Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Catfines Separation

Caricato da

banerjeeamlanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Catfines Separation

Caricato da

banerjeeamlanCopyright:

Formati disponibili

Westfalia Separator Mineraloil Systems

Mechanical Separation Division

Cat Fines Separation

Systems for cat fines removal from residual oils in refineries

Improve Oil Quality

Refining cat fines

During modern refining processes the residual oils from atmospheric and vacuum distillation are sent to a cracking tower. Here the long hydro-carbons are cracked with help of pulverised catalysts such as aluminium silicates which are mixed with the oil. This cracking process takes place at a temperature of approx.

500 C (930 F). A lot of these cat fines remain in the residues of the cracking tower and the distillates coming from the cracking process. These cat fines can be separated from the oils to recover them and / or to improve the oil quality.

Centrifuge plant for cat fines separation

2 Westfalia Separator

Mineraloil Systems

Atmospheric distillation

Vacuum distillation

Conversion plants Catalytic cracker Visbreaker Gas Gasoline Middle distillate Cracked gas oil Catalyst Gas Gasoline Middle distillate

Gas Gasoline Kerosine Middle distillate gas oil Crude oil

Gas Heavy gas oil Heavy vacuum fuel

Residues

Residues

Residues

Residues

Classical fuels Low-grade fuels

Typical refinery process

Effective Refining Principle

Combining disk stack centrifuges and bowl separator

Disk stack centrifuges for cat fines removal (operated as clarifier) Due to high product temperature oil instead of water as operating liquid recommended Downstream cat fines concentration with decanters possible

Separation Results

Catalyst fines removal from residual oils

Customer Benefits

Optimum oil quality as refinery product Higher sales prices for refinery product obtainable

Catalyst particles are recovered

These cat fines can be reinjected into catalyst tower and re-used

These top results can be achieved only with fuel oil treatment systems from Westfalia Separator.

Mineraloil Systems

3 Westfalia Separator

Check Investment for an Economical Solution

Receive an individual estimate

Please fill in the following questionnaire and send it back to fax no.: +49 25 22 / 77-17 78 or e-mail: mineraloilsystems@ gea-westfalia.de

Company: Contact: Phone: E-mail: Fax:

Oil specification

Viscosity: Density: Solid Content (Cat Fines):

St

@ @ %

C C

g/ml

Site conditions

Temperature min.: Temperature max.: Humidity: Hazardous area classification: Voltage / frequency:

C C %

Hz

Heating medium available on site: (electricity, thermal oil, steam)

Product infeed conditions

Temperature min.: Temperature max.: Required capacity:

C C l/h

Special remarks

Mineraloil Systems

4 Westfalia Separator

Heavy oil slurry from cat cracker unit Untreated heavy oil

Liquid phase

80 C (175 F) Heat in 120 C (250 F) F) Heat out

Treated heavy oil 0.1% ash

Treatment of operating liquid

Light cycle oil (for blending)

Decanters

Heat in

Operating liquid

Sludge

Solids (Disposal)

Complete cat fines removal plant

Payback in No Time

Only fuel oil treatment systems from Westfalia Separator boost your profit

Scope of supply 5 x OSC 50 self-cleaning disc stack centrifuges operated as clarifier for cat fines removal 1 x OTB 9 solid bowl separator for the treatment of the operating liquid Complete plant with auxiliary equipment Whole plant in Ex-design Payback within a short time The solution is the cat fines removal system from Westfalia Separator.

Fractionator Storage tank 260 C

FC LC

FC

105 C

Cat fines removal centrifuge G E

Pre-heater

FC

Cooler

FO

Feed for dilution

FC

Feed line

Flow chart of cat fines in the cracking process

5 Mineraloil Systems Westfalia Separator

Beverage Technology Dairy Technology Oils and Fats Processing Chemicals, Pharmaceuticals and Biotechnology Oils and Fats Recovery Starch Technology and Industrial Biotechnology Environmental Technology Marine Energy Oilfield Industry Engineering Second Hand Machinery Service

The information contained in this brochure merely serves as a non-binding description of our products and is without guarantee. Binding information, in particular relating to capacity data and suitability for specific applications, can only be provided within the framework of concrete inquiries. Printed on chlorine-free bleached paper www.papp.cc 9997-1180-000/0505 EN Printed in Germany Subject to modification

Westfalia Separator Mineraloil Systems GmbH Werner-Habig-Strae 1 59302 Oelde (Germany) Phone +49 25 22/77-0 Fax +49 25 22/77-17 78 mineraloilsystems@gea-westfalia.de www.westfalia-separator.com

Westfalia Separator Mineraloil Systems

Take the Best Separate the Rest A company of mg technologies group

Potrebbero piacerti anche

- CE Conformity 9997 1213 010Documento6 pagineCE Conformity 9997 1213 010banerjeeamlanNessuna valutazione finora

- Performance To Boost Power Generation - GEA Westfalia Separator EagleclassDocumento20 paginePerformance To Boost Power Generation - GEA Westfalia Separator EagleclassbanerjeeamlanNessuna valutazione finora

- DA - Cold Milk Procool ENDocumento8 pagineDA - Cold Milk Procool ENbanerjeeamlanNessuna valutazione finora

- Many CIP Processes Waste Time, Water and ProductionDocumento2 pagineMany CIP Processes Waste Time, Water and ProductionbanerjeeamlanNessuna valutazione finora

- Cleaning TechnologyDocumento71 pagineCleaning TechnologybanerjeeamlanNessuna valutazione finora

- Pulsation Systems: Setting The Standard For Durable and Consistent PulsationDocumento8 paginePulsation Systems: Setting The Standard For Durable and Consistent PulsationbanerjeeamlanNessuna valutazione finora

- GEA Westfalia Separator Soline: Advanced Soymilk ProcessingDocumento12 pagineGEA Westfalia Separator Soline: Advanced Soymilk ProcessingbanerjeeamlanNessuna valutazione finora

- WSG - Westfalia Separator Ecoforce enDocumento16 pagineWSG - Westfalia Separator Ecoforce enbanerjeeamlanNessuna valutazione finora

- 2016 Vesta BrochureDocumento8 pagine2016 Vesta BrochurebanerjeeamlanNessuna valutazione finora

- Production of Biodiesel With Separators PDFDocumento4 pagineProduction of Biodiesel With Separators PDFbanerjeeamlanNessuna valutazione finora

- 2010 Datasheet Mixer 160 280 enDocumento2 pagine2010 Datasheet Mixer 160 280 enbanerjeeamlanNessuna valutazione finora

- SDS 024 A4Documento4 pagineSDS 024 A4banerjeeamlanNessuna valutazione finora

- Butterfly Valves T-SmartDocumento100 pagineButterfly Valves T-SmartbanerjeeamlanNessuna valutazione finora

- WSST FW Varipond enDocumento6 pagineWSST FW Varipond enbanerjeeamlanNessuna valutazione finora

- MBR Decanter 9997 1227 020Documento8 pagineMBR Decanter 9997 1227 020banerjeeamlanNessuna valutazione finora

- Chevron Alba FSU EN - LQDocumento2 pagineChevron Alba FSU EN - LQbanerjeeamlanNessuna valutazione finora

- Bilgemaster 200 PDFDocumento7 pagineBilgemaster 200 PDFbanerjeeamlanNessuna valutazione finora

- 2 Gear Drive Decanters 010807Documento4 pagine2 Gear Drive Decanters 010807banerjeeamlanNessuna valutazione finora

- GEA Westfalia Separator WatchMaster PlusDocumento2 pagineGEA Westfalia Separator WatchMaster PlusbanerjeeamlanNessuna valutazione finora

- Instant Coffee 9997 1323 020Documento12 pagineInstant Coffee 9997 1323 020banerjeeamlanNessuna valutazione finora

- RR - Decanter GEA WS Ecoforce FishMaster CF 6000 Separating Decanter enDocumento2 pagineRR - Decanter GEA WS Ecoforce FishMaster CF 6000 Separating Decanter enbanerjeeamlanNessuna valutazione finora

- Decanter Control DCU7000Documento4 pagineDecanter Control DCU7000banerjeeamlanNessuna valutazione finora

- 2 Gear DriveDocumento4 pagine2 Gear DrivebanerjeeamlanNessuna valutazione finora

- Pharmaceutical Biotechnology 9997 8203 030Documento32 paginePharmaceutical Biotechnology 9997 8203 030banerjeeamlanNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Strategic Diamond - Elements of Strategy - HPCLDocumento2 pagineStrategic Diamond - Elements of Strategy - HPCLSyed fayas thanveer SNessuna valutazione finora

- National and International QHSE Compliances ObligationDocumento3 pagineNational and International QHSE Compliances ObligationleonelNessuna valutazione finora

- REICHARD - Environmental-Geology-1st-Edition PDFDocumento593 pagineREICHARD - Environmental-Geology-1st-Edition PDFJose Alvarez83% (6)

- WWT Unit 3 Preliminary and Primary TreatmentDocumento38 pagineWWT Unit 3 Preliminary and Primary TreatmentManish KumarNessuna valutazione finora

- Perry Anderson - Portugal and The End of Ultra-Colonialism 62 - IDocumento20 paginePerry Anderson - Portugal and The End of Ultra-Colonialism 62 - IEmanuelle SantosNessuna valutazione finora

- Gaseous FuelsDocumento5 pagineGaseous FuelsEmmanuel Jimenez-Bacud, CSE-Professional,BA-MA Pol Sci100% (1)

- Casebook Stern 2020Documento247 pagineCasebook Stern 2020Li WangNessuna valutazione finora

- Case Study Pakistan State OilDocumento4 pagineCase Study Pakistan State OilDavidparkash Mirza100% (1)

- Production and Utilization of Natural Gas Resources in Nigeria-A ReviewDocumento3 pagineProduction and Utilization of Natural Gas Resources in Nigeria-A ReviewDaniel DamboNessuna valutazione finora

- ASTM D4006 - 16e1Documento11 pagineASTM D4006 - 16e1Angel MurilloNessuna valutazione finora

- Training Courses Registration Information: Registration Type Package Includes Price, Rur, Incl. VAT (18%)Documento1 paginaTraining Courses Registration Information: Registration Type Package Includes Price, Rur, Incl. VAT (18%)UdhamNessuna valutazione finora

- Gordian: Associates, IncDocumento55 pagineGordian: Associates, InceducacionNessuna valutazione finora

- Issue 161 M (Edit)Documento215 pagineIssue 161 M (Edit)EddieNessuna valutazione finora

- Correlating The Chemical Engineering Plant Cost Index With Macro-Economic IndicatorsDocumento10 pagineCorrelating The Chemical Engineering Plant Cost Index With Macro-Economic IndicatorsCraftychemist100% (1)

- Mitigation of Wax in Oil PipelinesDocumento9 pagineMitigation of Wax in Oil PipelinesIsaac MuñozNessuna valutazione finora

- An ExaminationDocumento18 pagineAn ExaminationUtibe Tibz IkpembeNessuna valutazione finora

- SPE 30775 MS Chan PlotsDocumento9 pagineSPE 30775 MS Chan PlotsCordylus0824Nessuna valutazione finora

- Central Oman PlatformDocumento5 pagineCentral Oman PlatformMourad B. WassefNessuna valutazione finora

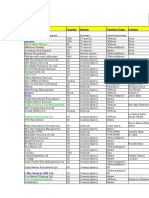

- Company Name Country Service Function/Type Contact: RigzoneDocumento4 pagineCompany Name Country Service Function/Type Contact: RigzonekokabawaNessuna valutazione finora

- Snapshotof Indias Oiland Gasdata March 2022 UploadDocumento38 pagineSnapshotof Indias Oiland Gasdata March 2022 UploadRonaldo DmelloNessuna valutazione finora

- Mini Oil Refinery PlantsDocumento3 pagineMini Oil Refinery Plantsdndudc100% (4)

- Vectron+1-6 300713 en 1.6Documento24 pagineVectron+1-6 300713 en 1.6kikokadolaNessuna valutazione finora

- MPR ProjectDocumento57 pagineMPR Projectdivyanshu MNessuna valutazione finora

- Layout Grounding Pt. Wilmar Nabati Indonesia - Padang: Tank FarmDocumento1 paginaLayout Grounding Pt. Wilmar Nabati Indonesia - Padang: Tank FarmYosafat VidoNessuna valutazione finora

- جهات تقويم المطابقة المقبولة لدى الهيئة على النظام الجديد 1 11 1438Documento13 pagineجهات تقويم المطابقة المقبولة لدى الهيئة على النظام الجديد 1 11 1438Wajid KNessuna valutazione finora

- Organic Chemistry 2Documento3 pagineOrganic Chemistry 266rdsmh2mwNessuna valutazione finora

- Biofuels Viet NamDocumento70 pagineBiofuels Viet NamTínNessuna valutazione finora

- Spe-6788-Pa-Hv (1) SpeDocumento13 pagineSpe-6788-Pa-Hv (1) SpeNixon AyalaNessuna valutazione finora

- Handbook of Pollution Control and Waste Minimization Ed. Abbas GhassemiDocumento516 pagineHandbook of Pollution Control and Waste Minimization Ed. Abbas Ghassemianhtuan66100% (1)