Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bicycle Boat

Caricato da

kascaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bicycle Boat

Caricato da

kascaCopyright:

Formati disponibili

FIG.

II

their spacing are clearly indicated in Figs. 2 and 4. Each frame consists of four pieces glued (marine glue) and screwed together, and notched to receive. the longitudinal memberssheer and chine battens. Both stem and stern are set at an angle, which should be taken into consideration when building the frame (see Fig. 3 ) . Details of the stem or nose block, which is cut from a piece of 2 x 8-in. spruce, are given in Fig. 1, part of the side being recessed Vi in. to take the side planking. Exact dimensions and method of cutting the stern from %-in. ash are given in Fig. 6. Note the additional reinforcing pieces provided across the top for the braces that support the bicycle frame, besides those that reinforce the deck directly under the rubber mats. When the frame has been finished, the side and bottom planking, which is cut from 12-ft. lengths of V4 x 12-in. sugar pine, is screwed on after the contacting portions of the frame have been covered with marine glue. Then, with the top off, the inside of the pontoons is given an application o paint, and the top, also o %-in. sugar pine, is glued and screwed on, using %-in. flat-head brass screws. The heads of the screws should be countersunk, and the resulting holes filled with hard water putty. After sanding each pontoon smooth, it is given a liberal application of airplane cement, and heavy muslin is stretched

over the surface. A hot iron is used to press the cloth securely to the wood as shown in Fig. 7. The seam should be made along the upper edge, where %-in. halfround m o l d i n g is applied, this being screwed on. A spruce keel of % x lViin. stock is screwed to the center of the bottom of each pontoon. It is neatly joined to the stem, after which a strip of brass is run over the stem and a few inches along the forward part of the keel. Each pontoon is provided with two air vents made up of pipe fitting's, to prevent the pontoon from bursting when the air inside expands in the heat of the sun. Be sure to apply glue to the fittings before screwing them in place over small holes drilled through the deck, to make them watertight. The pontoons are finished with a priming coat of shellac, four coats of goodquality exterior paint and finally a coat of spar varnish. Any desired color scheme may be followed. Next comes the adaptation of the bicycle. A girl's bicycle is best, since the lack of a crossbar affords more convenient mounting. Cut off the front and rear forks as shown in Fig. 8. The bracing consists of lengths of pipe, flattened at the ends and bolted to angle-iron crosspieces. At the front end, flat-iron clamps are used to hold the braces to the steering post, while the rear pipes are slipped over short stubs

121

or butts of the original fork, directly u n der the seat. The pipe should fit over the stubs snugly, and it has been found best to heat and slightly flatten the joint after assembly, so that it cannot come apart. One of the horizontal frame members, originally used to support the rear wheel, is cut off nearly flush with the housing of the pedal-crank bearing so that it will not interfere with the ring gear which is to be added later. The corresponding f r a m e member is cut off about halfway from the end, after which the cut portion is flattened and riveted to the r e a r angle-iron crosspiece. Fig. 10 shows how an automobile ring gear is bolted to the original pedal sprocket. It may be necessary to cut off the teeth of the sprocket to fit inside the recess of the gear. If desired, however, a brass disk may be substituted for the sprocket, in which case the disk should be the same thickness as the sprocket. A heavy piece of % x IV4in. flat iron, bolted to the frame as shown in Fig. 9, holds a bearing that supports the end of the 1-in. propeller shaft. This bearing is made from a pipe flange and short nipple filled with melted lead and drilled to receive the machined fitting on the end of the shaft. If you have no metal lathe, this fitting can be turned out quickly at any machine shop. The tapered portion should make a snug fit in the pinion gear, and a small pin, driven into the tapered portion, serves as a key for the gear. A bolt holds

"WASHERS -FLAN6E RUDDER SHAFT

the fitting on the shaft, while the latter runs through a bearing provided directly under the rear angle-iron crosspiece. This bearing and its hanger are made up of pipe fittings as shown in Fig. 11. The angle-iron crosspieces are fastened to the pontoons with lag screws in the a p proximate positions indicated in the detail above, and additional crosspieces of 1-in. stock are provided at the front and rear. The pontoons should be placed perfectly parallel, 33 in. from center to center. Steering is accomplished bj' means of a small sheet-metal rudder, connected with sashcord to the front-fork stub of the bicycle. If a commercial propeller is not available, one can be made from fairly heavy sheet metal. It should have a 15-in. diameter, with a hole drilled centrally to fit the shaft, end of which is threaded so that the propeller can be held securely between two nuts. Corrugated rubber mats are tacked to the deck of the pontoons on each side of the bicycle, and the craft is then ready to go.

Boat-Drawing Aid

When fairing lines on a boat drawing, an inexpensive substitute for a naval-architect's spline and ducks can be improvised

f r e m a s t r i p of p l a s t i c w h i c h is h e l d in p l a c e

on the drawing with tabs of masking tape. The plastic strip should be approximately Via x % x 30 in. and the tabs are spaced 2 in. apart as shown in the photo. A pin pressed into the drawing board at each end of the strip helps hold the shape of the curve.

122

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- 15 Foot SailboatDocumento4 pagine15 Foot SailboatAntónio OliveiraNessuna valutazione finora

- Sabot 8 FT Pram DinghyDocumento6 pagineSabot 8 FT Pram DinghyFrenchwolf420100% (2)

- 16 Foot Apache Outboard - PlansDocumento8 pagine16 Foot Apache Outboard - PlansRolando DaclanNessuna valutazione finora

- Multi SkiffDocumento6 pagineMulti SkiffScaramagnao Miao BauNessuna valutazione finora

- Happy Clam SkiffDocumento11 pagineHappy Clam SkifffccfNessuna valutazione finora

- Sailing SurfboardDocumento4 pagineSailing SurfboardFrenchwolf420100% (3)

- Corky 18 FT Sloop Diy PlansDocumento7 pagineCorky 18 FT Sloop Diy PlansFrenchwolf420100% (4)

- 8 FT SkiffDocumento3 pagine8 FT SkiffFrenchwolf420100% (3)

- Sea SkiffDocumento5 pagineSea SkiffFrenchwolf420100% (3)

- Rowboat Sail ConversionDocumento2 pagineRowboat Sail Conversionleather_nunNessuna valutazione finora

- Jump N JackDocumento5 pagineJump N JackFrenchwolf420100% (2)

- Merry MaidDocumento6 pagineMerry MaidFrenchwolf420100% (3)

- Paddle WheelDocumento4 paginePaddle WheelFrenchwolf420Nessuna valutazione finora

- 16 FT Sailing ScowDocumento7 pagine16 FT Sailing ScowFrenchwolf420100% (2)

- Arrow Outboard RunaboutDocumento4 pagineArrow Outboard RunaboutFrenchwolf420Nessuna valutazione finora

- Water Bug Tiny Paddle BoatDocumento5 pagineWater Bug Tiny Paddle BoatFrenchwolf420Nessuna valutazione finora

- Plywood RowboatDocumento7 paginePlywood RowboatAlphamatrix01Nessuna valutazione finora

- Rowboat 3 PieceDocumento3 pagineRowboat 3 PieceFrenchwolf420100% (1)

- Nereia PramDocumento2 pagineNereia PramFrenchwolf420100% (1)

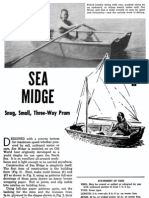

- Sea MidgeDocumento5 pagineSea MidgeFrenchwolf420Nessuna valutazione finora

- Pedal CatDocumento8 paginePedal CatFrenchwolf420Nessuna valutazione finora

- Pedal BoatDocumento4 paginePedal BoatFrenchwolf420Nessuna valutazione finora

- Car Top BoatDocumento4 pagineCar Top BoatFrenchwolf420Nessuna valutazione finora

- Row BoatDocumento2 pagineRow BoatBenjamin GoyaNessuna valutazione finora

- Paddle TurtleDocumento4 paginePaddle TurtleFrenchwolf420Nessuna valutazione finora

- Paddle BoatDocumento4 paginePaddle BoatFrenchwolf420Nessuna valutazione finora

- Paddle Bass BoatDocumento3 paginePaddle Bass BoatFrenchwolf420Nessuna valutazione finora

- 3 Piece BoatDocumento4 pagine3 Piece BoatFrenchwolf420Nessuna valutazione finora

- Motor Driven PaddleboardDocumento5 pagineMotor Driven PaddleboardFrenchwolf420100% (1)