Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BkA Guide Operating Masterflex Fixed-Speed Pump Drive & Easy-Load Pump Heads

Caricato da

Berkeley AnalyticalCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BkA Guide Operating Masterflex Fixed-Speed Pump Drive & Easy-Load Pump Heads

Caricato da

Berkeley AnalyticalCopyright:

Formati disponibili

BAA Guide 07-03_100107

BERKELEY ANALYTICAL ASSOCIATES

815 Harbour Way South, Unit 6 Richmond, CA 94804-3612 Tel: 510-236-2325 Fax: 510-236-2335 Email: baalab@berkeleyanalytical.com www.berkeleyanalytical.com

Operating Instructions for Masterflex Fixed-Speed Pump Drive and Easy-Load Pump Heads

BAA Guide 07-03 October 1, 2007

Introduction Peristaltic pumps are relatively inexpensive systems for the pumped collection of VOCs onto sorbent tubes for indoor air quality investigations. They additionally have the advantages of permitting the collection of multiple samples using a single pump and allowing the measurement of sampling air flow rates at the pump exhaust. This guide describes the operation of a simple, fixed-speed, peristaltic pump fitted with dual pump heads. System Description The Masterflex pump drive, pump heads, accessories, and tubing can be purchased from Cole-Parmer Instrument Co., Vernon Hills, IL, 800-323-4340 (www.coleparmer.com). Table 1 provides ordering information and pricing for a 60-rpm, dual head pump and tubing based on the 2007-2008 catalog listings. BAA has a limited number of 30-rpm, dual head pumps available on a rental basis. Please contact the laboratory for availability and pricing. Table 1. Purchase specifications for Masterflex dual-head pump system Catalog No. EW-07540-60 EW-77202-50 EW-07596-61 EW-06402-14 EW-06402-16 EW-06402-25 EW-06290-05 Description Fixed speed drive, 60 rpm, 115 VAC Two-Channel Easy-Load II pump head, Includes hardware (only 1 required) Pulse dampener Size 14 Norprene food grade tubing Size 16 Norprene food grade tubing Size 25 Norprene food grade tubing Straight disconnect, 1/8" to 7/32" 2007 Price $205.00/ea $215.00/ea $61.00/ea $40.00/50 ft $44.00/25 ft $59.00/25 ft $23.20/20

BAA Guide 07-03_100107

Loading the Flexible Tubing in the Pump Head 1. When changing the tubing size, retract both tubing retainers by pushing them in and upwards. These are the small black levers on both sides of the pump head. No adjustment is required when using the two-channel Easy-Load head. Lock a short section (approximately 1 ft) of flexible tubing in place in the pump head by pushing the loading lever 180o to the right. This is the large lever on the top of the pump head. On the inlet side of the pump head, adjust the tubing retainer downward and firmly against the tubing. Repeat this step on the outlet side of the head. No adjustment is required when using the two-channel Easy-Load head. To remove or replace the tubing, rotate the loading lever 180o to the left position.

2.

3.

4.

Operation of the 30-rpm Pump 1. 2. 3. The pump drive available from BAA has a fixed speed of 30 rpm. The drive shaft rotates clockwise. Table 2 gives the approximate flow rates and the sample times needed to collect a 6-L sample (typical size for most building investigations) for three different tubing sizes. Operate the pump for about 5 minutes with the flexible tubing in place but prior to installing the samplers to warm up the motor and stabilize the air flow rates. Check that the tubing retainers are properly adjusted so that the tubing does not "creep" through the pump heads.

Table 2. Sampling times for 30-rpm fixed-speed pump system Flow Rate (mL min-1) 6.3 24.0 50.0 Time for 6-L Sample (h/min) 15 h 50 min 4 h 10 min 2h

Tubing Size 14 16 25

Operation of the 60-rpm Pump 1. 2. The pump drive recommended in Table 1 has a fixed speed of 60 rpm. The drive shaft rotates clockwise. Table 3 gives the approximate flow rates and the sample times needed to collect a 6-L sample (recommended size for most building investigations) for three different tubing sizes. Operate the pump for about 5 minutes with the flexible tubing in place but prior to installing the samplers to warm up the motor and stabilize the air flow rates.

3.

BAA Guide 07-03_100107

Table 3. Sampling times for 60-rpm fixed-speed pump system Flow Rate (mL min-1) 13 48 100 Time for 6-L Sample (h/min) 7 h 40 min 2 h 5 min 1h

Tubing Size 14 16 25

Collection of Samples 1. 2. The dual-head configuration of the pump allows for the simultaneous collection of duplicate samples of VOCs on multisorbent samplers. Attach lengths of -in polyethylene or Teflon tubing fitted with -in Swagelok unions to the flexible tubing on the inlet sides of the pump heads. For the No. 14 and 16 tubing sizes, this connection can be made conveniently with the male end of a polyethylene straight disconnect and a short section of No. 25 tubing. Connect a sampler to the Swagelok union using a nut and -in Teflon ferrules. Do not use metal ferrules. The nut should be hand tightened so that the sampler cannot be pulled from the union. Be sure that the inlet of the sampler (e.g., the end with the two engraved rings) is pointed away from this connection. Alternately, use a short section of No. 25 tubing to connect a sampler to the -in tubing. Install both samplers, and initiate sampling by plugging in the pump to a 115 VAC outlet. Record the start time. Alternatively, a timer can be used to control the pump. Make air flow rate measurements at the outlet sides of the flexible tubing in the pump heads using a bubble flow meter, calibrated rotameter or other device. A pulse dampener may be required to reduce pulsation in the output flow. Do not make the measurements upstream of the samplers as this can result in sample contamination. At a minimum, make flow rate measurements near the beginning and end of each sampling period. Measure the flow rates at both pump heads. The beginning and ending flow rates for a sample should be within 15%, or better. The flow rate for a sample can be calculated as the average of the beginning and ending values. Measure and record the air temperature and atmospheric pressure so that the sample volumes can be corrected to standard indoor conditions (i.e., 25o C, 1 atm). At the end of the sampling period, terminate sampling by either removing the samplers from the Swagelok unions or by unplugging the pump. Record the stop time.

3.

4. 5. 6.

7.

Potrebbero piacerti anche

- CALGreen Low-Rise Residential Comparison To GreenPoint Rated and LEED For HomesDocumento9 pagineCALGreen Low-Rise Residential Comparison To GreenPoint Rated and LEED For HomesBerkeley AnalyticalNessuna valutazione finora

- Interior Paints & Coatings LEED v4 (Ballot Version) EQ Credit: Low-Emitting MaterialsDocumento1 paginaInterior Paints & Coatings LEED v4 (Ballot Version) EQ Credit: Low-Emitting MaterialsBerkeley AnalyticalNessuna valutazione finora

- Whitepaper - Impact of ATCM On Composite Wood ProductsDocumento6 pagineWhitepaper - Impact of ATCM On Composite Wood ProductsBerkeley AnalyticalNessuna valutazione finora

- CALGreen Non-Residential Comparison To LEED For Building Design & ConstructionDocumento7 pagineCALGreen Non-Residential Comparison To LEED For Building Design & ConstructionBerkeley AnalyticalNessuna valutazione finora

- Collection of Surface Wipe Samples For Analysis of Semi Volatile Organic Compounds (SVOCs)Documento2 pagineCollection of Surface Wipe Samples For Analysis of Semi Volatile Organic Compounds (SVOCs)Berkeley AnalyticalNessuna valutazione finora

- Green Product Registry TableDocumento1 paginaGreen Product Registry TableBerkeley AnalyticalNessuna valutazione finora

- Collection of Samples For Analysis of Volatile Organic Compounds (VOCs) in Indoor Air Using Sorbent TubesDocumento5 pagineCollection of Samples For Analysis of Volatile Organic Compounds (VOCs) in Indoor Air Using Sorbent TubesBerkeley AnalyticalNessuna valutazione finora

- BkA Guide Collection of SVOC Air Samples Using PUF CartridgesDocumento4 pagineBkA Guide Collection of SVOC Air Samples Using PUF CartridgesBerkeley AnalyticalNessuna valutazione finora

- Collection of Samples For Analysis of Volatile Organic Compounds (VOCs) in Indoor Air Using Sorbent TubesDocumento5 pagineCollection of Samples For Analysis of Volatile Organic Compounds (VOCs) in Indoor Air Using Sorbent TubesBerkeley AnalyticalNessuna valutazione finora

- Collection of Samples For Analysis of Formaldehyde and Other Carbonyls in Indoor Air Using DNPH CartridgesDocumento5 pagineCollection of Samples For Analysis of Formaldehyde and Other Carbonyls in Indoor Air Using DNPH CartridgesBerkeley AnalyticalNessuna valutazione finora

- BkA Guide Collection of Furniture Product Samples For ANSI-BIFMA M7.1Documento4 pagineBkA Guide Collection of Furniture Product Samples For ANSI-BIFMA M7.1Berkeley AnalyticalNessuna valutazione finora

- BkA Guide Collection of Building Product Samples For CDPH STD MethodDocumento6 pagineBkA Guide Collection of Building Product Samples For CDPH STD MethodBerkeley AnalyticalNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- CSE PP Lightning Protection PDFDocumento3 pagineCSE PP Lightning Protection PDFyxp2237Nessuna valutazione finora

- Datasheet Ic Carga Moto E4Documento48 pagineDatasheet Ic Carga Moto E4Xvier100Nessuna valutazione finora

- Manual Il NT Mrs19vautodetect 1.0Documento84 pagineManual Il NT Mrs19vautodetect 1.0Miguel Angel Pavon CarbonellNessuna valutazione finora

- Hoist and Crane SafeyDocumento60 pagineHoist and Crane SafeysergioNessuna valutazione finora

- Volume: Iih Section-Iii Operation and Control Philosophy: (PCA - CD-003.491798982Documento13 pagineVolume: Iih Section-Iii Operation and Control Philosophy: (PCA - CD-003.491798982Anonymous 5XvUbWynnNessuna valutazione finora

- Landers PMS Cost Proposalrev01 - Electric Pro 04apr2023Documento1 paginaLanders PMS Cost Proposalrev01 - Electric Pro 04apr2023IVM PhilsNessuna valutazione finora

- PIC16F877: Micro-Controller Project On: A Pic Controlled Weather MeterDocumento11 paginePIC16F877: Micro-Controller Project On: A Pic Controlled Weather MeterOdi IluobeNessuna valutazione finora

- Profibus InstallationGuideV9 - 2Documento44 pagineProfibus InstallationGuideV9 - 2inczeaNessuna valutazione finora

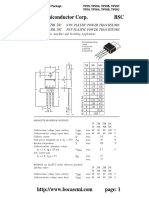

- Boca Semiconductor Corp. BSC: Continental Device India LimitedDocumento3 pagineBoca Semiconductor Corp. BSC: Continental Device India LimitedNadia Ayelen GonzalezNessuna valutazione finora

- System Allocation: ABS Warning Lamp Right Brake LampDocumento5 pagineSystem Allocation: ABS Warning Lamp Right Brake LampDadang Lukmanul HakimNessuna valutazione finora

- SW274 IG enDocumento16 pagineSW274 IG enThi KháchNessuna valutazione finora

- Mapa Eletrico Puma PDFDocumento6 pagineMapa Eletrico Puma PDFneoagricola agricolaNessuna valutazione finora

- Onkyo Repair-Tips (ET)Documento34 pagineOnkyo Repair-Tips (ET)perico1962100% (1)

- Contact Resistance Micro-Ohm Meter - Contact Resistance Tester Manufacturer From PuneDocumento7 pagineContact Resistance Micro-Ohm Meter - Contact Resistance Tester Manufacturer From PuneAtanu PanNessuna valutazione finora

- Sunwave SRC-3000 User ManualDocumento41 pagineSunwave SRC-3000 User ManualSebastianNessuna valutazione finora

- Crj-700 Fom ManualDocumento843 pagineCrj-700 Fom ManualFernando Martínez100% (5)

- Reddot R9757 (Rh40e) - 1Documento8 pagineReddot R9757 (Rh40e) - 1Rodny Romero0% (1)

- Power TransistorDocumento37 paginePower Transistorsaikarthick023Nessuna valutazione finora

- Zdu 2.5 4anDocumento5 pagineZdu 2.5 4anAllen BradleyNessuna valutazione finora

- JWB Test2 DigitDocumento5 pagineJWB Test2 DigitScalperNessuna valutazione finora

- RT7736GGEDocumento24 pagineRT7736GGEPedro AriasNessuna valutazione finora

- Automation: PLC S7 1200 Training PanelDocumento1 paginaAutomation: PLC S7 1200 Training PanelLulzim MulliqiNessuna valutazione finora

- Nlpkatalog GASDocumento27 pagineNlpkatalog GASSvilen KirilovNessuna valutazione finora

- Comptia A+ Page 1Documento2 pagineComptia A+ Page 1djkeo 2ddmNessuna valutazione finora

- DXR75 1000 June 1996Documento2 pagineDXR75 1000 June 1996SergiSerranoNessuna valutazione finora

- 04-68350A Manual CCN DM01-DI01 PDFDocumento47 pagine04-68350A Manual CCN DM01-DI01 PDFtaha50% (2)

- Catalogue SDocumento8 pagineCatalogue SSHINOS 3SNessuna valutazione finora

- Sperre HL2 90Documento1 paginaSperre HL2 90Eslam MamdouhNessuna valutazione finora

- Tps-Sch-Bd-Me-Ge-El-0001-A - Cable ScheduleDocumento5 pagineTps-Sch-Bd-Me-Ge-El-0001-A - Cable ScheduleBalamurugan ArumugamNessuna valutazione finora

- Step by Step Guide Brochure in Sharpening Hand SawDocumento2 pagineStep by Step Guide Brochure in Sharpening Hand Sawivil Jean ocoNessuna valutazione finora