Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Garnituri DIN 2697

Caricato da

Dumitru SorinaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Garnituri DIN 2697

Caricato da

Dumitru SorinaCopyright:

Formati disponibili

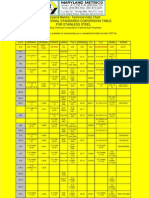

Grooved Gaskets with Standard Profile

Grooved Gaskets with Convex Profile

CONVEX Gaskets

EN IS

O 90

01

Profile Gaskets

Profile Gaskets with Covering Layers

Profile Gaskets

Profile Gaskets

Gasket Types

Page 3

Construction Materials

Page 3

Grooved Gaskets with Standard Profile

Page 4

Grooved Gaskets with Convex Profile

Page 5

CONVEX Gaskets

Page 6

Dimension Tables

Raised Face Flanges:

Pages 7-11 Works Standard 145 for DIN Flanges Works Standard 146 for ANSI B16.5 Flanges Works Standard 147 for ASME B16.47 Series A Flanges Works Standard 101 for DIN Flanges Works Standard 100 for ANSI B 16.5 Flanges Works Standard 136 for ASME 16.47 Series A Flanges To DIN 2697

For Groove to Groove Flanges

Page 11 To DIN 2512

Tongue and Groove Flanges

Page 12 To DIN 2691 To ANSI B 16.5

Male and Female Flanges

Page 12 To DIN 2692 To ANSI B16.5

Gasket Types

Materials of Construction

Grooved gaskets have been proved successful in all industrial applications. Grooved gaskets are found in conventional power plants as well as in the primary circuits of nuclear power plants. In the first case e.g. as heat exchanger gaskets or as closure gaskets, in the second case e.g. as manhole gaskets at the steam generator or at the standup pressure vessel. Also in the chemical and petro-chemical industries grooved gaskets have shown excellent results, particularly where both high-pressure and temperatures resulting high bolt loads are to be controlled. In order to protect the flanges from damage caused by the grooved gaskets sharp edges, these gaskets are used in practice with covering layers of PTFE, graphite, A.F.S.*, aluminum or silver. The flanges are then entirely protected. The profile geometry is selected to relate to the thickness of the covering layer of 0.5 mm (or in special case 1.0 mm). Kempchen has developed different profiles in order to meet the varying properties of the covering layer materials. However, the purpose of the relatively soft covering layers is not only to protect the flanges but also to seal at low minimum contact pressures. In the recesses of the grooved gaskets, filled with the layer material a triaxial state of stress is created. For these gaskets only the gasket supporting ring or the flange material limits the loading capacity. Consequently the stability of this combination is considerably higher than that of pure PTFE, graphite, A.F.S.*, aluminum or silver gaskets. Kempchen manufactures grooved gaskets from DN 10 up to a diameter of 3600mm. Also manufacturing facilities exist for larger diameters, customer requirements and oval or frame gaskets. For heat exchangers with baffles the gaskets are equipped with grooved ribs.

The sketch depicts centering rings for a nominal gasket thickness of 4mm.

1,5

Fig. 1

0,5 0,5

Fig. 2

1,0

Fig. 3

1,5

Fig. 4

1,0

Fig. 5

Profile gaskets are available to Kempchen works standard WN 100, WN 101, WN 136, WN 146 and WN 147. Grooved type gaskets to DIN 2697 are also available. Gaskets to work standards 100 and 101 are designed with only a single gasket width for all pressure ranges. According to theory the gasket width bD = (d2 - d1)/2 should increase with larger nominal pressures. The simplification in Kempchen standard 100 and 101 is possible because of the very large differences of and V, as stated in the application safety factor SB = /V. For difficult applications, e.g. high pressure and temperature changes, external forces and moments the gasket width should be determined referring to Kempchen publication "The Optimization of Static Gaskets".

Metal core materials

1.0333 1.4016 1.4301 1.4401 1.4541 1.4550 1.4571 1.4876 1.5415 1.7335 1.7362 2.0090 2.4066 2.4360 3.7025

Covering Materials

PTFE, graphite, asbestos free fiber and in special cases silver and aluminum are used. The covering layers are usually attached to the grooved metal gaskets with an adhesive. The thickness of the gasket as installed is increased by the compressed thickness of the covering layers. For austenitic pipelines, vessels and valves layers of PTFE or graphite are recommended. The covering material is either mounted without an adhesive or using an adhesive with low chloride content. Metallic covering layers for narrow gaskets with d1 [mm] bD < 0,5 d1[mm] can be manufactured as single inner eyelet. For bD > 0,5 d1 [mm] two-piece d1 [mm] jacket is proved.

0,15 0,15 s

CONVEX gasket frames for rectangular flanges are welded as mitre joints. Grooved gaskets are hard soldered. Gaskets for raised face flanges or for flat flanges are manufactured with a centering ring to center the gasket with the bolts. Centering rings less than 10 mm are a single part with the metal core. For wider centering rings a relieving groove is machined (figure 1). For applications with gaseous media it is recommended to use a loosely mounted centering ring. Loosely mounted centering rings are also advantageous for large temperature gradients between the inner and outer diameter. This type centering ring is either mounted in an outside groove (figures 2-4) or spot welded to the metal core (figure 5).

0,5

0,5

Profile Gaskets

3

Profile Gaskets

Standard Grooved Gaskets

The groove crests of the standard profile are located in a plane and the groove roots are parallel to them. This design is similar to DIN 2697. The soft sealing layer thickness is 0.5mm for graphite, A.F.S. *, aluminum and silver and 0,35mm for PTFE.

1.0 0.1 ~0.33 90 O

Profiles Profile B7A should be used for tongue and groove and for male and female flanges. Profile B9A is designed with a integrated centering ring for flat and raised face flanges. For applications with gaseous media and high temperature differences between inner and outer diameter, profile B15A designed with a loosely connected centering is recommended. Grooved profile ring type E7A is designed to seal groove to groove flanges.

0.45

This profile type should be used preferably for tongue and groove or male and female flanges. Kempchen standard 123 defines the minimum requirements.

Profile B7A

Cross-Section

Gasket Thickness and Groove Pitch

To Kempchen Standard 123 For tongue and groove flanges and male and female flanges. NPS to 80 resp.. to 3" from 100 to 300 resp. 4" to 12" from 350 to 900 resp. 14" to 36" over 900 resp. 36" DN t 1 1 1.5 1.5 s 1.5 2.0 2.5 3.0 B9A B15A E7A

Orders to DIN 2697 Standard groove type profile must be combined with graphite layer of 1.0 mm thickness and PTFE layers of 0.5 mm thickness.

90O 1,5

1.4541 aluminium

Profile Material

1.7335 graphite 1.4541 graphite 1.7335 PTFE

0,75

Standard Groove Profi- Rz = 16 le to DIN 2697

0.5 s 0.5

0,1

Critical notes on Gaskets without Layers According to DIN 2697 grooved gaskets can be used without covering layers. In general relatively soft metal is used to avoid the grooves from damaging the flange surfaces. To prevent this damages gaskets with soft covering layers are preferably used. The groove crests have a width of about 0.1mm. The contact diameter bD is calculated as bD = Z0.1, an equal surface pressure assumed. Z is defined as the number of teeth in the grooved profile. Grooved gaskets without covering layers have hollow spaces and no steady sealing behavior. In operation the groove crests get compressed. This leads to a sealing width of bD > Z0.1. Therefore Kempchen does not recommend using grooved gaskets without covering layers.

1.4541 PTFE**

1.4541 A.F.S.*

Recommended maximum flange surface roughness (max. peak to valley height) Recommended minimum and maximum surface pressures at 20C (68F) Recommended minimum and maximum surface pressures at 300C (572F)

m N/mm2 N/mm2

from to

25 50 15 450 30 390

50 100 15 450 301) 3901)

25 50 15 500 30 420

50 100 15 500 301) 4201)

25 50 45 500 -

12.5 25 80 500 95 420

12.5 25 125 500 140 420

v v

1 ) Grooved gaskets with PTFE layers are usable to 300C (572F) only with restrictions. * A.F.S. Asbestos Free Fiber Sheet up to 150C (302F). ** Depending on the media gaskets with PTFE layers or PTFE envelopes may develop electrostatic charges. Therefore gaskets and piping must necessarily be properly grounded.

1.4541 silver

0,3

B7A, B9A, B15A, E7A

The 'CONVEX' Grooved Gasket

Profiles B27A, B29A, B25A and E27A are "convex" grooved gaskets. Compared with standard design they have better sealing behavior. The crests have - as all other profiles - the same parallel plane. Bottoms of the grooves however follow a convex root form. Soft sealing covering layers of plastically moldable material form a thick padding in the middle of the profile. The higher specific contact pressure in the middle causes localized extraordinary good flow of the sealing covering layers into the flange surfaces unevenness and roughness. The soft sealing layer thickness is 0.5mm for graphite, A.F.S. *, aluminum and silver and 0,35mm for PTFE. The "convex" Grooved gaskets to profile B27A, B29A, B25A and E27A minimizes edge pressure due to flange rotation. Standard gaskets lift at the inner diameter under flange rotation conditions (about 1 degree max.) because the main force of the flanges is located more towards the outer side of the gasket diameter. With the newly developed profiles B27A, B29A, B25A and E27A the contact diameter bD is preserved. These gaskets are particularly suited for flange connections under cycling pressures and temperatures.

Profile Types Profile B27A is designed for tongue and groove and male and female type joints. For raised face and flat face flanges profile B29A is the proper choice. For high temperatures and gaseous media between inner and outer diameter profile B25A with loosely mounted centering ring is recommendable. Grooved gasket ring E27A is designed purposefully to fit groove to groove flanges.

Profile B27A B29A B25A E27A

Cross-Section

Surface pressures The soft layer material of the convex grooved gasket determines the minimal required surface pressure v. The maximum allowable surface pressure at temperature determines the force the gasket has to withstand. The metal core material determines .

dD

1.4541 aluminium

Profile Material

1.0038 graphite 1.5415 graphite 1.5415 PTFE**

B27A, B29A, B25A, E27A

1.4541 graphite 1.4828 grahpite 1.4541 PTFE** 1.4541 A.F.S.* 1.4541 silver 1.4828 silver

Recommended maximum flange surface roughness (max. peak to valley height) Recommended minimum and maximum surface pressures at 20C (68F) Recommended minimum and maximum surface pressures at 300C (572F)

m N/mm2 N/mm2

from to

25 50 15 350 20 210

25 50 15 450 20 330

50 100 15 450 201) 3301)

25 50 15 500 20 420

50 100 15 500 201) 4201)

25 50 40 500 -

25 50 15 500 20 420

12.5 25 70 500 80 420

12.5 25 100 500 110 420

12.5 25 100 500 110 500

v v

1 ) Grooved gaskets with PTFE layers are usable to 300C (572F) only with restrictions. * A.F.S. Asbestos Free Fiber Sheet up to 150C (302F). ** Depending on the media gaskets with PTFE layers or PTFE envelopes may develop electrostatic charges. Therefore gaskets and piping must necessarily be properly grounded.

Profile Gaskets

5

Profile Gaskets

CONVEX Gaskets

The soft sealing surfaces are easily and safely mounted on the convex shaped metal supporting surface with a nearly chlorine free adhesive. There are no grooves which could be filled with adhesive. The soft sealing layers are completely supported by the smooth surface of the convex metal ring. In comparison to grooved gaskets, where adherence lines are on the crests, the convex surface offers a more secure adherence to the metal core even for sensitive soft sealing layers. To facilitate handling, mounting and to prevent damage backing edges protect the soft sealing layers. It is possible to provide aluminum or silver metal layers. Convex gaskets as opposed to DIN or Kempchen Standard grooved type gaskets, flat or convex designs have the advantage in the elimination of the stress concentration in the groove bottoms. Damage due to stress corrosion cracking that occurs in zones of internal stresses or higher stresses due to in service conditions are therefore eliminated. Also damage due to load reversals that are possibly caused by a leakage stream are not expected to occur with the new convex gasketing with covering layers. Another means to reduce internal stress, even under high temperature differences, is the loosely mounted centering ring. Up to an including diameter of 3600mm convex gaskets can be machined in a seamless finish. Convex gaskets in frame shape e.g. for use in rectangular heat exchanges with right angle flanges can be supplied. References for pressures in excess of 200bar exist.

1 3 5 2 9 8 7 6 4

Description

1 Sealing part of soft plastic deformable material. 2 Metal support ring. 3 Metal centering ring 4/5 Inner and outer backing rings that protect the (1) seal ring against scratches and extrusion 6 Sealing area under increased surface pressure 7 Sloping area on the outer and inner sealing part cases decreasing surface pressure towards the backing edges to avoid edge pressure. 6/7 A smooth notch less surface area as the curved profile is manufactured without grooves. 8 Outside groove, which holds the centering ring and avoids overstressing of the outer metal backing edge in the event if rotating flanges. 9 Loosely mounted centering ring preventing high thermal or torsional stresses at elevated or high temperature differentials.

Profile

s 4-0.5

Cross-Section

B45A

bD

d2 d3 d1

B47A B49A

s = 0.5 mm up to DN 500, s = 1.0 mm DN 600 up to DN 1000, s = 1.5 mm from DN 1200.

1.4541 aluminium

Profile Material

1.0038 graphite 1.5415 graphite 1.5415 PTFE**

B45A, B47A, B49A

1.4541 graphite 1.4828 graphite 1.4541 PTFE** 1.4541 A.F.S.* 1.4541 silver 1.4828 silver

Recommended maximum flange surface roughness (max. peak to valley height) Recommended minimum and maximum surface pressures at 20C (68F) Recommended minimum and maximum surface pressures at 300C (572F)

m N/mm2 N/mm2

from to

25 50 20 350 30 210

25 50 20 450 30 330

50 100 20 450 301) 3301)

25 50 20 500 30 420

50 100 20 500 301) 4201)

25 50 45 500 -

25 50 20 500 30 420

12.5 25 70 500 80 420

12.5 25 100 500 110 420

12.5 25 100 500 110 500

v v

1 ) CONVEX gaskets with PTFE layers are usable to 300C (572F) only with restrictions. * A.F.S. Asbestos Free Fiber Sheet up to 150C (302F). ** Depending on the media, gaskets with PTFE layers or PTFE envelopes may develop electrostatic charges. Therefore gaskets and piping must necessarily be properly grounded.

Dimension Tables

Raised Face Flanges

2-0 , 5

d1 d2 d3

Works Standard 145 for DIN flanges

Order example for grooved gasket with covering layer, profile B29A, nominal diameter 100mm, nominal pressure 40 bar, works standard 145, of 1): Grooved gasket profile B29A, DN 100, PN 40, works standard 145, 1.4541 / graphite.

1

2

) Please specity material in any inquiry. ) Other thickness on request.

Dimensions in mm

10 15 20 25 32 40 50 65 80 100 125 150 175 200 250 300 350 400 450 500 600 700 800 900 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800

d1 d2 22 36 26 42 31 47 36 52 46 62 53 69 65 81 81 100 95 115 118 138 142 162 170 190 195 215 220 240 270 290 320 340 375 395 426 450 480 506 530 560 630 664 730 770 830 876 930 982 1040 1098 1250 1320 1440 1522 1650 1742 1850 1914 2050 2120 2250 2328 2460 2512 2670 2728 2890 2952

d2

d2

PN 250PN 400

PN 63PN 160

PN 10PN 40

DN

36 42 47 52 62 69 81 100 115 138 162 190 215 248 300 356 415 474 588 700 812 886 994 1110 1334 -

36 42 47 52 66 73 87 103 121 146 178 212 245 280 340 400 -

PN 10 46 51 61 71 82 92 107 127 142 162 192 217 247 272 327 377 437 489 539 594 695 810 917 1017 1124 1341 1548 1772 1972 2132 2384 2594 2794 3014

PN 16 46 51 61 71 82 92 107 127 142 162 192 217 247 272 328 383 443 495 555 617 734 804 911 1011 1128 1342 1542 1764 1964 2168 2378 -

PN 25 46 51 61 71 82 92 107 127 142 168 194 224 254 284 340 400 457 514 624 731 833 942 1042 1154 1364 1578 1798 2000 2230 -

PN 40 46 51 61 71 82 92 107 127 142 168 194 224 265 290 352 417 474 546 571 628 747 852 974 1084 1194 1398 1618 1830 -

PN 63 56 61 82 103 113 137 148 174 210 247 277 309 364 424 486 543 657 764 879 988 1108 1220 1452 -

d3 PN 100 PN 160 PN 250 PN 320 56 56 67 67 61 61 72 72 82 82 83 92 103 103 109 119 119 119 124 134 143 143 153 170 154 154 170 190 180 180 202 229 217 217 242 274 257 257 284 311 287 284 316 358 324 324 358 398 391 388 442 488 458 458 536 512 572 704 813 950 -

PN 400 67 78 104 135 150 192 207 256 301 348 402 442 -

d1 d2 d3

* thickness of metal core 3,80,2 mm for nominal thickness 4 mm.

4*

Profile Gaskets

7

42)

Profile Gaskets

Dimension Tables

Works Standard 146 for ANSI B16.5 flanges

Order example for grooved gasket with covering layer, profile B9A, nominal diameter 5 inches for ANSI flanges, class 600lbs, works standard 146, of 1):

Dimensions in mm

Grooved gasket profile B9A, 5", 600, works standard 146, 1.4541 / graphite.

1

) Please specity material in any inquiry.

Class 900-2500

Class 150-300

Class 400-600

NPS 1 1 1 2 2 3 3 4 5 6 8 10 12 14 16 18 20 24

d1 20 25 32 40 45 60 70 85 100 110 135 160 210 265 315 350 400 450 500 600

d2

d2

d2

30 35 42 56 61 80 90 105 120 130 155 180 230 285 335 370 425 480 535 640

30 35 42 56 61 80 90 105 120 130 155 180 230 295 350 390 445 500 555 665

30 35 42 56 61 80 90 110 135 165 195 250 315 375 405 460 525 575 685

Class 150 44,4 53,9 63,5 73,0 82,5 101,8 120,6 133,4 158,8 171,5 193,7 219,1 276,2 336,5 406,4 447,7 511,2 546,1 603,2 714,4

300 50,8 63,5 69,8 79,4 92,1 108,0 127,0 146,1 161,9 177,8 212,7 247,7 304,8 358,8 419,1 482,6 536,6 593,7 650,9 771,5

400 50,8 63,5 69,5 79,4 92,1 108,0 127,0 146,1 158,7 174,6 209,5 244,5 301,6 355,6 415,9 479,4 533,4 590,5 644,5 765,2

d3 600 50,8 63,5 69,5 79,4 92,1 108,0 127,0 146,1 158,7 190,5 238,1 263,5 317,5 396,9 454,0 488,9 561,9 609,6 679,5 787,4

900 60,3 66,7 76,2 85,7 95,2 139,7 161,9 165,1 203,2 244,5 285,8 355,6 431,8 495,3 517,5 571,5 635,0 695,3 835,0

1500 60,3 66,7 76,2 85,7 95,2 139,7 161,9 171,5 206,4 250,8 279,4 349,3 431,8 517,5 574,7 638,1 701,7 752,4 898,5

2500 66,7 73,0 82,5 101,6 114,3 142,8 165,1 193,7 231,7 276,2 314,3 384,1 473,0 546,1 -

Works Standard 147 for ANSI B16.5 series A flanges

Order example for grooved gasket with covering layer, profile B9A, nominal diameter 30 inches for ANSI flanges B16.47 series A, class 600lbs, works standard 147, of 1):

Dimensions in mm

Grooved gasket profile B9A, 30", 600, works standard 147, 1.4541 / graphite.

1

) Please specity material in any inquiry. required.

Class 900-2500

Class 150-300

Class 400-600

NPS 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60

d1 650 705 755 805 855 905 960 1010 1060 1110 1160 1210 1260 1310 1360 1410 1460 1510

d2

685 745 795 850 900 955 1015 1065 1120 1170 1225 1275 1330 1385 1435 1490 1540 1595

d2 705 765 820 875 930 985 1030 1085 1135 1190 1250 1300 1355 1405 1460 1515 1565 1625

d2 725 785 840 895 950 1005 1065 1120 1175 1230 1285 1340 -

Class 150 772 829 880 937 987 1045 1108 1159 1216 1273 1324 1381 1432 1489 1546 1603 1661 1711

300 832 895 949 1003 1054 1114 1051 1111 1162 1216 1270 1321 1375 1426 1489 1540 1591 1742

400 829 889 943 1000 1051 1114 1070 1124 1175 1229 1286 1343 1400 1451 1515 1565 1616 1680

d3 600 864 911 968 1019 1070 1127 1102 1153 1216 1267 1324 1388 1445 1495 1553 1610 1661 1730

900 880 943 1007 1070 1134 1197 1197 1248 1299 1365 1432 1483 -

Raised Face Flanges

Works Standard 101* For DIN flanges

42)

Order example for grooved gasket with covering layer, profile B29A, nominal diameter 100mm, nominal pressure 40 bar, works standard 101, of 1): Grooved gasket profile B29A, DN 100, PN 40, works standard 101, 1.4541 / graphite.

* Grooved gaskets to Kempchen standard 145, designed with a pressure range optimized sealing width, are also available. 1 ) Please specity material in any inquiry. 2 ) The thickness of the metal core is 3.80.2mm for a 4mm nominal thickness. Other thickness on request.

2-0,5

d1 d2 d3

Dimensions in mm

DN 10 15 20 25 32 40 50 65 80 100 125 150 175 200 250 300 350 400 450 500 600 700 800 900 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000 d1 22 26 31 36 46 53 65 81 95 118 142 170 195 224 275 325 375 426 480 530 630 730 830 930 1040 1250 1440 1650 1850 2050 2250 2460 2670 2890 3100 d2 36 42 47 52 66 73 87 103 121 144 176 204 229 258 315 365 420 474 528 578 680 780 880 980 1090 1310 1510 1730 1930 2130 2340 2550 2760 2980 3190 PN 10 46 51 61 71 82 92 107 127 142 162 192 217 247 272 327 377 437 489 539 594 695 810 917 1017 1124 1341 1548 1772 1972 2182 2384 2594 2794 3014 3228 PN 16 46 51 61 71 82 92 107 127 142 162 192 217 247 272 328 383 443 495 555 617 734 804 911 1011 1128 1342 1542 1764 1964 2168 2378 PN 25 46 51 61 71 82 92 107 127 142 168 194 224 254 284 340 400 457 514 624 731 833 942 1042 1154 1364 1578 1798 2000 2230 PN 40 46 51 61 71 82 92 107 127 142 168 194 224 265 290 352 417 474 546 571 628 747 852 974 1084 1194 1398 1618 1830 PN 63 56 61 82 103 113 137 148 174 210 247 277 309 364 424 486 543 657 764 879 988 1108 1220 1452 -

d3 PN 100 PN 160 PN 250 PN 320 PN 400 56 56 67 67 67 61 61 72 72 78 82 82 83 92 104 103 103 109 119 135 119 119 124 134 150 143 143 153 170 192 154 154 170 190 207 180 180 202 229 256 217 217 242 274 301 257 257 284 311 348 287 284 316 358 402 324 324 358 398 442 391 388 442 488 458 458 536 512 572 704 813 950 -

d1 d2 d3

* thickness of metal core 3,80,2 mm for nominal thickness 4 mm.

4*

Profile Gaskets

9

Profile Gaskets

Dimension Tables

Works Standard 100* For ANSI B16.5 flanges

Order example for grooved gasket with covering layer, profile B9A, nominal diameter 5 inches for ANSI flanges, class 600, works standard 100, of 1): Grooved gasket profile B9A, 5", 600, works standard 100, 1.4541 / graphite. NPS 1 1 1 2 2 3 3 4 5 6 8 10 12 14 16 18 20 24 d1 23,0 28,6 36,5 44,4 52,4 69,8 82,5 98,4 111,1 123,8 150,8 177,8 228,6 282,6 339,7 371,5 422,3 479,4 530,2 631,8 d2 33,3 39,7 47,6 60,3 69,8 88,9 101,6 123,8 136,5 154,0 182,6 212,7 266,7 320,7 377,8 409,6 466,7 530,2 581,0 682,6 Class 150 44,4 53,9 63,5 73,0 82,5 101,8 120,6 133,4 158,8 171,5 193,7 219,1 276,2 336,5 406,4 447,7 511,2 546,1 603,2 714,4 300 50,8 63,5 69,8 79,4 92,1 108,0 127,0 146,1 161,9 177,8 212,7 247,7 304,8 358,8 419,1 482,6 536,6 593,7 650,9 771,5 400 50,8 63,5 63,5 79,4 92,1 108,0 127,0 146,1 158,7 174,6 209,5 244,5 301,6 355,6 415,9 479,4 533,4 590,5 644,5 765,2

* Grooved gaskets to Kempchen standard 146, designed with a pressure range optimized sealing width, are also available. 1 ) Please specity material in any inquiry. 2 ) The thickness of the metal core is 3.80.2mm for a 4mm nominal thickness. Other thickness on request.

d3 600 50,8 63,5 69,5 79,4 92,1 108,0 127,0 146,1 158,7 190,5 238,1 263,5 317,5 396,9 454,0 488,9 561,9 609,6 679,5 787,4

900 60,3 66,7 76,2 85,7 95,2 139,7 161,9 165,1 203,2 244,5 285,8 355,6 431,8 495,3 517,5 571,5 635,0 695,3 835,0

1500 60,3 66,7 76,2 85,7 95,2 139,7 161,9 171,5 206,4 250,8 279,4 349,3 431,8 517,5 574,7 638,1 701,7 752,4 898,5

2500 66,7 73,0 82,5 101,6 114,3 142,8 165,1 193,7 231,7 276,2 314,3 384,1 473,0 546,1 -

Works Standard 136* For ASME B16.47 series A flanges

Order example for grooved gasket with covering layer, profile B9A, nominal diameter 30 inches for ASME B16.47 series A flanges, class 600, works standard 136, of 1)::

Dimensions in mm

Grooved gasket profile B9A, 30", class 600, works standard 136, 1.4541 / graphite.

10

NPS 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60

d1 690 740 800 845 895 950 960 1015 1065 1125 1175 1220 1270 1320 1375 1430 1485 1535

d1 740 790 850 905 955 1010 1020 1075 1125 1185 1235 1290 1350 1400 1455 1510 1565 1615

Class 150 772 829 880 937 987 1045 1108 1159 1216 1273 1324 1381 1432 1489 1546 1603 1661 1711

300 832 895 949 1003 1054 1114 1051 1111 1162 1216 1270 1321 1375 1426 1489 1540 1591 1742

d3 400 829 889 943 1000 1051 1114 1070 1124 1175 1229 1286 1343 1400 1451 1515 1565 1616 1680

600 864 911 968 1019 1070 1127 1102 1153 1216 1267 1324 1388 1445 1495 1553 1610 1661 1730

900 880 943 1007 1070 1134 1197 1197 1248 1299 1365 1432 1483 -

* Grooved gaskets to Kempchen standard 147, designed with a pressure range optimized sealing width, are also available.

1 2

) Please specity material in any inquiry. ) The thickness of the metal core is 3.80.2mm for a 4mm nominal thickness. Other thickness on request.

Raised Face Flanges Groove to Groove Flanges

DIN 2697

Order example for grooved gasket with covering layer, profile B7A, I.D. d1=115mm and O.D. d2=162mm of 1): Grooved gasket profile B7A, 115x162, DIN 2697, 1.4541 / graphite.

Dimensions in mm

Order example for grooved gasket with covering layer, profile B29A, I.D. d1=115mm and O.D. d2=180mm of 1): Grooved gasket profile B29A, 115x180, DIN 2697, 1.4541 / graphite.

DN 10 15 25 40 50 65 80 100 125 150 (175) 200 250 300 350 400

1

d13) 22 25 36 50 62 74 90 115 142 165 190 214 264 310 340 386

d2 40 45 68 88 102 122 138 162 188 218 260 285 345 410 465 535

z) 6 7 11 12 13 16 16 16 15 18 23 24 27 33 39 50

63 112 137 147 173 210 247 277 309 364 424 486 543

100 56 61 82 102 118 143 153 180 217 257 287 324 391 458 512 3 4

5) d3 for PN 160 250 56 61 72 82 82 102 108 118 123 143 153 153 170 180 202 217 242 257 284 284 316 324 358 388 442 458 -

320 67 72 92 118 133 170 190 229 274 311 358 398 488 -

400 67 77 103 135 150 192 207 256 301 348 442 -

) Please specity material in any inquiry. 2 ) Other thickness on request.

) Maximum nominal pipe diameter + 8mm. ) Z=number of groove tips. 5 ) Dimensions for nominal pressure PN 63 to Kempchen Standard 101.

DIN 2512*

Order example for grooved gasket with covering layer, profile E7A, for groove to groove flanges, nominal diameter 65mm of 1):

For Groove to Groove Flanges

Grooved gasket profile E7A, DN 65, DIN 2512, 1.4541 / graphite.

* For dimensions please see Kempchen bulletin "General Dimension Tables to DIN, ANSI, SPI, BS for Flat Gaskets". 1 ) Please specity material in any inquiry.

Please note that the thickness h of the metal core is increased about 3mm as compared to DIN 2512. In this case Kempchen does not use the usual two gaskets of each 2mm thick, but two covering layers of 0.5 mm thickness. Kempchen Standard 133 for ANSI B16.5* flanges. Order example for grooved gasket with covering layer, profile E7A, nominal diameter 5 inches, narrow type, of 1):

d1 d2

Grooved gasket profile E7A, works standard 133, narrow, 1.4541 / graphite.

* For dimensions please see Kempchen bulletin "General Dimension Tables to DIN, ANSI, SPI, BS for Flat Gaskets". 1 ) Please specity material in any inquiry.

Profile Gaskets

11

Profile Gaskets

For Tongue and Groove Flanges

For Male and Female Flanges

s2)

d1 d2 d2

d1

To DIN 2691*

Order example for grooved gasket with covering layer, profile B7A, nominal diameter 100mm, of 1): Grooved gasket profile B7A, DN 100, DIN 2691, 1.4541 / graphite. ANSI B 16.5* Example specification for grooved gasket with covering layer, profile B7A, nominal diameter 5 inches, wide type, of 1): Grooved gasket profile B7A, 5", ANSI B16.5, wide, tongue and groove, 1.4541 / graphite.

* For dimensions please see Kempchen bulletin "General Dimension Tables to DIN, ANSI, SPI, BS for Flat Gaskets"." 1 ) Please specity material in any inquiry.

2

DIN 2692*

Order example for grooved gasket with covering layer, profile B7A, nominal diameter 100mm, of 1): Grooved gasket profile B7A, DN 100, DIN 2692, 1.4541 / graphite. To ANSI B 16.5* Example specification for grooved gasket with covering layer, profile B7A, nominal diameter 5 inches, wide type, of 1): Grooved gasket profile B7A, 5", ANSI B16.5, male and female, wide, 1.4541 / graphite.

*

1

For dimensions please see bulletin " General Dimension Tables to DIN,

) For gasket thickness and number of grooves please see Kempchen Standard 123.

ANSI, SPI, BS for Flat Gaskets". ) Please specity material in any inquiry. 2 ) For gasket thickness and number of grooves please see Kempchen Standard 123.

kempchen & Co. GmbH Alleestr.4 D - 46049 Oberhausen Telefon ++49 208 8482-0 Telefax ++49 208 8482-285 E-mail: info@kempchen.de URL: www.kempchen.de

12

Gaskets Packings Expansion Joints Rubber and Plastic Parts

204e/03000003

s2)

Potrebbero piacerti anche

- Astm A193 PDFDocumento12 pagineAstm A193 PDFjoserodriguezherazoNessuna valutazione finora

- Astm A409 A409m 2001Documento6 pagineAstm A409 A409m 2001Roland CepedaNessuna valutazione finora

- BS en 1759-4 - 2003Documento20 pagineBS en 1759-4 - 2003Tausif LodhiNessuna valutazione finora

- Sanitary Fittings (MS 02 124 E) R2Documento4 pagineSanitary Fittings (MS 02 124 E) R2herysyam1980Nessuna valutazione finora

- V B01B0005B-15GB PDFDocumento20 pagineV B01B0005B-15GB PDFनिपुण कुमारNessuna valutazione finora

- Asme B18.16.6Documento1 paginaAsme B18.16.6Mario FonsecaNessuna valutazione finora

- Check Valve Nozzle Non - SlamDocumento16 pagineCheck Valve Nozzle Non - SlamPatricio AcuñaNessuna valutazione finora

- Vecom - Japanese BlackDocumento2 pagineVecom - Japanese Blackdiaccessltd_17172961Nessuna valutazione finora

- Astm A216 PDFDocumento4 pagineAstm A216 PDFilliasuddinNessuna valutazione finora

- Implications of NORSOK M-650 Standard in The OffshoreDocumento27 pagineImplications of NORSOK M-650 Standard in The OffshoreJoherNessuna valutazione finora

- Asme b16.20 StandardsDocumento1 paginaAsme b16.20 StandardsJakir HossainNessuna valutazione finora

- Renault Truck - KDocumento16 pagineRenault Truck - KPaul FisherNessuna valutazione finora

- Spe 76-222 Dec 2012Documento10 pagineSpe 76-222 Dec 2012akashdruva892Nessuna valutazione finora

- U1CDocumento4 pagineU1CAdriana HernandezNessuna valutazione finora

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocumento8 pagineHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesradziNessuna valutazione finora

- Triple-Offset Butterflyvalves PDFDocumento8 pagineTriple-Offset Butterflyvalves PDFDiwakar NigamNessuna valutazione finora

- Section 11 Piping Systems, Valves and Pumps: I - Part 1 GL 2012 Page 11-1Documento52 pagineSection 11 Piping Systems, Valves and Pumps: I - Part 1 GL 2012 Page 11-1Andy PhoenixNessuna valutazione finora

- Astm A703Documento15 pagineAstm A703Samuel TanaNessuna valutazione finora

- ISO 3834-1-2021 Criteria For Selecting Quality LevelDocumento10 pagineISO 3834-1-2021 Criteria For Selecting Quality LevelPushkar GopalNessuna valutazione finora

- Din en 1172 e 2010-07Documento16 pagineDin en 1172 e 2010-07Niko Zurabishvili100% (1)

- Bs 3293Documento18 pagineBs 3293nguyenmainam0% (1)

- Microindentation Hardness of Materials: Standard Test Method ForDocumento28 pagineMicroindentation Hardness of Materials: Standard Test Method ForSarvesh MishraNessuna valutazione finora

- Mech Malleable Iron Fittings Catalogue PDFDocumento12 pagineMech Malleable Iron Fittings Catalogue PDFics companyNessuna valutazione finora

- ASTM F1545 Plastic Lined Pipe 0803Documento6 pagineASTM F1545 Plastic Lined Pipe 0803JabranYounasNessuna valutazione finora

- ASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFDocumento7 pagineASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFJA KNessuna valutazione finora

- Pig Trap End Closure105671465 PDFDocumento24 paginePig Trap End Closure105671465 PDFashishNessuna valutazione finora

- Flans Chen Prospekt EngDocumento2 pagineFlans Chen Prospekt Englorenzinho290Nessuna valutazione finora

- SB - 622 PDFDocumento10 pagineSB - 622 PDFSamir ChaudharyNessuna valutazione finora

- Novus Sheet Materials PDFDocumento22 pagineNovus Sheet Materials PDFermusatNessuna valutazione finora

- ASTM A960-A960M-16aDocumento11 pagineASTM A960-A960M-16aGabriel Perez CruzNessuna valutazione finora

- Astmf436 PDFDocumento6 pagineAstmf436 PDFMiguel Angel Oncoy TahuaNessuna valutazione finora

- 229-79577 - EN - 10204 - Type - 3 - 2 - Certification - Services.2 Inspection Certification PDFDocumento2 pagine229-79577 - EN - 10204 - Type - 3 - 2 - Certification - Services.2 Inspection Certification PDFBranza TelemeaNessuna valutazione finora

- PI Tectyl-506 TE031-01Documento2 paginePI Tectyl-506 TE031-01nicusebpNessuna valutazione finora

- Dimensions of Heavy Hex Nuts..Documento3 pagineDimensions of Heavy Hex Nuts..Nadia HandayaniNessuna valutazione finora

- B670 07 PDFDocumento4 pagineB670 07 PDFedrNessuna valutazione finora

- Astm A 668 A668m 2013 PDFDocumento10 pagineAstm A 668 A668m 2013 PDFCarlos GuerraNessuna valutazione finora

- International Standard: Specification and Qualification of Welding Procedures For Metallic Materials - General RulesDocumento8 pagineInternational Standard: Specification and Qualification of Welding Procedures For Metallic Materials - General RulesRudi DaNessuna valutazione finora

- BS EN 1503-4 2002 Valves Materials For Bodies BonnetsDocumento10 pagineBS EN 1503-4 2002 Valves Materials For Bodies BonnetsолегNessuna valutazione finora

- Astm A194Documento11 pagineAstm A194Jarek CieslakNessuna valutazione finora

- Valves: Guidelines On Terminology For and FittingsDocumento30 pagineValves: Guidelines On Terminology For and FittingsNatalyaNessuna valutazione finora

- A FEDS Structural BoltsDocumento6 pagineA FEDS Structural BoltsCrimsonPoshNessuna valutazione finora

- Din 3760 KeçeDocumento13 pagineDin 3760 KeçeUfuk YürekNessuna valutazione finora

- Material Data Sheet en Aw 6082 Almgsi1Documento1 paginaMaterial Data Sheet en Aw 6082 Almgsi1pankajrs.mechengineer4502Nessuna valutazione finora

- Garlock Metal - Gaskets TorqueDocumento48 pagineGarlock Metal - Gaskets TorqueakenathorNessuna valutazione finora

- Surface Comparator Chart Sa 2 5Documento5 pagineSurface Comparator Chart Sa 2 5Vebryan SyahNessuna valutazione finora

- Api600 Valve Trim ChartDocumento2 pagineApi600 Valve Trim ChartBoankNessuna valutazione finora

- Din en 14399-3 - 2015Documento30 pagineDin en 14399-3 - 2015Dato LinNessuna valutazione finora

- Astm A744-A744m 2010Documento6 pagineAstm A744-A744m 2010Júlio RosaNessuna valutazione finora

- BS Iso 1817-2011Documento30 pagineBS Iso 1817-2011David JacksonNessuna valutazione finora

- Astm B446Documento5 pagineAstm B446MaxNessuna valutazione finora

- En 12560-6Documento18 pagineEn 12560-6DarshAwad100% (1)

- Bs 5351 1986 PDFDocumento31 pagineBs 5351 1986 PDFSSFPLNessuna valutazione finora

- Seamless Carbon Steel Boiler Tubes For High-Pressure ServiceDocumento2 pagineSeamless Carbon Steel Boiler Tubes For High-Pressure ServiceChandra ClarkNessuna valutazione finora

- ES 49BranchConnections PDFDocumento7 pagineES 49BranchConnections PDFprabuharan89Nessuna valutazione finora

- Instruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Documento8 pagineInstruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Ramon GarciaNessuna valutazione finora

- Compression Packing Selection Guide: Sealing Products For IndustryDocumento13 pagineCompression Packing Selection Guide: Sealing Products For IndustryAdverNessuna valutazione finora

- Asme Section Ii B SB-42Documento10 pagineAsme Section Ii B SB-42Monica SuarezNessuna valutazione finora

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987Da EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNessuna valutazione finora

- Profile SurveyDocumento10 pagineProfile Surveygalici2002Nessuna valutazione finora

- Specification Korbbogen Head PDFDocumento1 paginaSpecification Korbbogen Head PDFDumitru SorinaNessuna valutazione finora

- Cherry ClafoutisDocumento1 paginaCherry ClafoutisDumitru SorinaNessuna valutazione finora

- Cold Formed Heads PDFDocumento0 pagineCold Formed Heads PDFDumitru SorinaNessuna valutazione finora

- Tipuri de FileteDocumento1 paginaTipuri de FileteDumitru SorinaNessuna valutazione finora

- Filet NPTDocumento3 pagineFilet NPTDumitru SorinaNessuna valutazione finora

- BSPT Threads - British Standard Pipe Tapered Threads Whitworth Tapered Pipe Thread DIN 2999Documento1 paginaBSPT Threads - British Standard Pipe Tapered Threads Whitworth Tapered Pipe Thread DIN 2999Dumitru SorinaNessuna valutazione finora

- Legislatie Contract GermaniaDocumento6 pagineLegislatie Contract GermaniaDumitru SorinaNessuna valutazione finora

- Legislatie Contract GermaniaDocumento6 pagineLegislatie Contract GermaniaDumitru SorinaNessuna valutazione finora

- International Standards Conversion TableDocumento1 paginaInternational Standards Conversion TableThongchai AtinaruemitNessuna valutazione finora

- En10222 4-1999Documento12 pagineEn10222 4-1999Dumitru SorinaNessuna valutazione finora

- Geospatial World AwardDocumento1 paginaGeospatial World AwardDumitru SorinaNessuna valutazione finora

- BGB EngDocumento424 pagineBGB EngVlad PopaNessuna valutazione finora

- Stainless Steel SpecificationDocumento2 pagineStainless Steel SpecificationmariusdejNessuna valutazione finora

- Brortj 2Documento23 pagineBrortj 2nesrine10Nessuna valutazione finora

- Profile EuropeneDocumento49 pagineProfile Europenealexfabian10Nessuna valutazione finora

- Profile EuropeneDocumento49 pagineProfile Europenealexfabian10Nessuna valutazione finora

- Linux KernelDocumento8 pagineLinux KernelDumitru SorinaNessuna valutazione finora

- Tips - Asme b313 Training SeminarDocumento382 pagineTips - Asme b313 Training SeminarMarc Abellán EscuraNessuna valutazione finora

- Materials AlturasDocumento66 pagineMaterials AlturasDonald ToledoNessuna valutazione finora

- BCS 740 PowerSafe Parts DiagramDocumento61 pagineBCS 740 PowerSafe Parts DiagramAdriano Mancini100% (1)

- Broch Delta2FlySeries2WayControlValves 420C en 20200806Documento24 pagineBroch Delta2FlySeries2WayControlValves 420C en 20200806Ahmed Al-JewariNessuna valutazione finora

- DURAN BottleCaps-Connections-Accessories ENDocumento24 pagineDURAN BottleCaps-Connections-Accessories ENRitesh LamboleNessuna valutazione finora

- Adwea Approved Vendors ListDocumento316 pagineAdwea Approved Vendors ListMy HarvNessuna valutazione finora

- Method Statement DPE GL1 Cooling Water Line CleaningDocumento15 pagineMethod Statement DPE GL1 Cooling Water Line CleaningDheeraj Chowdary DhanekulaNessuna valutazione finora

- 1280a4-8230-Sp-0001 Rev F3Documento18 pagine1280a4-8230-Sp-0001 Rev F3Stephen LowNessuna valutazione finora

- Lube Pump Operator ManualDocumento8 pagineLube Pump Operator ManualSergeyNessuna valutazione finora

- Engine Kv6 RepairDocumento78 pagineEngine Kv6 RepairSören Christopher Lax100% (1)

- Dome Valve PDFDocumento6 pagineDome Valve PDFkawula alitNessuna valutazione finora

- PF 7 Released PartsDocumento96 paginePF 7 Released PartsDaniel Enrique Natividad CaroNessuna valutazione finora

- Greinstallation Manual AmeronDocumento38 pagineGreinstallation Manual AmeronA N MadhavanNessuna valutazione finora

- Patriot Sealing Technologies CatalogueDocumento27 paginePatriot Sealing Technologies Catalogueazeem bilalNessuna valutazione finora

- Aw Defects RemediesDocumento5 pagineAw Defects RemediesSiddiq RahimNessuna valutazione finora

- JB-Det Overhaul ManualDocumento64 pagineJB-Det Overhaul ManualMohdYasirNessuna valutazione finora

- FR3 Change From Mineral Oil in Transformer Na3072835Documento4 pagineFR3 Change From Mineral Oil in Transformer Na3072835classicalgasNessuna valutazione finora

- Flange Design & Bot Tightening0012Documento14 pagineFlange Design & Bot Tightening0012Gulzar AliNessuna valutazione finora

- 5 IDT - Full - Catalogue - 2015 - ENGDocumento173 pagine5 IDT - Full - Catalogue - 2015 - ENGGaurav BedseNessuna valutazione finora

- Petronas Technical Standards: Bolted Flange Joint Assembly (Amendments/Supplements To ASME PCC-1)Documento11 paginePetronas Technical Standards: Bolted Flange Joint Assembly (Amendments/Supplements To ASME PCC-1)Agus Marpaung0% (1)

- Daily Inword Gate Pass (D)Documento195 pagineDaily Inword Gate Pass (D)suria qaqcNessuna valutazione finora

- Pressure Points: "Let's Get Digital"Documento6 paginePressure Points: "Let's Get Digital"mohdfirdausNessuna valutazione finora

- Tabla Torque PikotekDocumento2 pagineTabla Torque PikotekHernando Diaz100% (2)

- 4GV23ENDocumento28 pagine4GV23ENLahire Solér JuniorNessuna valutazione finora

- F300bet'11 Fl300bet'11: (6ce1) (6CF1)Documento83 pagineF300bet'11 Fl300bet'11: (6ce1) (6CF1)Eñgr Erum ButtNessuna valutazione finora

- Bomba de Inyeccion Roosa MasterDocumento149 pagineBomba de Inyeccion Roosa MasterDarrinel Perez Ccordova100% (1)

- Aerodef India Manufacturing 2018, MumbaiDocumento13 pagineAerodef India Manufacturing 2018, MumbaiLuv ShroffNessuna valutazione finora

- Safety Valve Data SheetDocumento3 pagineSafety Valve Data SheetSarah Frazier100% (1)

- Leader Spiral Wound Gasket Type SRI: High Integrity SPW GasketsDocumento2 pagineLeader Spiral Wound Gasket Type SRI: High Integrity SPW Gasketsrusli bahtiarNessuna valutazione finora

- Installation ProcedureDocumento51 pagineInstallation Procedurecrni rokoNessuna valutazione finora