Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

9A03605 Design of Machine Elements - II

Caricato da

sivabharathamurthyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

9A03605 Design of Machine Elements - II

Caricato da

sivabharathamurthyCopyright:

Formati disponibili

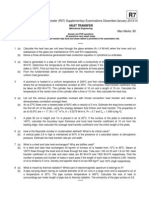

Code: 9A03605

B. Tech III Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013 DESIGN OF MACHINE ELEMENTS - II (Mechanical Engineering) Time: 3 hours Max. Marks: 70 Design data books are permitted in the examination hall. Answer any FIVE questions All questions carry equal marks ***** 1 (a) Distinguish between Hydrodynamic and Hydrostatic Bearings with figures. (b) How is rolling contact bearing are manufactured? Design and sketch a cast iron piston for a single acting four stroke I.C. engine with a 0.14 m cylinder bore 0.19 m stroke and 0.375 m connecting rod length. The maximum gas pressure is 3.5 N/mm2 and the engine speed is 600 rpm, it develops a brake mean effective pressure of 0.7 N/mm2 and uses 4.65 kJ/KW per second, check the piston for heat flow. (a) What is the function of connecting rod? (b) What are the usual ratio of the connecting rod length and the stroke of piston? How it is decided upon? Determine the maximum stress, if the direction of the load is reversed.

figure Contd. in Page 2 Page 1 of 2

Code: 9A03605 5

(a) Discuss the different types of belts and their material used for power transmission. (b) Discuss the various important parameters necessary for the selection of a particular drive for power transmission. A pair of helical gears is to transmit 15 KW. The teeth are 20 stub in diametral plane and have a helix angle of 45. The pinion runs at 10000 r.p.m. and has 80 mm pitch diameter. The gear has 320 mm pitch diameter. If the gears are made of cast steel having allowable static strength of 100 MPa; determine a suitable module and face width from static strength considerations and check the gears for wear, given es = 618 MPa. (a) Discuss the materials and practical applications for the various types of springs. (b) A helical spring is made from a wire of 6 mm diameter and has outside diameter of 75 mm. If the permissible shear stress is 350 MPa and modulus of rigidity 84 kN/mm2, find the axial load which the spring can carry and the deflection per active turn. (a) List the type of threads used in power screws. Give practical example for each type of threads. (b) State advantages and disadvantages of using different types of threads in power screws.

*****

Page 2 of 2

Code: 9A03605

B. Tech III Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013 DESIGN OF MACHINE ELEMENTS - II (Mechanical Engineering) Time: 3 hours Max. Marks: 70 Design data books are permitted in the examination hall. Answer any FIVE questions All questions carry equal marks ***** 1 (a) (b) (a) (b) (a) (b) What are the different bearing materials? Describe the various stages of friction in the case of plain bearings. List various liner materials used in the manufacturing of cylinder of I.C. engine. Explain design calculation of piston barrel and Gudgeon pin. Compare centre and side crank, crank shafts. Explain any one with neat sketch with design considerations. The crane hook carries a load of 20 kN, as shown in figure. The section at X-X is rectangular whose horizontal side is 100 mm. Find the stresses in the inner and outer fibers at the given section.

figure 5 (a) (b) What are the advantages and disadvantages of V-belt drive over flat belt drive? Derive the relation for the ratio of driving tensions of a V-belt. Contd. in Page 2 Page 1 of 2

Code: 9A03605 6 (a) (b) Write a short note on gear drives giving their merits and demerits.

It is required to design a pair of spur gears with 200 full depth involute teeth based on Lewis equation. The velocity factor is to be used to account for dynamic load. The pinion shaft is connected to a 10 KW, 1440 r.p.m motor. The starting torque of the motor is 150% of the rated torque. The speed reduction is 4:1. The pinion as well as the gear are made of plain carbon steel 40C8 ( = 600 N/mm2). The factor of safety can be taken as 1.5. Design the gear, specify their dimensions. A helical torsion spring of mean diameter 60 mm is made of a round wire of 6 mm diameter. If a torque of 6 N-m is applied on the spring, find the bending stress induced and the angular deflection of the spring in degrees. The spring index is 10 and modulus of elasticity for the spring material is 200 kN/mm2.The number of effective turns may be taken as 5.5. Design a leaf spring for the following specifications: Total load = 140 kN; number of springs supporting the load = 4; maximum number of leaves = 10; span of the spring = 1000 mm; permissible deflection = 80 mm. Take Youngs modulus, E = 200 kN/mm2 and allowable stress in spring material as 600 MPa. A bar is raised and lowered by two 40 mm square threads having a pitch of 10 mm. Determine the force required at a radius of 80 mm to raise or lower at 10000 N cross bar of a planer. The screw and nut materials are steel bronze respectively. The collar materials are steel and bronze respectively. The collar material is steel; it has an outside diameter of 76 mm and an inside diameter of 38 mm; coefficients of friction at threads and at collar are 0.11 and 0.13 respectively.

(a)

(b)

*****

Page 2 of 2

Code: 9A03605

B. Tech III Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013 DESIGN OF MACHINE ELEMENTS - II (Mechanical Engineering) Time: 3 hours Max. Marks: 70 Design data books are permitted in the examination hall. Answer any FIVE questions All questions carry equal marks ***** 1 (a) (b) Explain squeeze film lubrication. Find the Rating Life of the 50 mm bore, light series ball journal bearing under 6800 N radial load at 600 rpm. The load is out of balance and therefore rotates with inner ring. There is no shocking load. Explain the different parts of a trunk piston. Explain with figure. Explain cylinder liner distortion and cylinder lubrication. What are the methods and materials used in manufacturing crank shaft? Explain any one method with neat sketch. Determine the stresses at section X-X of the punch as shown in figure W = 2 kN.

2 (a) (b) 3 (a) (b) 4

Section X-X

Derive

T1 mv 2 T2 mv

2

=e

sin( / 2)

for a V belt, Where T1 and T2 are the tensions in the belt

and m mass of 1 m belt, coefficient of friction; angle of wrap. State the assumptions clearly. Contd. in Page 2

Page 1 of 2

Code: 9A03605

A cast steel spur pinion (d = 200 MPa) running at 450 r.p.m transmits 20 KW power to a cast iron gear (d = 80 MPa) running at approximately 112 r.p.m. the load is steady, design the drive and check for dynamic and wear loads. A semi-elliptical laminated vehicle spring to carry a load of 8000 N is to consist of seven leaves 75 mm wide, two of the leaves extending the full length of the spring. The spring is to be 1.1 m in length and attached to the axle by two U-bolts 80 mm apart. The bolts hold the central portion of the spring so rigidly that they may be considered equivalent to a band having a width equal to the distance between the bolts. Assume a design stress for spring material as 350 MPa. Determine: (i) Thickness of leaves. (ii) Deflection of spring. (iii) Diameter of eye. (iv) Length of leaves and (v) Radius to which leaves should be initially bent. (a) Show that the efficiency of self locking screws is less than 50 percent. (b) What is self locking property of threads and where it is necessary? *****

Page 2 of 2

Code: 9A03605

B. Tech III Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013 DESIGN OF MACHINE ELEMENTS - II (Mechanical Engineering) Time: 3 hours Max. Marks: 70 Design data books are permitted in the examination hall. Answer any FIVE questions All questions carry equal marks ***** 1 A bearing is required for a 35 mm shaft. It is to operate for 8 hrs per day. 5 days per week for 5 years and is to carry a stationary radial load of 2250 N at 1500 rpm, inner ring rotating. There is a possibility of light shock. Select a suitable bearing (a) What are the functions of a trunk piston? Explain with figure. (b) Explain good qualities of good cylinder liners. (a) What are the Shims and their uses explain? (b) Write about Crush in connecting rod. A ring is made of a 5 cm diameter round bar as shown in figure. Calculate the stresses at point, A and B.

figure 5 A pulley is driven by a flat belt running at a speed of 600 m/min. The coefficient of friction between the pulley and the belt is 0.3 and the angle of lap is 160. If the maximum tension in the belt is 700 N; find the power transmitted by a belt. Contd. in Page 2 Page 1 of 2

Code: 9A03605

A helical cast steel gear with 300 helix angle has to transmit 25 KW at 2000 r.p.m. if the gear has 25 teeth, determine the necessary module and face width of the gear. The tooth profile is 200 full depth involute and static strength of the gear material is 56 MPa. Take the face width of the gear as 3 time the normal pitch and velocity factor (Cv) = where v is the pitch line velocity in m/s.

15 , 15 + v

Design and draw a valve spring of a petrol engine for the following operating conditions : Spring load when the valve is open = 500 N. Spring load when the valve is closed = 350 N. Maximum inside diameter of spring = 30 mm. Length of the spring when the valve is open = 40 mm. Length of the spring when the valve is closed = 50 mm. Maximum permissible shear stress = 450 MPa. (a) How does the helix angle influence on the efficiency of square threaded screw? (b) Discuss the various types of power threads. Give atleast two practical applications for each type. Discuss their relative advantages and disadvantages.

*****

Page 2 of 2

Potrebbero piacerti anche

- Control Systems (CS) Notes As Per JntuaDocumento203 pagineControl Systems (CS) Notes As Per Jntuasivabharathamurthy100% (3)

- R5410201 Neural Networks & Fuzzy LogicDocumento1 paginaR5410201 Neural Networks & Fuzzy LogicsivabharathamurthyNessuna valutazione finora

- SSC Telugu (FL) (AP)Documento232 pagineSSC Telugu (FL) (AP)sivabharathamurthyNessuna valutazione finora

- SSC Social Textbook (AP)Documento100 pagineSSC Social Textbook (AP)sivabharathamurthyNessuna valutazione finora

- R7410407 Operating SystemsDocumento1 paginaR7410407 Operating SystemssivabharathamurthyNessuna valutazione finora

- 9A13701 Robotics and AutomationDocumento4 pagine9A13701 Robotics and AutomationsivabharathamurthyNessuna valutazione finora

- 07A4EC01 Environmental StudiesDocumento1 pagina07A4EC01 Environmental StudiessivabharathamurthyNessuna valutazione finora

- R7410506 Mobile ComputingDocumento1 paginaR7410506 Mobile ComputingsivabharathamurthyNessuna valutazione finora

- Code: R7311306: (Electronics & Control Engineering)Documento1 paginaCode: R7311306: (Electronics & Control Engineering)sivabharathamurthyNessuna valutazione finora

- R7311506 Operating SystemsDocumento1 paginaR7311506 Operating SystemssivabharathamurthyNessuna valutazione finora

- R7312301 Transport Phenomena in BioprocessesDocumento1 paginaR7312301 Transport Phenomena in BioprocessessivabharathamurthyNessuna valutazione finora

- 9A05707 Software Project ManagementDocumento4 pagine9A05707 Software Project ManagementsivabharathamurthyNessuna valutazione finora

- R7311006 Process Control InstrumentationDocumento1 paginaR7311006 Process Control InstrumentationsivabharathamurthyNessuna valutazione finora

- R7311205 Distributed DatabasesDocumento1 paginaR7311205 Distributed DatabasessivabharathamurthyNessuna valutazione finora

- R7310106 Engineering GeologyDocumento1 paginaR7310106 Engineering GeologysivabharathamurthyNessuna valutazione finora

- R5310406 Digital CommunicationsDocumento1 paginaR5310406 Digital CommunicationssivabharathamurthyNessuna valutazione finora

- R7310306 Heat TransferDocumento1 paginaR7310306 Heat Transfersivabharathamurthy100% (1)

- R7310506 Design & Analysis of AlgorithmsDocumento1 paginaR7310506 Design & Analysis of AlgorithmssivabharathamurthyNessuna valutazione finora

- R7310406 Digital CommunicationsDocumento1 paginaR7310406 Digital CommunicationssivabharathamurthyNessuna valutazione finora

- R7310206 Linear Systems AnalysisDocumento1 paginaR7310206 Linear Systems AnalysissivabharathamurthyNessuna valutazione finora

- 9A15502 Digital System DesignDocumento4 pagine9A15502 Digital System Designsivabharathamurthy100% (1)

- R5310204 Power ElectronicsDocumento1 paginaR5310204 Power ElectronicssivabharathamurthyNessuna valutazione finora

- 9A23501 Heat Transfer in BioprocessesDocumento4 pagine9A23501 Heat Transfer in BioprocessessivabharathamurthyNessuna valutazione finora

- 9A14503 Principles of Machine DesignDocumento8 pagine9A14503 Principles of Machine DesignsivabharathamurthyNessuna valutazione finora

- 9A04504 Digital IC ApplicationsDocumento4 pagine9A04504 Digital IC ApplicationssivabharathamurthyNessuna valutazione finora

- 9A21506 Mechanisms & Mechanical DesignDocumento8 pagine9A21506 Mechanisms & Mechanical DesignsivabharathamurthyNessuna valutazione finora

- 9A05505 Operating SystemsDocumento4 pagine9A05505 Operating SystemssivabharathamurthyNessuna valutazione finora

- 9A10505 Principles of CommunicationsDocumento4 pagine9A10505 Principles of CommunicationssivabharathamurthyNessuna valutazione finora

- 9A03505 Heat TransferDocumento4 pagine9A03505 Heat TransfersivabharathamurthyNessuna valutazione finora

- 9A02505 Electrical Machines-IIIDocumento4 pagine9A02505 Electrical Machines-IIIsivabharathamurthyNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Millennium Development GoalsDocumento6 pagineMillennium Development GoalsSasha Perera100% (2)

- Aryan Civilization and Invasion TheoryDocumento60 pagineAryan Civilization and Invasion TheorySaleh Mohammad Tarif 1912343630Nessuna valutazione finora

- Vmware It Academy Program May2016Documento26 pagineVmware It Academy Program May2016someoneNessuna valutazione finora

- English 6, Quarter 1, Week 7, Day 1Documento32 pagineEnglish 6, Quarter 1, Week 7, Day 1Rodel AgcaoiliNessuna valutazione finora

- Deictics and Stylistic Function in J.P. Clark-Bekederemo's PoetryDocumento11 pagineDeictics and Stylistic Function in J.P. Clark-Bekederemo's Poetryym_hNessuna valutazione finora

- (LaSalle Initiative) 0Documento4 pagine(LaSalle Initiative) 0Ann DwyerNessuna valutazione finora

- CIVE2304 C1-1 Hydrological CycleDocumento54 pagineCIVE2304 C1-1 Hydrological CyclenaserNessuna valutazione finora

- Group 3 Presenta Tion: Prepared By: Queen Cayell Soyenn Gulo Roilan Jade RosasDocumento12 pagineGroup 3 Presenta Tion: Prepared By: Queen Cayell Soyenn Gulo Roilan Jade RosasSeyell DumpNessuna valutazione finora

- HAI ROBOTICS Introduction ENV2022.0829 MarketingDocumento40 pagineHAI ROBOTICS Introduction ENV2022.0829 MarketingKit WooNessuna valutazione finora

- DOMESDocumento23 pagineDOMESMukthesh ErukullaNessuna valutazione finora

- Lesson 3 - Adaptation AssignmentDocumento3 pagineLesson 3 - Adaptation AssignmentEmmy RoseNessuna valutazione finora

- LhiannanDocumento6 pagineLhiannanGreybornNessuna valutazione finora

- HSG 2023 KeyDocumento36 pagineHSG 2023 Keyle827010Nessuna valutazione finora

- Promotion of Coconut in The Production of YoghurtDocumento4 paginePromotion of Coconut in The Production of YoghurtԱբրենիկա ՖերլինNessuna valutazione finora

- Enzymes WorksheetDocumento5 pagineEnzymes WorksheetgyunimNessuna valutazione finora

- Deep Sea 500 Ats ManDocumento18 pagineDeep Sea 500 Ats ManLeo Burns50% (2)

- How To Build Yam Chips Production PlantDocumento11 pagineHow To Build Yam Chips Production PlantVu Thieu TuanNessuna valutazione finora

- Class 12 Unit-2 2022Documento4 pagineClass 12 Unit-2 2022Shreya mauryaNessuna valutazione finora

- Introduction To Human MovementDocumento5 pagineIntroduction To Human MovementNiema Tejano FloroNessuna valutazione finora

- Al-Farabi Fusul Al MadaniDocumento107 pagineAl-Farabi Fusul Al MadaniDaniel G.G.100% (1)

- All About History History of Communism - 4th Edition 2022Documento148 pagineAll About History History of Communism - 4th Edition 2022Duke100% (1)

- SST Vs BBTDocumento7 pagineSST Vs BBTFlaxkikare100% (1)

- Service M5X0G SMDocumento98 pagineService M5X0G SMbiancocfNessuna valutazione finora

- Exam Ref 70 483 Programming in C by Wouter de Kort PDFDocumento2 pagineExam Ref 70 483 Programming in C by Wouter de Kort PDFPhilNessuna valutazione finora

- High Intermediate 2 Workbook AnswerDocumento23 pagineHigh Intermediate 2 Workbook AnswernikwNessuna valutazione finora

- Opening Checklist: Duties: Monday Tuesday Wednesday Thursday Friday Saturday SundayDocumento3 pagineOpening Checklist: Duties: Monday Tuesday Wednesday Thursday Friday Saturday SundayAlven BlancoNessuna valutazione finora

- Angeles City National Trade SchoolDocumento7 pagineAngeles City National Trade Schooljoyceline sarmientoNessuna valutazione finora

- Bsa2105 FS2021 Vat Da22412Documento7 pagineBsa2105 FS2021 Vat Da22412ela kikayNessuna valutazione finora

- Idoc - Pub - Pokemon Liquid Crystal PokedexDocumento19 pagineIdoc - Pub - Pokemon Liquid Crystal PokedexPerfect SlaNaaCNessuna valutazione finora

- Water Flow Meter TypesDocumento2 pagineWater Flow Meter TypesMohamad AsrulNessuna valutazione finora