Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fo

Caricato da

Eko NbsDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fo

Caricato da

Eko NbsCopyright:

Formati disponibili

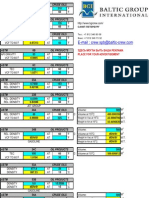

::::::: Fuel Oil Table :::::::

http://www.bunkering.co.kr/table/dtls-fuel.htm

Fuel Oil (ASTM D396-86) *ASTM

No.1 0.8499 (35 min) 38(100) -18*(0) 1.4 2.2 1.3 2.1 215(420) 288(550) 0.5 3 0.15 0.05

Grade

Specific Gravity, 60/60oF(deg API) Flash point, oC(oF) Pour point, oC(oF) Kinematic Viscosity, mm2/s (cSt)* @ 38oC (100oF) @ 40oC (104oF) Max. Min. Min. Max. Min. Max. Min. Max.

*ASTM

No.2 0.8762 (30min) 38(100) -6*(20) 2.0* 3.6 1.9* 3.4 (32.6) (37.9) 282*(540) 338(640) 0.5 3 0.35 0.05

*ASTM

No.4 (Light) 0.8762 ** (30max)** 38(100) -6*(20) 2.0 5.8 (32.6) (45) 0.05 (0.50)**

*ASTM

No.4 55(130) -6*(20) 5.8 26.4 ** 5.5 24.0 ** (45) (125) 0.10 (0.50)**

*ASTM

No.5 (Light) 55(130) >26.4 65 ** >24.0 (58) ** 5.0 8.9 ** (>125) (300) 0.15 (1.00)**

*ASTM

No.5 (Heavy) 55(130) >65 194 ** >58 (168) ** 9.0 14.9 ** (>300) (900) (23) (40) 0.15 (1.00)**

*ASTM

No.6 60(140)** 15.0 50.0 (>900) (9000) (>45) (300) (2.00)**

@100oC Min. (212oF) Max. Universal Min. @ 38oC (100oF) Max. Furol @ 50oC (122oF) 10 % Point 90 % Point Min. Max. Max. Min.

Saybolt Viscosity

Distillation Temperature, o o C( F)

Max. Sulfur content, % mass Max. Corrosion copper strip Ash, % mass Carbon residue, 10 %, %m Water and sediment, % vol Max. Max. Max. Max.

ASTM Grade : To meet special operation conditions, modifications of individual limiting requirements may be agreed upon between purchaser, seller, and manufacturer. It is the intent of these classifications that failure to meet any requirement of a given grade does not automatically place an oil in the next lower grade unless in fact it meets all requirements of lower grade.

* 1 cSt = 1 mm2/s

Kinematic viscosity is the ratio of the absolute viscosity to the density. The theoretical unit is the Stokes. As these units are large, it is usual to divide them by 100, to give a smaller unit called centistokes (cSt), and these are the units used for marine fuel. For more information, just click here.

1 dari 3

27/03/2013 11:15

::::::: Fuel Oil Table :::::::

http://www.bunkering.co.kr/table/dtls-fuel.htm

* Lower or higher pour points may be specified whenever required by conditions of storage or use.

When pour point less than -18oC(0oF) is specified, the minimum viscosity for grade No.2 shall be 1.7 cSt(31.5SUS) and the minimum 90% point shall be waived.

* Viscosity values in parentheses are for information only and not necessarily limiting. ** The amount of water by distillation plus the sediment by extraction shall not exceed the value

shown in the table. For Grade ASTM No.6 fuel oil, the amount of sediment by extraction shall not exceed 0.50 weight %, and a deduction in quantity shall be made for all water and sediment in excess of 1.0 weight %.

** Where low sulfur fuel oil is required, fuel oil falling in the viscosity range of a lower numbered

grade down to and including No.4 may be supplied by agreement between purchaser and supplier. The viscosity range of the initial shipment shall be identified and advance notice shall be required when changing from one viscosity range to another. This notice shall be in sufficient time to permit the user to make the necessary adjustments.

** This limit guarantees a minimum heating value and also prevents misrepresentation and

misapplication of this product as Grade ASTM No.2.

** Where low sulfur fuel oil is required, Grade ASTM No.6 fuel oil will be classified as low pour

+15oC(60oF) max or high pour (no max). Low pour fuel oil should be used unless all tanks and lines are heated.

* Grade ASTM No.1-D ASTM No.2-D ASTM No.4-D ASTM No.1

Description

A volatile distillate fuel for engines in service requiring frequent changes in speed and load. A distillate fuel of lower volatility for engines in industrial and heavy mobile service. A blended (distillate plus heavy fuel) fuel for low and medium speed engines. ASTM No.1 is a light distillate intended for use in burners of the vaporizing type in which the oil is converted to a vapor by contact with a heated surface or by radiation. High volatility is necessary to ensure that evaporation proceeds with a minimum of residue. ASTM No.2 is a heavier distillate than grade No.1. It is intended for use in atomizing type burners which spray the oil into a combustion chamber where the tiny droplets burn while in suspension. This grade of oil is used in most domestic burners and in many medium capacity commercial-industrial burners where its ease of handling and ready availability sometimes justify its higher cost over the residual fuels. ASTM No.4(Light) is usually a light residual but it sometimes is a heavy distillate. It is intended for use both in pressure-atomizing commercialindustrial burners not requiring higher cost distillates and in burners equipped to atomize oils of higher viscosity. Its permissible viscosity range allows it to be pumped and atomized at relatively low storage temperatures. ASTM No.4 is usually a light residual but it sometimes is a heavy distillate. It is intended for use in burners, equipped with devices that atomize oils of higher viscosity than domestic burners can handle. Its permissible viscosity range allows it to be pumped and atomized at relatively low storage temperatures. Thus, in all but extremely cold weather it requires no

ASTM No.2

ASTM No.4 (Light)

ASTM No.4

2 dari 3

27/03/2013 11:15

::::::: Fuel Oil Table :::::::

http://www.bunkering.co.kr/table/dtls-fuel.htm

preheating for handling.

ASTM No.5 (Light) ASTM No.5 (Heavy)

ASTM No.5(Light) is residual fuel of intermediate viscosity for burners capable of handling fuel more viscous than grade No.4 without preheating. Preheating may be necessary in some types of equipment for burning and in colder climates for handling. ASTM No.5(Heavy) is a residual fuel more viscous than Grade No.5(Light) and is intended for use in similar service. Preheating may be necessary in some types of equipment for burning and in colder climates for handling. ASTM No.6, sometimes referred to as "Bunker C", is a high-viscosity oil used mostly in commercial and industrial heating. It requires preheating in the storage tank to permit pumping, and additional preheating at the burner to permit atomizing. The extra equipment and maintenance required to handle this fuel usually preclude its use in small installations.

ASTM No.6

3 dari 3

27/03/2013 11:15

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Unit 6Documento13 pagineUnit 6VeronicaNessuna valutazione finora

- Leica 307 ManualDocumento4 pagineLeica 307 ManualRaluca Sandu100% (2)

- OPEC - OPEC Share of World Crude Oil ReservesDocumento2 pagineOPEC - OPEC Share of World Crude Oil ReservesEko NbsNessuna valutazione finora

- Refining Crude Oil: Step 1 - SeparationDocumento24 pagineRefining Crude Oil: Step 1 - Separationho-faNessuna valutazione finora

- Vessel VolumesDocumento61 pagineVessel VolumesaliNessuna valutazione finora

- Storage Tanks Inspection ReportDocumento15 pagineStorage Tanks Inspection ReportAreo Tolulope A80% (5)

- Rumus CCI 4737Documento5 pagineRumus CCI 4737Eko NbsNessuna valutazione finora

- Flammability HazardsDocumento3 pagineFlammability HazardsEko NbsNessuna valutazione finora

- Ashampoo Burning Studio 2017 KEYDocumento1 paginaAshampoo Burning Studio 2017 KEYEko NbsNessuna valutazione finora

- Basics of Gas FlaringDocumento2 pagineBasics of Gas Flaringprakharkumar100% (1)

- To: Lab. Kilang Cepu From: Jaelani Attn: Bapak Eko BS Our Ref: SAK-094/IV/17 Fax No: Date: 26 April 2017 CC: Page (S) : 1 of 1Documento2 pagineTo: Lab. Kilang Cepu From: Jaelani Attn: Bapak Eko BS Our Ref: SAK-094/IV/17 Fax No: Date: 26 April 2017 CC: Page (S) : 1 of 1Eko NbsNessuna valutazione finora

- Pump CalcDocumento121 paginePump Calcravirawat15Nessuna valutazione finora

- Downloaded LicensesDocumento1 paginaDownloaded LicensesEko NbsNessuna valutazione finora

- Hazardous Zone, Class, DivisionDocumento26 pagineHazardous Zone, Class, DivisionHạo Nam-Born To WinNessuna valutazione finora

- Spec Kabel NYYDocumento2 pagineSpec Kabel NYYburhansuciptoNessuna valutazione finora

- XyleneDocumento2 pagineXyleneEko NbsNessuna valutazione finora

- Pothomizer Scan 2Documento1 paginaPothomizer Scan 2Eko NbsNessuna valutazione finora

- RootDocumento6 pagineRootEko NbsNessuna valutazione finora

- Windows 8 ProDocumento1 paginaWindows 8 ProEko NbsNessuna valutazione finora

- Serial Ashampoo Uninstaler 4Documento1 paginaSerial Ashampoo Uninstaler 4Eko NbsNessuna valutazione finora

- Calculate heating value of fuel oilDocumento5 pagineCalculate heating value of fuel oilEko NbsNessuna valutazione finora

- Windows 8 ProDocumento1 paginaWindows 8 ProEko NbsNessuna valutazione finora

- Extension RodsDocumento2 pagineExtension RodsEko NbsNessuna valutazione finora

- Windows 8 ProDocumento1 paginaWindows 8 ProEko NbsNessuna valutazione finora

- Astm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your AdvertisementDocumento25 pagineAstm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your Advertisementsachyn7Nessuna valutazione finora

- GBKilangDocumento1 paginaGBKilangEko NbsNessuna valutazione finora

- Cci 4737Documento7 pagineCci 4737Eko NbsNessuna valutazione finora

- Chapter-6 IscaDocumento1 paginaChapter-6 IscakishorejiNessuna valutazione finora

- VDP08 Technical CatalogueDocumento47 pagineVDP08 Technical CatalogueAdal VeraNessuna valutazione finora

- Operating Instructions, FormulaDocumento35 pagineOperating Instructions, FormulaandymulyonoNessuna valutazione finora

- Fire Risk AssessmentDocumento13 pagineFire Risk Assessmentteuku zulfikarNessuna valutazione finora

- Pressure Vessel Rivets Welded Joints MDSP PrimeDocumento16 paginePressure Vessel Rivets Welded Joints MDSP PrimeIvanNessuna valutazione finora

- Achievements Under EpiraDocumento6 pagineAchievements Under EpiraLyn Dela Cruz DumoNessuna valutazione finora

- Conventional and Non-Conventional Energy Resources of India: Present and FutureDocumento8 pagineConventional and Non-Conventional Energy Resources of India: Present and FutureAnkit SharmaNessuna valutazione finora

- Portable Low-Frequency Acoustic Seismic System HMS-620Documento2 paginePortable Low-Frequency Acoustic Seismic System HMS-620AntoNessuna valutazione finora

- Challenges in PavementsDocumento23 pagineChallenges in PavementsSomeshwar Rao ThakkallapallyNessuna valutazione finora

- Niveau S Longrine Type Pou05-S Section 20x25: A-A B-B C-C D-DDocumento1 paginaNiveau S Longrine Type Pou05-S Section 20x25: A-A B-B C-C D-DAWOUNANGNessuna valutazione finora

- QUS 303 CONSTRUCTION ECONOMICSDocumento21 pagineQUS 303 CONSTRUCTION ECONOMICSjudexnams1on1Nessuna valutazione finora

- Pipeline Tow MethodDocumento25 paginePipeline Tow MethodctrlaltdestroyNessuna valutazione finora

- SteelKote EP ZN HS: High-Build Zinc-Rich Epoxy PrimerDocumento3 pagineSteelKote EP ZN HS: High-Build Zinc-Rich Epoxy Primerprasanth cp100% (1)

- W 7570 enDocumento276 pagineW 7570 enthedoors89Nessuna valutazione finora

- Quotation 615-4078 BabulalDocumento14 pagineQuotation 615-4078 Babulaldevrajan631Nessuna valutazione finora

- TMC 421 PDFDocumento82 pagineTMC 421 PDFJamie MooreNessuna valutazione finora

- Internet Controlled Multifunctional UGV For SurvellianceDocumento74 pagineInternet Controlled Multifunctional UGV For SurvellianceMd Khaled NoorNessuna valutazione finora

- 2:4 Decoder: DECODER: A Slightly More Complex Decoder Would Be The N-To-2n Type Binary Decoders. These TypesDocumento6 pagine2:4 Decoder: DECODER: A Slightly More Complex Decoder Would Be The N-To-2n Type Binary Decoders. These TypesPavithraRamNessuna valutazione finora

- Sallyport MBI Bifold BrochureDocumento6 pagineSallyport MBI Bifold BrochureameraldaherNessuna valutazione finora

- Oksd Icwh 1993 RoisumDocumento40 pagineOksd Icwh 1993 RoisumKamalam CloudsoftNessuna valutazione finora

- WATCHDocumento9 pagineWATCHGANTORONessuna valutazione finora

- 95 - 737-General-InformationDocumento3 pagine95 - 737-General-InformationffontanaNessuna valutazione finora

- Nature of Acidity and Lime Requirement in Acid Soils of ManipurDocumento8 pagineNature of Acidity and Lime Requirement in Acid Soils of ManipurIJASRETNessuna valutazione finora

- The Shand CCS Feasibility Study Public ReportDocumento124 pagineThe Shand CCS Feasibility Study Public ReportSai RuthvikNessuna valutazione finora

- Calgon Tech SpecDocumento4 pagineCalgon Tech SpecDanStratoNessuna valutazione finora

- Staircase Preliminary Design Based On NBC and IS CodeDocumento10 pagineStaircase Preliminary Design Based On NBC and IS CodeEducation. HubNessuna valutazione finora

- 3 Phase Induction Motors Objective Questions With AnswersDocumento3 pagine3 Phase Induction Motors Objective Questions With AnswersMohan Raj0% (2)

- Murray Loop Test To Locate Ground Fault PDFDocumento2 pagineMurray Loop Test To Locate Ground Fault PDFmohdNessuna valutazione finora