Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Eflex Cable Conduit Work Procedure

Caricato da

Raden ArmanadiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Eflex Cable Conduit Work Procedure

Caricato da

Raden ArmanadiCopyright:

Formati disponibili

Corrugated Hard Polyethylene Pipe

For Labor and Cost Savings

In Underground Cable Installation

2

May be buried at

a shallow depth

Cables may be drawn in at a

long length

Adaptable to ground

subsidence

25t

30cm

The corrugated structure enhances the

compression strength. When buried at

a depth of 30 cm, the pipes may with-

stand loads from 25-ton trucks in mo-

tion.

The corrugated structure reduces the

surface area that comes into contact

with cables, which reduces friction.

The plastic and elastic properties allow

the pipe conduits to follow the motions

of earthquake and ground subsidence.

A track record of more than 40 years

in Japan: EFLEX, underground electrical

cable protective pipe

Comparing cables buried directly with cables laid inside pipe conduits (EFLEX)

Direct burial In pipe conduits (EFLEX)

Example installations

Effects on

cables

During installation Easily damaged Hard to damage

During operation

Since cables are in direct contact with the soil, they

are susceptible to water and loads that could cause

failures. Cables also tend to become damaged during

excavation work by other companies.

Since cables are protected inside pipe conduits, they

are unlikely to fail.

Cables are not easily damaged by the excavation work

of other companies.

During cable addition and renewal Excavation is needed, requiring time and expense. Cables can be added or replaced without excavation.

Cables

Pipe conduit Cables

Cables

Pipe conduit Cables

Friction coeffcient

EFLEX 0.3

Lined steel pipe 0.5

Hume pipe 0.7

Hard vinyl pipe 0.4

Easy to transport

and work

Easy to detour around

obstacles

Fewer joints

r5D D

r

May be bent manually, and the allow-

able bending radius is fve times or

more of the outer diameter of the pipe

conduit

Features of EFLEX

EFLEX 1.0 kg

Lined steel pipe 13.1 kg

Hume pipe 26.5 kg

Hard vinyl pipe 3.4 kg

(per 100 m)

30: 300 m 200: 40 m

Lightweight Easy to bend Long products

Robust Low friction Plasticity and elasticity

3

The standard dimensions of EFLEX are

as shown in the table below. A pilot wire

is inserted inside EFLEX during produc-

tion. It is connected with the cable pilot

wire to pull the cable into the pipe. EFLEX

is, as a rule, shipped from the factory,

wound in a coil. A pilot wire has an allow-

able tensile strength of 50 kg.

Pitch

I

n

n

e

r

d

i

a

m

e

t

e

r

O

u

t

e

r

d

i

a

m

e

t

e

r

Pilot wire

0

0

0.5

1

1.5

0.5 1 1.5 2 2.5 3

Burial depth (m)

EFLEX deformation

ratio when a 25-ton

truck drove over it

200

150

125

100

80

65

50

40

30

D

e

f

o

r

m

a

t

i

o

n

r

a

t

i

o

(

%

)

Product features

Flattened compression property

When the compression test stipulated by JIS

C 3653 (Annex 1 to Installation methods of

power cables buried ground) was conducted,

the deformation ratio was less than 3.5% in all

cases.

Resistance against loads

When a 25-ton truck drove over a location where EFLEX has been bur-

ied at a depth of 30 cm from the ground surface, the deformation ratio

was less than 3.5%, demonstrating suffcient resistance against loads.

250 mm

Resistance against loads

Flattened compression property

Nominal

diameter (mm)

Load

Deformation

ratio

N {kgf}

30 373 38.0 3.5%

40 501 51.1 3.5%

50 612 62.5 3.5%

65 804 82.0 3.5%

80 969 98.9 3.5%

100 1225 125.0 3.5%

125 1518 154.9 3.5%

150 1805 184.2 3.5%

200 2412 246.1 3.5%

EFLEX boasts the product lineup

from 30 to 200

When purchasing EFLEX, it is recommended that its nominal diameter be more than 1.5 times as large as the outer diameter of the cable to be accommodated.

The allowable bending radius should be fve times or more of the EFLEX outer diameter.

If cables are not drawn in for a long time, the pilot wires could corrode. Replace them with plastic order wires to suit the conditions of use. When drawing in

cables, replace pilot wires with order wires for the purpose.

Keep away from fre

Product No.

Outer diameter

(approx. in mm)

Inner diameter

(approx. in mm)

Pitch

(approx. in mm)

Reference weight

(approx. in kg/m)

Standard length of

product bundle (m)

Standard dimensions of product bundle

Outer diameter x width (approx. in m)

FP-30 40 30 10 0.2 300 1.2 0.5

FP-40 54 42 13 0.3 200 1.5 0.65

FP-50 65 50 17 0.4 200 1.6 0.7

FP-65 85 66 21 0.6 100 1.6 0.65

FP-80 102 80 25 0.7 100 1.7 0.7

FP-100 130 100 32 1.0 100 2.0 0.8

FP-125 160 125 39 1.5 50 1.6 1.2

FP-150 189 150 47 2.0 50 1.8 1.3

FP-200 253 200 55 3.5 40 2.251.1

FP-

Standard dimensions table

Underground Cable Conduit EFLEX

4

Bellmouth

P.6

Joints with Other Types of

Pipe Conduits

P.7

Waterproof Cap

P.6

AQUAFIT

P.5

EFLEX Clamp

P.6

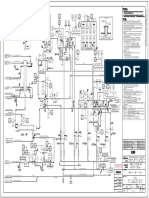

EFLEX Work Procedures

EFLEX System

Various components are combined to protect cables inside EFLEX

1 2 3

4 5 6

Long and easy-to-bend EFLEX saves labor and shortens work times when laying conduits.

Roll the grip to extend the cables.

Make sure that the cables do not wind while they are being laid.

Compact the ground under EFLEX, especially near the manhole.

Pierce with rods for testing, to discern whether cable-laying conditions are acceptable.

Feel free to order our Work Procedure document for details.

5

Main body

Water expansion

nonwoven fabric

EFLEX

D

L

Product No.

Outer dia. D

(approx. in mm)

Length L

(approx. in mm)

FSA-30 44 52

FSA-40 60 72

FSA-50 70 90

FSA-65 90 115

FSA-80 111 135

FSA-100 140 175

FSA-125 172 182

FSA-150 201 190

FSA-200 260 270

Cross section before water absorption Cross section after water absorption

Work procedures

O Twist the joint at one end of EFLEX.

O Line one end of EFLEX up with another.

O Twist the joint twisted in O back so that

the connecting part is centered.

Excellent waterproofng

property of non-woven

water-expansion cloth

When non-woven, water-expansion

cloth comes into contact with water, it

expands immediately and stops wa-

ter from seeping.

O O O

Before

water absorption

After

water absorption

FSA-

AQUAFIT (Straight Joining Procedure for Joining EFLEX System Together)

Do not remove from the bag until immediately before working, as a non-woven water-expansion cloth has been used.

Avoid storing in places exposed to high temperature and humidity or direct sunlight.

Avoid using in places where a large volume of water will penetrate the duct part.

* AQUAFIT of radius between 125 and 200 can be worked more smoothly using a belted wrench and

other tools. Cut the edge of EFLEX perpendicularly.

6

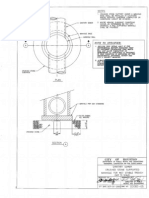

FM-

Bellmouth

Manhole (hand hole)

EFLEX

Outside

L

Inside

D

T

d

After EFLEX has been fxed to the man-

hole, the bellmouth should be attached

to the end part of EFLEX to enhance the

appearance and prevent cables from be-

ing scratched of damaged while being

pulled in. The bellmouth can be screwed

easily into the EFLEX.

D1

L

2

L

1

Clamp sleeve

Bushing

EFLEX

Terminal box

D2

D3

For 30-100 mm

L

L

Collar

Rubber packing

Bellmouth

EFLEX

Terminal box

For 125-200 mm

D

Product

No.

Bushing

(approx. in mm)

Connecting tube

(approx. in mm)

Hole dia.

(approx.

in mm)

D1 L1 D2 D3 L2

CL-30 51 13 50 41.9 76 42.7

CL-40 77 18 73 59.6 96 60.4

CL-50 88 18 90 75.2 105 76.0

CL-65 101 18 104 87.9 136 88.7

CL-80 117 22 116 100.3 151 102.7

CL-100 132 24 135 113.0 178 115.4

Product

No.

Collar

(approx. in mm)

Hole dia.

(approx.

in mm)

L D

CL-125 41 191 170

CL-150 47 228 200

CL-200 63 290 265

CL-

If EFLEX units are ftted to a terminal box,

use the EFLEX clamps as shown in the

Figure.

A hole such as that indicated in the Table

below should be opened on the EFLEX

ftting plane of the terminal box to match

the diameter of EFLEX used.

EFLEX Clamp (connector)

Waterproof cap

Sealing tape

PVC tape

Pilot wire

100 mm for 100 and less

150 mm for 125 and above

C

C

C

Kinds: 9 types

FFC-30, 40, 50, 65, 80, 100, 125,

150, 200

Composition

Waterproof cap, sealing tape, and

PVC tape

FFC-

Screw the water cap onto the outside of EFLEX (the amount of EFLEX protruding from

a wall should match the amount of taping). Wrap sealing tape around the boundary line

of EFLEX and secure its end with PVC tape.

Waterproof Cap for EFLEX End

Bellmouth

Product

No.

Outer dia.

DT (approx.

in mm)

Inner dia.

d (approx.

in mm)

Length

L (approx.

in mm)

FM-30 50 26 40

FM-40 65 36 50

FM-50 78 45 60

FM-65 97 60 75

FM-80 115 74 85

FM-100 144 93 105

FM-125 176 116 130

FM-150 205 141 150

FM-200 272 189 185

7

C C C C C C

CSleeve

CSR packing

CCut ring

CCollar

CSealing tape

EFLEX vul-co

CPVC tape

EFLEX

Pipe of another kind (such as steel pipe)

Components C to C are used only with H-type joints. (For the AQ-type, water is sealed with

the non-woven water-expansion cloth inside the sleeve.)

The forms differ slightly depending on the product Nos.

Joining tube

Epoxy putty

EFLEX Vul-co

EFLEX

Pipe of another kind (such as steel pipe)

PVC tape

CC CC

C

C

AQ-type and H-type joints for another kind pipes

FT--

A type joining part

C

C

C

Joints with Other Types of Pipe Conduits (connecting EFLEX with pipes of another kind)

Epoxy putty (wall surface

waterproofing material)

EFLEX

Bellmouth

Manhole (hand hole)

Mortar

a

b c

Nominal

diameter

a (mm) b (mm) c (mm)

30 100 20 10 20

125 or more 20 10 30

Use when EFLEX is attached to a manhole for laying

cables at a place with high groundwater level.

Base agent:

0.25 kg x 2;

hardening agent:

0.25 kg x 2

EPOAL (In bags) 1 kg

EFLEX Hole diameter

on wall surface

(approx. in mm)

Epoxy putty

amount used (kg)

Product No.

Outer diameter

(approx. in mm)

FP-30 40 80 0.5

FP-40 54 100 0.5

FP-50 65 110 0.5

FP-65 85 130 1.0

FP-80 102 160 1.0

FP-100 130 180 1.5

FP-125 160 210 2.0

FP-150 189 260 4.0

FP-200 253 310 5.5

Epoxy putty amount used (Per location)

EPOKAN (In cans) Total weight: 3 kg

Epoxy Putty (wall surface waterproofng material)

Base agent:

1.5 kg;

hardening agent:

1.5 kg

Special packing is necessary for export. (UN classifcation 'Class 9' material is included in products.)

If you require a joint for connecting different types of pipes, please contact us with the sizes of the pipes.

Please be sure to use it immediately after opening the can or bag.

Place in hot water in winter when it is hard.

Special packing is necessary for export.

(UN classification 'Class 9' material is included in products.)

HEAD OFFICE

Marunouchi Nakadori Bldg., 2-3, Marunouchi 2-chome,

Chiyoda-ku, Tokyo 100-8322, Japan

Phone: +81-3-3286-3195 Fax: +81-3-3286-3454

e-mail: kanro@ho.furukawa.co.jp

AMERICAN FURUKAWA, INC. (AFI)

47677 Galleon Drive, Plymouth, MI 48170 U.S.A.

Phone: +1-734-446-2200 Fax: +1-734-446-2260

FURUKAWA ELECTRIC EUROPE LTD. (FEEL)

3rd Floor, Newcombe House, 43-45, Notting Hill Gate,

London W11 3FE, U.K.

Phone: +44-20-7313-5300 Fax: +44-20-7313-5310

FURUKAWA ELECTRIC SINGAPORE PTE. LTD. (FES)

10 Anson Road, #25-08, International Plaza, Singapore 079903

Phone: +65-6224-4686 Fax: +65-6224-2362

FURUKAWA SHANGHAI LTD. (FSL)

Room 1006, Hongyi Plaza, 288 Jiujiang Road, Shanghai 200001,

P.R.China

Phone: +86-21-3366-5301 Fax: +86-21-3366-5315

FURUKAWA ELECTRIC HONG KONG LTD. (FEHK)

Suite 1810, 18/F, Tower 2, 33 Canton Road, Tsim Sha Tsui, Kowloon,

Hong Kong

Phone: +852-2512-8938 Fax: +852-2512-9717

FURUKAWA (THAILAND) CO., LTD. (FTC)

29 Vanissa Building 6th Floor, Room 6D, Soi Chidlom,

Ploenchit Road, Lumpini,Pathumwan, Bangkok 10330, Thailand

Phone: +66-2-655-1205 Fax: +66-2-655-1208

FURUKAWA INDUSTRIAL S.A. PRODUTOS ELETRICOS (FISA)

Rua Hasdrubal Bellegard, 820 Cidade Industrial Curitiba

Cep 81460-120, Curitiba, P.R. Brazil

Phone: +55-41-3341-4000 Fax: +55-41-3341-4141

Sales Division: So Paulo

Phone: +55-11-5501-5800 e-mail: cmo@furukawa.com.br

PT. FURUKAWA ELECTRIC INDONESIA

Sucaco Building, 6th Floor Jl. Kebon Sirih No.71, Jakarta-10340

Phone: +62-21-3190-6212 Fax: +62-21-3190-6407

http://www.furukawa.co.jp/english/

PE-021 2E2 TR 100

A New Multi-hole Pipe of Unit-type Pursu-

ing Work Laborsaving and Cost Reduction.

Other Relevant Products

The information box project, the so-called CCBox Project,

is being promoted by the Ministry of Land, Infrastructure and

Transport, aimed at promotion of underground laying of

electric cables as well as early realization of advanced in-

formation society. To respond to such demands of the times,

Furukawa Electric has developed a multi-hole pipe of syn-

thetic resin as a cable duct material using recycled plastics.

We hope the customer will make use of our materials system

for underground cable laying that we have developed in pur-

suit of work laborsaving, shortening of work periods and cost

reduction.

FURUKAWA FK SYSTEM

MULTI-HOLE PIPE OF

SYNTHETI C RESI N KOTA-KUN

Waste plastics from electric wire and cable sheathes that were

conventionally disposed of as industrial waste are recycled to

be born again as this cable protection trough. Thanks to its

superior impact resistance, high resistance against salt and

chemicals along with fame retardance, Green-Trough can be

used for a long time with excellent stability. It also offers out-

standing workability and a possible reduction in construction

period due to its light weight, and reduces the exchange work

of troughs thus helping to reduce industrial waste as well as

to preserve resources.

Thanks to Its Weight Only 25% of Concrete Trough

in Addition to Its Superior Workability,

Green-Trough Promises Shortening of Working

Period and Reduction of Working Costs.

GREEN-TROUGH

Export Control Regulations

The products and/or technical information presented in this publication may be subject to

the application of the Foreign Exchange and Foreign Trade Act and other related laws and

regulations in Japan.

In addition, the Export Administration Regulations (EAR) of the United States may be

applicable.

In cases where exporting or reexporting the products and/or technical information presented

in this publication, customers are requested to follow the necessary procedures at their own

responsibility and cost.

Please contact the Ministry of Economy, Trade and Industry of Japan or the Department of

Commerce of the United States for details about procedures.

The products and their appearances, as described in this brochure, are subject to change for

improvement without prior notice.

Potrebbero piacerti anche

- Burndy Substation Catalog Cual 2013 LoresDocumento459 pagineBurndy Substation Catalog Cual 2013 LoresVelu Samy100% (1)

- HDPE Pipe Butt Welding ProceduresDocumento7 pagineHDPE Pipe Butt Welding ProceduresRaden Armanadi100% (4)

- Tricocat PDFDocumento44 pagineTricocat PDFJuan PabloNessuna valutazione finora

- Maintain pipeline temperature with skin effect trace heatingDocumento7 pagineMaintain pipeline temperature with skin effect trace heatingSivagurunathan SpNessuna valutazione finora

- M50 enDocumento338 pagineM50 entomwilkinsNessuna valutazione finora

- Fibox Enclosure 4.1 US WebDocumento181 pagineFibox Enclosure 4.1 US WebParwito Wit100% (1)

- Accesorios UnistrutDocumento76 pagineAccesorios UnistrutLuisxMiguelNessuna valutazione finora

- Control Panel Space OptimizationDocumento12 pagineControl Panel Space Optimizationyopy_yogieNessuna valutazione finora

- Catalogo Rev FDocumento44 pagineCatalogo Rev FtelephonicaNessuna valutazione finora

- News Eplan en UsDocumento152 pagineNews Eplan en UsKilyNessuna valutazione finora

- Surge Protec IIDocumento14 pagineSurge Protec IIRaj ChavanNessuna valutazione finora

- Chapter 1 The AutomobileDocumento20 pagineChapter 1 The AutomobilePengleng100% (1)

- Q1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332Documento2 pagineQ1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332JHONATAN RODRIGUEZ VENTONessuna valutazione finora

- For Harsh and Hazardous Locations: Exe EnclosuresDocumento79 pagineFor Harsh and Hazardous Locations: Exe EnclosuresSimon LyonNessuna valutazione finora

- Cable LaddersDocumento236 pagineCable LaddersAjithNessuna valutazione finora

- Fan Coil Unit - SaiverDocumento8 pagineFan Coil Unit - SaiverRyan Au YongNessuna valutazione finora

- Catalog TURCKDocumento307 pagineCatalog TURCKBadrian BadbadNessuna valutazione finora

- Rittal Industrial Enclosure SolutionsDocumento76 pagineRittal Industrial Enclosure SolutionsIbrahimElKelanyNessuna valutazione finora

- 132kV XLPE Cable Accessory Factory Test ProcedureDocumento7 pagine132kV XLPE Cable Accessory Factory Test Procedurerenjithas2005Nessuna valutazione finora

- Bushing PDFDocumento92 pagineBushing PDFYigit SarıkayaNessuna valutazione finora

- Parker Substrate 4250-InTRAFLOW Dec 2003Documento12 pagineParker Substrate 4250-InTRAFLOW Dec 2003Laurence MalanumNessuna valutazione finora

- Saleh Zaid Alquraishi Co Intro - 220425 - 040104Documento11 pagineSaleh Zaid Alquraishi Co Intro - 220425 - 040104Mohamed ZafonNessuna valutazione finora

- MK Electric Cable Tray Brochure (Middle East) PDFDocumento150 pagineMK Electric Cable Tray Brochure (Middle East) PDFAnonymous tW1zTL2ltNessuna valutazione finora

- Over All Drawings of PMCC-5 Panel-R0Documento24 pagineOver All Drawings of PMCC-5 Panel-R0GreenOlive ControlsNessuna valutazione finora

- Victor Lighting CatalogueDocumento128 pagineVictor Lighting Cataloguebee398100% (1)

- Valvula Reductora de Presion Bermad Area 675 720-ULDocumento4 pagineValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNessuna valutazione finora

- LT/HT Power & Control Cables Price List (July 2013Documento6 pagineLT/HT Power & Control Cables Price List (July 2013Cpgeorge JohnNessuna valutazione finora

- Force Ksb-Omega-Pump Sarcina Pe Flanse PDFDocumento19 pagineForce Ksb-Omega-Pump Sarcina Pe Flanse PDFRusu DimaNessuna valutazione finora

- Reliable Fire Protection SolutionsDocumento16 pagineReliable Fire Protection SolutionsZaheer AhamedNessuna valutazione finora

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri8Documento1 paginaPGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri8wibowo wibowoNessuna valutazione finora

- Building Automation & Control Catalog 2007Documento176 pagineBuilding Automation & Control Catalog 2007Molnár Sándor0% (2)

- Dehn Catalogue Safety EquipmentDocumento196 pagineDehn Catalogue Safety EquipmentIrfan AshrafNessuna valutazione finora

- Ezy StrutDocumento96 pagineEzy Strutqwerty99ytrNessuna valutazione finora

- This Typical Is Also Valid For:: 03 06/2020 BSP AS BUILT JZB JZB Ismail IsmailDocumento38 pagineThis Typical Is Also Valid For:: 03 06/2020 BSP AS BUILT JZB JZB Ismail IsmailMohammed AltafNessuna valutazione finora

- Price List Siemens Low Voltage Power Distribution Products 01-10-2012Documento44 paginePrice List Siemens Low Voltage Power Distribution Products 01-10-2012svatantrayabhinava0% (1)

- ElettroDocumento16 pagineElettroNikhil RajanNessuna valutazione finora

- PECON Condense Catalogue 2013Documento36 paginePECON Condense Catalogue 2013Manoj AggarwalNessuna valutazione finora

- Cable Erection PhilosophyDocumento26 pagineCable Erection PhilosophyRAJIV RANJANNessuna valutazione finora

- Ansg286 07 526D R3 PDFDocumento50 pagineAnsg286 07 526D R3 PDFLester JoseNessuna valutazione finora

- High Speed DoorsDocumento64 pagineHigh Speed DoorsTgNessuna valutazione finora

- RasGas Barzan Onshore Project Revision Description FormDocumento40 pagineRasGas Barzan Onshore Project Revision Description FormJayce PinedaNessuna valutazione finora

- JB Schedule for 3.0 MT Expansion Project Piping and Instrumentation DiagramDocumento42 pagineJB Schedule for 3.0 MT Expansion Project Piping and Instrumentation DiagramJagadeesan ShanmugamNessuna valutazione finora

- 2005 Cable Glands Catalogue from Thomas & BettsDocumento13 pagine2005 Cable Glands Catalogue from Thomas & BettsGanesh TigadeNessuna valutazione finora

- 20100PE-DW02-0006 Rev1 11-SD-2122Documento1 pagina20100PE-DW02-0006 Rev1 11-SD-2122Jovit BeaNessuna valutazione finora

- Enduro FRP Cable Management Systems Catalog 05-11Documento44 pagineEnduro FRP Cable Management Systems Catalog 05-11xaaabbb_550464353Nessuna valutazione finora

- Electrical Materials List For Construction ProjectsDocumento17 pagineElectrical Materials List For Construction Projectsmuhammad robithNessuna valutazione finora

- On-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemDocumento4 pagineOn-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemgohviccNessuna valutazione finora

- Assembly Instructions for 501/414 Exd IIC/Exe II ExtD Cable GlandDocumento2 pagineAssembly Instructions for 501/414 Exd IIC/Exe II ExtD Cable GlandFoe AungNessuna valutazione finora

- Ash KKSDocumento56 pagineAsh KKSAnonymous ahdhFMaNessuna valutazione finora

- Cable Tray Lay Out 1Documento1 paginaCable Tray Lay Out 1ferdinandz_010Nessuna valutazione finora

- LPG-1102-E-EL-ELS-001 - Electrical Load Schedule - Rev. ADocumento11 pagineLPG-1102-E-EL-ELS-001 - Electrical Load Schedule - Rev. ARadhaNessuna valutazione finora

- Va2-Dl01-P0zen-090001-Packing ProcedureDocumento66 pagineVa2-Dl01-P0zen-090001-Packing ProcedureHiep100% (1)

- TII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsDocumento11 pagineTII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsBorn ToSinNessuna valutazione finora

- NEC Cable Tray Sizing ProgramDocumento9 pagineNEC Cable Tray Sizing ProgramSimsim GendyNessuna valutazione finora

- Cable Ladder LeafletDocumento8 pagineCable Ladder LeafletMohsan AbbasNessuna valutazione finora

- Catalogue GlandDocumento72 pagineCatalogue Glanda.r.sarateNessuna valutazione finora

- Sports High MastDocumento2 pagineSports High MastmaxtamNessuna valutazione finora

- Detector CO2 ParcajeDocumento93 pagineDetector CO2 ParcajeStratulat Lucian-IonutNessuna valutazione finora

- Deluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVDocumento5 pagineDeluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVmuthuvelaaNessuna valutazione finora

- PexFlex - LogstorDocumento10 paginePexFlex - LogstorZeljko RisticNessuna valutazione finora

- Cable FittingsDocumento108 pagineCable FittingspvkrishnajiNessuna valutazione finora

- Trench Bushings Cot 24kv To 550kvDocumento24 pagineTrench Bushings Cot 24kv To 550kvdsanmi0% (1)

- NKT 12-42kv GB BsDocumento54 pagineNKT 12-42kv GB BsvhgiaoNessuna valutazione finora

- Why 3D Networks in Hospitality Updated 10 Nov 2014 (Ohne FCS, Caward, Certification)Documento55 pagineWhy 3D Networks in Hospitality Updated 10 Nov 2014 (Ohne FCS, Caward, Certification)Raden ArmanadiNessuna valutazione finora

- Permen Perindustrian RI No 42 2010Documento7 paginePermen Perindustrian RI No 42 2010Raden ArmanadiNessuna valutazione finora

- WWT Eagle Industry Indonesia - BAB II DrawingDocumento12 pagineWWT Eagle Industry Indonesia - BAB II DrawingRaden ArmanadiNessuna valutazione finora

- Jl. Warung Ampel To JLDocumento2 pagineJl. Warung Ampel To JLRaden ArmanadiNessuna valutazione finora

- Water Treatment Plant, Engineering Flow DiagramDocumento1 paginaWater Treatment Plant, Engineering Flow DiagramRaden ArmanadiNessuna valutazione finora

- Water PenetrationDocumento6 pagineWater PenetrationRaden ArmanadiNessuna valutazione finora

- WWT Eagle Industry Indonesia - BAB IV Equipt ListDocumento104 pagineWWT Eagle Industry Indonesia - BAB IV Equipt ListRaden ArmanadiNessuna valutazione finora

- Weather Report 2014 Oct, Cikarang Pusat AreaDocumento722 pagineWeather Report 2014 Oct, Cikarang Pusat AreaRaden ArmanadiNessuna valutazione finora

- WWT Eagle Industry Indonesia - BAB III Electrical DrawingDocumento20 pagineWWT Eagle Industry Indonesia - BAB III Electrical DrawingRaden ArmanadiNessuna valutazione finora

- Solar Home System PDFDocumento10 pagineSolar Home System PDFRaden ArmanadiNessuna valutazione finora

- WWT Eagle Industry Indonesia - BAB I Technical SpecificationDocumento17 pagineWWT Eagle Industry Indonesia - BAB I Technical SpecificationRaden ArmanadiNessuna valutazione finora

- Cable Sheath Voltage Limiters PresentationDocumento8 pagineCable Sheath Voltage Limiters PresentationRaden ArmanadiNessuna valutazione finora

- 02082-05 Crushed Stone Supported Manhole For Wet Stable TrenchDocumento1 pagina02082-05 Crushed Stone Supported Manhole For Wet Stable TrenchRaden ArmanadiNessuna valutazione finora

- Estate Regulation Industrial Area (Giic) - Deltamas - CikarangDocumento48 pagineEstate Regulation Industrial Area (Giic) - Deltamas - CikarangRaden Armanadi100% (1)

- EFLEXSPECDocumento4 pagineEFLEXSPECRaden ArmanadiNessuna valutazione finora

- Earthing of MV and LV DistributionDocumento9 pagineEarthing of MV and LV DistributionmentongNessuna valutazione finora

- Jesus' Greatest CommandmentDocumento6 pagineJesus' Greatest CommandmentRaden ArmanadiNessuna valutazione finora

- Weather - Catalog VANTAGE PRO2Documento3 pagineWeather - Catalog VANTAGE PRO2Raden ArmanadiNessuna valutazione finora

- Jesus' Greatest CommandmentDocumento6 pagineJesus' Greatest CommandmentRaden ArmanadiNessuna valutazione finora

- Manholes PresentationDocumento143 pagineManholes PresentationMar MaslanNessuna valutazione finora

- Armanadi ResumeDocumento8 pagineArmanadi ResumeRaden ArmanadiNessuna valutazione finora

- WWT Signal Hart 11 DecDocumento1 paginaWWT Signal Hart 11 DecRaden ArmanadiNessuna valutazione finora

- Aluminum Vs CopperDocumento7 pagineAluminum Vs Copperc.a.g.p.Nessuna valutazione finora

- Inspection and Test Procedure For LV cable-EEPDocumento4 pagineInspection and Test Procedure For LV cable-EEPRaden ArmanadiNessuna valutazione finora

- Grease Trap RefferenceDocumento5 pagineGrease Trap RefferenceRaden ArmanadiNessuna valutazione finora

- What Is His (God) Name.?Documento42 pagineWhat Is His (God) Name.?RiyasudheenNessuna valutazione finora

- Epsolar: Instruction ManualDocumento32 pagineEpsolar: Instruction ManualRaden ArmanadiNessuna valutazione finora

- Unbalanced Load CalculationDocumento2 pagineUnbalanced Load CalculationRaden ArmanadiNessuna valutazione finora

- MTO Pipa Steel Welded SpiralDocumento4 pagineMTO Pipa Steel Welded SpiralrudiawanNessuna valutazione finora

- TSP0013 Steam Tracing DesignDocumento23 pagineTSP0013 Steam Tracing DesignFabio TemporiniNessuna valutazione finora

- Oisd 142Documento170 pagineOisd 142poojaupes100% (2)

- API 618 Compressors1Documento2 pagineAPI 618 Compressors1Rhama WijayaNessuna valutazione finora

- Technical Specifications For The Installation of Telecoms Mast and TowersDocumento134 pagineTechnical Specifications For The Installation of Telecoms Mast and TowersNkechi KokoNessuna valutazione finora

- Safety Piping Color CodesDocumento2 pagineSafety Piping Color CodesSandip DasNessuna valutazione finora

- FPB 22.14 Rev.01 - Access To Heavy Duty Gas Turbine Enclosures With The Unit in OperationDocumento27 pagineFPB 22.14 Rev.01 - Access To Heavy Duty Gas Turbine Enclosures With The Unit in Operationwaqar ahmadNessuna valutazione finora

- Hydro TestingDocumento12 pagineHydro TestinggshdavidNessuna valutazione finora

- Control Valve Technical DrawingDocumento4 pagineControl Valve Technical DrawingNitin ZoreNessuna valutazione finora

- 2 Compliance StatementDocumento15 pagine2 Compliance StatementMelvin Angelo LopenarioNessuna valutazione finora

- Supplementary Specification To API Standard 672 Packaged, Integrally Geared Centrifugal Air CompressorsDocumento36 pagineSupplementary Specification To API Standard 672 Packaged, Integrally Geared Centrifugal Air CompressorsAjay LambaNessuna valutazione finora

- Pipe Mill and Coating Yard - Qualification: DNV-OSS-313Documento24 paginePipe Mill and Coating Yard - Qualification: DNV-OSS-313Eyoma EtimNessuna valutazione finora

- API-570 SAMPLE Closed Book ExamDocumento12 pagineAPI-570 SAMPLE Closed Book ExamuttamNessuna valutazione finora

- Shell - Tube InstallationDocumento1 paginaShell - Tube InstallationSandra GilbertNessuna valutazione finora

- Hydraulic and Pneumatic EquipmentDocumento194 pagineHydraulic and Pneumatic Equipmentomesh2008Nessuna valutazione finora

- Method Statement Water Supply Work For BuildingDocumento3 pagineMethod Statement Water Supply Work For BuildingRosnani Ambo sakkaNessuna valutazione finora

- Pompe Eau BL5Documento17 paginePompe Eau BL5psteNessuna valutazione finora

- 39 Mouse-PadDocumento1 pagina39 Mouse-Padzhang_taoNessuna valutazione finora

- Centropelet Zv16: Technical InstructionsDocumento28 pagineCentropelet Zv16: Technical InstructionsRenārs BērtiņšNessuna valutazione finora

- Analysis of Rate For Delhi - 2012 (Vol - I) .Documento712 pagineAnalysis of Rate For Delhi - 2012 (Vol - I) .Ramachandra SahuNessuna valutazione finora

- EBCS-9-2013 - Plumbing Services Final Draft PDFDocumento259 pagineEBCS-9-2013 - Plumbing Services Final Draft PDFDawit Solomon97% (29)

- Bayag-O, Israel T. Gaspar, Paul M. Pion, Reden S. Arch. Robert V. Romero, Maehp, UapDocumento99 pagineBayag-O, Israel T. Gaspar, Paul M. Pion, Reden S. Arch. Robert V. Romero, Maehp, UapReden Salve PionNessuna valutazione finora

- Manual de Instalação, Operação e Controle - Bomba de CalorDocumento12 pagineManual de Instalação, Operação e Controle - Bomba de CalorBruno PorcelNessuna valutazione finora

- TITAS GAS PURCHASE ORDER FOR LINE PIPESDocumento10 pagineTITAS GAS PURCHASE ORDER FOR LINE PIPESAnonymous jvaG8m7Nessuna valutazione finora

- AWWA M11ed4Documento16 pagineAWWA M11ed4авдей александр33% (3)

- 3.manual of Sunken Portion Waterproofing Method WorkDocumento2 pagine3.manual of Sunken Portion Waterproofing Method WorklkovijayNessuna valutazione finora

- Pip Vesta002 Atmospheric Storage Tank Specification (Supplement To API Standard 650)Documento19 paginePip Vesta002 Atmospheric Storage Tank Specification (Supplement To API Standard 650)Rajesh PanchalNessuna valutazione finora

- SPC-FD-00-G00-Part 08 of 12-Division 23 (1 of 2)Documento310 pagineSPC-FD-00-G00-Part 08 of 12-Division 23 (1 of 2)marco.w.orascomNessuna valutazione finora