Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3 Way Catalytic Converter

Caricato da

Gowtham KarthikCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3 Way Catalytic Converter

Caricato da

Gowtham KarthikCopyright:

Formati disponibili

Three-way catalytic converters have the additional advantage of controlling the emission of nitrogen oxides, in particular nitrous oxide,

a greenhouse gas over three hundred times more potent than carbon dioxide and currently the most ozone-depleting substance. Technological improvements including three-way catalytic converters have led to motor vehicle nitrous oxide emissions in the US falling to 8.2% of anthropogenic nitrous oxide emissions in 2008, from a high of 17.77% in 1998. Since 1981, "three-way" (oxidation-reduction) catalytic converters have been used in vehicle emission control systems in the United States and Canada; many other countries have also adopted stringent vehicle emission regulations that in effect require three-way converters on gasoline-powered vehicles. The reduction and oxidation catalysts are typically contained in a common housing, however in some instances they may be housed separately. A three-way catalytic converter has three simultaneous tasks:

1. Reduction of nitrogen oxides to nitrogen and oxygen: 2NOx xO2 + N2 2. Oxidation of carbon monoxide to carbon dioxide: 2CO + O2 2CO2 3. Oxidation of unburnt hydrocarbons (HC) to carbon dioxide and water: CxH2x+2 + [(3x+1)/2]O2 xCO2 + (x+1)H2O. These three reactions occur most efficiently when the catalytic converter receives exhaust from an engine running slightly above the stoichiometric point. This point is between 14.6

and 14.8 parts air to 1 part fuel, by weight, for gasoline. The ratio for Autogas (or liquefied petroleum gas (LPG)), natural gas and ethanol fuels is each slightly different, requiring modified fuel system settings when using those fuels. In general, engines fitted with 3-way catalytic converters are equipped with a computerized closed-loop feedback fuel injectionsystem using one or more oxygen sensors, though early in the deployment of threeway converters, carburetors equipped for feedback mixture control were used. Three-way catalysts are effective when the engine is operated within a narrow band of airfuel ratios near stoichiometry, such that the exhaust gas oscillates between rich (excess fuel) and lean (excess oxygen) conditions. However, conversion efficiency falls very rapidly when the engine is operated outside of that band of air-fuel ratios. Under lean engine operation, there is excess oxygen and the reduction of NOx is not favored. Under rich conditions, the excess fuel consumes all of the available oxygen prior to the catalyst, thus only stored oxygen is available for the oxidation function. Closed-loop control systems are necessary because of the conflicting requirements for effective NO x reduction and HC oxidation. The control system must prevent the NOx reduction catalyst from becoming fully oxidized, yet replenish the oxygen storage material to maintain its function as an oxidation catalyst. Three-way catalytic converters can store oxygen from the exhaust gas stream, usually when the air-fuel ratio goes lean. When insufficient oxygen is available from the exhaust stream, the stored oxygen is released and consumed (see cerium(IV) oxide). A lack of sufficient oxygen occurs either when oxygen derived from NOx reduction is unavailable or when certain maneuvers such as hard acceleration enrich the mixture beyond the ability of the converter to supply oxygen.

Potrebbero piacerti anche

- Basic Emission Control SystemsDocumento5 pagineBasic Emission Control SystemsNadhirah JohaNessuna valutazione finora

- CDGI’s CHAMELI DEVI SCHOOL OF ENGINEERING, INDORE Department of Mechanical Engineering Session: 2015-16 Subject Code:ME-607 SEMINAR ON CATALYTIC CONVERTERDocumento20 pagineCDGI’s CHAMELI DEVI SCHOOL OF ENGINEERING, INDORE Department of Mechanical Engineering Session: 2015-16 Subject Code:ME-607 SEMINAR ON CATALYTIC CONVERTERSanskarrRathiiNessuna valutazione finora

- Engine Deisgn For Low EmissionsDocumento33 pagineEngine Deisgn For Low EmissionsRaphael LomonacoNessuna valutazione finora

- Catalytic Converter Anna University NotesDocumento17 pagineCatalytic Converter Anna University NotesHêartìin Praveen100% (1)

- Air Mass Sensor With Frequency OutputDocumento2 pagineAir Mass Sensor With Frequency OutputXaockaNessuna valutazione finora

- Gasoline Particulate FiltersDocumento23 pagineGasoline Particulate FiltersvigneshwaranNessuna valutazione finora

- Implementation of Turbocharger On A FSAE Car: Powertrain Subsystem Team KART, Formula SAE Team of IIT KharagpurDocumento11 pagineImplementation of Turbocharger On A FSAE Car: Powertrain Subsystem Team KART, Formula SAE Team of IIT KharagpurAbhimanyu Das100% (1)

- Chesterton 860 Moldable Polymer Gasketing Datasheet PDFDocumento2 pagineChesterton 860 Moldable Polymer Gasketing Datasheet PDFHumberto ParisNessuna valutazione finora

- Bosch Fuel LubricityDocumento4 pagineBosch Fuel LubricityvictorpoedeNessuna valutazione finora

- IJERT-2015 Special Issue Structural Thermal Analysis Exhaust ManifoldDocumento4 pagineIJERT-2015 Special Issue Structural Thermal Analysis Exhaust ManifoldKarthikNessuna valutazione finora

- Exhaust Gas Analysis - Part One PDFDocumento4 pagineExhaust Gas Analysis - Part One PDFFabricio LimaNessuna valutazione finora

- Motoplat Information and TestingDocumento3 pagineMotoplat Information and TestingMizioNessuna valutazione finora

- SIEMENS VDO-Sensores para Gestao de MotorDocumento131 pagineSIEMENS VDO-Sensores para Gestao de MotorJonathanNessuna valutazione finora

- Pollutant Formation in Si EnginesDocumento9 paginePollutant Formation in Si EnginesChirudeep Reddy100% (1)

- Free-Piston Engine - Wikipedia, The Free EncyclopediaDocumento4 pagineFree-Piston Engine - Wikipedia, The Free EncyclopediaSai DasNessuna valutazione finora

- Secondary Air Injection (AIR) SystemDocumento2 pagineSecondary Air Injection (AIR) Systemrodrigo alexis aravena ponceNessuna valutazione finora

- Emission TestsDocumento30 pagineEmission TestsBoobalakrishnan A R MoorthyNessuna valutazione finora

- SI Engine Combustion StagesDocumento4 pagineSI Engine Combustion Stagesmailsk123Nessuna valutazione finora

- Vidya Vardhaka College of Engineering Mysuru: "Diesel Particulate Filter"Documento15 pagineVidya Vardhaka College of Engineering Mysuru: "Diesel Particulate Filter"dhanalakshmi k sNessuna valutazione finora

- CAN BusDocumento7 pagineCAN BusMihnea DobreNessuna valutazione finora

- Cumbusiton Test WurthDocumento1 paginaCumbusiton Test WurthDiogov32Nessuna valutazione finora

- Factors Affecting Car Fuel ConsumptionDocumento23 pagineFactors Affecting Car Fuel ConsumptionScribd898989100% (1)

- Panda Injection DescriptionDocumento20 paginePanda Injection DescriptionmvrhtNessuna valutazione finora

- Mitsubushi's Torque Vectoring TechnologyDocumento8 pagineMitsubushi's Torque Vectoring TechnologyVaisakh N NairNessuna valutazione finora

- Engine Performance Optimization - GT PowerDocumento2 pagineEngine Performance Optimization - GT Powermanoj262400/2Nessuna valutazione finora

- E31 Relays and FusesDocumento1 paginaE31 Relays and FusesAndre Vershun Pernell II100% (1)

- MCQDocumento3 pagineMCQAshok KumarNessuna valutazione finora

- Dual Clutch Transmission - Seminar Report, PPT, PDF For MechanicalDocumento5 pagineDual Clutch Transmission - Seminar Report, PPT, PDF For MechanicalSachin Yadav100% (3)

- Catalytic ConverterDocumento11 pagineCatalytic ConverterAJ MukunNessuna valutazione finora

- Fiat Marelli PDFDocumento21 pagineFiat Marelli PDFmazacotesNessuna valutazione finora

- BYPASS Map SENSORDocumento3 pagineBYPASS Map SENSORKushal ExpertNessuna valutazione finora

- Week 1 M-Motronic Systems LectureDocumento16 pagineWeek 1 M-Motronic Systems LectureAhmed El-helwNessuna valutazione finora

- E46 IHKR System Components and OperationDocumento15 pagineE46 IHKR System Components and OperationSalisburNessuna valutazione finora

- Wheelhub Integration of Electric Motor in FSEDocumento35 pagineWheelhub Integration of Electric Motor in FSEShivam WankhedeNessuna valutazione finora

- Hydro Pneumatic Braking SytemDocumento11 pagineHydro Pneumatic Braking Sytempramo_dass100% (1)

- SSP 190 Adjustable TurbochargerDocumento32 pagineSSP 190 Adjustable TurbochargerDamir Miholić100% (1)

- Automotive Flow Sensors ExplainedDocumento27 pagineAutomotive Flow Sensors Explainedamirul lex100% (1)

- Gasoline Direct InjectionDocumento7 pagineGasoline Direct InjectionRavichandran GNessuna valutazione finora

- Balancing of Tractor EngineDocumento17 pagineBalancing of Tractor EngineManish ChoudharyNessuna valutazione finora

- Design of Exhaust ManifoldDocumento10 pagineDesign of Exhaust ManifoldAafreen MushtaqNessuna valutazione finora

- Engine Knock Sensors - Part TwoDocumento4 pagineEngine Knock Sensors - Part TwoFabricio LimaNessuna valutazione finora

- AVO Turbo Install GuideDocumento23 pagineAVO Turbo Install GuideThomas Havier100% (1)

- AC Pressure Chart R-134a Temperature Pressure ChartDocumento3 pagineAC Pressure Chart R-134a Temperature Pressure ChartJoseph Tchagou PoumoNessuna valutazione finora

- HVAC System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor ServiceDocumento17 pagineHVAC System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor ServiceDareyoss NegussieNessuna valutazione finora

- (Part 1) SAE Intake Concepts Using Ricardo WAVE-VECTIS 1D-3D Coupled Modeling TechniquesDocumento24 pagine(Part 1) SAE Intake Concepts Using Ricardo WAVE-VECTIS 1D-3D Coupled Modeling TechniquesSarah WilliamsNessuna valutazione finora

- 17 Engine and Emission ControlDocumento38 pagine17 Engine and Emission ControlJoaoBorgesNessuna valutazione finora

- Cis Information DiagnosisDocumento17 pagineCis Information DiagnosisrezakecilNessuna valutazione finora

- GdiDocumento22 pagineGdiAnonymous ysrxggk21c100% (1)

- 2021.12.08 Ligier Js PX BrochureDocumento14 pagine2021.12.08 Ligier Js PX BrochureMarco BerettaNessuna valutazione finora

- Farm Machinery Internal Combustion EnginesDocumento67 pagineFarm Machinery Internal Combustion Engineschoongwenkang100% (2)

- Project HCCI EngineDocumento109 pagineProject HCCI EnginePhuc Dang MinhNessuna valutazione finora

- Gasoline Engine Fuel Systems ExplainedDocumento57 pagineGasoline Engine Fuel Systems ExplainedsmithworkNessuna valutazione finora

- HCCI Engine PDFDocumento29 pagineHCCI Engine PDFSumeet PandeyNessuna valutazione finora

- BMW Vanos Bolt RecallDocumento6 pagineBMW Vanos Bolt Recallasdfga100% (1)

- Hybrid Electric Vehicles: Principles and Applications with Practical PerspectivesDa EverandHybrid Electric Vehicles: Principles and Applications with Practical PerspectivesNessuna valutazione finora

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectDa EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectNessuna valutazione finora

- Progress in Biomass Conversion: Volume 3Da EverandProgress in Biomass Conversion: Volume 3Kyosti V. SarkanenNessuna valutazione finora

- Diesel Catalytic Converters As Emission Control DevicesDocumento19 pagineDiesel Catalytic Converters As Emission Control Deviceskk ppNessuna valutazione finora

- StockAndSales 1422 31012017190146Documento3 pagineStockAndSales 1422 31012017190146Gowtham KarthikNessuna valutazione finora

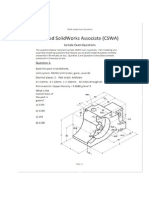

- CSWA Exam Practice QuestionsDocumento26 pagineCSWA Exam Practice QuestionsManuel Norberto Montoya Quezada100% (1)

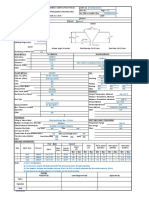

- Edgeam Setting WaveformDocumento2 pagineEdgeam Setting WaveformGowtham KarthikNessuna valutazione finora

- Edgeam Setting WaveformDocumento2 pagineEdgeam Setting WaveformGowtham KarthikNessuna valutazione finora

- Edgecam Getting Started 2015 R1Documento82 pagineEdgecam Getting Started 2015 R1Gowtham KarthikNessuna valutazione finora

- Computer Aided Process Computer Aided Process PlanningDocumento9 pagineComputer Aided Process Computer Aided Process PlanningDick Man0% (1)

- Edgecam Getting Started 2015 R1Documento82 pagineEdgecam Getting Started 2015 R1Gowtham KarthikNessuna valutazione finora

- SolidWorks CSWADocumento7 pagineSolidWorks CSWAkannankrivNessuna valutazione finora

- Edgecam Getting Started 2015 R1Documento82 pagineEdgecam Getting Started 2015 R1Gowtham KarthikNessuna valutazione finora

- Name: Write Description For The Given Images. Duration: 15 Minutes DateDocumento5 pagineName: Write Description For The Given Images. Duration: 15 Minutes DateGowtham KarthikNessuna valutazione finora

- Sipcot SriperumbudurDocumento3 pagineSipcot Sriperumbudurkarrpi67% (3)

- Whats NewDocumento55 pagineWhats NewGowtham KarthikNessuna valutazione finora

- Cutting Speed Feed and DOCDocumento22 pagineCutting Speed Feed and DOCtnchsgNessuna valutazione finora

- Gear Technical FundamentalsDocumento176 pagineGear Technical Fundamentalsjoe9000Nessuna valutazione finora

- University Wp-Content Uploads 2013 03 Advanced-IC-Engine-NotesDocumento19 pagineUniversity Wp-Content Uploads 2013 03 Advanced-IC-Engine-NotesNaren NathanNessuna valutazione finora

- CNC PresentationDocumento37 pagineCNC PresentationMarvin BelenNessuna valutazione finora

- Chapter 1 QuizDocumento7 pagineChapter 1 QuizRichie Sơn NguyễnNessuna valutazione finora

- Counter Flow Heat ExchangerDocumento8 pagineCounter Flow Heat ExchangerGowtham KarthikNessuna valutazione finora

- Structural Adhesives-Trends and Driving ForcesDocumento24 pagineStructural Adhesives-Trends and Driving ForcesGowtham KarthikNessuna valutazione finora

- ASO Trans2013Documento2 pagineASO Trans2013Gowtham KarthikNessuna valutazione finora

- Sheet FormingDocumento4 pagineSheet Formingvenkat_222123Nessuna valutazione finora

- Sheet FormingDocumento4 pagineSheet Formingvenkat_222123Nessuna valutazione finora

- TDI41 Tank Inspection Repair & Alteration API 653 Sec 9Documento13 pagineTDI41 Tank Inspection Repair & Alteration API 653 Sec 9Faizal Sattu100% (2)

- WWW Visionalloys Com Stainless Steel Fasteners HTMLDocumento4 pagineWWW Visionalloys Com Stainless Steel Fasteners HTMLNikhil JainNessuna valutazione finora

- Carbofill Dec08Documento4 pagineCarbofill Dec08Cristian Andres Araya CisternasNessuna valutazione finora

- Automatic Wall Painting MachineDocumento9 pagineAutomatic Wall Painting MachineaalekhNessuna valutazione finora

- Painting Procedure For Structural Steel Rev 00Documento13 paginePainting Procedure For Structural Steel Rev 00Ranjan KumarNessuna valutazione finora

- Foundry Engineering MSE-316 Course OverviewDocumento25 pagineFoundry Engineering MSE-316 Course OverviewMuhammad AsimNessuna valutazione finora

- Why nanocrystals get softer with decreasing grain sizeDocumento8 pagineWhy nanocrystals get softer with decreasing grain sizeSaadFarooqNessuna valutazione finora

- Revised PT Program April-May 2021 30% Discount Metal TestingDocumento2 pagineRevised PT Program April-May 2021 30% Discount Metal TestingSaravanan PNessuna valutazione finora

- 2019 Y5 Work Book 1 (Practical 3) SolutionsDocumento9 pagine2019 Y5 Work Book 1 (Practical 3) SolutionsChenluyingNessuna valutazione finora

- Aws D8.1M 2013Documento40 pagineAws D8.1M 2013vishesh dharaiya100% (3)

- Sika Lightcrete I-500: Admixture For Lightweight ConcreteDocumento3 pagineSika Lightcrete I-500: Admixture For Lightweight ConcreteAmmar A. AliNessuna valutazione finora

- Rockwool Vs GlasswoolDocumento8 pagineRockwool Vs Glasswooly2karein100% (1)

- Introduction To Mass TransferDocumento44 pagineIntroduction To Mass TransferGhazanferAliNessuna valutazione finora

- Cat. IV Toughened Glass InsulatorDocumento8 pagineCat. IV Toughened Glass InsulatorFernando GasparNessuna valutazione finora

- Mix Proportioning of M80 Grade Self-Compacting ConDocumento3 pagineMix Proportioning of M80 Grade Self-Compacting ConfaseehNessuna valutazione finora

- Nanotechnology: A Platform For Education ChangeDocumento7 pagineNanotechnology: A Platform For Education Changeapi-251873743Nessuna valutazione finora

- Notes:: 6"-12" PIPE Flowline Removable AnchorDocumento1 paginaNotes:: 6"-12" PIPE Flowline Removable Anchornarutothunderjet216Nessuna valutazione finora

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocumento2 paginePetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNessuna valutazione finora

- Asme b31.3 InterpretationsDocumento18 pagineAsme b31.3 InterpretationsMallela Sampath KumarNessuna valutazione finora

- DEGASSING AGENT AF 100 - Ind1 - AngDocumento1 paginaDEGASSING AGENT AF 100 - Ind1 - AngFrench Corvette50% (2)

- Exp. 4 LipidsDocumento6 pagineExp. 4 LipidsAna LuisaNessuna valutazione finora

- Chemistry: Pearson EdexcelDocumento16 pagineChemistry: Pearson EdexcelHosni ShowikeNessuna valutazione finora

- Tut 9 - PH 102 - 30052023Documento1 paginaTut 9 - PH 102 - 30052023PS SuryaNessuna valutazione finora

- Materials for shoes, optical lenses and water bottlesDocumento3 pagineMaterials for shoes, optical lenses and water bottlesJpricarioNessuna valutazione finora

- Analyisis of en of AM350Documento15 pagineAnalyisis of en of AM350Jesús JáquezNessuna valutazione finora

- Internet Standards for Irrigation EquipmentDocumento19 pagineInternet Standards for Irrigation EquipmentHarindu VyasNessuna valutazione finora

- Basics of Reinforced Concrete Design: OutlineDocumento10 pagineBasics of Reinforced Concrete Design: OutlineariNessuna valutazione finora

- Manual For ConcretingDocumento43 pagineManual For Concretinglwin_oo2435Nessuna valutazione finora

- Hardness Conversion Chart, Carbide DepotDocumento4 pagineHardness Conversion Chart, Carbide DepotMiguel A. FloresNessuna valutazione finora

- Steel I-Beam Calculation Design CheckDocumento9 pagineSteel I-Beam Calculation Design CheckSuresh DevarajanNessuna valutazione finora