Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lab 4: Positional Servo Using P.I.D Control Positional Servo Using P.I.D Control

Caricato da

Eugene Jin LeowTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lab 4: Positional Servo Using P.I.D Control Positional Servo Using P.I.D Control

Caricato da

Eugene Jin LeowCopyright:

Formati disponibili

Control Lab#4: Positional Servo using P.I.

D Control 4-1 4

Lab 4: Positional Servo using P.I.D Control

4.1 Objective To understand proportional plus integral plus derivative control action. action To become familiar with proportional plus integral plus derivative (P.I.D) Controllers. Controllers

4.2 Proportional and Derivative Control Derivative feedback control involves using the rate of change of the error signal to reduce overshoot. When a step input is applied, the error initially rises to a high value and then decreases as the system nears alignment. The initial high rate of change of error results in the derivative output producing a very short positive peak. As the motor accelerates to maximum speed, the error signal begins to decrease. This results in the derivative decreasing to a negative value, rising to zero when the motor has reached its maximum speed and the error becomes constant. The process then reverses producing a negative spike as the motor reverses at maximum overshoot. In a proportional feedback system, the error signal is used to control the motor drive. The error signal does not go negative (producing reverse torque) until the step input goes negative. The important point oint is that due to the overshoot of the error signal, no reverse torque can be applied via the motor to slow it down until after it has passed through alignment. However a combination of error and its derivative becomes negative before alignment causing the motor to provide reverse torque and stop the overshoot. As the motor slows towards alignment the derivative component drops towards zero. If too much derivative component is added the response becomes slow. The best response depends on the application but small amount of overshoot is tolerable in exchange for a reasonable response speed. Expressed mathematically the motor control voltage, V is given by: V = error + derivative of error = V + dV/dt When the two gain factors are added: V = Kp( V + Kd(dV/dt) ) Where Kp is the proportional gain and Kd the derivative gain.

4.3 Proportional and Integral Control The reason that in a purely proportional control system there must be a residual following error is simple. As the motor is driven only by error, if there were none the motor would stop! Hence if the system is static the error can be zero because there is no requirement to drive the motor. However as soon as the motor is required to move there must be following error.

Control Lab#4: Positional Servo using P.I.D Control 4-1 4 KM40501/ 1213(2)

Control Lab#4: Positional Servo using P.I.D Control 4-2

Increasing the gain reduces the following error that is needed to keep the motor turning. For a fixed speed, the signal required to drive the motor is fixed. Therefore the higher the gain, the smaller the following error can be to provide that drive. The faster the input changes, the faster the motor needs to go in order to follow the input. So, for a fixed gain, the larger the following error must become to supply the drive. Suppose that the motor is being driven in order to follow an increasing input. The following error is a constant value. A sum of all the previous errors would be rising continuously and, if this component were added to the motor drive signal, the motor would speed up and the following error reduce. This would in turn make the integral component level off at a value just enough to keep the motor running at the correct speed to make the error zero. The system always tries to maintains a state of zero following error. The important point is that now even though the following error may be zero, the motor can still be driven by the integral component. Expressed mathematically the motor control voltage, V is given by: V = error + integral of error = V + V dt When gain factors are added: V = Kp ( V + Ki (V dt) ) Where Kp is the proportional gain and Ki the integral gain.

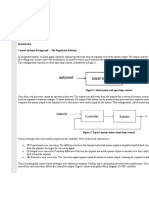

4.4 Proportional, Derivative and Integral Control The combination of the three terms (proportional, integral and derivative) can be thought of as separate characteristics. Proportional, to provide the general error driven control signal. Integral, so that there does not have to be a residual error to provide the control signal. Derivative, to give the system stability and hence reduce overshoot. However, in some ways the derivative and integral terms act against each other and are all controlled by one overall gain, making the analysis much more involved. The error control channel is like this:

Expressed mathematically the motor control voltage, V is given by: V = error + integral of error + derivative of error = V + V dt + dV/dt

Control Lab#4: Positional Servo using P.I.D Control 4-2 KM40501/ 1213(2)

Control Lab#4: Positional Servo using P.I.D Control 4-3

When gain factors are added then: V = Kp ( V + Ki ( V dt) + Kd (dV/dt) ) Where Kp = proportional gain = integral gain Ki Kd = derivative gain. 4.5 Sample Time All practicals within this assignment allow the modification of the sample time. This parameter controls how often the computer checks the state of the mechanical unit and makes adjustments. Taking too few samples can inhibit the performance of the system, since the mechanical unit may go beyond a set point without the computer noticing. Taking too many samples has the potential to put a load on your computer, causing other processes to be potentially 'starved' of processor time. When designing a controller, a comprimise between the required response and the available processing resources of a digital controller must be met. 4.6 Practical 1 : Proportional Control with Derivative Action #1 In this practical you will investigate the effect of adding a derivative component to the error signal used to control the motor. Note: In the previous assignment it became clear that increasing the gain in order to reduce error caused the system to become unstable, with a large overshoot in response to a step input. This can be corrected to some extent by adding a derivative component to the error signal. This component is simply the rate of change of error and, as the motor is driven by the error, could be obtained from a tachometer. However, in a computer controlled system such as this, it is easiest to derive the signal directly from the error by calculation. #2 Here the derivative is generated by taking the difference between successive error values. The sampling rate can be varied using the set sample time control box. Initially it is set to 100 milliseconds. Adjust the sample time and observe the behavior of the controller. Different time settings will cause different effects. This diagram shows how the system blocks are configured for this practical.

#3

Control Lab#4: Positional Servo using P.I.D Control 4-3 KM40501/ 1213(2)

Control Lab#4: Positional Servo using P.I.D Control 4-4

#4

Make the appropriate patching on the DIGITAL UNIT 33-120 as shown Fig.4.2

Fig. 4.2: Patching diagram Positional servo using P.I.D control

#5

Use the square wave input. Set derivative gain to zero, increase the proportional gain and observe the overshoot when the gain is high. Increase the derivative gain. Notice the overshoot reduces and the stability improves. Use the Display box to select the display parameters and input excitation. Now use the triangle input. Note that following error reduces with high proportional gain, but is slightly increased by the derivative component. Proportional Gain Derivative Gain

#6

#7

Control Lab#4: Positional Servo using P.I.D Control 4-4 KM40501/ 1213(2)

Control Lab#4: Positional Servo using P.I.D Control 4-5

#8

Set the proportional gain high and the derivative gain to zero. Observe the overshoot on the measured signal. Increase the derivative gain. Explain how the derivative gain reduces the overshoot on the measured signal. ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ Set the proportional gain to a mid-value and set the derivative gain to zero. Observe the measured output. Now increase the derivative gain to a similar value as the proportional gain. Explain why the response becomes slow with high derivative gain. ___________________________________________________________________________ ___________________________________________________________________________ __________________________________________________________________________ Given that proportional and derivative control will always gives a steady state error and has a slow response, suggest some suitable applications. ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________

#9

#10

4.7 Practical 2: Proportional Control with Integral Action Note: In this practical the effect of integral action is investigated. In the previous assignment, it could be seen that unless the system is static there is always a residual following error. Increasing the gain reduces it but, in purely proportional control, it can never be zero. By adding a component consisting of the sum of all the previous error samples, following error can be reduced considerably. This component corresponds to the mathematical integration process and hence is called integral action. Integral action has the disadvantage of slowing down the general response and, while reducing the average following error, will often increase its peak value. Only a small amount of integral gain can be added before the system becomes very unstable. The sample rate may be adjusted as in the previous practical. This diagram shows how the system blocks are connected for this practical. #11 Patching diagram is same with the previous practical. Use the triangle wave input. With the integral gain set to zero, observe the following error. Add integral action by increasing the integral gain slowly. Notice that the average error decreases but as the motor reverses the response is worse.

#12

Control Lab#4: Positional Servo using P.I.D Control 4-5 KM40501/ 1213(2)

Control Lab#4: Positional Servo using P.I.D Control 4-6

Note: Use the square wave input to observe the step response. Use the Display box to select the display parameters and input excitation. Note only a little integral action can be added before the system becomes unstable.

Proportional Gain Derivative Gain #13 Set the integral gain to zero. Increase the proportional gain and observe the following error. Why does the following error occur? Why can`t the following error be reduced to zero when there is no integral gain? ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ Set the proportional gain to maximum and increase the integral gain slowly. Why does the system become unstable when the integral gain is increased? ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________

#14

#15

Increase the rate of change of input using the control on the mechanical unit. Observe the error and measured value. Set the rate of change of input back to a low value and apply the brake on the side of the mechanical unit. Observe the error and measured value. Do these results make proportional and integral control suitable for fast continual load variations and high inertia applications? ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________

Control Lab#4: Positional Servo using P.I.D Control 4-6 KM40501/ 1213(2)

Control Lab#4: Positional Servo using P.I.D Control 4-7

4.8 Practical 3: Proportional Control with Integral and Derivative Action Note: In this practical the ideas of proportional integral and derivative control are combined into a PID or Three Term Controller. In concept, by adding the characteristics of all three components the best possible system performance should be obtainable. Of course with three gains to set the adjustment of such a system is more difficult and the mathematical analysis quite involved. However a reasonable approximation can be made by simple experimentation, using your experience of the characteristics of each term alone. Try adjusting the sampling rate and see what effect it has on the system. Remember that like many engineering problems there is no one perfect solution. This diagram shows how the system blocks are configured for this practical.

#16

Patching diagram is same with the two previous practical.

4.9 Full P.I.D Control #17 #18 Use both triangle and square wave inputs to investigate the effect of the three gain terms. Start with only proportional gain and then add derivative action. When the system is stable, add a small amount of integral gain and observe carefully the effects. Adjust all three gains and note their interactive nature. Use the Display box to select the display parameters and input excitation. Notice that the best step response is not accompanied by minimum following error. Proportional Gain Integral Gain Derivative Gain

Control Lab#4: Positional Servo using P.I.D Control 4-7 KM40501/ 1213(2)

Control Lab#4: Positional Servo using P.I.D Control 4-8

#19

Describe the process which occurs when an input is applied to the motor, in terms of the effects which the proportional, derivative and integral feedback have on the measured output. ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ Compare the values which are set for the three gains in the practical with similar values set in the maths model. Is the measured value output the same for both cases? ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________ What other factors will affect the practical which do not occur in the maths model? ___________________________________________________________________________ ___________________________________________________________________________ ___________________________________________________________________________

#20

#21

Control Lab#4: Positional Servo using P.I.D Control 4-8 KM40501/ 1213(2)

Control Lab#4: Positional Servo using P.I.D Control 4-9

Group Members: 1.______________________________ 3.______________________________ 5.______________________________

2. _____________________________ 4. _____________________________ 6. _____________________________

4.1 Positional Servo using P.I.D Control #7 Proportional Gain Derivative Gain

#12 Proportional Gain Derivative Gain

#18 Proportional Gain Integral Gain Derivative Gain

Control Lab#4: Positional Servo using P.I.D Control 4-9 KM40501/ 1213(2)

Potrebbero piacerti anche

- Control of DC Motor Using Different Control StrategiesDa EverandControl of DC Motor Using Different Control StrategiesNessuna valutazione finora

- Advanced Process Control: Beyond Single Loop ControlDa EverandAdvanced Process Control: Beyond Single Loop ControlNessuna valutazione finora

- PIIIDDocumento12 paginePIIIDLionel81Nessuna valutazione finora

- EVMS Full Notes PDFDocumento78 pagineEVMS Full Notes PDFNaveen DhanurajNessuna valutazione finora

- MX009 - Proportional Integral Derivative Control PDFDocumento5 pagineMX009 - Proportional Integral Derivative Control PDFjorgemdp5Nessuna valutazione finora

- Zero OneDocumento12 pagineZero OneNestor Daniel Gonzales ArévaloNessuna valutazione finora

- Implementing A PID Controller Using A PICDocumento15 pagineImplementing A PID Controller Using A PICJavier CharrezNessuna valutazione finora

- Pid Without A PHD PDFDocumento14 paginePid Without A PHD PDFGiovanni Eliezer100% (2)

- PID Control ArdunioDocumento8 paginePID Control ArdunioSyed Abdul Haseeb AhmedNessuna valutazione finora

- Proportional Integral Derivative (PID)Documento27 pagineProportional Integral Derivative (PID)GilagidkidNessuna valutazione finora

- IoT2x Module 4 PID ActivityDocumento5 pagineIoT2x Module 4 PID Activityvanishree raNessuna valutazione finora

- Apc Term PaperDocumento9 pagineApc Term PaperDarshan MalaniNessuna valutazione finora

- Pid MSP PDFDocumento6 paginePid MSP PDFAlberto Corona MartinezNessuna valutazione finora

- PID Without A PHDDocumento16 paginePID Without A PHDirfanexpertNessuna valutazione finora

- Examining The Fundamentals of PID ControlDocumento7 pagineExamining The Fundamentals of PID ControlbariNessuna valutazione finora

- PID ControllersDocumento6 paginePID ControllersNguyễn HảiNessuna valutazione finora

- Pid ControllerDocumento20 paginePid ControllerHarshal InamdarNessuna valutazione finora

- Designing PID AlgorithmDocumento7 pagineDesigning PID AlgorithmVu Duc TruongNessuna valutazione finora

- Error Squared ControlDocumento4 pagineError Squared ControlBen SahraouiNessuna valutazione finora

- University of Benghazi: Department of Electrical and Electronics EngineeringDocumento12 pagineUniversity of Benghazi: Department of Electrical and Electronics EngineeringAhmed AlhadarNessuna valutazione finora

- Pid ExplainedDocumento4 paginePid ExplainedShiva Sai BuraNessuna valutazione finora

- Assignment - 2: PID Controller Block DiagramDocumento4 pagineAssignment - 2: PID Controller Block DiagramSmakshi ChoudharyNessuna valutazione finora

- PID Without A PHDDocumento7 paginePID Without A PHDEEpro808Nessuna valutazione finora

- PID ControllerDocumento22 paginePID ControllerFoo He XuanNessuna valutazione finora

- Mesb333 Pid ControlDocumento13 pagineMesb333 Pid ControlMohd KhairiNessuna valutazione finora

- PID ControllerDocumento5 paginePID ControllerAbhilash MallikarjunaNessuna valutazione finora

- PID Control of Mechanical System Using Suitable Simulation SoftwareDocumento12 paginePID Control of Mechanical System Using Suitable Simulation Softwareanagha joshiNessuna valutazione finora

- Name: Roll: Year: Department: Subject: Subject CodeDocumento11 pagineName: Roll: Year: Department: Subject: Subject CodeMayukh BiswasNessuna valutazione finora

- Experiment 4Documento13 pagineExperiment 4Usama NadeemNessuna valutazione finora

- Study of ON OFF P PI PD PID ControllerDocumento10 pagineStudy of ON OFF P PI PD PID ControllerMaddy SharmaNessuna valutazione finora

- Unit 3 PLC PDFDocumento15 pagineUnit 3 PLC PDFMahesh ShendeNessuna valutazione finora

- A Simple Method For Servo Motor Tuning - National InstrumentsDocumento5 pagineA Simple Method For Servo Motor Tuning - National InstrumentsSan BanNessuna valutazione finora

- Lab 4Documento4 pagineLab 4Vu LeNessuna valutazione finora

- PID Controller Working Principle Explained For BeginnersDocumento6 paginePID Controller Working Principle Explained For BeginnersPramillaNessuna valutazione finora

- Unit 3Documento11 pagineUnit 3mayuraher9511Nessuna valutazione finora

- Implementing A PID Control System On A Microcontroller: Using The Example of A Microchip PIC 18F4550Documento12 pagineImplementing A PID Control System On A Microcontroller: Using The Example of A Microchip PIC 18F4550Venkatesan SundaramNessuna valutazione finora

- Experiment No.1: Now Manually Move The AVS-1 Bar To Control The Flow Through The Valve in To The ContainerDocumento16 pagineExperiment No.1: Now Manually Move The AVS-1 Bar To Control The Flow Through The Valve in To The ContainerfahadfiazNessuna valutazione finora

- Lab 5 ReportDocumento12 pagineLab 5 ReportMelaku DinkuNessuna valutazione finora

- Lecture - PID ControllerDocumento30 pagineLecture - PID ControllerCyril Felix100% (1)

- Feed Forwards Augment PID ControlDocumento10 pagineFeed Forwards Augment PID ControlGeorge MarkasNessuna valutazione finora

- Control Systems Background - The Regulation ProblemDocumento19 pagineControl Systems Background - The Regulation ProblemHilmy Pramuditya FhansuriNessuna valutazione finora

- Introduction: PID Controller Design: Sistemas de ControlDocumento15 pagineIntroduction: PID Controller Design: Sistemas de ControlPatricio EncaladaNessuna valutazione finora

- Servo MotorDocumento19 pagineServo Motormubashir100% (1)

- Three Term ControlDocumento7 pagineThree Term ControlcataiceNessuna valutazione finora

- Lab 5 Reportgroup Name IdDocumento16 pagineLab 5 Reportgroup Name IdMelaku DinkuNessuna valutazione finora

- Group 4 Lab 5Documento16 pagineGroup 4 Lab 5Melaku DinkuNessuna valutazione finora

- Ic 2003Documento21 pagineIc 2003Dinesh KumarNessuna valutazione finora

- Introduction To PID ControlDocumento6 pagineIntroduction To PID ControlIonescu ViorelNessuna valutazione finora

- What Is PID - TutorialDocumento5 pagineWhat Is PID - Tutorialsocrates19582405Nessuna valutazione finora

- Working or Operation of PID ControllerDocumento7 pagineWorking or Operation of PID Controllerjohn glenn magnoNessuna valutazione finora

- PID ControllerDocumento10 paginePID ControllerFarid HazwanNessuna valutazione finora

- ET401 Lab Self-Regulating Single Tank Level Control: Modeling and Tuning Profs Sarnacki, Owen, Olivari, Tefft Fall 2019Documento4 pagineET401 Lab Self-Regulating Single Tank Level Control: Modeling and Tuning Profs Sarnacki, Owen, Olivari, Tefft Fall 2019essameldinNessuna valutazione finora

- Lab 05 (Servo)Documento4 pagineLab 05 (Servo)hitesh89Nessuna valutazione finora

- Theory SERVO Linear Position ControlDocumento7 pagineTheory SERVO Linear Position ControlEnMaa 96Nessuna valutazione finora

- PID Control ToolkitDocumento6 paginePID Control ToolkitRobin PathakNessuna valutazione finora

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsDa EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNessuna valutazione finora

- Projects With Microcontrollers And PICCDa EverandProjects With Microcontrollers And PICCValutazione: 5 su 5 stelle5/5 (1)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosDa EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosValutazione: 5 su 5 stelle5/5 (1)

- Effect On Oleochemical IndustryDocumento32 pagineEffect On Oleochemical IndustryEugene Jin LeowNessuna valutazione finora

- D - Internet - Myiemorgmy - Intranet - Assets - Doc - Alldoc - Document - 16245 - Engineering Competency Development PDFDocumento88 pagineD - Internet - Myiemorgmy - Intranet - Assets - Doc - Alldoc - Document - 16245 - Engineering Competency Development PDFEugene Jin LeowNessuna valutazione finora

- Auger Compactor - ENDocumento4 pagineAuger Compactor - ENEugene Jin LeowNessuna valutazione finora

- Guidance 2010ADAStandards PRT PDFDocumento170 pagineGuidance 2010ADAStandards PRT PDFruletherockNessuna valutazione finora

- G 22 N EFA-Det4-IIA-... - 1,2 Type SheetDocumento2 pagineG 22 N EFA-Det4-IIA-... - 1,2 Type SheetEugene Jin LeowNessuna valutazione finora

- Submission of Building Plans by Professional Engineer With PEPCAnd ArchitectsDocumento5 pagineSubmission of Building Plans by Professional Engineer With PEPCAnd Architectsgilbert850507Nessuna valutazione finora

- Flexible Hose DatasheetDocumento1 paginaFlexible Hose DatasheetEugene Jin LeowNessuna valutazione finora

- Pages From c2TRDocumento15 paginePages From c2TRsammar_10Nessuna valutazione finora

- 1.3 VortragEmdenDierkerDocumento37 pagine1.3 VortragEmdenDierkerDian Agung NugrohoNessuna valutazione finora

- Caesar II App Guide PDFDocumento3 pagineCaesar II App Guide PDFAnonymous O0lyGOShYGNessuna valutazione finora

- Valve Selection & Specification Guide For Building Services: Ahead of The FlowDocumento20 pagineValve Selection & Specification Guide For Building Services: Ahead of The FlowSimónSilvaRubio100% (1)

- Geometry of Marine PropellersDocumento78 pagineGeometry of Marine PropellersDiane TrujilloNessuna valutazione finora

- Data Sheet Width Flange BeamDocumento32 pagineData Sheet Width Flange BeamIrvan IskandarNessuna valutazione finora

- 2012 StarLNG Brochure - Issue 2.0Documento28 pagine2012 StarLNG Brochure - Issue 2.0iaxdenNessuna valutazione finora

- Principles of Composite Materials. (GIBSON) .Documento446 paginePrinciples of Composite Materials. (GIBSON) .lui11111100% (9)

- Corrosion - Allowance FromDocumento2 pagineCorrosion - Allowance FromEugene Jin LeowNessuna valutazione finora

- Item 565.14200008 - Non-Guided Polytetrafluoroethylene (Ptfe) Sliding BearingDocumento5 pagineItem 565.14200008 - Non-Guided Polytetrafluoroethylene (Ptfe) Sliding BearingEugene Jin LeowNessuna valutazione finora

- Check Valve CatalogDocumento44 pagineCheck Valve Catalogkamal_mdNessuna valutazione finora

- Acoustic Induced VibrationDocumento33 pagineAcoustic Induced VibrationEugene Jin Leow100% (1)

- OTC Paper 13210, 2001 Taco TerpstraDocumento21 pagineOTC Paper 13210, 2001 Taco TerpstraParilla13Nessuna valutazione finora

- BAA 08-017 FinalDocumento22 pagineBAA 08-017 FinalEugene Jin LeowNessuna valutazione finora

- Internal Combustion Engine CyclesDocumento27 pagineInternal Combustion Engine CyclesEugene Jin LeowNessuna valutazione finora

- Engineering CompositesDocumento193 pagineEngineering CompositesMelih AltıntaşNessuna valutazione finora

- 59318A - FASTFACTS - Sulfinert Coatings For Sampling, Transfer, and Analysis OfSulfur Compounds To Less Than 20ppbDocumento2 pagine59318A - FASTFACTS - Sulfinert Coatings For Sampling, Transfer, and Analysis OfSulfur Compounds To Less Than 20ppbEugene Jin LeowNessuna valutazione finora

- Industrial Renewal and Inter-Firm Relations in TheDocumento61 pagineIndustrial Renewal and Inter-Firm Relations in TherentozNessuna valutazione finora

- 2) Numerical Simulations of A Fully Submerged Propeller Subject To VentilationDocumento18 pagine2) Numerical Simulations of A Fully Submerged Propeller Subject To VentilationEugene Jin LeowNessuna valutazione finora

- Lab 4: Positional Servo Using P.I.D Control Positional Servo Using P.I.D ControlDocumento9 pagineLab 4: Positional Servo Using P.I.D Control Positional Servo Using P.I.D ControlEugene Jin LeowNessuna valutazione finora

- Wageningen B-Series ChartsDocumento33 pagineWageningen B-Series ChartsTullio Opatti100% (2)

- Marine PropellerDocumento19 pagineMarine PropellerEugene Jin LeowNessuna valutazione finora

- Lecture 02 - Acoustics + Psychoacoustics PDFDocumento115 pagineLecture 02 - Acoustics + Psychoacoustics PDFpaolokboardNessuna valutazione finora

- 2011 JC1 H2 Chemistry Promo P2Documento19 pagine2011 JC1 H2 Chemistry Promo P2joshua_98548Nessuna valutazione finora

- Answers & Solutions: For For For For For NTSE (Stage-I) 2017-18Documento20 pagineAnswers & Solutions: For For For For For NTSE (Stage-I) 2017-18Manish GoyalNessuna valutazione finora

- Tutorial Sheet (ME324) 2018-19Documento1 paginaTutorial Sheet (ME324) 2018-19Asif SadarNessuna valutazione finora

- Cleaning Validation ProtocolDocumento6 pagineCleaning Validation ProtocolVega life sciences100% (1)

- DatumsDocumento22 pagineDatumsAlberto LobonesNessuna valutazione finora

- History of MaichewDocumento2 pagineHistory of MaichewSehabom Geberhiwot100% (1)

- 17 Capacitors and Inductors in AC CircuitsDocumento12 pagine17 Capacitors and Inductors in AC CircuitsAbhijit PattnaikNessuna valutazione finora

- Asymptotes Tutorial: Horizontal Vertical Slant and HolesDocumento30 pagineAsymptotes Tutorial: Horizontal Vertical Slant and Holesgregory_k_sherman100% (1)

- D 6988 - 03 Medicion de CalibreDocumento7 pagineD 6988 - 03 Medicion de CalibreMiguelAngelPerezEsparzaNessuna valutazione finora

- 17 Reinforced ConcreteDocumento46 pagine17 Reinforced ConcreteJetty CruzNessuna valutazione finora

- Presentation Dr. Fahmida Gulshan 1Documento30 paginePresentation Dr. Fahmida Gulshan 1Vishal SharmaNessuna valutazione finora

- Chapter V Beam Deflections 5.4Documento3 pagineChapter V Beam Deflections 5.4Joshua John JulioNessuna valutazione finora

- 1697 Dzyan Kitabi Qedim Qutsal Oghreti Bilim Arashdirma Qurupu 1971 61sDocumento67 pagine1697 Dzyan Kitabi Qedim Qutsal Oghreti Bilim Arashdirma Qurupu 1971 61strametesa100% (1)

- Theory of Elasticity and Plasticity. (CVL 622) M.Tech. CE Term-2 (2017-18)Documento2 pagineTheory of Elasticity and Plasticity. (CVL 622) M.Tech. CE Term-2 (2017-18)er.praveenraj30Nessuna valutazione finora

- 1 - SetsDocumento2 pagine1 - SetsHerald MulanoNessuna valutazione finora

- S Puiching10 F3Documento8 pagineS Puiching10 F3Carlos TorresNessuna valutazione finora

- Problem SetDocumento2 pagineProblem SetCrystal DimaanoNessuna valutazione finora

- SPHL Sample ProblemsDocumento20 pagineSPHL Sample ProblemsĐức TiếnNessuna valutazione finora

- Niosh Lift Push PullDocumento15 pagineNiosh Lift Push Pullahuan huanNessuna valutazione finora

- 2021 HSC Mathematics Extension 2 Hardest QuestionDocumento3 pagine2021 HSC Mathematics Extension 2 Hardest QuestionThe Sydney Morning HeraldNessuna valutazione finora

- A Facile Synthesis, Characterization of N-Substituted 7-Methoxy 3-Phenyl 4 (3-Piperzin - 1-Yl-Propoxy) Chromen-2-OneDocumento21 pagineA Facile Synthesis, Characterization of N-Substituted 7-Methoxy 3-Phenyl 4 (3-Piperzin - 1-Yl-Propoxy) Chromen-2-OneNalla Umapathi ReddyNessuna valutazione finora

- Full Text of "Waterproofing EngineeringDocumento966 pagineFull Text of "Waterproofing Engineeringmazharul43Nessuna valutazione finora

- 1.'motivation For SoC Design - by Raveendra SomanaDocumento13 pagine1.'motivation For SoC Design - by Raveendra SomanaSantosh Shivapuji100% (1)

- Sajb 411952 969Documento18 pagineSajb 411952 969samirNessuna valutazione finora

- White Pigments For Flexible Packaging InksDocumento8 pagineWhite Pigments For Flexible Packaging InksHOANGVUNL1988Nessuna valutazione finora

- Regular Solution TheoryDocumento4 pagineRegular Solution TheoryLouie G NavaltaNessuna valutazione finora

- Drilling Fluids, Drill String, CirculatingDocumento10 pagineDrilling Fluids, Drill String, CirculatingBianca Quiroga AndiaNessuna valutazione finora

- BOF Plant Write UpDocumento20 pagineBOF Plant Write UpKalyan HalderNessuna valutazione finora

- F ChartDocumento7 pagineF Charthemal4379Nessuna valutazione finora