup.com [7] (n.d.). Retrieved nov 2012, from fiber 2 fashion: http//www.fiber2fashion.com [8]Saroj Bala, Factors Influencing Costing of Woven Fabrics, The Indian Textile Journal, 2003 [9]Dean J W and Bowen D E., 1994, Management Theory and Total Quality: Improving Research and Practice and Theory Development, the Academy of Management Review 19, (3) PP 392-418. [10]O.H. Khan, A Study of Six Sigma Implementation and Critical Success Factor, Pakistans Ninth International Convention on Quality Improvement, Karachi, Pakistan, pp. 1-12, Nov. 2005 [11]Hawken, Paul, Amory Lovins, and L. Hunter Lovins. Natural Capitalism: Creating the Next Industrial Revolution (New York Little, Brown and Company, 1999) [12] Florida, R. Lean and Green The Move to Environmentally Conscious Manufacturing. California Management Review 39, (1996) 80-105 [13]Environmental Technology Best Practice Programmed. (1996). saving money through waste minimization raw material use, GG25, Crown Copyright. [14] M.Mahajan, Statistical Quality Control, Dhanpat Rai & Co. (P) LTD. pp.186-206,

Authors Biographies: Md. Mazedul Islam The author is associated as Lecturer in the Department of Textile Engineering at Daffodil International University, Dhaka, Bangladesh. His research interest fields are- Apparel production and Merchandising, Production Management. Industrial Engineering, Apparel and fabric finishing, Textile and Apparel Quality control, Apparel Brand management, Apparel Washing etc. Adnan Maroof Khan The author is associated as Lecturer in the Department of Textile Engineering at Daffodil International University,

163

January 2013. Vol. 1, No.4

ISSN 2305-8269

International Journal of Engineering and Applied Sciences

2012 EAAS & ARF. All rights reserved

www.eaas-journal.org

Dhaka, Bangladesh. His research interest fields areGarments Technology, Production Management, Garments Quality Control & Management, Textile Coloration & Fabric Structure and design, etc. Md. Mashiur Rahman Khan Assistant Professor & Head, Department of Apparel Manufacturing Engineering, Bangladesh University of textiles.

164

Potrebbero piacerti anche

- Chapter 5 - Production Planning and ControlDocumento43 pagineChapter 5 - Production Planning and Controlzoomerfins22Nessuna valutazione finora

- Fabric and Apparel Performance Testing ProtocolDocumento23 pagineFabric and Apparel Performance Testing Protocolzoomerfins22Nessuna valutazione finora

- SOP of Fabric InspectionDocumento6 pagineSOP of Fabric Inspectionmorshed_mahamud7055100% (3)

- Fabric and Apparel Performance Testing ProtocolDocumento23 pagineFabric and Apparel Performance Testing Protocolarikingkong7027100% (1)

- Productivity Improvement ChecklistDocumento6 pagineProductivity Improvement Checklistzoomerfins22Nessuna valutazione finora

- Spreading and Cutting of Apparel ProductsDocumento95 pagineSpreading and Cutting of Apparel Productszoomerfins2297% (30)

- C-TPAT Requirements For Import Suppliers - v3 (English Version)Documento12 pagineC-TPAT Requirements For Import Suppliers - v3 (English Version)zoomerfins22Nessuna valutazione finora

- Atlanta Apparel2012.SmlDocumento64 pagineAtlanta Apparel2012.Smlzoomerfins22Nessuna valutazione finora

- Psychometric Success Abstract Reasoning - Practice Test 1Documento13 paginePsychometric Success Abstract Reasoning - Practice Test 1Ambrose Zaffar75% (16)

- Work Measurement Techniques - MostDocumento31 pagineWork Measurement Techniques - Mostzoomerfins22Nessuna valutazione finora

- Manufacturingexcellence 111025224005 Phpapp02Documento65 pagineManufacturingexcellence 111025224005 Phpapp02zoomerfins22Nessuna valutazione finora

- Maynard Operation Sequence Technique (MOST)Documento8 pagineMaynard Operation Sequence Technique (MOST)VivekNessuna valutazione finora

- Marker ModesDocumento6 pagineMarker ModesSumit KumarNessuna valutazione finora

- The Balanced Scorecard ApproachDocumento15 pagineThe Balanced Scorecard ApproachRobin PalmerNessuna valutazione finora

- Man Ex KL479Documento23 pagineMan Ex KL479Ankit DixitNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Maintenance ManagementDocumento218 pagineMaintenance Managementzoomerfins22100% (17)

- Psychometric Success Numerical Ability - Reasoning Practice Test 1Documento7 paginePsychometric Success Numerical Ability - Reasoning Practice Test 1mita000Nessuna valutazione finora

- Psychometric Success Spatial Ability - Practice Test 1 PDFDocumento12 paginePsychometric Success Spatial Ability - Practice Test 1 PDFsalica4gbNessuna valutazione finora

- Embroidery TrainingDocumento30 pagineEmbroidery Trainingzoomerfins22Nessuna valutazione finora

- Psychometric Success Numerical Ability - Computation Practice Test 1 PDFDocumento7 paginePsychometric Success Numerical Ability - Computation Practice Test 1 PDFMudiare UjeNessuna valutazione finora

- Psychometric Success Mechanical Reasoning - Practice Test 1 PDFDocumento12 paginePsychometric Success Mechanical Reasoning - Practice Test 1 PDFKonul AlizadehNessuna valutazione finora

- Lycra HistoryDocumento20 pagineLycra HistorySwapnil PatilNessuna valutazione finora

- World Cat - Global Quality Assurance: Title: Best Practice Factory Handbook To: (PUMA/WC,)Documento68 pagineWorld Cat - Global Quality Assurance: Title: Best Practice Factory Handbook To: (PUMA/WC,)zoomerfins22Nessuna valutazione finora

- World Cat - Global Quality Assurance: Title: Best Practice Factory Handbook To: (PUMA/WC,)Documento68 pagineWorld Cat - Global Quality Assurance: Title: Best Practice Factory Handbook To: (PUMA/WC,)zoomerfins22Nessuna valutazione finora

- WRAP HandbookDocumento63 pagineWRAP Handbookzoomerfins220% (1)

- Aerie Inspection ManualDocumento40 pagineAerie Inspection Manualzoomerfins2250% (4)

- A&F Method OfInspectionDocumento26 pagineA&F Method OfInspectionzoomerfins22100% (1)

- F-02 Fabric Inspection ManualDocumento13 pagineF-02 Fabric Inspection Manualzoomerfins22100% (1)

- Sewing With Knit FabricDocumento8 pagineSewing With Knit FabricGarmentLearnerNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Cold Fangs (Fangs Series # 2)Documento313 pagineCold Fangs (Fangs Series # 2)mjay moredoNessuna valutazione finora

- Jamacian DreamsDocumento2 pagineJamacian Dreamsapi-315179675Nessuna valutazione finora

- Week 16 Final ExaminationDocumento3 pagineWeek 16 Final ExaminationDaniela QuiamcoNessuna valutazione finora

- Backhoe WORK PLAN JsaDocumento1 paginaBackhoe WORK PLAN JsaMax McguireNessuna valutazione finora

- Cang KirDocumento4 pagineCang Kirli_ce100% (1)

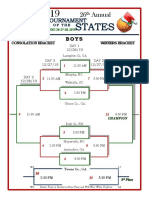

- 2019-20 Bos Boys and Girls BracketsDocumento2 pagine2019-20 Bos Boys and Girls Bracketsapi-181954481Nessuna valutazione finora

- Assembly Manual: Hobie CatsyDocumento17 pagineAssembly Manual: Hobie CatsyGiulio Sergio GiraudiNessuna valutazione finora

- Phenolphthalein IndicatorDocumento6 paginePhenolphthalein IndicatorwindaratlinNessuna valutazione finora

- NoitcelesDocumento69 pagineNoitcelesAngela CudiaNessuna valutazione finora

- WashingDocumento22 pagineWashingNeelam SharmaNessuna valutazione finora

- ZoroastrianDocumento5 pagineZoroastrianMahram KalantariNessuna valutazione finora

- My Year of No Spending (Advanced)Documento5 pagineMy Year of No Spending (Advanced)Phung Thanh Thom100% (2)

- A/KT Mountaineer Armor: 1800 A/Kt Tracker Utility Vest: 100Documento24 pagineA/KT Mountaineer Armor: 1800 A/Kt Tracker Utility Vest: 100abcNessuna valutazione finora

- Unit Test 4 ExtensionDocumento2 pagineUnit Test 4 ExtensionCamilaNessuna valutazione finora

- Material Testing: Ankur SaxenaDocumento70 pagineMaterial Testing: Ankur SaxenaMehak B Arora100% (1)

- Types of PPEDocumento14 pagineTypes of PPEgshdavidNessuna valutazione finora

- She Matters: A Life in Friendships by Susanna SonnenbergDocumento22 pagineShe Matters: A Life in Friendships by Susanna SonnenbergSimon and Schuster100% (1)

- Katalog NSU Max - de .EnDocumento73 pagineKatalog NSU Max - de .EnGuille GimenoNessuna valutazione finora

- Laboratory Orientation ChecklistDocumento2 pagineLaboratory Orientation ChecklistRanaZahid Latif100% (1)

- Compresor PDFDocumento39 pagineCompresor PDFvyt1923Nessuna valutazione finora

- Final Draft Constitution and By-Laws January, 2011Documento9 pagineFinal Draft Constitution and By-Laws January, 2011Hazel Torres BadayosNessuna valutazione finora

- Canterbury Tales CharactersDocumento28 pagineCanterbury Tales Characterskcafaro59Nessuna valutazione finora

- Accessories (Personality Development)Documento37 pagineAccessories (Personality Development)Debi Bahinting Ouano-Rota71% (7)

- Women and The Islamic Veil - Deconstructing Implications of Orientalism, State, and Feminism Through An Understanding of Performativity, Cultivation of Piety and Identity, andDocumento73 pagineWomen and The Islamic Veil - Deconstructing Implications of Orientalism, State, and Feminism Through An Understanding of Performativity, Cultivation of Piety and Identity, andHamza SaidiNessuna valutazione finora

- Designed by Lisa Borum: AdvancedDocumento5 pagineDesigned by Lisa Borum: AdvancedREEM MNessuna valutazione finora

- Arts 7 LasDocumento78 pagineArts 7 LasDherry's Jhean Batara BalisiNessuna valutazione finora

- Garments Accessories TrimsDocumento42 pagineGarments Accessories TrimsAbulHasanNessuna valutazione finora

- Steering and Wheel Alignment DiagnosisDocumento23 pagineSteering and Wheel Alignment DiagnosismohamedashrafsayedNessuna valutazione finora

- Linde Forklift 394 02 h40 h45 h50 Spare Parts List de FR en It Es ZHDocumento22 pagineLinde Forklift 394 02 h40 h45 h50 Spare Parts List de FR en It Es ZHmichellewhite070288pka100% (61)

- PermutitDocumento70 paginePermutitAlfredo HernandezNessuna valutazione finora